Pistol Grip Drill Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432105 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Pistol Grip Drill Market Size

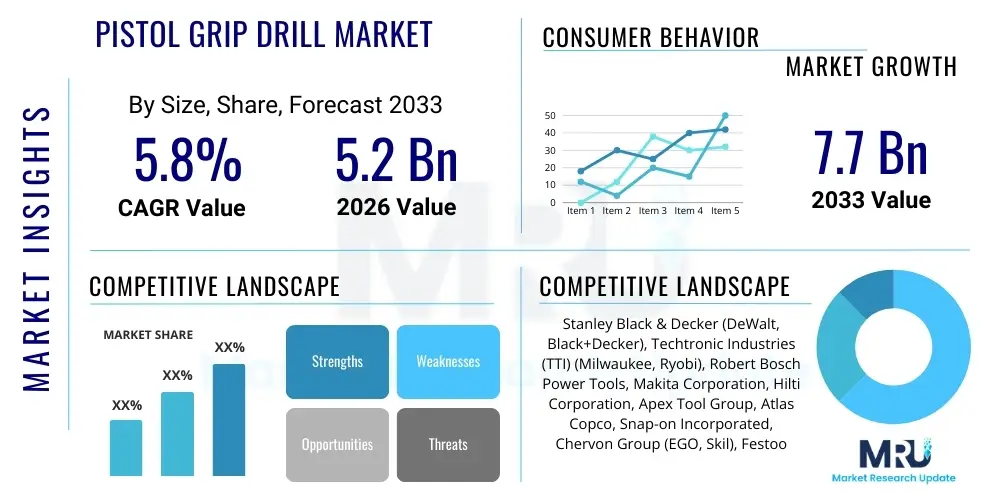

The Pistol Grip Drill Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 5.2 Billion in 2026 and is projected to reach USD 7.7 Billion by the end of the forecast period in 2033.

Pistol Grip Drill Market introduction

The Pistol Grip Drill Market encompasses the global sales and distribution of handheld power tools designed primarily for drilling holes or driving fasteners, characterized by an ergonomic grip positioned perpendicular to the main body, offering superior control and balance. These drills are essential instruments across numerous sectors, including residential construction, large-scale commercial infrastructure development, automotive repair and manufacturing, and intricate woodworking projects. The market is broadly categorized by power source (corded and cordless) and motor technology (brushed and increasingly brushless motors), catering to both professional trade users and do-it-yourself (DIY) enthusiasts.

Product sophistication has increased substantially, with modern pistol grip drills featuring variable speed controls, hammer functions, enhanced torque settings, and highly efficient lithium-ion battery systems in the cordless segment. Major applications include boring holes in diverse materials such as wood, metal, and masonry, as well as the rapid assembly and disassembly of structures using various driver bits. The key benefit derived from using these tools is enhanced productivity, precision, and reduced manual effort compared to traditional methods, making them indispensable on modern construction sites and assembly lines.

Driving factors propelling market expansion include rapid urbanization, leading to sustained demand for housing and commercial structures, particularly in emerging economies. Furthermore, technological advancements in battery performance, reducing charge times and increasing operational runtime, have significantly boosted the appeal of cordless pistol grip drills, allowing users greater freedom of movement and access to remote work areas. The growing trend of home renovation and DIY projects post-pandemic has also stimulated demand for mid-range and consumer-grade models.

Pistol Grip Drill Market Executive Summary

The global Pistol Grip Drill Market exhibits robust growth, primarily driven by the transition towards professional-grade cordless tools utilizing advanced lithium-ion battery technology and high-efficiency brushless motors. Current business trends indicate a strong focus on ergonomics, tool longevity, and smart tool integration, where manufacturers are embedding IoT capabilities for inventory management and performance diagnostics. Geographically, Asia Pacific is positioned as the fastest-growing region, fueled by massive government investments in infrastructure development and burgeoning manufacturing hubs, while North America and Europe maintain dominance in terms of adopting premium, high-torque models for specialized applications.

Regional trends reveal market maturity in developed Western nations, characterized by replacement demand and a strong emphasis on brand loyalty and specialized features (e.g., impact functionality). In contrast, developing regions are experiencing initial high penetration rates as traditional manual labor methods are replaced by power tools. Regulatory trends promoting workplace safety and noise reduction are also influencing design shifts, pushing manufacturers toward lighter, more vibration-dampened models. This dual market dynamic—sophistication in the West and high volume growth in the East—defines the global landscape.

Segmentation trends highlight the overwhelming dominance and forecasted rapid growth of the cordless segment over corded models, despite the latter's retained importance in heavy-duty, continuous applications where maximum power is required. Within the motor segment, brushless technology is rapidly eroding the share of conventional brushed motors due to superior energy efficiency, reduced maintenance, and increased lifespan. End-user segmentation shows sustained robust demand from the professional construction and industrial sectors, alongside a resilient consumer market driven by accessible pricing and DIY content proliferation.

AI Impact Analysis on Pistol Grip Drill Market

Common user questions regarding AI's influence on the Pistol Grip Drill Market typically revolve around operational efficiency, predictive maintenance, and the integration of smart features. Users frequently inquire about how AI can optimize battery life, predict tool failure before it occurs (reducing downtime), and whether AI-driven analytics can improve drilling precision or speed for complex tasks. Key themes emerging from these queries are centered on transforming standard power tools into 'smart' assets that provide actionable data back to the user or management system, thereby minimizing operational costs and maximizing labor efficiency on job sites. There is a high expectation that AI will standardize performance across different operators and environments, ensuring consistent quality in large-scale construction projects.

The integration of artificial intelligence and machine learning algorithms is set to revolutionize the manufacturing process and the operational lifetime of pistol grip drills. In manufacturing, AI optimizes the supply chain by predicting component demand, streamlining assembly, and enhancing quality control through automated visual inspection systems. For the end-user, AI-enabled sensors can monitor usage patterns, temperature, torque output, and vibration levels. This data is processed to provide real-time feedback to the user, suggesting optimal settings for different materials, thereby reducing the risk of material damage or tool overheating. This shift moves the product from a simple mechanical device to a sophisticated, data-generating asset.

Looking forward, AI is expected to enable true adaptive tools. Future pistol grip drills might utilize embedded AI to automatically adjust speed and torque based on material resistance detected during the initial contact phase, optimizing the drilling process autonomously. This level of automation ensures longevity for both the tool and the battery pack while guaranteeing precise outcomes regardless of operator skill level. Furthermore, predictive fleet management enabled by AI allows large construction firms to schedule maintenance proactively, vastly improving asset utilization and contributing to a higher return on investment (ROI) for professional tool purchases.

- Enhanced Predictive Maintenance: AI algorithms analyze usage data (load, temperature, cycles) to forecast component failure, triggering proactive service alerts.

- Optimized Battery Management: Machine learning models maximize lithium-ion battery lifespan and performance by optimizing charging and discharge cycles based on usage profile.

- Automated Torque/Speed Adjustment: AI embedded systems dynamically modify tool settings in real-time based on material density and resistance for optimal performance and safety.

- Integrated Safety Features: AI can detect user fatigue or hazardous operation angles and automatically reduce power output or engage safety stops.

- Supply Chain and Inventory Optimization: AI streamlines logistics and component sourcing for manufacturers, reducing production lead times and costs.

DRO & Impact Forces Of Pistol Grip Drill Market

The Pistol Grip Drill Market is strongly influenced by the growth drivers stemming from global construction and infrastructure boom, particularly in emerging markets, coupled with relentless innovation in battery technology which makes cordless tools increasingly competitive with their corded counterparts in terms of power and runtime. These drivers are tempered by significant restraints, primarily related to the high initial investment required for professional-grade brushless cordless systems and ongoing vulnerability to global supply chain disruptions affecting semiconductor components necessary for advanced motor control and battery management systems. Opportunities are significant in expanding smart tool adoption, enabling IoT integration for fleet management, and addressing the growing demand for sustainable, lighter-weight tools that comply with stringent environmental and occupational safety regulations.

Impact forces are driven by substitution risk (low to moderate, as no viable alternative currently replaces the core function of drilling/driving), competitive intensity (high, characterized by frequent product launches and aggressive pricing strategies among major multinational players), and bargaining power of suppliers (moderate, fluctuating based on raw material availability, especially lithium and cobalt). The bargaining power of buyers is significant in the large commercial and industrial segments where procurement often occurs in bulk, leading to demands for tailored warranty and service packages. The key market dynamics demonstrate a mature, yet highly competitive environment where product differentiation through technology (brushless, battery capacity) remains the primary success metric.

The primary driver of the market remains the global shift towards professionalization of trades and the resultant requirement for durable, high-performance tools. This is particularly noticeable in developing nations where construction techniques are rapidly modernizing. Conversely, the restraint imposed by the cyclical nature of the construction industry, which can be vulnerable to macroeconomic downturns or lending rate fluctuations, consistently influences short-term market stability. However, the continuous refinement of brushless motor technology, which delivers superior efficiency and reliability, offers a powerful mitigating factor, ensuring that the long-term trend remains positive, favoring premium, technology-enabled tools.

Segmentation Analysis

The Pistol Grip Drill Market is primarily segmented based on Power Source, Motor Type, Application, and End-User. This segmentation allows for precise market analysis, differentiating between high-volume consumer segments and high-value professional industrial segments. The increasing adoption of advanced technology is evident across all segmentation categories, particularly the shift toward cordless technology driven by the enhanced energy density and reduced cost of lithium-ion batteries. Understanding these segments is crucial for manufacturers to tailor product development, pricing strategies, and distribution channels, ensuring products meet the specific torque, runtime, and durability requirements of distinct end-users, from residential DIYers to heavy-duty industrial operators.

- Power Source

- Cordless (Battery Powered)

- Corded (Electric)

- Motor Type

- Brushed Motors

- Brushless Motors

- Application

- Drilling (Wood, Metal, Masonry)

- Driving (Fastening)

- End-User

- Industrial and Commercial (Construction, Automotive, Manufacturing)

- Residential and DIY (Home Improvement)

Value Chain Analysis For Pistol Grip Drill Market

The value chain for the Pistol Grip Drill Market begins with upstream activities focused on raw material sourcing, primarily metals (steel, aluminum, copper for windings), plastics, and critical components such as lithium for batteries, semiconductors, and specialized gear mechanisms. Key suppliers in the upstream segment include Li-ion cell manufacturers and specialized electronic control unit providers. Efficient sourcing and quality control at this stage are critical, especially given the global volatility in raw material commodity prices and the reliance on Asian suppliers for battery components. Manufacturers must maintain robust relationships with these suppliers to ensure a consistent flow of high-quality, cost-effective inputs.

The midstream involves the core manufacturing process, encompassing motor assembly, injection molding for casings, final tool assembly, and rigorous testing and quality assurance procedures. Companies frequently employ automated assembly lines and lean manufacturing principles to maximize efficiency and maintain competitive pricing. Research and development (R&D) plays a crucial role here, driving innovation in motor efficiency (brushless designs), ergonomics, and integrated safety features. The goal in manufacturing is to balance high volume production with the increasing complexity of modern tool electronics.

The downstream segment focuses on distribution and sales. Distribution channels are varied, including direct sales to major industrial contractors, indirect sales through large big-box retailers (e.g., Home Depot, Lowe's), specialized industrial supply houses (e.g., Grainger), and the rapidly expanding e-commerce platform. Direct channels are vital for maintaining relationships with professional users, offering specialized service and warranty support. Indirect channels, particularly retail and online platforms, are critical for volume sales and reaching the residential/DIY market. Post-sales service and warranty provision constitute the final link, enhancing customer loyalty and brand reputation, which is particularly important for premium professional tools.

Pistol Grip Drill Market Potential Customers

The primary potential customers and end-users of pistol grip drills span a wide spectrum, ranging from high-volume, professional industrial users requiring durable, high-torque instruments to casual residential users seeking versatile, user-friendly tools for occasional home maintenance. Professional customers, who represent the highest value segment, include large general contractors engaged in commercial and residential building construction, automotive maintenance and manufacturing shops requiring precision and repetition, and specialized trade professionals such as electricians, plumbers, and HVAC technicians who rely on these tools daily for installation and repair work.

Within the industrial and commercial segments, the focus is on tool performance metrics such as maximum torque, battery run-time longevity, and motor type (predominantly brushless for heavy use). These users prioritize total cost of ownership (TCO), factoring in tool lifespan, maintenance requirements, and compatibility with existing battery platforms. Large corporations often procure tools through direct contracts or specialized industrial distributors, seeking volume discounts and comprehensive service agreements that minimize equipment downtime.

The residential and DIY market segment constitutes the other major customer base. These buyers are typically sensitive to initial purchase price but value convenience, light weight, and sufficient power for common household tasks. Purchasing decisions in this segment are heavily influenced by retail promotions, brand recognition, and ease of use, often leveraging big-box retail stores and online marketplaces. This segment fuels demand for entry-level and mid-range cordless models designed for general purpose applications, contributing significantly to overall market volume.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.2 Billion |

| Market Forecast in 2033 | USD 7.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Stanley Black & Decker (DeWalt, Black+Decker), Techtronic Industries (TTI) (Milwaukee, Ryobi), Robert Bosch Power Tools, Makita Corporation, Hilti Corporation, Apex Tool Group, Atlas Copco, Snap-on Incorporated, Chervon Group (EGO, Skil), Festool Group, Koki Holdings (HiKOKI), Ingersoll Rand, Positec Tool Corporation (Worx), Metabo, FEIN Power Tools, ZF Friedrichshafen AG, AIMCO, Panasonic Corporation, C. & E. Fein GmbH, Generac Power Systems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pistol Grip Drill Market Key Technology Landscape

The technology landscape of the Pistol Grip Drill Market is rapidly evolving, moving away from conventional electric motors and towards intelligent, battery-powered systems. The most impactful technological innovation is the widespread adoption of brushless DC motors (BLDC). Unlike traditional brushed motors that rely on carbon brushes which wear out and generate heat, brushless motors use electronic commutators. This results in superior efficiency, longer runtime per battery charge, significantly reduced heat generation, and a vastly extended tool lifespan, making them the standard for professional-grade pistol grip drills across all major manufacturers.

Complementing the motor advancement is the persistent evolution of lithium-ion (Li-ion) battery technology. Recent advancements focus on increasing energy density, which translates to lighter battery packs with longer operating times, often featuring advanced thermal management systems to prevent overheating during high-demand usage. Fast charging capabilities and standardized battery platforms (allowing one battery to fit multiple tools within a brand's ecosystem) are critical selling points that enhance user convenience and reduce the overall investment required for professional users managing a large fleet of tools. Furthermore, smart battery packs incorporate microprocessors to communicate with the tool and charger, optimizing power delivery and extending the overall cycle life of the pack.

Beyond core power components, the incorporation of advanced electronics and micro-sensors is defining the next generation of tools. These technologies facilitate features such as electronic torque control, which allows users to set precise torque limits to prevent overtightening fasteners. Vibration dampening technology, often utilizing sophisticated gearing and internal counterweights, is also standard in high-end models, improving ergonomics and reducing operator fatigue. Connectivity, often through Bluetooth or proprietary wireless protocols, allows for tool tracking, performance logging, and remote settings adjustment, feeding into the broader trend of Internet of Things (IoT) integration on construction sites for improved asset management and operational oversight.

Regional Highlights

Regional dynamics play a crucial role in shaping the Pistol Grip Drill Market, reflecting differences in construction spending, labor costs, and adoption rates of advanced technology. North America and Europe currently represent the largest market value share, characterized by high demand for premium, brushless cordless tools (18V and above) driven by stringent professional standards and a strong DIY culture. These markets focus heavily on replacement cycles and require specialized tools for renovation and sophisticated infrastructure projects. Manufacturers prioritize durability, ergonomic design, and comprehensive warranty coverage in these regions.

Asia Pacific (APAC) is projected to be the engine of future market growth, primarily due to unprecedented levels of government and private investment in massive infrastructure projects, rapid urbanization, and expansion of the manufacturing sector (particularly in China, India, and Southeast Asian nations). While initial adoption often favors cost-effective, high-volume products, the professional segment is quickly transitioning to cordless brushless technology as power accessibility and efficiency become paramount on increasingly sophisticated construction sites. The large, addressable population also drives significant volume in the entry-level and consumer segments.

Latin America (LATAM) and the Middle East & Africa (MEA) represent evolving markets. LATAM shows strong potential driven by housing development and mining activities, relying primarily on cost-effective tools but with increasing demand for mid-range quality. MEA's growth is concentrated in key oil-rich nations undertaking large-scale commercial and industrial construction (e.g., UAE, Saudi Arabia). The challenge in these regions often relates to distribution network reliability and managing local power supply fluctuations, making high-capacity, reliable cordless tools highly desirable for job site independence.

- North America (US and Canada): Market characterized by high penetration of cordless, premium brands (DeWalt, Milwaukee). Dominant segment is professional construction and remodeling, emphasizing high voltage platforms (18V/20V and above) and smart tool integration for fleet management.

- Europe (Germany, UK, France): Focus on regulatory compliance regarding safety and noise. Strong demand for specialized, highly accurate tools, particularly from professional tradesmen and woodworking specialists. Germany holds a large share due to robust manufacturing and engineering sectors.

- Asia Pacific (China, India, Japan): Highest growth potential globally, driven by infrastructure development and rapid industrialization. China acts as both a massive consumer market and a major global manufacturing hub for power tools. Increasing shift towards local manufacturing and cost-competitive brushless alternatives.

- Latin America: Emerging market with high sensitivity to price. Growth is driven by residential construction and expansion of automotive repair services. Demand is rising for entry-level and mid-range cordless solutions offering flexibility.

- Middle East & Africa (MEA): Growth tied heavily to large-scale urban development and energy infrastructure projects. High demand for durable tools capable of performing in extreme climate conditions. Key market players focus on establishing localized service centers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pistol Grip Drill Market.- Stanley Black & Decker (DeWalt, Black+Decker)

- Techtronic Industries Co. Ltd. (TTI) (Milwaukee, Ryobi, AEG)

- Robert Bosch Power Tools GmbH

- Makita Corporation

- Hilti Corporation

- Apex Tool Group, LLC

- Atlas Copco AB

- Snap-on Incorporated

- Chervon Group (EGO, Skil)

- Festool Group GmbH

- Koki Holdings Co., Ltd. (HiKOKI)

- Ingersoll Rand Inc.

- Positec Tool Corporation (Worx, Kress)

- Metabo (Koki Holdings)

- FEIN Power Tools GmbH

- ZF Friedrichshafen AG

- AIMCO (Assembly Industrial Machinery Co.)

- Panasonic Corporation

- C. & E. Fein GmbH

- Generac Power Systems, Inc.

Frequently Asked Questions

Analyze common user questions about the Pistol Grip Drill market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between brushed and brushless pistol grip drills?

Brushless pistol grip drills utilize electronic commutation instead of carbon brushes, resulting in superior energy efficiency, longer battery run-time, greater durability, and reduced maintenance compared to traditional brushed motors, making brushless the preferred technology for professional users.

Which factors are driving the dominance of cordless pistol grip drills over corded models?

The dominance is driven primarily by advancements in lithium-ion battery technology, offering increased energy density, faster charging, and extended operational run-time. This eliminates the need for power cords, providing unmatched mobility, safety, and operational flexibility on diverse job sites.

How does the integration of IoT impact professional pistol grip drill fleet management?

IoT integration allows professionals to remotely track tool location, monitor usage statistics (cycles, load, performance), implement predictive maintenance scheduling, and remotely manage torque settings, significantly optimizing asset utilization and reducing costly downtime across large tool fleets.

Which geographical region exhibits the fastest growth rate for the Pistol Grip Drill Market?

The Asia Pacific (APAC) region is forecasted to exhibit the fastest growth rate, propelled by massive government spending on infrastructure development, rapid urbanization, and the increasing modernization and professionalization of the construction and manufacturing sectors in key economies like China and India.

What are the typical end-user segments for high-torque professional pistol grip drills?

High-torque professional drills are primarily utilized by the Industrial and Commercial segment, including general construction contractors, specialized trades (electricians, plumbers), automotive maintenance facilities, and heavy manufacturing operations, where durability and consistent power are non-negotiable requirements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager