Plasma Cutting Torches Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432600 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Plasma Cutting Torches Market Size

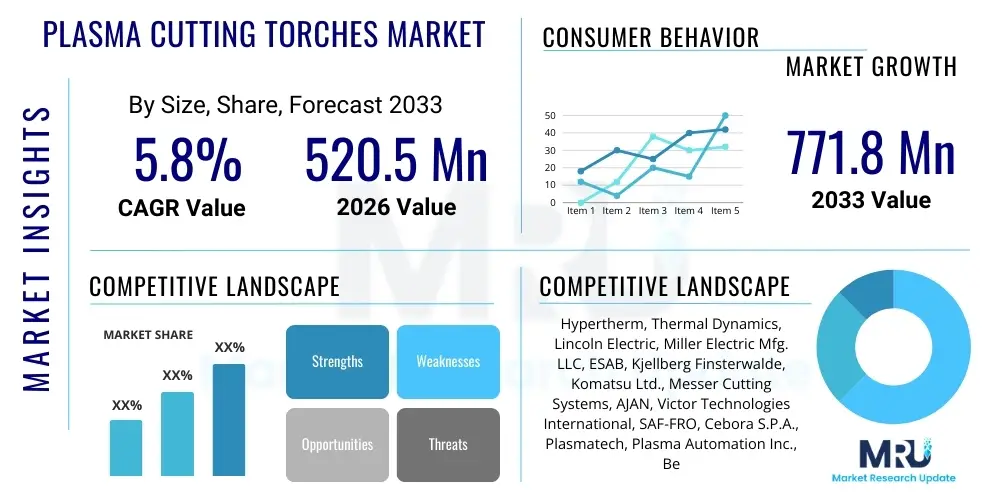

The Plasma Cutting Torches Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $520.5 Million in 2026 and is projected to reach $771.8 Million by the end of the forecast period in 2033.

Plasma Cutting Torches Market introduction

The Plasma Cutting Torches Market encompasses the design, manufacturing, and distribution of specialized equipment used to cut electrically conductive materials, such as steel, aluminum, brass, and copper, using an accelerated jet of hot plasma. Plasma torches operate by creating an electrical arc between an electrode within the torch and the workpiece, which is then constricted by a swirling gas (like air, oxygen, nitrogen, or argon) to produce a high-velocity, high-temperature plasma stream capable of precise and rapid material severance. This technology is superior to traditional oxy-fuel cutting methods in terms of speed, versatility across material types, and ability to cut thick metals with minimal heat distortion, making it indispensable across various heavy and light manufacturing sectors.

The primary applications of plasma cutting torches span critical industrial domains including automotive manufacturing, heavy machinery fabrication, shipbuilding, aerospace, and construction infrastructure projects. In the automotive sector, these torches are vital for chassis modification and high-speed production line adjustments. For the construction and infrastructure industries, plasma technology facilitates efficient on-site cutting and structural steel preparation. The inherent benefits, such as enhanced cutting speeds, superior edge quality, reduced need for secondary finishing operations, and the ability to operate in highly automated CNC environments, significantly drive their adoption globally.

Major factors propelling the market growth include the robust expansion of the global infrastructure and construction sectors, coupled with the increasing trend towards industrial automation and the need for higher precision in fabrication processes. The continuous advancements in power source technology, particularly the shift toward inverter-based systems, have resulted in lighter, more energy-efficient, and portable plasma cutting solutions, broadening their accessibility to smaller workshops and mobile maintenance teams. Furthermore, rising demand for customized fabrication in emerging economies, alongside rigorous quality standards in specialized manufacturing, reinforce the necessity for high-definition plasma cutting equipment, stimulating market demand across multiple geographies.

Plasma Cutting Torches Market Executive Summary

The Plasma Cutting Torches Market is currently undergoing a significant technological transformation characterized by the integration of advanced digital controls and enhanced portability, fundamentally reshaping business dynamics. Key business trends indicate a strong market shift towards high-definition plasma systems, which offer unparalleled precision and improved productivity, specifically catering to sectors requiring intricate cuts on thick materials, such as heavy machinery and shipbuilding. Regional trends highlight the Asia Pacific (APAC) region, driven by massive investments in infrastructure development and rapid industrialization, as the primary growth engine. This growth is closely followed by North America and Europe, where demand is fueled by the modernization of existing manufacturing facilities and the adoption of energy-efficient, environmentally compliant cutting solutions to meet stringent regulatory frameworks. Strategic mergers and acquisitions focused on expanding technology portfolios, particularly in robotics and CNC integration capabilities, remain a central competitive element for leading market participants navigating global supply chain complexities and seeking optimized distribution networks.

Segment-wise, the market sees robust growth in the Consumables segment due to the inherent wear-and-tear nature of electrodes and nozzles, dictating recurring revenue streams for manufacturers and distributors. Within the product type segmentation, automated systems, including robotic and CNC-integrated torches, are experiencing faster growth rates compared to handheld systems, reflecting the overarching industry trend toward automation and maximizing throughput in factory settings. The rise of inverter technology in power sources is enhancing the performance and efficiency of all cutting classes, making plasma cutting more appealing for diverse applications ranging from lightweight maintenance tasks to continuous industrial fabrication. Furthermore, the increasing focus on material waste reduction and operational efficiency is propelling the demand for multi-gas plasma systems capable of optimizing cut quality across various metal compositions.

In summation, the market outlook remains highly positive, supported by resilient demand from core end-user industries like automotive repair, aerospace component fabrication, and energy infrastructure projects. The industry's strategic direction involves deep integration with Industry 4.0 principles, emphasizing smart manufacturing, predictive maintenance, and remote diagnostics facilitated by connected torch systems. Manufacturers are increasingly focused on developing specialized torch designs for specific applications, such as underwater cutting or beveling operations, expanding the potential scope and utility of plasma technology. Successful penetration hinges on balancing technological innovation with cost-effectiveness, ensuring that advanced plasma solutions remain accessible to both large-scale fabrication facilities and smaller job shops worldwide.

AI Impact Analysis on Plasma Cutting Torches Market

User queries regarding the impact of Artificial Intelligence (AI) on the Plasma Cutting Torches Market commonly center on how AI will automate the cutting process, improve cut quality consistency, and mitigate the reliance on highly skilled operators. Users frequently ask about the implementation of AI-driven vision systems for real-time material recognition, optimization of nesting patterns to reduce material scrap, and the potential for predictive maintenance algorithms to minimize costly downtime associated with consumable failures. Concerns often revolve around the initial capital investment required for adopting AI-enabled systems and the subsequent training needed for the existing workforce to manage these sophisticated tools. The key expectations are that AI will usher in a new era of "self-optimizing" plasma systems that dynamically adjust parameters (like current, gas flow, and speed) based on real-time feedback and historical data, leading to unprecedented levels of efficiency and significantly extending the lifespan of critical torch consumables.

- AI-enabled Parameter Optimization: Automated real-time adjustments of cutting variables (amperage, gas mix) based on material thickness and wear status, maximizing quality and speed.

- Predictive Maintenance: AI algorithms analyze vibration, temperature, and current feedback to forecast consumable failure (nozzles, electrodes), scheduling preemptive replacement and reducing unplanned downtime.

- Enhanced Nesting and Material Utilization: Machine learning optimizes plate nesting layouts, minimizing kerf waste and increasing overall yield per sheet of raw material.

- Robotic Path Planning and Collision Avoidance: AI improves the efficiency and safety of robotic plasma cutting cells by optimizing torch movement trajectories and preventing collisions in complex 3D environments.

- Automated Quality Control (QC): Vision systems coupled with AI evaluate cut edges for squareness and slag formation instantly, flagging quality deviations without human intervention.

- Operator Skill Augmentation: AI systems provide real-time guidance and diagnostics to human operators, accelerating training and enabling less experienced staff to achieve expert-level results consistently.

DRO & Impact Forces Of Plasma Cutting Torches Market

The dynamics of the Plasma Cutting Torches Market are heavily influenced by a confluence of driving forces, inherent limitations acting as restraints, and emerging technological and economic opportunities, all synthesized into a set of distinct impact forces. A primary driver is the accelerating global shift towards industrial automation, requiring highly efficient and repeatable cutting solutions integrated into robotic arms and CNC machines across diversified manufacturing facilities. Simultaneously, the persistent demand for higher precision in complex fabrication tasks, particularly within the energy and aerospace sectors where material tolerances are extremely tight, necessitates the continuous adoption of advanced high-definition plasma systems. However, the market faces significant restraints, including the high cost of initial investment required for high-end plasma equipment and the continuous expenditure associated with frequently replacing consumables (electrodes, nozzles, shields), which can be prohibitive for smaller enterprises operating on thin margins. Additionally, the technical skills gap in operating and maintaining sophisticated multi-gas plasma cutting systems presents an ongoing challenge to widespread adoption, particularly in developing regions, requiring substantial training commitment from end-users.

Opportunities for market expansion are predominantly centered on the development and commercialization of next-generation power sources, such as compact and extremely portable inverter-based systems, making professional-grade plasma cutting more accessible for mobile applications and field repairs. Furthermore, the growing focus on processing unconventional and advanced materials, including composite metals and high-strength steels used in modern construction and defense applications, opens new avenues for specialized plasma torch designs tailored for these demanding cutting environments. Sustainability initiatives also present a crucial opportunity, as manufacturers introduce energy-efficient systems that minimize power consumption and reduce toxic fume emissions compared to older thermal cutting technologies, aligning with stricter global environmental regulations. The digitalization of fabrication processes, leveraging technologies like the Industrial Internet of Things (IIoT) for remote monitoring and diagnostics, further optimizes plasma torch performance and lifecycle management.

The net impact forces on the market are strongly positive, indicating a high impetus for growth, largely due to technological superiority over alternative cutting methods and the robust economic recovery driving infrastructure spending globally. The market exhibits high substitution threat from laser and waterjet cutting technologies, especially in very thin material or extremely high-precision applications, requiring constant innovation in plasma technology to maintain competitive differentiation in speed and material thickness capacity. The bargaining power of suppliers is moderate, as key components like high-frequency power electronics and specific gas mixtures are specialized, yet the large number of plasma torch manufacturers maintains competitive pricing pressures. Overall, the dominant impact force remains the technological imperative to integrate plasma cutting into fully automated, data-driven smart factories, pushing the industry toward smaller, faster, and smarter torch systems capable of dynamic adjustments and seamless connectivity within complex manufacturing ecosystems.

Segmentation Analysis

The Plasma Cutting Torches Market segmentation provides a crucial framework for understanding the diverse product offerings and their strategic positioning across various end-user requirements and operational scales. The market is fundamentally segmented based on the torch type (handheld vs. mechanized), the power source technology (conventional vs. inverter), the gas type utilized (single gas vs. multi-gas), and the application scale (low current, medium current, high current). The distinction between handheld and mechanized torches is critical, with handheld systems dominating job shops and repair operations due to portability, while mechanized torches are central to high-volume production lines integrated with CNC or robotic systems. The continuous drive toward energy efficiency and portability is heavily influencing the power source segment, where inverter-based systems are rapidly displacing older conventional transformer-based power supplies due to their smaller footprint, lighter weight, and superior arc control capabilities, offering manufacturers a competitive edge.

- By Product Type:

- Handheld Plasma Torches

- Mechanized Plasma Torches (CNC/Robotic Integration)

- By Technology:

- Conventional Plasma Cutting Torches

- High Definition (HD) Plasma Cutting Torches

- Inverter-based Plasma Torches

- By Current Rating (Amperage):

- Low Current (Under 50 Amps)

- Medium Current (50 Amps to 150 Amps)

- High Current (Above 150 Amps)

- By Consumable Type:

- Electrodes

- Nozzles/Tips

- Swirl Rings

- Shield Caps

- By End-User Industry:

- Automotive and Transportation

- Heavy Machinery and Fabrication

- Shipbuilding and Marine

- Aerospace and Defense

- Construction and Infrastructure

- General Manufacturing and Job Shops

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Plasma Cutting Torches Market

The value chain for the Plasma Cutting Torches Market begins with the upstream sourcing and procurement of highly specialized raw materials and electronic components. This includes high-grade copper and tungsten for electrodes, ceramics for insulators, specialized plastics for torch bodies, and advanced power electronics (such as IGBTs and MOSFETs) crucial for inverter technology power supplies. Manufacturers rely heavily on a specialized supplier base for these components, where quality and consistency are paramount for the torch's performance and longevity, leading to strong reliance on certified suppliers for reliable sourcing. The subsequent manufacturing phase involves complex assembly, precision machining of consumables, and rigorous testing of the power source and torch connection systems to ensure safety and performance metrics are met. Quality control at this stage is critical, especially for high-definition systems where micron-level precision in consumable manufacturing directly impacts cut quality and electrode life.

The downstream segment of the value chain is characterized by a sophisticated distribution network essential for reaching the diverse global customer base, spanning large industrial fabricators and small maintenance crews. Distribution channels are bifurcated into direct sales channels, typically utilized for high-value, large-scale CNC and robotic plasma systems where technical consultation and installation support are required, and indirect channels. The indirect channels rely heavily on authorized industrial distributors, equipment dealers, and specialized welding and cutting supply houses, which are vital for distributing high-volume consumables and handheld units. E-commerce platforms are increasingly gaining traction, particularly for replacement consumables and entry-level portable cutting units, offering rapid global accessibility and streamlined logistics for standardized products, enhancing market penetration in geographically dispersed regions.

The efficiency of the value chain is increasingly determined by robust logistics and effective aftermarket support, including rapid spare parts delivery and technical troubleshooting services, particularly in industrial settings where downtime is extremely costly. Effective inventory management of consumables at the distributor level is crucial to meeting immediate end-user demand and preventing operational interruptions in fabrication shops. Successful companies leverage integrated digital platforms to manage inventory, track product performance data from connected systems, and streamline the flow of both equipment and consumables from the point of manufacture to the point of use. This integrated approach ensures competitive pricing, minimizes lead times, and strengthens customer relationships through reliable technical service and prompt parts availability.

Plasma Cutting Torches Market Potential Customers

The primary customer base for the Plasma Cutting Torches Market consists of various industrial and commercial entities heavily engaged in metal processing, fabrication, and repair activities. These end-users are defined by their recurrent need for efficient, high-speed, and precise cutting of ferrous and non-ferrous metals. The core customer segments include large-scale manufacturing enterprises in the heavy machinery sector, such as agricultural equipment producers and construction vehicle manufacturers, where plasma cutting is essential for preparing thick plates and complex structural components used in their assemblies. Furthermore, independent fabrication and welding job shops, which require versatile tools capable of handling customized small-batch orders and diverse material thicknesses, represent a large volume customer segment, favoring portable and medium-amp handheld plasma systems due to their flexibility and ease of use in diverse work environments.

Beyond general fabrication, highly specialized industries constitute critical end-users demanding high-definition plasma solutions for stringent quality requirements. This includes the shipbuilding and marine sector, which relies on plasma cutting for forming massive hull plates and specialized structural sections with minimal thermal distortion. Similarly, the aerospace and defense industries are key consumers, utilizing advanced mechanized plasma torches for preparing high-strength, lightweight alloys used in airframe and military vehicle production where cut edge integrity and repeatability are non-negotiable standards. The maintenance, Repair, and Overhaul (MRO) segment, encompassing automotive repair garages, pipeline maintenance teams, and HVAC installation contractors, represents a significant market for lower-amperage, highly portable plasma cutters that facilitate quick, on-site metal remediation and modification work.

The purchasing decisions of these potential customers are driven by several factors: the required throughput volume, the precision specifications (often dictated by specific industry certifications), the range of material types handled, and the total cost of ownership, which heavily factors in consumable lifespan and energy efficiency. Large industrial customers prioritize integration capabilities with existing CNC infrastructure and robust after-sales technical support, whereas smaller customers prioritize portability, ease of operation, and a competitive initial investment price. Targeting these specific industry needs through specialized torch designs, application-specific training, and customized financing options is crucial for market penetration and maximizing long-term customer loyalty across the diverse potential customer spectrum.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $520.5 Million |

| Market Forecast in 2033 | $771.8 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hypertherm, Thermal Dynamics, Lincoln Electric, Miller Electric Mfg. LLC, ESAB, Kjellberg Finsterwalde, Komatsu Ltd., Messer Cutting Systems, AJAN, Victor Technologies International, SAF-FRO, Cebora S.P.A., Plasmatech, Plasma Automation Inc., Beijing Time Technologies Co., Ltd., Shenzhen Huayuan Electric Co., Ltd., The Voestalpine Group, Koike Aronson Inc., Harris Products Group, Ador Welding Limited |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plasma Cutting Torches Market Key Technology Landscape

The technological landscape of the Plasma Cutting Torches Market is characterized by intense innovation focused on enhancing cut quality, maximizing consumable life, and improving system connectivity and integration. High Definition (HD) Plasma technology remains a cornerstone, utilizing extremely tight arc constriction and specialized gas mixes (like F5 or H35) to produce near-laser quality cuts with exceptional edge perpendicularity and minimal dross. This technology is critical for high-tolerance industries, directly addressing the demand for finished parts that require little to no secondary machining. The continuous evolution of HD systems involves specialized torch designs that incorporate liquid cooling and advanced shielding mechanisms to manage the intense thermal loads generated, thereby significantly extending the operational duration of electrodes and nozzles and improving the cost-efficiency of the cutting process in high-amperage applications.

A second crucial technological trend is the pervasive adoption of advanced inverter power source technology. Modern plasma cutters utilize IGBT (Insulated Gate Bipolar Transistor) and MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) based inverter circuits, which convert high-frequency alternating current into stable direct current for the plasma arc. This results in significantly smaller, lighter, and more energy-efficient power supplies compared to traditional transformer-based systems, enabling superior arc starting capabilities and more consistent output even under fluctuating input power conditions. The portability conferred by inverter technology has profoundly democratized plasma cutting, allowing professional-grade performance to be delivered in highly compact units suitable for field work, remote construction sites, and small fabrication shops without sacrificing cutting power or speed across a reasonable range of material thicknesses.

Furthermore, the integration of smart features and digital connectivity is rapidly changing how plasma torches are utilized and maintained. Modern mechanized plasma systems are increasingly equipped with built-in sensors, proprietary software interfaces, and Ethernet capabilities, facilitating seamless communication with CNC controllers and centralized manufacturing execution systems (MES). This integration enables remote monitoring, automated data logging of cutting parameters, and real-time diagnostics, which are essential for achieving the goals of Industry 4.0—namely, predictive maintenance and maximizing uptime through data-driven insights. Key innovations also include patented consumable designs, such as vent-to-atmosphere technology and optimized gas flow paths, engineered specifically to manage gas dynamics and enhance the focused energy density of the plasma jet, ensuring cleaner cuts and significantly lengthening the maintenance cycle of critical torch components across various operational environments.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market for plasma cutting torches, primarily driven by unprecedented rates of urbanization and massive government investments in infrastructure, particularly in countries like China, India, and Southeast Asian nations. The expansion of manufacturing bases, coupled with significant growth in shipbuilding, automotive production, and general steel fabrication, fuels the demand for both handheld units (for smaller workshops and maintenance) and high-volume mechanized systems (for large fabrication plants). Competitive pricing and increasing domestic technological capabilities within this region contribute to its dominance. Furthermore, the push toward adopting mechanized and automated manufacturing solutions to enhance productivity and quality across various sectors ensures sustained high demand growth rates over the forecast period.

- North America: North America is a mature market characterized by the early adoption of advanced, high-definition plasma cutting technology and a strong focus on automation and quality control. Demand is principally driven by the recovery and modernization of the manufacturing sector, robust activity in aerospace and defense, and a continuous requirement for high-precision cutting solutions in energy infrastructure projects (oil, gas, and renewable energy). The emphasis here is less on sheer volume and more on technological sophistication, with high penetration rates of CNC-integrated plasma tables and a strong market for premium, inverter-based portable systems due to stringent labor standards and the high cost of skilled manual labor.

- Europe: The European market maintains a substantial share, propelled by Germany’s strong machinery and automotive manufacturing sector and significant activity in shipbuilding and complex industrial fabrication across Western Europe. Regulatory frameworks emphasizing energy efficiency and reduced emissions favor the adoption of modern inverter technology and environmentally conscious plasma systems. The market is highly focused on quality, reliability, and precision, leading to high adoption rates of high-definition and multi-gas plasma solutions. The shift toward sustainable manufacturing practices and the integration of robotics within existing production lines are key demand catalysts in this region.

- Latin America (LATAM): The LATAM market is experiencing steady growth, although constrained by economic volatility in some key countries. Demand is driven primarily by infrastructure construction, resource extraction industries (mining and oil & gas), and necessary repair and maintenance operations. The market predominantly favors cost-effective, durable handheld plasma systems and mid-range mechanized solutions. Brazil and Mexico are the largest national markets within the region, exhibiting growing industrial activity that is slowly transitioning toward more automated cutting solutions as foreign investment increases manufacturing capacity.

- Middle East and Africa (MEA): The MEA region is witnessing growth catalyzed by major ongoing and planned energy projects, particularly in Saudi Arabia and the UAE, alongside diversification efforts into non-oil sectors like tourism infrastructure and heavy construction. The high demand for structural steel preparation in rapid construction projects (e.g., ports, railways, large commercial complexes) requires robust plasma cutting equipment. While the market for consumables is high, adoption of advanced HD systems is often tied to large-scale, state-backed industrial projects, with a strong preference for durable, high-amperage systems capable of handling challenging environmental conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plasma Cutting Torches Market.- Hypertherm, Inc.

- Thermal Dynamics (Victor Technologies International)

- Lincoln Electric Holdings, Inc.

- Miller Electric Mfg. LLC (ITW)

- ESAB Corporation

- Kjellberg Finsterwalde Plasma und Maschinen GmbH

- Komatsu Ltd.

- Messer Cutting Systems GmbH

- AJAN CNC Machinery

- Cebora S.P.A.

- Plasmatech, Inc.

- Plasma Automation Inc.

- Beijing Time Technologies Co., Ltd.

- Shenzhen Huayuan Electric Co., Ltd.

- The Voestalpine Group

- Koike Aronson Inc./Koike Sanso Kogyo Co., Ltd.

- Harris Products Group (Lincoln Electric)

- Ador Welding Limited

- Kemppi Oy

- Weldwell New Zealand Ltd.

Frequently Asked Questions

Analyze common user questions about the Plasma Cutting Torches market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between High Definition (HD) and Conventional Plasma Cutting?

HD plasma cutting utilizes tighter arc constriction and specialized gas management to achieve superior cut quality, higher angular accuracy, and minimal bevel, resulting in near-laser quality cuts on thicker materials. Conventional plasma, while faster on thin metals and more cost-effective, offers lower precision and requires more post-cut finishing.

How are environmental regulations influencing the demand for plasma cutting systems?

Environmental regulations, particularly concerning energy consumption and air quality, drive demand for modern inverter-based plasma systems. These systems are significantly more energy-efficient and, when paired with appropriate fume extraction equipment, help end-users comply with increasingly strict workplace safety and emission standards compared to older thermal cutting technologies.

Which end-user segment drives the highest recurring revenue in the Plasma Cutting Torches Market?

The recurring revenue is predominantly driven by the consumables segment, specifically electrodes, nozzles, and shield caps. High-volume manufacturing and fabrication shops, due to continuous use and the inherently limited lifespan of these components, generate the highest replacement demand, creating a sustained revenue stream for manufacturers.

What role does CNC integration play in the future growth of mechanized plasma torches?

CNC integration is critical, transforming plasma torches from manual tools into high-throughput industrial assets. Integration allows for precise, repeatable, and complex cutting operations, automated nesting to minimize scrap, and seamless data exchange, directly aligning with the manufacturing industry's move towards automated, smart factory environments and maximizing material utilization.

What are the key benefits of portable inverter plasma cutters over traditional power supplies?

Portable inverter plasma cutters offer drastically reduced size and weight, making them ideal for mobile maintenance and field applications. They provide higher energy efficiency, better arc starting reliability, and superior control over the cutting current, ensuring consistent performance even when using unstable or low-voltage power sources common on job sites.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager