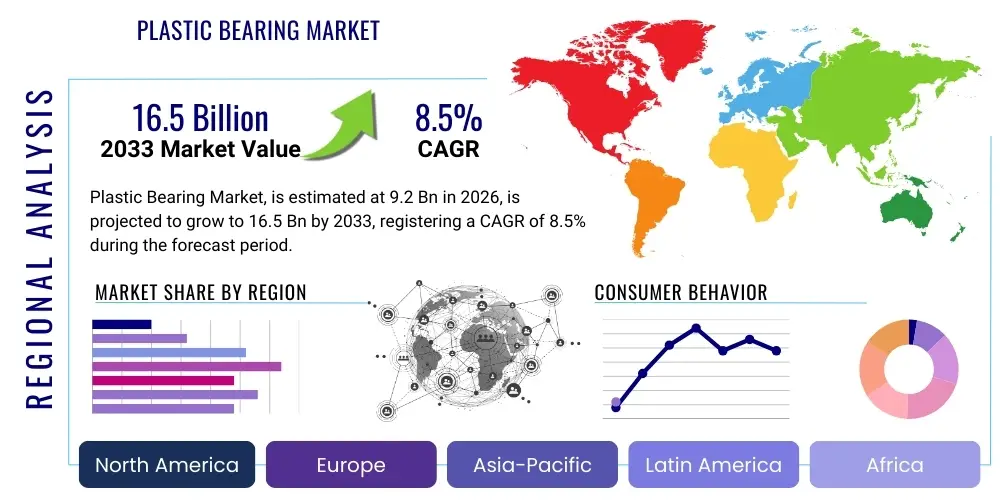

Plastic Bearing Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439996 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Plastic Bearing Market Size

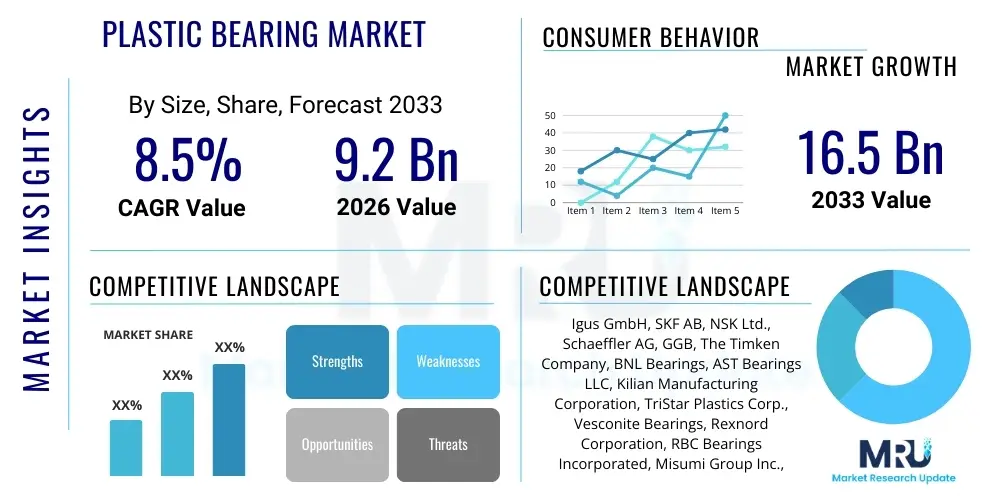

The Plastic Bearing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 9.2 Billion in 2026 and is projected to reach USD 16.5 Billion by the end of the forecast period in 2033.

Plastic Bearing Market introduction

The global Plastic Bearing Market constitutes a pivotal segment within the broader industrial components landscape, distinguished by its innovative utilization of advanced polymer materials to engineer lightweight, corrosion-resistant, and frequently self-lubricating bearing solutions. These specialized bearings are meticulously designed to surmount the inherent limitations often encountered with traditional metallic bearings, particularly in operational environments that are prone to moisture, aggressive chemicals, or where electrical insulation, non-magnetic properties, and exceptionally quiet operation are paramount design considerations. The market's product portfolio is extensive, encompassing a diverse array of bearing types, including plain bearings, ball bearings, thrust bearings, and linear bearings, each meticulously crafted from high-performance engineering plastics such as acetal, nylon, ultra-high molecular weight polyethylene (UHMW-PE), polyether ether ketone (PEEK), and polytetrafluoroethylene (PTFE). The selection of specific polymer blends and composites is precisely tailored to meet the exacting demands of various application-specific performance criteria.

The versatility and advantageous properties of plastic bearings enable their widespread adoption across a multitude of industries. In the rapidly evolving automotive sector, these bearings play a crucial role in the ongoing drive for vehicle lightweighting, directly contributing to enhanced fuel efficiency, reduced emissions, and improved performance across various components, ranging from intricate interior mechanisms like seat adjusters and window regulators to critical engine auxiliary systems and electric vehicle subsystems. The highly sensitive medical and healthcare industry heavily leverages plastic bearings for precision instruments, sophisticated diagnostic equipment, and patient care devices, valuing their inherent inertness, sterilizability, smooth and precise operation, and resistance to bodily fluids. Furthermore, the stringent hygiene demands of the food and beverage industry necessitate the widespread adoption of plastic bearings for processing, conveying, and packaging machinery, benefiting immensely from their non-corrosive nature, resistance to aggressive washdown chemicals, and the elimination of external lubrication, thereby ensuring uncompromising hygiene standards and extended operational longevity without contamination risks.

The primary benefits that are vigorously driving the widespread adoption and continuous expansion of plastic bearings encompass their intrinsic resistance to corrosion and chemical degradation, the elimination of external lubrication requirements which significantly reduces maintenance burden and contamination risks, substantial weight reduction compared to conventional metal alternatives leading to energy savings, and superior vibration dampening characteristics that result in noticeably quieter operation. These cumulative advantages translate directly into significantly reduced lifecycle maintenance costs, substantially extended service life in challenging environmental conditions, and marked improvements in overall system efficiency and reliability. Coupled with a growing global emphasis on energy efficiency, environmental sustainability, and the circular economy across diverse industrial sectors, the plastic bearing market is currently experiencing a period of robust and sustained growth. Key driving factors include the accelerating global demand for lightweight and compact components in the automotive, aerospace, and robotics industries, the pervasive expansion of automation and robotics in advanced manufacturing processes, and increasingly stringent regulatory requirements pertaining to hygiene, material safety, and energy consumption in critical end-use sectors like medical, food processing, and consumer electronics.

Plastic Bearing Market Executive Summary

The Plastic Bearing Market is currently navigating a period of profound and dynamic transformation, characterized by the emergence and consolidation of several critical business, regional, and segment trends that collectively shape its growth trajectory and competitive landscape. From a business perspective, the market is primarily driven by relentless innovation in material science, with leading manufacturers making substantial investments in the research and development of advanced polymer compounds. These efforts are focused on engineering materials that offer significantly enhanced mechanical strength, superior temperature resistance, improved wear performance, and advanced chemical inertness, thereby effectively broadening the functional application envelope for plastic bearings into previously inaccessible environments. A prominent trend is the pronounced shift towards highly customized and application-specific solutions, where bearing designs and material compositions are precisely engineered to meet the unique operational parameters, environmental challenges, and lifecycle expectations of particular industries and individual customer needs. Furthermore, the market is witnessing an escalation in strategic collaborations and partnerships between specialized raw material suppliers and plastic bearing manufacturers, aiming to optimize production processes, integrate innovative material technologies, and deliver holistic solutions that enhance overall product reliability, accelerate market responsiveness, and facilitate knowledge transfer across the value chain.

Regionally, the Asia Pacific continues its trajectory as the undeniable powerhouse dominating the global plastic bearing market. This leadership is underpinned by its unparalleled robust manufacturing base, pervasive rapid industrialization, and substantial growth across key sectors such as automotive, electronics, and general industrial production, particularly within economic giants like China, India, Japan, and South Korea. The region benefits significantly from extensive infrastructure development projects, a burgeoning middle-class population, and an increasing penetration of industrial automation, all of which stimulate escalating demand across various end-use industries. Europe and North America, while representing more mature and established markets, are characterized by a strong and sustained focus on high-performance, precision engineering applications and the adoption of cutting-edge sustainable manufacturing practices. These regions exhibit substantial uptake in the medical, aerospace, and advanced industrial machinery sectors, driven by stringent regulatory frameworks and a commitment to technological superiority. Both continents are also at the vanguard of adopting smart manufacturing paradigms and industrial automation, further intensifying the demand for sophisticated and specialized plastic bearing solutions that offer enhanced efficiency and longevity.

Analysis of segmentation trends unequivocally highlights an increasing and strategic preference for ultra-high-performance plastics such as PEEK, PTFE, and specialized composites in the most demanding applications. This preference, despite the associated higher material costs, is driven by their superior chemical resistance, exceptional temperature tolerance, and advanced mechanical properties that are critical for extreme operating conditions. Plain bearings consistently maintain the largest market share owing to their inherent design simplicity, cost-effectiveness, ease of integration, and remarkable versatility across an expansive array of general-purpose and specialized applications. Concurrently, ball bearings are experiencing accelerated traction, particularly in applications requiring minimized friction, higher rotational speeds, and enhanced precision. The automotive industry steadfastly remains the single largest end-use segment, propelled by the persistent and critical need for vehicle lightweighting, improved fuel efficiency, reduced emissions, and the explosive growth of the electric vehicle (EV) market. Parallel to this, the medical and food and beverage sectors are exhibiting robust and accelerated growth, fueled by increasingly stringent hygiene standards, regulatory compliance, and the unyielding demand for maintenance-free components capable of withstanding harsh cleaning regimes, sterilization processes, and ensuring pristine, contamination-free operational environments.

AI Impact Analysis on Plastic Bearing Market

The pervasive integration of Artificial Intelligence (AI) is poised to fundamentally redefine and profoundly reshape the Plastic Bearing Market, directly addressing common user inquiries regarding the optimization of product development lifecycles, enhancement of manufacturing processes, and significant improvements in operational efficiency. Users are demonstrating a keen and growing interest in understanding how AI can facilitate more accurate and predictive material selection, enable the precise prediction of bearing performance under a vast array of simulated operational conditions, and intelligently streamline the entire supply chain, from the initial sourcing of raw polymer materials to the final distribution of the finished plastic bearing product. The overarching theme permeating these user concerns reflects a strong expectation that AI will catalyze the development of technologically superior plastic bearings, characterized by significantly improved durability, substantially reduced lifecycle costs, and remarkably faster time-to-market. AI’s sophisticated analytical and predictive capabilities are anticipated to play a crucial role in minimizing inherent design flaws, proactively predicting potential mechanical failures long before they manifest, and ultimately fostering a more responsive, efficient, and intelligently managed manufacturing ecosystem across the entire plastic bearing industry.

- Predictive Maintenance Integration: AI-driven algorithms meticulously analyze vast quantities of operational data collected from machinery equipped with plastic bearings, enabling highly accurate predictions of bearing wear patterns and identifying potential failure points well in advance. This proactive approach facilitates scheduled maintenance and minimizes costly unplanned downtime, optimizing operational continuity.

- Optimized Material Selection and Design: AI algorithms can rapidly process and analyze extensive datasets encompassing various material properties, environmental conditions, and specific application requirements. This allows for intelligent recommendations of the optimal polymer composites or blends for bespoke bearing designs, significantly reducing the iterative trial-and-error phase in material development and selection.

- Advanced Simulation and Generative Design: AI tools substantially enhance Computer-Aided Design (CAD) and Computer-Aided Engineering (CAE) software by automating numerous design iterations. They can simulate complex stress distributions, thermal behaviors, and wear patterns with unprecedented accuracy, leading to the creation of superior bearing geometries that offer extended service life and enhanced performance characteristics.

- Automated Quality Inspection and Control: Vision-based AI systems deploy sophisticated image recognition and machine learning techniques to perform highly accurate, consistent, and rapid quality checks throughout the manufacturing process. These systems can identify microscopic defects, surface imperfections, and dimensional inaccuracies, ensuring every plastic bearing adheres to stringent quality specifications, thereby minimizing waste and elevating overall product reliability.

- Supply Chain Optimization and Resilience: AI-powered analytics significantly improve inventory management practices, generate highly accurate demand forecasts, and intelligently optimize logistics and transportation routes for both raw materials and finished products. This leads to substantial reductions in operational costs, enhanced supply chain resilience against disruptions, and improved delivery timelines.

- Smart Manufacturing and Real-time Process Control: AI monitors and processes real-time production parameters within manufacturing environments, such as injection molding temperatures, pressures, and cooling rates. This enables instantaneous, data-driven adjustments to ensure optimal manufacturing conditions, minimize defect rates, and significantly improve production throughput and efficiency in plastic bearing fabrication.

- Accelerated Customization and Personalization: AI facilitates rapid prototyping and enables efficient mass customization by quickly adapting bearing designs and manufacturing processes to fulfill highly specific customer requirements. This capability allows manufacturers to cater effectively to niche market demands and specialized applications with unprecedented speed and precision.

DRO & Impact Forces Of Plastic Bearing Market

The Plastic Bearing Market is intricately shaped by a dynamic and often complex interplay of various drivers, inherent restraints, emerging opportunities, and broader macroeconomic and technological impact forces that collectively dictate its growth trajectory and competitive landscape. A paramount driver fueling market expansion is the unrelenting global demand for lightweight components across a spectrum of industries, most notably in the automotive and aerospace sectors. In these industries, even marginal weight reduction directly translates into substantial improvements in fuel efficiency, reduced emissions, and enhanced operational performance, making plastic bearings an indispensable solution. The inherent corrosion and chemical resistance of plastic bearings render them critically valuable and often irreplaceable in harsh and aggressive operational environments where traditional metallic bearings would rapidly degrade. Furthermore, their unique self-lubricating properties significantly reduce or entirely eliminate the need for external lubrication and subsequent maintenance, leading to substantial cost savings and extended operational life. The pervasive global push towards advanced automation and robotics in modern manufacturing and logistics further amplifies the demand for high-performance, low-friction, and maintenance-free bearing solutions capable of operating reliably in continuous, high-duty cycles without extensive upkeep. Moreover, increasingly stringent environmental regulations and a heightened industrial focus on sustainable manufacturing practices strongly favor plastic bearings due to their often lower energy consumption during operation and their growing potential for recyclability and reduced environmental footprint.

Despite these compelling drivers, the market is simultaneously constrained by several significant factors. Plastic bearings, by their fundamental material nature, generally exhibit lower intrinsic load-bearing capacities and possess more restrictive temperature limitations when directly compared to their metallic counterparts. This inherent characteristic often restricts their widespread applicability in extreme-stress, high-impact, or persistently high-temperature operating conditions, necessitating careful material selection and application-specific design. There also persists a historical and sometimes lingering perception among a segment of end-users that plastic bearings are inherently less durable or robust than metal bearings, a misconception that requires continuous industry education, rigorous testing, and clear demonstration of the remarkable advancements in modern polymer technology and composite engineering. Furthermore, the global volatility in the prices of critical raw materials, such as various high-performance engineering plastics, additives, and reinforcements, can unpredictably impact manufacturing costs, profit margins, and overall market competitiveness, creating challenges for consistent pricing and supply chain stability. The absence of universally recognized, standardized testing protocols and performance benchmarks for specialized plastic bearing materials across all diverse applications can also act as a significant market adoption hurdle, leading to slower integration rates in more conservative and safety-critical industries.

Conversely, numerous promising opportunities are strategically positioned to catalyze substantial market expansion and technological advancement. The rapid and transformative growth of the electric vehicle (EV) market worldwide presents an exceptionally significant opportunity, as plastic bearings contribute vitally to both vehicle lightweighting and noise reduction in EV powertrains, auxiliary systems, and interior components. The continuously expanding medical device sector, driven by an aging global population, increasing healthcare expenditures, and relentless technological innovations, offers exceptionally fertile ground for plastic bearings due to their unparalleled biocompatibility, sterilizability, and precision movement capabilities. Similarly, the dynamic food processing and packaging industries are in perpetual pursuit of components that not only meet increasingly rigorous hygiene and safety standards but also demonstrate exceptional resistance to harsh cleaning agents and continuous washdown environments. Groundbreaking advancements in additive manufacturing (3D printing) are revolutionizing the production landscape, enabling the creation of extraordinarily complex, highly customized plastic bearing geometries with intricately enhanced internal structures, superior performance characteristics, and dramatically reduced lead times, thereby unlocking entirely new avenues for innovation and application-specific solutions. Moreover, ongoing intensive research and development into advanced high-performance polymer composites, hybrid materials, and nanocomposites promises to decisively overcome many existing material limitations, significantly expanding the functional envelope of plastic bearings and broadening their addressable market into even more demanding industrial and technological applications.

Segmentation Analysis

The Plastic Bearing Market is meticulously segmented to offer a granular and insightful understanding of its diverse constituent components, intricate growth dynamics, and the specific niches it addresses across the industrial landscape. This comprehensive segmentation strategy typically categorizes the market based on crucial parameters such as material type, distinct bearing type, and the predominant end-use industry. This multi-faceted approach effectively reflects the wide array of applications and the highly specific performance requirements that these innovative components are engineered to fulfill. A thorough comprehension of these distinct segments is absolutely critical for accurately identifying key areas of pronounced growth, deciphering the competitive landscapes within various sub-markets, and pinpointing strategic opportunities for investment, innovation, and market penetration within the broader plastic bearing industry. Each delineated segment inherently highlights unique characteristics and specific demand drivers that propel technological advancements, material research, and product development, thereby allowing for a nuanced, informed, and highly targeted market assessment.

- By Material: This segment categorizes plastic bearings based on the primary polymer or composite material used in their construction, each offering distinct mechanical, thermal, and chemical properties tailored for specific applications.

- Acetal (POM): Known for high strength, stiffness, low friction, and excellent dimensional stability; often used for general-purpose applications.

- Nylon (PA): Offers good strength, wear resistance, and chemical resistance; can be reinforced for higher performance.

- Ultra-High Molecular Weight Polyethylene (UHMW-PE): Exceptional abrasion resistance, low coefficient of friction, and high impact strength; ideal for aggressive wear applications.

- Polyether Ether Ketone (PEEK): High-performance polymer with excellent mechanical strength, chemical resistance, and high-temperature capability; suitable for demanding environments.

- Polytetrafluoroethylene (PTFE): Renowned for its extremely low friction, non-stick properties, and wide operating temperature range; often used in self-lubricating applications.

- Polypropylene (PP): Cost-effective, good chemical resistance, and lightweight; suitable for lighter load and less demanding applications.

- Polyphenylene Sulfide (PPS): Offers excellent chemical and thermal resistance, along with good mechanical properties; often used in challenging industrial environments.

- Others (e.g., Polyurethane, Thermoplastic Elastomers, various custom Composites with fibers or fillers): Includes specialized and hybrid materials designed for niche applications requiring unique combinations of properties.

- By Type: This segment classifies plastic bearings based on their structural design and intended motion, impacting their load capacity, speed capabilities, and application suitability.

- Plain Bearings (Bushings, Sleeve Bearings): Simplest type, relying on a sliding surface; dominant due to cost-effectiveness, simplicity, and versatility.

- Ball Bearings: Utilize rolling elements (balls) to reduce friction; suitable for higher speeds and precise rotational applications.

- Roller Bearings (e.g., Tapered, Cylindrical): Employ cylindrical or tapered rollers for higher load capacities than ball bearings.

- Thrust Bearings: Designed to support axial loads; commonly used in applications with axial forces.

- Linear Bearings: Facilitate linear motion along a shaft or rail; used in automation and precision positioning systems.

- Mounted Bearings: Bearings housed in an assembly, simplifying installation and providing protection.

- Specialty Bearings: Custom-designed bearings for unique application challenges, often involving complex geometries or multi-functional integration.

- By End-Use Industry: This segment identifies the major sectors that are the primary consumers of plastic bearings, reflecting the specific needs and regulatory requirements of each industry.

- Automotive: Crucial for lightweighting, noise reduction, and corrosion resistance in interior components, steering systems, braking systems, powertrain auxiliaries, and increasingly, electric vehicle (EV) components.

- Medical & Healthcare: Essential for surgical instruments, diagnostic equipment, laboratory automation, patient beds, and prosthetics due to biocompatibility, sterilizability, and precision.

- Food & Beverage: Utilized in processing machinery, packaging equipment, conveyor systems, and bottling lines for hygiene, resistance to washdown chemicals, and lubrication-free operation.

- Industrial Machinery: Applied in textile machinery, printing machinery, agricultural equipment, robotics, and material handling systems for efficiency, reduced maintenance, and durability.

- Consumer Goods: Integrated into home appliances (e.g., washing machines, refrigerators), fitness equipment, recreational vehicles, and office equipment for quiet operation, low cost, and durability.

- Aerospace & Defense: Valued for lightweight properties and performance in challenging thermal and chemical environments in aircraft interior mechanisms, landing gear systems, and control surfaces.

- Marine: Used in propulsion systems, deck machinery, and underwater vehicles where corrosion resistance to saltwater and low maintenance are critical.

- Chemical Processing: Benefits from the extreme chemical resistance of certain plastic bearings in pumps, valves, and mixing equipment.

- Electronics & Semiconductors: Applied in precision positioning systems and cleanroom environments where non-magnetic properties and particulate control are essential.

- Others (e.g., Construction, Renewable Energy, Water Treatment): Includes diverse applications in heavy equipment, solar tracking systems, wind turbines, and fluid management systems.

Value Chain Analysis For Plastic Bearing Market

The value chain for the Plastic Bearing Market is an intricate, multi-tiered structure that initiates with the foundational supply of specialized raw materials and systematically extends through complex, precision-driven manufacturing processes, culminating in sophisticated distribution channels that ultimately reach a diverse and extensive array of end-users across numerous industrial sectors. At the critical upstream end of this value chain, the market is predominantly influenced by major petrochemical and specialty chemical companies. These entities specialize in the advanced production of high-performance engineering plastics such as acetal, nylon, PEEK, PTFE, and various custom composites. These raw material suppliers conduct extensive and continuous research and development to formulate innovative polymer compounds with precisely tailored mechanical, thermal, chemical, and tribological properties specifically optimized for demanding bearing applications. Their unwavering ability to consistently deliver superior quality, highly pure, and innovative material solutions is absolutely fundamental to the ultimate performance capabilities, reliability, and longevity of the subsequent plastic bearing products. Strategic alliances, long-term supply agreements, and joint development initiatives between these raw material producers and plastic bearing manufacturers are commonplace, ensuring a stable, reliable, and technologically progressive supply chain for these highly specialized polymers and their derivative forms.

Positioned centrally within the value chain, the midstream segment encompasses the core activities of plastic bearing manufacturers. These specialized companies meticulously transform the raw polymer materials into highly engineered, finished bearing components utilizing a diverse suite of advanced manufacturing techniques. These processes include precision injection molding, advanced machining (e.g., CNC turning, milling), compression molding, and, with increasing prominence, cutting-edge additive manufacturing (3D printing) technologies. Bearing manufacturers often specialize in particular bearing types, material families, or target specific end-use industries, thereby developing deep expertise and proprietary processes. They employ exceptionally stringent quality control measures at every stage of production and leverage sophisticated engineering expertise to ensure precise dimensional accuracy, optimal surface finishes, and consistent performance characteristics that meet or exceed demanding industry standards. This crucial stage also extensively involves design and engineering activities, where manufacturers frequently collaborate closely with clients to co-develop custom bearing solutions that are specifically tailored to address unique application challenges, environmental constraints, and operational requirements. Sustained investment in state-of-the-art manufacturing technologies, automation, and digital twins is paramount for achieving operational efficiency, cost-effectiveness, and maintaining a decisive competitive advantage in this highly specialized and technologically driven segment of the market.

At the downstream end of the value chain, the meticulously manufactured plastic bearings are disseminated to a broad spectrum of end-users through a combination of meticulously managed direct and indirect distribution channels. Direct sales channels typically involve plastic bearing manufacturers selling directly to large, often global, Original Equipment Manufacturers (OEMs) or key industrial clients. This approach is frequently supported by dedicated sales teams, highly skilled technical support engineers, and comprehensive application development services. Direct engagement fosters deep communication, enables the provision of highly tailored technical solutions, and cultivates robust, long-term strategic relationships. Conversely, indirect distribution encompasses a comprehensive network of specialized industrial distributors, wholesalers, and niche industrial suppliers who maintain extensive inventories of plastic bearings. These partners provide broad regional or even global market coverage, comprehensive warehousing solutions, efficient logistics services, and often critical first-level technical support to customers. These distributors play an absolutely vital role in reaching smaller and medium-sized enterprises (SMEs), MRO (Maintenance, Repair, and Operations) customers, and highly specialized niche markets that may not be directly accessible to manufacturers. The strategic choice of distribution channel is typically predicated on factors such as the scale and complexity of the customer’s operations, the technical intricacy of the product, the required geographic reach, and the desired level of customer engagement, with an accelerating trend towards integrated online platforms and e-commerce solutions emerging to streamline procurement, enhance market accessibility, and provide immediate access to technical specifications and product availability for a significantly broader customer base.

Plastic Bearing Market Potential Customers

The Plastic Bearing Market serves an exceptionally wide and diverse array of potential customers across virtually every industrial sector, primarily comprising industries that actively seek innovative bearing solutions offering a unique combination of lightweight properties, exceptional corrosion resistance, inherent self-lubrication, and remarkably quiet operation. These characteristics are particularly critical in challenging environmental conditions where traditional metal bearings would either prematurely fail or necessitate prohibitively expensive maintenance. These diverse end-users are universally driven by a compelling need to continually enhance their product performance, substantially reduce ongoing maintenance and operational costs, improve overall energy efficiency in their machinery, and rigorously adhere to an ever-tightening landscape of regulatory standards related to safety, hygiene, and environmental impact. The multifaceted benefits intrinsic to plastic bearings enable them to penetrate and thrive in numerous industrial sectors, adeptly addressing highly specific operational demands with precisely tailored and optimized solutions. Key target customers are those actively involved in the design, manufacturing, assembly, or ongoing operation of equipment and machinery where precision, cleanliness, extended longevity, reduced weight, and minimal noise are paramount and non-negotiable considerations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 9.2 Billion |

| Market Forecast in 2033 | USD 16.5 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Igus GmbH, SKF AB, NSK Ltd., Schaeffler AG, GGB, The Timken Company, BNL Bearings, AST Bearings LLC, Kilian Manufacturing Corporation, TriStar Plastics Corp., Vesconite Bearings, Rexnord Corporation, RBC Bearings Incorporated, Misumi Group Inc., Poly Hi Solidur, Inc. (M. Holland Company), Thomson Industries, Inc., Bearings Inc., Dotmar Engineering Plastic Products, C.R. Laurence Co., Inc., Oiles Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plastic Bearing Market Key Technology Landscape

The Plastic Bearing Market is in a perpetual state of evolution, driven and continuously shaped by significant advancements across several interdependent key technological areas. These innovations are absolutely instrumental in relentlessly enhancing product performance, substantially expanding application versatility into new frontiers, and dramatically improving manufacturing efficiency across the entire production lifecycle. At the very core of this dynamic technological landscape are sophisticated innovations in material science, particularly within the specialized field of polymer engineering. Extensive and continuous research and development efforts are singularly focused on creating novel polymer compounds, advanced composites, and hybrid materials that offer a superior combination of mechanical strength, significantly higher temperature resistance, drastically improved wear properties, and exceptional chemical inertness. This includes the pioneering development of highly effective self-lubricating additives, advanced fiber reinforcements (e.g., carbon fiber, glass fiber), and cutting-edge nano-fillers that collectively bolster the durability, increase load capacity, and extend the operational lifespan of plastic bearings, enabling them to perform reliably and efficiently in increasingly demanding environments that were once exclusively the domain of traditional metal bearings. The ability to precisely tailor and fine-tune material properties to the most stringent application-specific requirements represents a fundamental and continuously evolving technological driver.

Regional Highlights

- North America: This region is characterized by a high rate of adoption of advanced plastic bearing solutions, particularly driven by robust demand in the medical device, aerospace, and high-tech industrial sectors. Stringent quality standards, a strong emphasis on innovation in material science, and the development of specialized high-performance applications are key regional drivers. The rapidly expanding electric vehicle (EV) market in the US and Canada also significantly contributes to the escalating market demand for lightweight and quiet plastic bearings.

- Europe: As a mature market with deeply entrenched industrial and automotive manufacturing bases, Europe consistently exhibits substantial demand for plastic bearings. This is significantly influenced by stringent environmental regulations promoting lightweighting, energy efficiency, and reduced carbon footprints. Countries such as Germany, France, and Italy are global hubs for advanced manufacturing, precision engineering, and robotics, driving high uptake in industrial machinery, renewable energy (e.g., wind turbines), and sophisticated medical applications. The region is also at the forefront of sustainable polymer development and circular economy initiatives within bearing manufacturing.

- Asia Pacific (APAC): APAC stands out as the largest and most dynamically growing market for plastic bearings globally. This growth is vigorously propelled by rapid industrialization, the expansive and continuously modernizing manufacturing capabilities, and significant, sustained growth in key sectors such as automotive, consumer electronics, and general industrial production across economic powerhouses like China, India, Japan, and South Korea. The region benefits from extensive infrastructure development, a burgeoning middle class driving consumer goods demand, and a competitive manufacturing environment, further fueling market expansion through both domestic consumption and exports.

- Latin America: This region is experiencing steady and promising growth in the plastic bearing market, primarily driven by increasing industrialization, significant infrastructure development projects, and a robust, expanding automotive production base. Brazil and Mexico are pivotal contributors to this regional growth, with rising demand for plastic bearings in agricultural machinery, sophisticated food processing equipment, and general industrial applications as regional economies continue to mature and modernize. Investments in manufacturing and resource extraction also contribute to market traction.

- Middle East and Africa (MEA): The MEA market for plastic bearings, while currently representing a smaller share, is an emerging region with considerable long-term growth potential. This growth is underpinned by substantial investments in infrastructure development, diversification initiatives away from traditional oil and gas sectors, and an expanding manufacturing footprint. Demand is gradually increasing, particularly in industrial equipment, construction machinery, and water treatment facilities, where the inherent corrosion resistance, durability, and low maintenance requirements of plastic bearings are highly valued attributes for harsh operating conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plastic Bearing Market.- Igus GmbH

- SKF AB

- NSK Ltd.

- Schaeffler AG

- GGB

- The Timken Company

- BNL Bearings

- AST Bearings LLC

- Kilian Manufacturing Corporation

- TriStar Plastics Corp.

- Vesconite Bearings

- Rexnord Corporation

- RBC Bearings Incorporated

- Misumi Group Inc.

- Poly Hi Solidur, Inc. (M. Holland Company)

- Thomson Industries, Inc.

- Bearings Inc.

- Dotmar Engineering Plastic Products

- C.R. Laurence Co., Inc.

- Oiles Corporation

Frequently Asked Questions

Analyze common user questions about the Plastic Bearing market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of plastic bearings over traditional metal bearings?

Plastic bearings offer several key advantages, including inherent corrosion and chemical resistance, self-lubrication (often eliminating the need for external grease or oil, reducing maintenance and contamination risks), significant weight reduction which improves energy efficiency, noticeably quieter operation due to superior vibration dampening properties, and electrical insulation. These benefits collectively lead to reduced lifecycle costs, extended service life in challenging environments, and improved overall system performance.

Which industries primarily utilize plastic bearings, and why are they preferred?

Plastic bearings are widely adopted across diverse industries due to their unique properties. Major sectors include automotive (for lightweighting, noise reduction, and corrosion resistance), medical and healthcare (due to biocompatibility, sterilizability, and precision), food and beverage processing (for hygiene, resistance to washdown chemicals, and lubrication-free operation), industrial machinery (for efficiency, reduced maintenance, and durability in various applications), and consumer goods (for quiet operation, cost-effectiveness, and design flexibility).

What specific materials are commonly used in the manufacturing of plastic bearings, and what are their applications?

Common materials for plastic bearings include Acetal (POM) for general-purpose applications due to its strength and low friction; Nylon (PA) for good wear and chemical resistance; Ultra-High Molecular Weight Polyethylene (UHMW-PE) for exceptional abrasion resistance; Polyether Ether Ketone (PEEK) for high-performance, high-temperature, and chemical-resistant applications; and Polytetrafluoroethylene (PTFE) for extremely low friction and non-stick properties. Each material is selected based on the specific operational demands of the application.

Are plastic bearings suitable for high-load or high-temperature applications, or are there limitations?

While traditional plastic bearings typically have lower load capacities and temperature limits compared to metal bearings, significant advancements in engineering plastics and specialized composites (ee.g., PEEK, reinforced polymers) are continuously expanding their capabilities. These advanced plastic bearings can perform effectively in moderate-to-high load and elevated temperature applications. However, for extremely high-stress, high-impact, or persistently extreme temperature environments, metal bearings may still be more suitable, necessitating careful engineering evaluation for optimal selection.

How do plastic bearings contribute to global sustainability efforts and environmental responsibility?

Plastic bearings contribute to sustainability in several ways. Their lightweight nature facilitates reduced vehicle and machinery weight, leading to improved fuel efficiency and lower carbon emissions. Their self-lubricating properties minimize the reliance on petroleum-based greases and oils, reducing environmental contamination. Furthermore, the extended service life of plastic bearings reduces material consumption and waste, and advancements in polymer recycling are increasing their end-of-life circularity, aligning with broader sustainable manufacturing and resource efficiency goals.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager