Plastic Casters Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437508 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Plastic Casters Market Size

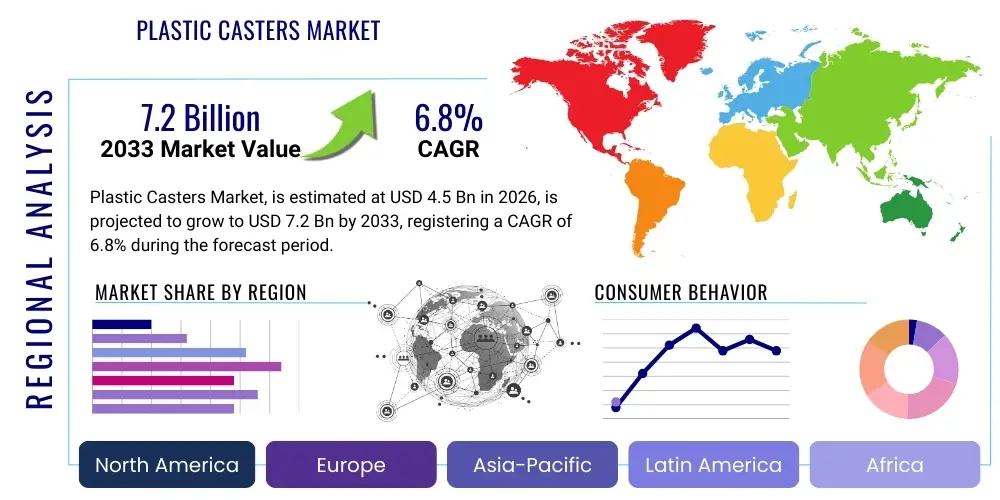

The Plastic Casters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 7.2 Billion by the end of the forecast period in 2033.

Plastic Casters Market introduction

The Plastic Casters Market encompasses the manufacturing and distribution of non-metallic wheels, typically integrated into a frame or housing, used for mobility in a wide range of equipment. These components are predominantly fabricated from robust polymers such as nylon, polyurethane, polypropylene, and engineered plastics, offering distinct advantages over traditional metallic casters, including superior corrosion resistance, lighter weight, non-marking characteristics, and often, cost-effectiveness. The fundamental function of plastic casters is to facilitate the smooth, ergonomic, and controlled movement of objects, fixtures, and machinery in environments demanding cleanliness, noise reduction, or chemical inertness.

Major applications driving the demand for plastic casters span multiple high-growth sectors. In the healthcare industry, plastic casters are essential for hospital beds, medical carts, diagnostic equipment, and mobility aids, benefiting from their silent operation and easy sterilization properties. Within the institutional and commercial sectors, they are extensively utilized in office furniture, retail displays, serving trolleys, and light-duty industrial material handling equipment. Furthermore, advancements in polymer science have led to the development of high-performance plastic composites capable of handling medium-to-heavy loads, expanding their penetration into traditional industrial domains previously dominated by metal alternatives.

Key driving factors propelling market expansion include the global shift towards lighter manufacturing components, stringent hygiene regulations in medical and food processing sectors, and the rapid expansion of e-commerce necessitating efficient, high-speed material handling systems. The increasing focus on ergonomic workplace solutions and the inherent durability and resistance to harsh cleaning agents offered by engineered plastics further solidify the market's robust trajectory. The adaptability of plastic casters in terms of design, color, and size allows for extensive customization, meeting the precise aesthetic and functional requirements of diverse original equipment manufacturers (OEMs).

Plastic Casters Market Executive Summary

The Plastic Casters Market is currently characterized by significant momentum, driven primarily by strong adoption in the medical and institutional segments, coupled with technological advancements focusing on durability and integration. Current business trends highlight a marked preference for thermoplastic polyurethane (TPU) and high-density nylon due to their optimal balance of elasticity and load-bearing capacity, respectively. Market players are strategically investing in injection molding technologies that allow for intricate, multi-component caster designs, integrating features such as directional locking mechanisms and precision bearings directly into the plastic housing. Sustainability is an emerging trend, with manufacturers exploring bio-based and recycled polymers to reduce the environmental footprint of production, appealing to eco-conscious buyers in developed economies.

Regionally, the Asia Pacific (APAC) stands out as the predominant growth engine, fueled by rapid industrialization, burgeoning manufacturing output, and significant investments in healthcare infrastructure, particularly in China and India. North America and Europe maintain maturity, focusing instead on high-end, specialized products such as electrically conductive casters for static-sensitive environments and integrated smart casters featuring tracking capabilities. These mature markets emphasize regulatory compliance (e.g., REACH, RoHS) and advanced engineering design, commanding higher price points for specialized applications in sectors like aerospace and pharmaceuticals. This dynamic regional landscape dictates varying strategic priorities, from volume production in APAC to innovation leadership in Western markets.

Segmentation analysis reveals that the institutional and furniture application segment commands the largest market share, owing to high volume demand for office chairs, tables, and display fixtures. However, the medical segment is projected to register the fastest Compound Annual Growth Rate, driven by the aging global population and continuous modernization of hospital equipment. In terms of material, Nylon casters remain popular for heavy-duty institutional tasks, while Polyurethane is increasingly favored across all segments for its noise reduction and floor protection qualities. The trend towards higher load capacity plastic casters is notable, bridging the gap between medium-duty plastic solutions and traditional heavy-duty metallic offerings, ensuring market resilience against competitive materials.

AI Impact Analysis on Plastic Casters Market

User inquiries regarding AI's influence in the Plastic Casters Market center on three critical themes: enhancing manufacturing efficiency, optimizing supply chain logistics, and improving product design through simulation. Users frequently ask how AI-driven predictive maintenance can reduce equipment downtime in high-volume production facilities, and whether machine learning algorithms are being used to identify optimal polymer blends for specific application requirements (e.g., stress resistance, chemical exposure). Furthermore, there is significant interest in how AI can optimize inventory management of thousands of caster variants across global distribution networks, ensuring faster delivery and reduced warehousing costs, thereby transforming traditional, often reactive, production planning into a data-driven, predictive system.

- AI-driven optimization of injection molding parameters, resulting in reduced material waste and enhanced component consistency.

- Implementation of predictive maintenance models for molding machinery, minimizing unscheduled production stoppages.

- Use of machine learning in material science to rapidly test and identify new, high-performance polymer composites for specialized casters.

- Advanced demand forecasting systems optimizing production schedules based on real-time end-user application trends.

- Integration of vision systems powered by AI for automated quality control inspection of finished caster components.

- Supply chain optimization through AI, ensuring efficient routing and lower logistical costs for raw polymer granules and finished products.

- Simulation and generative design tools utilizing AI to engineer ultra-lightweight and durable caster designs before physical prototyping.

DRO & Impact Forces Of Plastic Casters Market

The Plastic Casters Market exhibits a compelling interplay of drivers and restraints that define its growth trajectory. The primary drivers include the burgeoning global geriatric population, necessitating increased production of medical mobility equipment like wheelchairs and hospital carts, where non-corrosive and quiet casters are paramount. Additionally, the rapid modernization of retail and institutional infrastructure worldwide fuels consistent demand for non-marking, aesthetically pleasing, and easy-to-maneuver casters used in store fixtures, office furniture, and logistical equipment. The lower manufacturing cost of plastic casters compared to stainless steel or cast iron alternatives, coupled with enhanced customization options in color and material composition, further acts as a powerful market stimulant.

However, the market is constrained by intrinsic limitations inherent to plastic materials. The primary restraint is the inherently lower maximum load-bearing capacity of most standard plastic casters when compared to heavy-duty metallic counterparts, restricting their utilization in high-stress, very heavy industrial applications such as foundries or massive machinery transport. Furthermore, fluctuations in the price and supply of petrochemical-derived raw materials, such as polypropylene and nylon resins, directly impact manufacturing costs and margin stability, posing operational challenges for market participants. The lack of standardized testing protocols across all regional markets also sometimes creates confusion regarding specified load limits and durability claims.

Significant opportunities exist in the development of specialized caster types, particularly in smart mobility solutions integrated with IoT sensors for inventory tracking and predictive maintenance in automated warehouses. The shift towards sustainable manufacturing presents a vast opportunity for manufacturers focusing on high-performance recycled plastics and bio-plastics, meeting corporate sustainability goals of major end-users. Impact forces operating on the market include the rapid pace of technological innovation (e.g., development of highly durable composite plastics resisting extreme temperatures and chemicals—a strong external force) and internal competitive pressures forcing price reductions and rapid product cycle innovation. These combined forces mandate continuous technological evolution and strategic supply chain management for sustained profitability.

Segmentation Analysis

The Plastic Casters Market is extensively segmented based on material type, load capacity, application, and distribution channel, providing a clear framework for understanding market dynamics and targeted strategic development. The diversity in segmentation reflects the necessity for specialized caster characteristics to meet the precise demands of heterogeneous end-user environments, ranging from sterile medical settings to corrosive industrial floors. Analyzing these segments is critical for identifying high-growth niches, such as the increasing demand for medium-to-heavy duty polyurethane casters, which offer an optimal balance between impact absorption and weight capacity, distinguishing them from the high-volume, light-duty nylon furniture casters.

Material segmentation, comprising nylon, polypropylene, and polyurethane, dictates the fundamental properties of the caster, including hardness, chemical resistance, and noise level. Polyurethane, for instance, is seeing expanded use due to its non-abrasive nature and excellent grip, making it ideal for finished or sensitive flooring. Load capacity segmentation defines suitability, categorizing products into light, medium, and heavy duty, addressing equipment ranging from file cabinets to transport dollies. Application segmentation (Medical, Institutional, Industrial) highlights the industry-specific regulatory and functional requirements that drive product development and pricing strategies across the market.

Furthermore, geographic segmentation is paramount, with APAC driving volume growth and North America and Europe leading technological innovation and high-margin product sales. The continuous evolution within these segments, particularly the push for greater sustainability in material selection and integration of electronic features (e.g., electric brakes, automated steering), ensures ongoing disruption and expansion within the overall market scope. Understanding the precise cross-section of material and application—such as antimicrobial nylon casters specifically designed for surgical environments—is key to maximizing market penetration and profitability.

- By Material Type:

- Nylon Casters

- Polyurethane (PU) Casters

- Polypropylene (PP) Casters

- Thermoplastic Rubber (TPR) Casters

- Phenolic Casters

- Other Engineered Plastics

- By Load Capacity:

- Light Duty (Below 100 lbs)

- Medium Duty (100 lbs - 300 lbs)

- Heavy Duty (Above 300 lbs)

- By Application/End-User:

- Medical and Healthcare Equipment (Hospital Beds, Carts, Diagnostic Machines)

- Institutional (Office Furniture, Schools, Libraries, Food Service)

- Industrial and Warehouse (Carts, Dollies, Storage Racks, Assembly Lines)

- Retail and Commercial Displays

- Residential and DIY

- By Caster Type:

- Swivel Casters

- Rigid Casters

- Brake Casters (Total Lock, Directional Lock)

- Stem Casters

- Plate Casters

Value Chain Analysis For Plastic Casters Market

The value chain for the Plastic Casters Market begins with the highly concentrated upstream segment focused on raw material procurement, primarily the supply of polymer resins derived from petrochemical feedstocks (e.g., nylon, PU, PP pellets). Fluctuations in crude oil prices directly impact the cost structure at this initial stage. Key strategic decisions here involve securing long-term contracts with major chemical manufacturers to ensure stable supply and predictable pricing. The quality of these inputs is paramount, as defects in the polymer can compromise the final caster's load rating and durability, requiring stringent quality control checks before the material moves into the manufacturing process. Manufacturers specializing in specific performance characteristics, such as anti-microbial or static-dissipative plastics, gain competitive advantage through proprietary material relationships.

The midstream phase involves manufacturing, characterized by high capital investment in precision injection molding and extrusion machinery. Manufacturers often employ automated assembly lines for housing components, wheels, and associated fittings like bearings and axles. Efficiency in this stage is driven by advanced mold design, minimizing cycle times, and optimizing material utilization to reduce scrap rates. Backward integration, where large caster manufacturers produce their own proprietary wheel materials or housing, is a common strategy to maintain quality control and reduce reliance on third-party suppliers for core components. Regulatory compliance, particularly concerning environmental standards and material safety (such as phthalate regulations), is a critical factor influencing manufacturing practices.

The downstream segment involves distribution, sales, and aftermarket support. Distribution channels are bifurcated into direct sales to large Original Equipment Manufacturers (OEMs)—who require highly customized, high-volume batches—and indirect sales through extensive networks of industrial distributors, material handling specialists, and e-commerce platforms servicing Maintenance, Repair, and Operations (MRO) buyers and smaller institutional clients. The shift towards e-commerce necessitates robust digital catalogs and accurate technical specifications to facilitate easy selection. Providing specialized technical support and managing warranty claims constitutes the final element, ensuring customer satisfaction and repeat business, particularly for heavy-duty and medical-grade casters where safety and reliability are non-negotiable.

Plastic Casters Market Potential Customers

Potential customers for the Plastic Casters Market are highly diverse but can be broadly categorized into three primary purchasing groups: Original Equipment Manufacturers (OEMs), Maintenance, Repair, and Operations (MRO) end-users, and specialized Institutional Buyers. OEMs, such as manufacturers of medical devices (hospital beds, surgical carts), office furniture (ergonomic chairs, filing cabinets), and material handling equipment (light-duty trolleys, shelving units), represent the largest volume segment. These buyers prioritize integration compatibility, adherence to strict performance specifications (e.g., chemical resistance, non-marking), and competitive long-term pricing, often requiring bespoke designs developed collaboratively with the caster supplier. Strategic partnerships with key OEMs ensure stable, high-volume orders for caster producers.

MRO buyers and industrial distributors constitute the secondary, high-frequency purchasing group. These customers require replacement casters for existing machinery, carts, and fixtures that have reached the end of their service life or require an upgrade in performance (e.g., switching to quiet polyurethane from standard nylon). The MRO market demands broad inventory availability, short lead times, and easy access through online catalogs or local industrial supply houses. This segment focuses heavily on total cost of ownership, durability, and compatibility with existing equipment standards, driving demand for versatile and standardized product lines.

Specialized institutional buyers, encompassing governmental facilities, large universities, airports, and high-specification food processing plants, often require casters with unique certifications or features. For instance, food processors demand FDA-compliant materials that can withstand high-pressure washdowns, while hospitals require antimicrobial and electro-conductive casters for specialized environments. These customers prioritize compliance with sector-specific regulations and technical robustness over sheer cost savings, demanding detailed documentation regarding material composition, load testing, and hygiene standards. Targeting these high-specification niches offers higher margin opportunities compared to the standard commercial furniture market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 7.2 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | TENTE International, Blickle, Colson Group, RWM Casters, Caster Concepts, Shepherd Caster, Hamilton Caster, Revvo Caster, P&H Casters, Sumech Caster, Darcor, Albacete Industrial, Bestway Caster & Wheel, Durable Casters, J.P. Casters, Kaster, CE-MAT, Caster Connection, Stellana AB, Pemko. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plastic Casters Market Key Technology Landscape

The technological evolution within the Plastic Casters Market is centered on material science advancements and integration of digital intelligence. A primary focus involves refining injection molding processes to achieve tighter tolerances and complex geometries, allowing manufacturers to embed features like precision ball bearings or multi-component braking systems directly into the polymer structure, reducing assembly complexity and cost. New proprietary polymer blends are continuously being developed to overcome the traditional weaknesses of plastic, specifically focusing on enhanced resistance to dynamic loads, extreme temperatures (both hot and cold sterilization cycles in medical applications), and aggressive cleaning chemicals. For example, reinforced nylon composites incorporating glass fiber or carbon nanotubes are bridging the performance gap with metallic solutions for medium-to-heavy duty applications.

A significant technological shift is the introduction of smart casters, leveraging the Internet of Things (IoT). These casters incorporate low-power sensors capable of monitoring parameters such as usage intensity, load weight, temperature, and potentially detecting bearing wear or impending failure. This data is transmitted wirelessly to central management systems, enabling predictive maintenance schedules, optimizing asset utilization, and providing valuable data insights into facility workflow and logistics efficiency. This level of digitalization transforms the caster from a simple mechanical component into an active data node, highly valued in automated warehouses and sophisticated healthcare environments where downtime is extremely costly.

Furthermore, design technology, particularly through advanced computer-aided design (CAD) and finite element analysis (FEA), plays a crucial role in optimizing the structural integrity of plastic caster components without adding unnecessary weight. Manufacturers are utilizing these tools to simulate real-world stress scenarios, ensuring that lightweight plastic housings can safely manage specified dynamic and static loads. Innovations in tread design, utilizing non-marking thermoplastic elastomers (TPE) and specialized polyurethane formulas, are also critical for maximizing floor protection, noise reduction, and rolling ease, meeting the growing ergonomic and environmental standards demanded by commercial and institutional end-users globally.

Regional Highlights

- Asia Pacific (APAC): APAC dominates the global Plastic Casters Market in terms of volume and is projected to exhibit the highest growth rate during the forecast period. This dominance is attributable to the region's expansive manufacturing base, particularly in China, which serves as a global hub for furniture, medical devices, and light industrial equipment production. Rapid urbanization and massive government investment in public infrastructure and healthcare modernization across India and Southeast Asian nations further accelerate the adoption of plastic casters for institutional and mobile medical equipment. Lower manufacturing labor costs and proximity to raw material suppliers also contribute to the region's cost competitiveness.

- North America: North America represents a mature, high-value market focused on specialty and compliance-driven products. Demand is concentrated in the medical and highly automated logistics sectors, where investment in high-performance, precision-engineered plastic casters (including antimicrobial and IoT-enabled smart casters) is robust. Strict regulatory standards (e.g., FDA requirements for medical equipment) drive technological innovation, pushing manufacturers to offer premium products with certified quality and traceability. The region shows strong demand for high-load capacity plastic composites capable of replacing metal in specific medium-duty industrial applications due to corrosion concerns.

- Europe: Europe is characterized by a strong emphasis on ergonomic design, sustainability, and stringent workplace safety regulations. Market growth is driven by the institutional and commercial furniture segments, where noise reduction and superior floor protection are critical. European consumers and industries exhibit a growing preference for casters made from recycled or bio-based plastics, aligning with regional circular economy objectives. Germany, in particular, leads the demand for high-quality industrial plastic casters used in highly efficient factory automation and internal logistics systems.

- Latin America (LATAM): The LATAM market is showing steady growth, primarily fueled by infrastructure projects and expanding retail sector modernization, driving demand for standard light-duty and institutional casters. Market development is often sensitive to economic stability and exchange rate fluctuations, but countries like Brazil and Mexico are emerging as key manufacturing hubs, increasing internal consumption and export capabilities for plastic components.

- Middle East and Africa (MEA): Growth in the MEA region is driven largely by massive investment in new healthcare facilities, particularly within the Gulf Cooperation Council (GCC) countries. The demand is skewed towards specialized medical-grade casters that can withstand high ambient temperatures and intensive cleaning protocols. Infrastructure development for tourism and institutional facilities also necessitates robust, aesthetic plastic casters.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plastic Casters Market.- TENTE International GmbH

- Blickle Räder+Rollen GmbH u. Co. KG

- Colson Group (Caster Corporation)

- RWM Casters Inc.

- Caster Concepts Inc.

- Shepherd Caster Corporation

- Hamilton Caster & Mfg. Co.

- Revvo Caster Company, Inc.

- P&H Casters Co.

- Sumech Caster Co., Ltd.

- Darcor Casters and Wheels

- Albacete Industrial S.A.

- Bestway Caster & Wheel Co.

- Durable Casters & Wheels

- J.P. Casters & Wheels

- Kaster Casters

- CE-MAT Casters

- Caster Connection Inc.

- Stellana AB

- Pemko Manufacturing

Frequently Asked Questions

Analyze common user questions about the Plastic Casters market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors are driving the projected growth in the Plastic Casters Market?

Market growth is primarily driven by the increasing global demand for lightweight, corrosion-resistant, and non-marking components, especially within the rapidly expanding medical and institutional sectors. Additionally, advancements in polymer technology enhancing load-bearing capacity and the shift towards automated material handling systems are significant contributors to market expansion.

How does plastic compare to metal in terms of caster performance?

Plastic casters offer superior advantages in weight, noise reduction, floor protection, and resistance to water and chemicals (corrosion). While traditional metal casters typically handle significantly heavier loads, modern engineered plastic composites (like reinforced nylon and specialized polyurethane) are closing the gap, offering durable, medium-to-heavy duty solutions suitable for controlled environments.

Which plastic material type holds the largest market share by revenue?

Polyurethane (PU) casters are rapidly gaining prominence and command a substantial revenue share due to their versatile properties, including excellent shock absorption, non-marking performance, and optimal traction, making them highly favored across industrial, institutional, and high-end medical applications requiring floor preservation and quiet operation.

What is the role of IoT and smart technology in the Plastic Casters Market?

IoT technology is being integrated into casters (smart casters) through embedded sensors to monitor usage, track location, measure load, and predict component failure. This capability significantly improves logistics efficiency, enables predictive maintenance in automated facilities, and provides critical operational data for asset management in hospitals and warehouses.

Which geographic region is expected to show the fastest growth rate?

The Asia Pacific (APAC) region is projected to register the fastest Compound Annual Growth Rate (CAGR) due to rapid industrialization, massive manufacturing output, and extensive investments in healthcare infrastructure across major economies like China and India, leading to high volume demand for institutional and light-industrial casters.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager