Pipe Jacking Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436787 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Pipe Jacking Machines Market Size

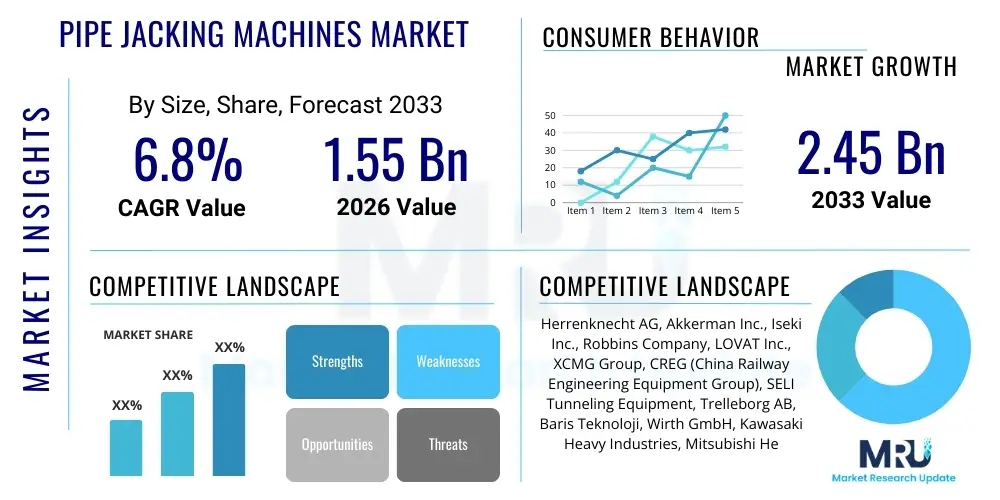

The Pipe Jacking Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.55 Billion in 2026 and is projected to reach USD 2.45 Billion by the end of the forecast period in 2033.

Pipe Jacking Machines Market introduction

The Pipe Jacking Machines Market encompasses specialized equipment used primarily in trenchless technology for installing underground pipelines, ducts, and culverts without disrupting the surface infrastructure. These machines facilitate the thrusting of pipes, usually concrete or steel, through the ground from a jacking pit to a reception pit. This method, often preferred over traditional cut-and-cover techniques, significantly reduces construction time, minimizes environmental impact, and avoids severe traffic and surface disruption, making it indispensable for urban infrastructure projects.

The core product within this market includes various types of tunneling and microtunneling machines, differentiated based on diameter, ground conditions (e.g., rock, soil, mixed face), and steering precision requirements. Major applications span critical infrastructure sectors such as water and sewage systems, telecommunications ducting, oil and gas pipelines, and underground pedestrian or vehicular crossings. The market's resilience is driven by ongoing global urbanization trends, which necessitate robust and quickly deployable solutions for expanding and upgrading complex underground utility networks, particularly in dense metropolitan areas where traditional trenching is infeasible.

Key benefits derived from utilizing pipe jacking technology include superior accuracy in alignment and grade control, enhanced worker safety compared to open-trench methods, and cost-effectiveness in challenging geological environments or under existing structures. Driving factors include increasing governmental investment in sustainable infrastructure development, stringent regulations favoring trenchless methods for environmental protection, and technological advancements in guidance systems and cutter head designs that improve operational efficiency across diverse soil compositions.

Pipe Jacking Machines Market Executive Summary

The Pipe Jacking Machines Market is experiencing robust growth fueled by accelerated global urbanization and a persistent need for modernizing aging utility infrastructure across developed economies. Business trends indicate a shift towards fully automated, remote-controlled microtunneling systems capable of high-precision boring in restrictive urban environments. Manufacturers are focusing heavily on integrating advanced monitoring and control systems (such as laser guidance and gyroscope technology) to ensure tighter tolerances and higher safety standards, responding directly to contractor demands for reduced downtime and minimized risk on complex projects.

Regionally, the Asia Pacific (APAC) market remains the primary growth engine, driven by massive infrastructure spending in countries like China and India on new sewage, water supply, and metro rail projects. Europe and North America exhibit stable growth, concentrating primarily on replacement and rehabilitation projects, with a strong emphasis on sustainability and minimizing environmental footprints. The Middle East and Africa (MEA) are also emerging as significant markets due to large-scale urban development plans and critical water management projects, particularly in Gulf Cooperation Council (GCC) countries.

Segment trends reveal that the slurry machine segment, favored for its ability to handle high water pressure and unstable ground, dominates by machine type, while the application segment is led by sewer and wastewater pipeline installation. There is a noticeable increase in demand for smaller diameter machines (less than 1,500 mm) due to the proliferation of telecommunication and utility duct installation projects in highly congested urban centers. Furthermore, the market is characterized by intense competition focused on service contracts, equipment customization, and providing comprehensive on-site support, rather than merely selling machinery.

AI Impact Analysis on Pipe Jacking Machines Market

Common user questions regarding AI in the Pipe Jacking Machines market frequently revolve around how AI can enhance operational safety, predictive maintenance schedules, and the accuracy of automated steering systems. Users are keen to understand if AI can effectively process real-time geological data from sensors (such as ground pressure, torque, and slurry density) to make instantaneous adjustments, thereby mitigating risks of collapse or machine damage. Furthermore, there is significant interest in using AI algorithms for optimizing project planning, calculating material usage (like lubrication fluids or spoil removal capacity), and ultimately reducing overall project costs and timelines.

The integration of Artificial Intelligence and Machine Learning (ML) algorithms is set to revolutionize the efficiency and safety profile of pipe jacking operations. AI algorithms are increasingly being deployed to analyze vast datasets collected by Tunnel Boring Machine (TBM) sensors, allowing for highly accurate predictions regarding cutter head wear, required thrust force adjustments, and potential ground settlement issues before they become critical. This shift from reactive maintenance to predictive, AI-driven maintenance significantly boosts machine uptime and extends the operational life of highly expensive tunneling equipment, addressing a major concern for contractors.

Furthermore, AI facilitates superior control in complex boring maneuvers. Advanced ML models can interpret real-time data from laser guidance and gyro systems, providing operators with immediate, optimized steering commands to maintain precise line and grade, even when encountering heterogeneous ground conditions. This enhanced automation reduces reliance on manual interpretation of complex data streams, thereby minimizing human error and allowing for faster project completion, positioning AI as a crucial enabler for next-generation trenchless construction.

- Enhanced Predictive Maintenance: AI models forecast equipment failures, minimizing downtime and maintenance costs.

- Optimized Steering and Guidance: Real-time ML algorithms refine steering inputs based on immediate geological feedback, ensuring alignment accuracy.

- Automated Data Interpretation: AI processes sensor data (pressure, torque, slurry flow) faster than human operators for dynamic operational adjustments.

- Improved Safety Protocols: ML detects anomalies indicative of unstable ground or hazardous conditions, alerting crews proactively.

- Resource Optimization: Algorithms calculate optimal slurry mixtures, lubrication requirements, and energy consumption for efficiency.

- Project Risk Mitigation: AI simulates potential risks (e.g., ground heave, settlement) based on geotechnical input, improving initial planning.

DRO & Impact Forces Of Pipe Jacking Machines Market

The Pipe Jacking Machines Market is predominantly driven by massive global expenditure on underground infrastructure, necessitated by rapid population expansion and the replacement of outdated water and sewage systems. Restraints largely center around the high initial capital investment required for machinery acquisition and the scarcity of highly specialized, skilled labor necessary to operate and maintain these complex systems. Opportunities are significantly present in the development of lightweight, modular equipment suitable for smaller, localized utility projects and in leveraging Public-Private Partnerships (PPPs) to fund large-scale municipal infrastructure upgrades. Impact forces such as governmental sustainability mandates and increasing urbanization pressure are strongly pushing contractors toward adopting trenchless technologies over traditional methods.

A primary driver is the necessity for sustainable urban development. As cities globally become denser, the economic and social costs associated with open-trench construction—traffic congestion, noise pollution, and business interruption—become prohibitive. Pipe jacking technology offers an environmentally friendlier alternative that complies with increasingly strict regulatory frameworks favoring minimal surface disruption. Moreover, rapid advancements in material science are leading to lighter, more durable pipes and components, improving the operational viability of pipe jacking in challenging geological formations and under high water tables, thus expanding the potential scope of projects.

However, the market faces significant restraints. The complexity of operating microtunneling machines demands highly experienced engineers and technicians, creating a bottleneck in market expansion, particularly in emerging economies. Furthermore, fluctuations in raw material prices (steel for casing and machine parts) directly impact manufacturing costs and, consequently, the final price of the equipment. These high costs, coupled with a long depreciation cycle for the machinery, present a substantial barrier to entry for smaller construction firms, concentrating market power among a few large civil engineering contractors who can afford the sizable investment.

Segmentation Analysis

The Pipe Jacking Machines Market segmentation provides a clear insight into the diverse requirements of the construction industry, focusing primarily on the technical capabilities of the machines, the materials they handle, and the end-use applications. Segmentation is critical for manufacturers to tailor their R&D investments and product portfolios, ensuring machines are optimized for specific geological conditions (e.g., hard rock versus soft ground) and project parameters (e.g., diameter and length of bore). The market is segmented broadly by machine type (e.g., Slurry Microtunneling Machines, Earth Pressure Balance Machines), pipe diameter, and application type (e.g., sewage, water, telecommunications).

The segmentation by diameter highlights the difference between small-scale utility installations and large-scale infrastructure projects. Small diameter machines (below 1,500 mm) are experiencing rapid adoption due to the sheer volume of urban utility installation and rehabilitation work, particularly in crowded city centers where space is extremely limited. Conversely, large diameter machines (above 3,000 mm), while fewer in volume, represent significant high-value contracts associated with major metro lines, large storm drain systems, and critical water conveyance tunnels, often requiring customized, high-power equipment.

Segmentation by end-user application reveals that the water and wastewater sector remains the largest consumer, driven by continuous public health mandates and environmental compliance. This sector requires high-precision, long-lasting installations. Meanwhile, the transportation segment, covering railway and roadway crossings, is rapidly growing as infrastructure expansion efforts prioritize minimizing traffic disruption by using trenchless techniques underneath existing routes.

- By Machine Type:

- Slurry Microtunneling Machines (SMM)

- Earth Pressure Balance Machines (EPBM)

- Auger Boring Machines (ABM)

- Open Shield Machines (OSM)

- By Pipe Diameter:

- Below 1,500 mm

- 1,500 mm to 3,000 mm

- Above 3,000 mm

- By Application:

- Water and Wastewater Utilities

- Oil and Gas Pipelines

- Telecommunication and Power Cable Ducting

- Transportation (Roadway/Railway Crossings)

- Storm Drains and Tunnels

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Pipe Jacking Machines Market

The value chain for the Pipe Jacking Machines Market begins with the upstream procurement of essential raw materials, primarily specialized high-strength steel alloys, hydraulic components, and precision sensor systems. Manufacturers (Tier 1 suppliers) design, assemble, and customize the complex tunneling equipment, focusing heavily on R&D to incorporate advanced cutting technology and guidance systems. Quality control and rigorous testing are critical upstream activities due to the demanding operational environments these machines face. Efficient inventory management of spare parts and replacement cutter heads is vital for supporting downstream operations and minimizing project delays.

Midstream activities involve the distribution channel, which is typically a mix of direct sales, particularly for large, bespoke TBMs, and specialized dealership networks providing localized sales, rentals, and maintenance support. Given the high cost and complexity of the equipment, financing and leasing services often play a crucial role in enabling sales. The market is increasingly characterized by partnerships between machine manufacturers and specialized trenchless contractors, allowing for knowledge sharing and tailored machine design specific to regional geological challenges.

Downstream activities are dominated by specialized civil engineering firms and construction contractors who are the ultimate end-users. These firms utilize the machines for infrastructure projects defined by governmental or private utility organizations. Crucial downstream support includes technical training, on-site supervision, immediate maintenance, and the supply of consumable materials such as bentonite slurry and lubrication gels. The success of the value chain relies heavily on the integration of manufacturer services with contractor execution capabilities, emphasizing a service-centric model over pure equipment sales.

Pipe Jacking Machines Market Potential Customers

The primary potential customers for Pipe Jacking Machines are large civil engineering and construction firms specializing in trenchless technology and underground infrastructure development. These firms operate globally on major public and private works contracts, requiring specialized, high-capacity equipment for long bores or large diameter pipe installations. Their purchasing decisions are driven by factors such as machine reliability, steering accuracy, speed of boring, and the manufacturer’s ability to provide comprehensive, global field support, given the project-based nature of their work.

Secondary but crucial customers include municipal authorities, governmental Public Works Departments, and various utility owners (water, sewage, gas, telecom). Although these entities may not directly purchase the machines, they dictate the project scope, specifications, and often the technology required through tendering processes. Their environmental and regulatory requirements heavily influence the adoption rate of trenchless methods, making them pivotal stakeholders in the market's trajectory.

Furthermore, specialized drilling and boring contractors, often focused on smaller, localized utility connection projects or residential developments, form another key customer base. These firms typically seek smaller, more maneuverable auger boring or compact microtunneling units that offer flexibility and lower operating costs, often preferring leasing or rental models over outright purchase due to project variability.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.55 Billion |

| Market Forecast in 2033 | USD 2.45 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Herrenknecht AG, Akkerman Inc., Iseki Inc., Robbins Company, LOVAT Inc., XCMG Group, CREG (China Railway Engineering Equipment Group), SELI Tunneling Equipment, Trelleborg AB, Baris Teknoloji, Wirth GmbH, Kawasaki Heavy Industries, Mitsubishi Heavy Industries, Hitachi Zosen Corporation, VMT GmbH, Terratec Tunneling, BÖGL & KRONE GmbH, Shanghai Tunnel Engineering Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pipe Jacking Machines Market Key Technology Landscape

The technology landscape of the Pipe Jacking Machines Market is predominantly defined by advancements in precision guidance, real-time ground monitoring, and sophisticated slurry management systems. Modern pipe jacking operations rely heavily on laser-based guidance systems, often supplemented by gyroscope sensors and Inertial Navigation Systems (INS), which provide millimeter-level accuracy over long distances, crucial for maintaining grade and alignment, especially in challenging mixed-face geology. The integration of advanced sensor technology allows for continuous data collection on parameters such as thrust pressure, torque, and material excavated, enabling dynamic operational adjustments to prevent steering errors or potential ground instability.

Another pivotal technological development involves the optimization of cutter head and face support mechanisms. For microtunneling in soft ground and under high water pressure, Slurry Microtunneling Machines are equipped with sophisticated systems for mixing and separating excavated material (spoil). These systems are critical for maintaining face stability during boring. Earth Pressure Balance (EPB) machines utilize the excavated soil itself as a pressure medium, requiring intelligent control systems to regulate the pressure exerted on the tunnel face precisely, minimizing surface settlement and ensuring safety in densely populated urban areas.

Furthermore, the increasing adoption of telematics and Internet of Things (IoT) technologies facilitates remote monitoring and control of pipe jacking operations. Operators can manage complex boring cycles from a centralized control room, often miles away from the construction site, improving safety and operational consistency. This remote capability is integral to leveraging predictive maintenance schedules, allowing manufacturers and contractors to monitor the health of key components like hydraulic pumps and cutter segments, scheduling maintenance before catastrophic failures occur, thereby maximizing machine availability.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand and technological adoption within the Pipe Jacking Machines Market, reflecting differing levels of infrastructural maturity, geological conditions, and regulatory environments.

- Asia Pacific (APAC): Dominates the global market due to unprecedented levels of investment in new infrastructure projects, particularly in water and sanitation systems, and massive urban rail network expansion in China, India, and Southeast Asia. The region is characterized by high demand for both small and large diameter machines.

- North America: Exhibits stable growth focused primarily on replacing and rehabilitating aging infrastructure, especially in metropolitan areas. The market emphasizes precision and safety, driving demand for advanced, automated microtunneling machines compliant with strict environmental standards.

- Europe: A mature market characterized by a focus on environmental sustainability and complex, shallow tunnel bores beneath historical city centers. European nations, particularly Germany and the UK, are leaders in technological adoption, favoring EPB and specialized machines for dense, varied geological strata.

- Middle East and Africa (MEA): Emerging as a high-growth region driven by extensive urban development, utility expansion, and large-scale water conveyance projects (e.g., sewage master plans in GCC countries). Infrastructure resilience against extreme weather events is a key purchasing factor.

- Latin America (LATAM): Growth is tied to sporadic governmental spending on public infrastructure, with significant potential in major economies like Brazil and Mexico for upgrading water distribution and sewage networks, often utilizing technology imported from Europe or North America.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pipe Jacking Machines Market.- Herrenknecht AG

- Akkerman Inc.

- Iseki Inc.

- Robbins Company

- LOVAT Inc.

- XCMG Group

- CREG (China Railway Engineering Equipment Group)

- SELI Tunneling Equipment

- Trelleborg AB

- Baris Teknoloji

- Wirth GmbH

- Kawasaki Heavy Industries

- Mitsubishi Heavy Industries

- Hitachi Zosen Corporation

- VMT GmbH

- Terratec Tunneling

- BÖGL & KRONE GmbH

- Shanghai Tunnel Engineering Co. Ltd.

- Dressta Co. Ltd.

- China Communications Construction Company Ltd. (CCCC)

Frequently Asked Questions

Analyze common user questions about the Pipe Jacking Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the adoption of Pipe Jacking Machines over traditional excavation methods?

The primary factor driving adoption is the increasing necessity for trenchless installation in urbanized environments. Pipe jacking minimizes surface disruption, preserves existing infrastructure, and significantly reduces the social and economic costs associated with traffic closures and traditional open-trench construction, ensuring compliance with modern environmental regulations.

How do slurry microtunneling machines (SMM) differ from earth pressure balance machines (EPBM)?

SMMs use a pressurized fluid (slurry) to balance the pressure at the tunnel face and transport excavated spoil to the surface, making them ideal for unstable ground and high water table conditions. EPBMs use the excavated soil mixed with conditioning agents to maintain face stability, typically preferred in cohesive or mixed-face soil types where water pressure is manageable.

Which geographical region represents the largest market share for pipe jacking equipment?

The Asia Pacific (APAC) region currently holds the largest market share due to continuous, large-scale infrastructure investment, particularly in China and India, focusing on expanding urban sewage, water, and transit utility networks to meet rapid population growth demands.

What role does Artificial Intelligence play in modern pipe jacking operations?

AI is increasingly used for advanced steering guidance, optimizing cutter head performance, and implementing predictive maintenance. AI algorithms analyze real-time geotechnical data from sensors to provide immediate, precise operational adjustments, significantly enhancing boring accuracy and reducing machine downtime.

What are the key technical constraints affecting pipe jacking project complexity?

Key constraints include heterogeneous ground conditions (mixed-face geology), which complicate face stabilization; the required accuracy over long, curved alignments; and the management of high hydrostatic pressure, all of which necessitate highly specialized machine configurations and expert operational teams.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager