Pipe Wrenches Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433691 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Pipe Wrenches Market Size

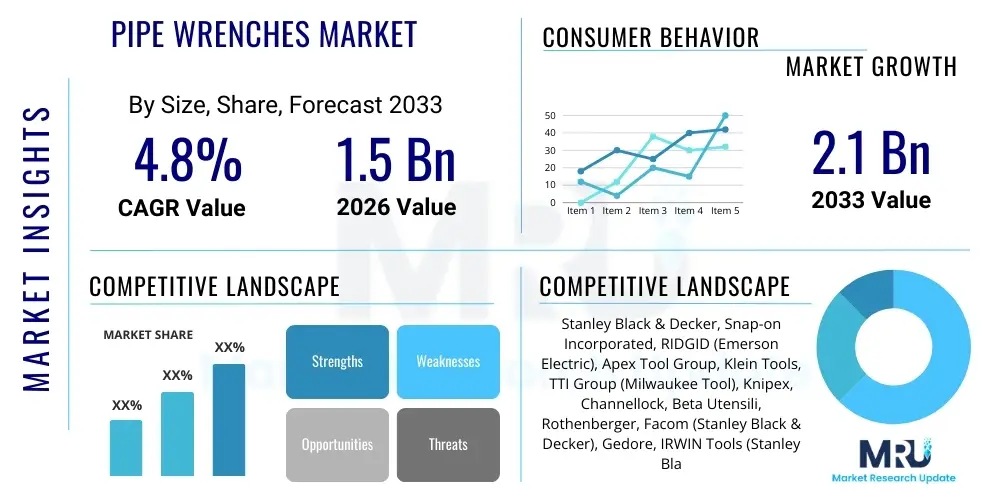

The Pipe Wrenches Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.1 Billion by the end of the forecast period in 2033. This consistent growth trajectory is primarily underpinned by robust expansion within the global infrastructure development sector, particularly in emerging economies where extensive residential and commercial construction projects necessitate reliable plumbing and piping maintenance tools. Furthermore, the persistent demand from the aging infrastructure repair and replacement activities in developed nations provides a stable revenue stream for specialized pipe wrench manufacturers, reinforcing the overall market valuation.

The calculation of market size reflects not only the volume sales of standard adjustable and non-adjustable pipe wrenches but also the increasing adoption of specialized variants such as aluminum and heavy-duty models tailored for specific industrial applications, including oil and gas, and chemical processing plants. The shift toward lighter, yet equally durable, aluminum alloy wrenches in commercial settings is contributing positively to value growth, even as price competition remains significant in the standard cast iron segment. Market size projections account for evolving material science and manufacturing innovations designed to enhance tool ergonomics and longevity, driving replacement cycles among professional end-users.

Pipe Wrenches Market introduction

The Pipe Wrenches Market encompasses the global trade and consumption of various hand tools specifically designed for gripping, turning, tightening, and loosening rigid pipes, fittings, and associated cylindrical materials, predominantly utilized in plumbing, HVAC, and industrial maintenance operations. These tools, characterized by their adjustable jaws and rugged construction, are indispensable in applications requiring substantial torque and robust engagement with round or polygonal surfaces. Key product types include straight, offset, end, and specialized chain or strap wrenches, each optimized for different accessibility and application requirements across diverse operational environments.

Major applications of pipe wrenches span across residential, commercial, and industrial sectors. In residential plumbing, they are crucial for installing and repairing water and sewer lines. Commercially, they are heavily employed in large-scale construction, utility maintenance, and institutional facilities management. Industrially, they are vital components of maintenance toolkits in oil and gas refineries, chemical processing plants, and heavy manufacturing sectors where high-pressure piping systems demand precision and strength during assembly and routine upkeep. The inherent simplicity and robust design of the pipe wrench ensure its continuous relevance despite the emergence of more sophisticated, powered tools.

The market is primarily driven by escalating global construction output, coupled with the increasing need for infrastructure repair and retrofitting across aging utility networks. Furthermore, stringent safety regulations concerning pipeline integrity, especially in the energy sector, mandate the use of high-quality, reliable hand tools for maintenance, thereby sustaining demand. The widespread professional use of pipe wrenches, offering high leverage and adjustable versatility, underscores their foundational role in maintaining the functional integrity of modern piping infrastructure globally.

Pipe Wrenches Market Executive Summary

The Pipe Wrenches Market is experiencing dynamic shifts characterized by a focus on material innovation and enhanced ergonomic design to meet the evolving demands of professional tradespeople globally. Business trends indicate a move toward premiumization, where manufacturers are emphasizing lightweight aluminum alloys and specialized coatings to improve durability and user comfort, commanding higher price points and margin potential. Regional trends highlight significant investment in Asia Pacific, driven by rapid urbanization and massive infrastructure projects, establishing it as the fastest-growing market. Meanwhile, North America and Europe maintain dominance in terms of market value, driven by strict regulatory standards and the continuous expenditure on maintaining complex, established industrial piping networks.

Segment trends reveal that the straight pipe wrench continues to dominate the market by volume due to its general utility, though specialized segments, particularly the offset and end pipe wrenches, are showing faster value growth driven by their necessity in constrained access environments typical of modern commercial construction. The oil and gas application segment, focused on heavy-duty, high-torque tools, remains a crucial revenue driver, highly sensitive to global capital expenditure cycles in the energy sector. Overall, the market remains competitive, necessitating continuous product differentiation and supply chain efficiency among key players to maintain market share against generic alternatives.

AI Impact Analysis on Pipe Wrenches Market

Common user questions regarding AI's impact on the Pipe Wrenches Market often revolve around manufacturing efficiency, supply chain optimization, and the potential for AI-driven maintenance scheduling that might reduce the frequency of manual repairs. Users are keen to understand how smart factories utilizing AI for predictive maintenance might influence the demand curve for traditional hand tools. The analysis suggests that while AI will not directly replace the physical function of a pipe wrench, it is fundamentally transforming the upstream manufacturing processes through automation, quality control, and predictive maintenance of production equipment, leading to higher product consistency and reduced operational costs for manufacturers. Downstream, AI's role in optimizing inventory and logistics ensures that the right wrench is available at the right location, improving supply chain responsiveness, particularly for specialized or high-demand models required for urgent field repairs.

Furthermore, the integration of AI and IoT (Internet of Things) tools in smart infrastructure monitoring is generating precise data on pipe system failure points. This data enables manufacturers to develop specialized pipe wrenches that are perfectly suited for anticipated failure scenarios or complex repair requirements, moving the market towards highly customized, data-driven tool solutions. Although the core product remains mechanical, AI indirectly influences product development cycles, market forecasting, and the efficiency of the distribution channels connecting manufacturers to end-users who are increasingly relying on data-driven workflow management in sectors like utilities and oil and gas.

- AI optimizes manufacturing processes, improving the consistency and quality control of pipe wrench production.

- Predictive maintenance analytics, often AI-driven, can anticipate equipment failures, slightly altering routine maintenance tool demand but increasing demand for emergency repair tools.

- AI enhances supply chain logistics and inventory management, ensuring optimal stock levels of diverse wrench types across regional distribution centers.

- Data generated by AI-enabled asset monitoring influences the design and specialization of next-generation pipe wrenches tailored for specific system requirements.

- Machine learning models aid in market demand forecasting, enabling manufacturers to adjust production volumes effectively, avoiding overstock or shortages.

DRO & Impact Forces Of Pipe Wrenches Market

The dynamics of the Pipe Wrenches Market are primarily shaped by a confluence of powerful drivers (D), significant restraints (R), emerging opportunities (O), and influential impact forces. The primary drivers include global urbanization and the massive expansion of public infrastructure requiring complex piping systems, alongside the robust maintenance demands associated with aging utility grids in mature markets. Conversely, the market faces restraints such as intense price competition from low-cost manufacturers, coupled with the slow adoption rate of specialized, higher-priced ergonomic tools among cost-sensitive independent contractors. This market balance is further influenced by the cyclical nature of capital investment in the construction and energy sectors.

Opportunities for growth are abundant, notably through the increasing adoption of lightweight materials, such as aluminum alloys, which appeal to professional users seeking reduced physical strain, and the market expansion into specialized fields like renewable energy installations (e.g., geothermal systems) and precision HVAC. The convergence of these factors defines the market’s impact forces, where technological advancements in metallurgy and design ergonomics push the market towards premium offerings, while economic instability in major developing regions periodically dampens large-scale infrastructure spending, creating fluctuations in demand for core mechanical hand tools. Strategic alignment with maintenance service providers and targeting niche industrial applications remain critical for sustained profitability in this established tool category.

Segmentation Analysis

The Pipe Wrenches Market is comprehensively segmented based on product type, material composition, and key application areas, reflecting the diverse requirements of end-users ranging from residential plumbers to heavy industrial maintenance crews. Segmentation by type differentiates between standard adjustable wrenches (straight) and specialized designs (offset, end, strap), catering to accessibility needs and specific pipe sizes. Material segmentation, notably between traditional cast iron, lightweight aluminum, and highly durable alloy steel, dictates the tool's performance parameters, weight, and intended duty cycle. Understanding these segments is crucial for manufacturers in tailoring their product portfolios to capture specific pockets of demand and for distributors in optimizing their inventory selection to match local market requirements.

Application segmentation reveals the highest consumption areas, with residential and commercial plumbing acting as foundational markets, while the high-value segments of Oil & Gas and specialized industrial maintenance drive innovation in heavy-duty and non-sparking tool variants. This granular segmentation allows market stakeholders to identify high-growth niches, such as tools specifically engineered for high-precision environments or for use with modern, composite piping materials, moving beyond the traditional reliance on standardized metal pipe systems. The inherent versatility of pipe wrenches means that successful penetration requires addressing the unique durability, leverage, and weight constraints imposed by each specific end-use sector.

- By Type:

- Straight Pipe Wrench

- Offset Pipe Wrench

- End Pipe Wrench

- Aluminum Pipe Wrench (often overlaps with material)

- Chain Pipe Wrench

- Strap Wrench

- By Material:

- Cast Iron

- Aluminum

- Alloy Steel

- Other Composites

- By Application:

- Residential Plumbing and Repair

- Commercial Construction

- Oil & Gas (Midstream and Downstream)

- HVAC (Heating, Ventilation, and Air Conditioning)

- Automotive and Heavy Machinery Maintenance

- Utility and Infrastructure Maintenance

Value Chain Analysis For Pipe Wrenches Market

The value chain for the Pipe Wrenches Market commences with the upstream activities centered on raw material procurement, primarily sourcing ferrous metals (cast iron, alloy steel) and non-ferrous metals (aluminum) from global commodity markets. High-quality material suppliers specializing in durable tool-grade metals are crucial, as material integrity directly dictates the tool’s strength and longevity, which are non-negotiable professional requirements. This phase involves intensive quality control and metallurgical processing to ensure the metal possesses the necessary toughness and wear resistance required for high-torque applications. Upstream efficiency significantly impacts manufacturing costs and, consequently, the final product pricing and competitiveness.

Midstream activities involve sophisticated manufacturing processes, including forging, casting, machining, and heat treatment, necessary to produce the adjustable jaw, handle, and housing components with high precision. Leading manufacturers heavily invest in advanced Computer Numerical Control (CNC) machining and automated assembly lines to minimize tolerances and maximize production throughput. Downstream, the distribution channel is highly diversified, ranging from direct sales to large industrial buyers (e.g., utility companies, oil refineries) to indirect sales through complex networks involving master distributors, wholesalers, major industrial supply retailers (e.g., Grainger, Fastenal), and local hardware stores. The effectiveness of the indirect channel, particularly the penetration into specialized trade outlets, determines market reach and accessibility for the vast majority of professional and DIY users.

Direct sales are prevalent for specialized, high-volume orders for major corporate clients, offering streamlined logistics and dedicated support. However, the majority of the market relies on the indirect channel, where specialized industrial and plumbing supply houses play a crucial role by providing immediate availability, local expertise, and bundling opportunities with complementary tools and supplies. The reliance on established brands through these channels underscores the importance of strong brand equity and maintaining rigorous quality standards to ensure trust among professional end-users who cannot afford tool failure on critical job sites.

Pipe Wrenches Market Potential Customers

The Pipe Wrenches Market targets a broad spectrum of professional end-users and organizational buyers whose operational mandates involve the construction, installation, maintenance, or demolition of piping and conduit systems. The primary cohort of potential customers consists of licensed plumbers, HVAC technicians, steamfitters, and specialized pipe fitters working across residential and commercial construction sites. These individuals prioritize durability, ergonomic design, and brand reputation, often purchasing premium products that withstand daily rigorous use. Institutional customers, such as municipal water treatment facilities and public utility companies, represent stable, high-volume buyers for heavy-duty and specialized wrenches required for infrastructural repair and maintenance cycles.

Furthermore, significant buying power resides within large industrial sectors. This includes major oil and gas exploration and production companies, petrochemical refineries, chemical processing plants, and power generation facilities (both conventional and renewable energy). These industrial customers necessitate extremely specialized tools, sometimes requiring non-sparking materials for hazardous environments, and often procure tools through centralized procurement systems under stringent safety and quality specifications. The maintenance departments of large manufacturing entities and heavy equipment repair workshops also constitute a vital customer base, needing robust tools for fluid and hydraulic line maintenance.

The rise of high-quality DIY and semi-professional consumers, particularly in developed markets where home maintenance and renovation projects are common, also contributes significantly to market demand, though they typically target the mid-range price segment. Targeting potential customers requires understanding their specific operational environment—whether it demands lightweight tools for ceiling work (HVAC), extreme leverage for stubborn joints (oil and gas), or standard reliability for routine residential tasks (plumbing). Successful marketing strategies must address the unique pain points and usage frequency of each distinct end-user group to maximize sales velocity and market penetration.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.1 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Stanley Black & Decker, Snap-on Incorporated, RIDGID (Emerson Electric), Apex Tool Group, Klein Tools, TTI Group (Milwaukee Tool), Knipex, Channellock, Beta Utensili, Rothenberger, Facom (Stanley Black & Decker), Gedore, IRWIN Tools (Stanley Black & Decker), Monument Tools, Teng Tools, Armstrong Tools, Superior Tool Co., Reed Manufacturing, C.K Tools, Williams (Snap-on). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pipe Wrenches Market Key Technology Landscape

The key technology landscape of the Pipe Wrenches Market is less about digital disruption and more focused on continuous, incremental innovations in materials science, precision engineering, and ergonomic design, all aimed at enhancing tool performance and user safety. Advances in metallurgy, particularly the development of high-strength alloy steels and lightweight aluminum alloys, are pivotal. These materials allow manufacturers to produce tools that are significantly lighter without compromising the torque capacity or durability required for heavy-duty industrial applications. Heat treatment technologies, specifically targeted hardening processes, are utilized to ensure the jaws maintain exceptional grip and resistance to wear and deformation, extending the operational lifespan of the tool under extreme stress conditions typical in oil and gas environments.

Precision manufacturing techniques, including advanced forging and CNC machining, are critical for maintaining tight tolerances, ensuring the smooth and reliable adjustment mechanism (heel jaw and hook jaw) remains functional over thousands of use cycles. This precision is vital for minimizing slippage, which is a key safety concern for professional tradespeople. Furthermore, the incorporation of advanced powder coating and anti-corrosion finishes, particularly important in humid or chemically aggressive environments, represents a necessary technological adaptation. These coatings ensure the longevity and sustained functionality of the adjustment mechanisms when exposed to water, chemicals, or extreme weather conditions encountered in exterior utility maintenance.

Ergonomics constitutes another significant technological area. Modern designs integrate non-slip, molded rubber grips and optimized handle shapes based on biomechanical studies to reduce hand fatigue and prevent repetitive strain injuries. Although seemingly simple, these ergonomic improvements directly influence user preference and purchasing decisions among professional contractors, positioning ergonomically superior tools as high-value propositions. The combination of lightweight materials, precise manufacturing, and user-centric design represents the core technological drivers enhancing tool efficiency and market differentiation within the traditionally mechanical sector of pipe wrenches.

Regional Highlights

Regional dynamics significantly influence the Pipe Wrenches Market, reflecting varying levels of infrastructural maturity, industrial activity, and construction expenditure globally. North America, encompassing the United States and Canada, remains a dominant market in terms of value, driven by high labor costs necessitating efficient, high-quality tools, and continuous investment in the maintenance and upgrade of expansive oil, gas, and water utility infrastructure. The presence of major manufacturing headquarters and a mature distribution network further solidifies its position, where premium brands command strong loyalty.

Asia Pacific (APAC) is projected to exhibit the highest growth rate during the forecast period. This rapid expansion is fueled by unprecedented urbanization, massive government initiatives in building residential and commercial infrastructure (especially in India, China, and Southeast Asian nations), and burgeoning industrialization, particularly in chemical and processing plants. While this region also accommodates a large segment of low-cost manufacturers, the increasing adoption of Western quality standards in large-scale professional projects is driving demand for durable, internationally certified tools. This dual market structure—low-cost volume vs. high-quality value—defines the competitive landscape in APAC.

Europe represents a stable and mature market, characterized by strict regulatory requirements regarding tool quality and worker safety. Demand is primarily driven by meticulous maintenance of older building stock, rigorous adherence to modern plumbing codes, and sophisticated industrial maintenance requirements in Germany, the UK, and France. The Middle East and Africa (MEA), particularly the GCC states, are high-growth spots directly tied to major energy projects and new city development initiatives, generating substantial intermittent demand for heavy-duty and specialized industrial pipe wrenches used in pipeline construction and refinery maintenance.

- North America: Market leader by value; stable demand from established infrastructure maintenance; preference for premium, high-quality, branded tools (e.g., RIDGID, Snap-on).

- Asia Pacific (APAC): Fastest-growing region driven by massive urbanization, new infrastructure build-out, and expanding industrial base in China and India; increasing adoption of standardized, professional-grade tools.

- Europe: Mature market characterized by stringent safety standards and high focus on precision; demand sustained by building retrofitting and industrial maintenance sectors.

- Latin America (LATAM): Emerging market with growth tied to commodity cycles and intermittent infrastructure investments; high price sensitivity but growing need for professional tools in large energy projects (e.g., Brazil, Mexico).

- Middle East & Africa (MEA): Demand strongly correlated with oil and gas capital expenditure and large construction projects (e.g., Saudi Arabia, UAE); significant requirement for heavy-duty, non-sparking industrial wrenches.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pipe Wrenches Market.- Stanley Black & Decker

- Snap-on Incorporated

- RIDGID (Emerson Electric)

- Apex Tool Group

- Klein Tools

- TTI Group (Milwaukee Tool)

- Knipex

- Channellock

- Beta Utensili

- Rothenberger

- Facom (Stanley Black & Decker)

- Gedore

- IRWIN Tools (Stanley Black & Decker)

- Monument Tools

- Teng Tools

- Armstrong Tools

- Superior Tool Co.

- Reed Manufacturing

- C.K Tools

- Williams (Snap-on)

Frequently Asked Questions

Analyze common user questions about the Pipe Wrenches market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors are driving the demand for aluminum pipe wrenches?

Demand for aluminum pipe wrenches is primarily driven by the professional need for lighter tools that reduce user fatigue, especially when working overhead or for extended periods. Aluminum offers significant weight reduction compared to traditional cast iron while maintaining sufficient durability and meeting the required torque standards for commercial plumbing and maintenance tasks.

How does the Oil & Gas sector influence the pipe wrenches market?

The Oil & Gas sector is a critical high-value driver, demanding specialized, heavy-duty, and often non-sparking pipe wrenches for maintenance on high-pressure pipelines, valves, and refinery equipment. Capital expenditure cycles in this sector directly correlate with demand for large-format and highly durable industrial-grade tools.

What is the current trend in pipe wrench manufacturing technology?

The current technological trend focuses heavily on material science and ergonomics. Manufacturers are utilizing advanced alloy steels for increased wear resistance and investing in precision forging and CNC machining to ensure minimal jaw slippage. Ergonomic grips and lighter materials are prioritized to improve safety and operational efficiency for the end-user.

Which region is expected to show the fastest growth in the pipe wrenches market?

The Asia Pacific (APAC) region is projected to register the highest Compound Annual Growth Rate (CAGR). This growth is attributed to rapid urbanization, immense government spending on new commercial and residential infrastructure, and the continuous expansion of industrial sectors across developing economies like India and China.

What are the primary differences between straight and offset pipe wrenches?

Straight pipe wrenches are standard tools offering maximum leverage for open access work. Offset pipe wrenches feature a distinct head angle relative to the handle, designed specifically to facilitate turning pipes and fittings located in tight or constrained spaces, such as near walls, corners, or clustered machinery, enhancing versatility in complex installations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager