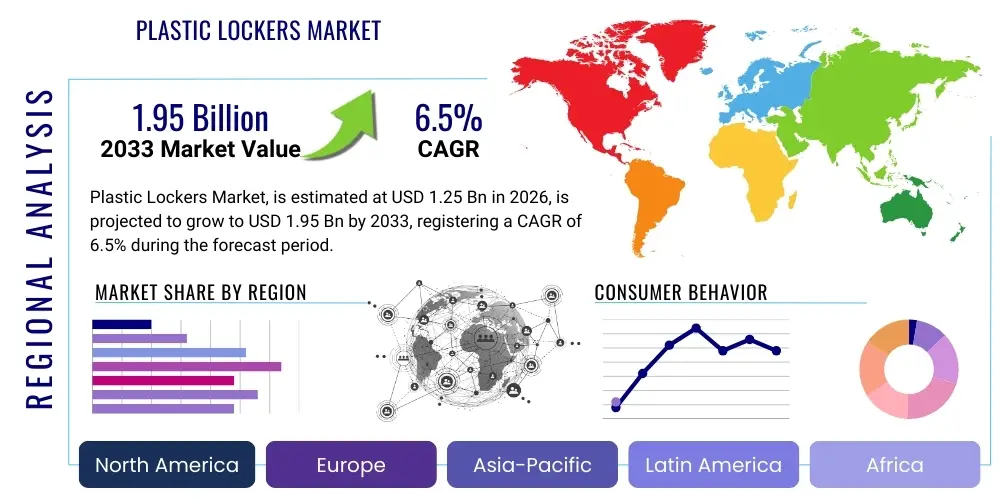

Plastic Lockers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438987 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Plastic Lockers Market Size

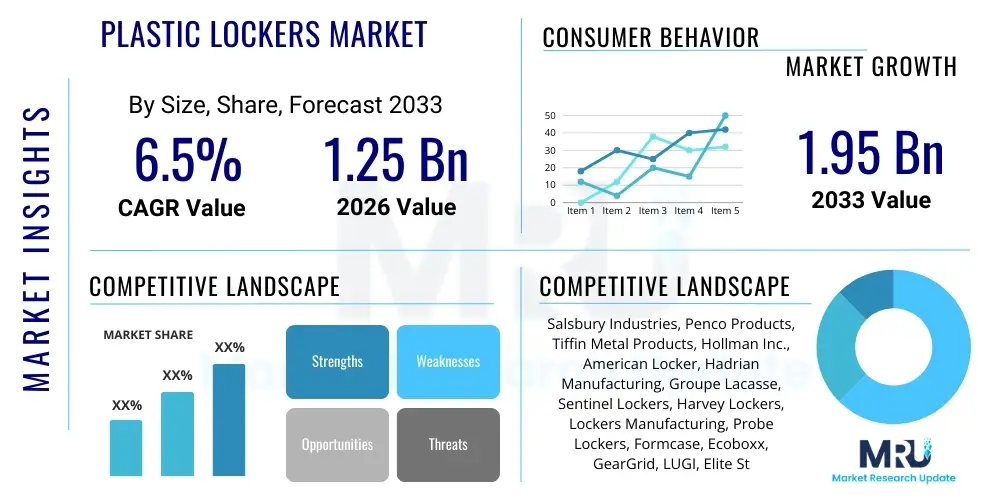

The Plastic Lockers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.95 Billion by the end of the forecast period in 2033.

Plastic Lockers Market introduction

The Plastic Lockers Market encompasses the manufacturing, distribution, and sale of storage solutions constructed primarily from high-density polyethylene (HDPE), polypropylene (PP), and other durable engineered plastics. These modern storage units offer significant advantages over traditional metal or wood alternatives, notably superior resistance to corrosion, moisture, vandalism, and harsh chemical environments. This inherent durability makes plastic lockers highly suitable for a diverse range of applications, spanning educational institutions, aquatic centers, healthcare facilities, industrial settings, and corporate offices where hygiene and longevity are paramount concerns. The market growth is fundamentally driven by increasing global infrastructure development, stringent hygiene standards in public and private facilities, and the rising demand for lightweight, customizable, and sustainable storage options.

Plastic lockers serve critical organizational and security functions, providing secure personal storage for employees, students, and patrons. Product descriptions typically highlight features such as modular design for scalable installation, various locking mechanisms (including digital and RFID options), UV resistance for outdoor use, and ease of cleaning. Major applications include use in changing rooms (gyms and spas), secure student book bags and personal effects storage in schools, and contamination control environments in food processing and pharmaceuticals. The versatility in size, color, and configuration allows these lockers to integrate seamlessly into diverse architectural and functional requirements, further broadening their market appeal across multiple industry verticals.

Key driving factors propelling the market expansion include the significant cost-effectiveness over the product lifecycle compared to traditional materials, largely due to minimal maintenance requirements and resistance to rust and denting. Furthermore, regulatory compliance related to hygiene and sanitation, particularly in the post-pandemic era, has elevated the adoption rate of non-porous and easily sanitized plastic surfaces. The industry is also benefiting from advancements in plastic manufacturing techniques, allowing for the creation of aesthetically pleasing and structurally robust modular units that address specific spatial and security demands across commercial and institutional sectors globally.

Plastic Lockers Market Executive Summary

The Plastic Lockers Market is characterized by robust expansion, fueled by strong underlying business trends emphasizing hygiene, durability, and customization in storage solutions. A pivotal trend involves the shift towards eco-friendly manufacturing, utilizing recycled plastics and sustainable production processes, responding directly to corporate sustainability mandates and consumer preference for green products. Furthermore, integration of smart technology, such as keyless entry and networked locker systems managed via mobile applications, is becoming standard in corporate and high-end fitness facilities, enhancing user experience and administrative control. This technology integration represents a significant opportunity for competitive differentiation and market penetration, especially in developed economies seeking high-efficiency organizational tools.

Geographically, the market exhibits high growth potential in the Asia Pacific (APAC) region, driven by massive investments in public and educational infrastructure development, coupled with rapid urbanization and commercial facility expansion, especially in emerging economies like India and China. North America and Europe, while mature markets, maintain dominance in terms of value, primarily due to high adoption rates of premium, high-security, and technologically integrated plastic lockers in specialized sectors such as healthcare and high-security offices. Regional trends indicate a strong correlation between per capita infrastructure spending and the demand for high-quality, long-lasting storage solutions, positioning key industrialized regions as continuous sources of demand for advanced plastic locker systems.

Segmentation trends highlight the dominance of the High-Density Polyethylene (HDPE) segment, attributed to its superior impact resistance and suitability for wet environments like swimming pools and laundries, driving substantial volume sales. By application, the educational sector remains the largest consumer, necessitated by the need for student storage that can withstand heavy use and potential vandalism. However, the corporate and industrial segment is witnessing the fastest growth, primarily due to stringent safety regulations requiring secure storage for personal protective equipment (PPE) and personal devices, necessitating highly durable and fire-resistant plastic options. Manufacturers are increasingly focusing on specialized solutions tailored for niche markets, such as antimicrobial coatings for healthcare lockers, to maximize segment penetration and maintain competitive advantage.

AI Impact Analysis on Plastic Lockers Market

User inquiries regarding AI's influence on the Plastic Lockers Market predominantly revolve around supply chain optimization, smart inventory management, and the enhancement of user interaction through intelligent locker systems. Common concerns center on how AI can predict demand fluctuations to prevent inventory shortages, especially for modular components, and whether AI-driven access control systems offer superior security and efficiency compared to current digital solutions. Users are keen to understand if predictive maintenance models, powered by AI, can significantly extend the operational lifespan of high-value locker installations by flagging potential mechanical failures in digital locks or structural fatigue in high-stress applications. The key expectation is that AI integration will primarily automate operational tasks and personalize the user experience, moving beyond simple storage to a managed asset control system.

In response to these inquiries, AI is transforming the operational efficiency of the plastic locker ecosystem, not just the product itself. AI algorithms are being employed in the manufacturing phase for quality control, analyzing structural stress points in newly molded components and optimizing material usage to reduce waste, thereby lowering production costs and improving product consistency. Furthermore, in large-scale deployments, especially within logistics hubs or major corporate headquarters, AI-driven utilization tracking allows facility managers to dynamically reallocate locker resources, ensuring maximum occupancy and justifying capital expenditure. This capability moves lockers from static assets to dynamic, manageable resources, optimizing facility planning and reducing downtime associated with manual inventory audits.

The consumer-facing impact is most pronounced in smart locker systems. AI-enabled software facilitates facial recognition or biometric authentication for access, providing a touchless and highly secure experience, particularly relevant in hygiene-sensitive environments. Furthermore, AI analytics can personalize storage usage patterns, alerting users to forgotten items, managing short-term rentals in public spaces autonomously, and providing immediate diagnostic feedback on system health. This evolution towards intelligent storage solutions positions plastic lockers as an integral component of the smart building infrastructure, enhancing both security protocols and overall organizational efficiency by minimizing administrative overhead required for system management.

- AI-Powered Predictive Maintenance: Anticipates failures in digital locking mechanisms, reducing operational downtime.

- Supply Chain Optimization: Uses machine learning to forecast material demand (HDPE, PP) and optimize complex logistics routes for modular components.

- Intelligent Access Control: Implements biometric and facial recognition systems for secure, touchless user authentication.

- Dynamic Resource Allocation: AI algorithms optimize locker assignment and utilization rates in high-traffic environments like campuses or transit hubs.

- Manufacturing Quality Assurance: Machine vision systems monitor plastic molding processes for defects, ensuring high structural integrity and consistency.

DRO & Impact Forces Of Plastic Lockers Market

The Plastic Lockers Market dynamics are defined by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively shape the market's trajectory and profitability. Key drivers, such as the increasing need for durable and non-corrosive storage in moisture-heavy environments (e.g., swimming pools, coastal facilities, and food processing plants), sustain baseline market demand. However, the most significant impetus stems from the growing awareness and mandate for hygiene standards, pushing facilities worldwide to replace porous or rust-prone metal lockers with easily sanitized plastic alternatives. Concurrently, opportunities arise from the innovative application of sustainable materials, particularly recycled and bio-based plastics, addressing environmental compliance and appealing to the rising segment of ecologically conscious consumers and corporations.

Restraints primarily revolve around the initial capital expenditure associated with high-grade plastic locker systems, which can sometimes exceed that of basic metal units, posing a barrier to adoption in budget-constrained public sectors, especially in developing nations. Furthermore, concerns regarding the long-term structural integrity and fire resistance of certain lower-grade plastics, though largely mitigated by advanced manufacturing standards (like fire-retardant additives), necessitate continuous consumer education and stringent regulatory adherence. These inherent material perceptions require manufacturers to invest heavily in certifications and marketing that emphasize advanced durability and safety features.

The impact forces are largely driven by competitive pricing strategies among key manufacturers, advancements in injection molding and rotational molding techniques that improve product aesthetics and modularity, and the rapid pace of digital transformation in facility management. The collective effect of these forces creates a highly responsive market where innovation in materials science (e.g., self-healing polymers, antimicrobial surfaces) and integration with IoT platforms determines market leadership. This sustained push for integration and durability ensures the plastic locker segment continues to capture market share from traditional material segments.

Segmentation Analysis

The Plastic Lockers Market is highly fragmented and segmented based on material type, design, locking mechanism, and end-user application. Understanding these segments is crucial for strategic market positioning, allowing manufacturers to tailor products to specific durability, security, and aesthetic requirements. The primary segmentation drivers are durability requirements (dictating material choice like HDPE vs. PP) and security needs (determining the complexity of the locking mechanism, from basic padlocks to integrated electronic systems). The end-user classification is perhaps the most dynamic, with distinct needs observed across the educational, leisure, healthcare, and industrial sectors, each demanding specialized features such as resistance to chemicals or extreme tamper-proofing.

- By Material Type:

- High-Density Polyethylene (HDPE)

- Polypropylene (PP)

- Acrylonitrile Butadiene Styrene (ABS)

- Other Engineered Plastics

- By Design/Configuration:

- Modular Lockers

- Standard Single Door Lockers

- Multi-Tier Lockers (2-Tier, 3-Tier, 4-Tier)

- Z-Shape Lockers

- By Locking Mechanism:

- Keyed Locks

- Padlock Hasp

- Electronic Keypad Locks

- RFID/NFC Locks

- Coin-Operated Locks

- By Application/End-User:

- Educational Institutions (Schools, Universities)

- Sports and Leisure (Gyms, Spas, Aquatic Centers)

- Corporate Offices and Commercial

- Healthcare and Pharmaceuticals

- Industrial and Manufacturing Facilities

- Retail and Transportation Hubs

Value Chain Analysis For Plastic Lockers Market

The value chain for the Plastic Lockers Market begins with upstream activities focused on raw material procurement, primarily sourcing high-grade plastic resins such as HDPE and PP. This phase is highly susceptible to volatility in global petrochemical pricing, which directly impacts manufacturing costs. Key upstream considerations include ensuring a consistent supply of quality, often recycled, polymers that meet specified structural and fire-resistance standards. Strategic partnerships with major chemical and polymer suppliers are critical here to stabilize input costs and ensure material traceability, especially for sustainable product lines. Efficiency in material conversion, minimizing scrap, and optimizing energy consumption during the molding process are crucial determinants of manufacturing profitability.

Downstream analysis focuses on the distribution and end-user application segments. The distribution channel is multifaceted, relying heavily on specialized industrial distributors, contract furniture suppliers, and direct sales channels targeting large institutional projects (schools, hospitals). The choice of distribution model depends on the end-user scale; for instance, large governmental or educational tenders often favor direct engagement, while smaller commercial projects utilize regional dealers. Effective downstream activities require robust logistics capabilities, particularly for handling large, bulky modular components, and superior installation and after-sales service to maintain customer satisfaction and secure repeat business.

Direct and indirect channels each play a significant role. Direct sales provide higher control over pricing and customer feedback but require substantial internal sales infrastructure. Indirect channels, through wholesalers and e-commerce platforms, offer wider geographical reach and lower fixed overheads. The increasing relevance of Business-to-Business (B2B) e-commerce platforms is streamlining indirect sales, allowing specialized plastic locker manufacturers to reach a global clientele more effectively. Therefore, optimization of the value chain demands seamless coordination between material science R&D, advanced manufacturing technology, and a strategically integrated distribution network capable of delivering both custom solutions and standard modular products efficiently.

Plastic Lockers Market Potential Customers

The primary end-users and buyers in the Plastic Lockers Market are diverse, reflecting the product's versatility across multiple functional environments. Educational institutions, ranging from primary schools to large university campuses, constitute a foundational segment, driven by persistent demand for durable student storage solutions that can withstand heavy daily use and resist damage from moisture or accidental spills. Procurement in this sector often involves large volume purchases dictated by municipal or state-level tender processes, prioritizing longevity and ease of maintenance.

Another major customer base includes the Sports, Leisure, and Wellness industries, encompassing fitness centers, public pools, recreational facilities, and exclusive spas. In these environments, plastic lockers are essential due to their non-corrosive properties, superior performance in humid, wet conditions, and inherent resistance to mildew and bacterial growth. These customers often seek aesthetically pleasing designs, customized color palettes, and advanced electronic locking systems to enhance member experience and security.

The fastest-growing potential customer segments include corporate facilities and specialized industrial environments, such as food and beverage processing plants, chemical laboratories, and cleanroom settings. These sectors require lockers that adhere to strict hygiene and contamination control standards, making the non-porous, chemical-resistant nature of high-grade plastic an indispensable attribute. Industrial buyers prioritize specific safety features, such as slope tops for easy cleaning and integrated ventilation, ensuring compliance with occupational safety and health regulations while securely storing specialized gear and employee personal belongings.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.95 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Salsbury Industries, Penco Products, Tiffin Metal Products, Hollman Inc., American Locker, Hadrian Manufacturing, Groupe Lacasse, Sentinel Lockers, Harvey Lockers, Lockers Manufacturing, Probe Lockers, Formcase, Ecoboxx, GearGrid, LUGI, Elite Storage Solutions, FSP Global, Lockers Australia, Plastic Locker Systems, Secure Storage. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plastic Lockers Market Key Technology Landscape

The Plastic Lockers Market leverages several advanced technologies across manufacturing and functionality to enhance product quality and user experience. Manufacturing techniques are heavily reliant on sophisticated injection molding and rotational molding processes, particularly for complex, seamless, and structurally robust modular designs. Rotational molding (rotomolding) is increasingly preferred for producing large, stress-free parts with uniform wall thickness, which significantly contributes to the longevity and impact resistance of HDPE lockers used in demanding environments like construction sites or public amenities. Furthermore, advanced material science involves the integration of specialized additives, such as UV stabilizers for outdoor applications and fire-retardant chemicals, ensuring compliance with stringent safety regulations and expanding the scope of application.

On the functional side, the technology landscape is dominated by the integration of Internet of Things (IoT) and smart locking systems. These advancements replace traditional mechanical locking with sophisticated electronic solutions, including Bluetooth connectivity, RFID proximity sensors, and biometric scanners. IoT enablement allows facility managers to monitor locker usage in real-time, perform remote diagnostics, and implement dynamic access control, which is essential for maximizing efficiency in large corporate or educational installations. The software accompanying these systems often utilizes cloud-based platforms for centralized management, providing secure data logs and integration capabilities with wider building management systems (BMS).

Further technological advancements include the development of antimicrobial surface treatments and recycled plastic utilization. Manufacturers are applying nanotechnology-based coatings that actively inhibit the growth of bacteria and viruses, a critical feature driving adoption in healthcare and fitness sectors. Simultaneously, the focus on closed-loop recycling and the development of high-performance polymers derived from post-consumer or post-industrial waste addresses sustainability mandates. These technological shifts not only improve the product's functional lifespan and hygienic profile but also significantly reduce the environmental footprint, positioning plastic lockers as a modern, responsible storage choice in a circular economy framework.

Regional Highlights

- North America: Dominates the market value due to high replacement cycles in institutional facilities, widespread adoption of smart locker technologies in corporate and fitness sectors, and stringent safety regulations demanding durable, non-flammable materials. The U.S. remains the largest consumer, driven by continuous infrastructure investment in education and healthcare.

- Europe: Characterized by strong demand for aesthetically pleasing and sustainable locker solutions. Northern European countries lead in adopting recycled plastic materials and require high modularity for space-efficient installations. Regulatory push towards workplace hygiene and efficient asset management fuels steady growth.

- Asia Pacific (APAC): The fastest-growing region, powered by rapid urbanization, massive investment in public infrastructure (schools, railways, bus terminals), and rising consumer expenditure on leisure and fitness centers, particularly in high-population economies like China, India, and Southeast Asia. The focus is currently on volume and cost-effectiveness, though smart lockers are gaining traction in tier-one cities.

- Latin America (LATAM): Exhibits moderate growth, largely influenced by economic stability and investments in commercial property development. Demand is concentrated in the educational and mining sectors, where resistance to harsh environmental conditions and durability are key purchasing criteria.

- Middle East and Africa (MEA): Shows high potential driven by large-scale hospitality, tourism, and infrastructure projects, particularly in the GCC countries. The harsh climate necessitates lockers with superior UV and heat resistance, making high-grade plastic solutions highly preferred over metal alternatives susceptible to corrosion from high humidity and sand.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plastic Lockers Market.- Salsbury Industries

- Penco Products

- Tiffin Metal Products

- Hollman Inc.

- American Locker

- Hadrian Manufacturing

- Groupe Lacasse

- Sentinel Lockers

- Harvey Lockers

- Lockers Manufacturing

- Probe Lockers

- Formcase

- Ecoboxx

- GearGrid

- LUGI

- Elite Storage Solutions

- FSP Global

- Lockers Australia

- Plastic Locker Systems

- Secure Storage

Frequently Asked Questions

Analyze common user questions about the Plastic Lockers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of plastic lockers compared to traditional metal units?

Plastic lockers, typically made of HDPE, offer superior resistance to rust, moisture, and corrosion, making them ideal for wet environments like gyms and pools. They are also non-porous, highly hygienic, require minimal maintenance, and are significantly more resistant to denting and vandalism, offering a longer operational lifespan.

Which material segment, HDPE or PP, dominates the Plastic Lockers Market?

High-Density Polyethylene (HDPE) currently dominates the market by volume, primarily due to its exceptional strength-to-density ratio, high impact resistance, and suitability for modular, heavy-duty applications, particularly in educational and high-traffic leisure settings.

How is technology influencing the security and management of modern plastic locker systems?

Technology integration is shifting lockers towards smart, networked systems. Electronic keypad, RFID, and biometric locks provide enhanced security and keyless access. IoT platforms enable centralized, real-time management of locker allocation, usage monitoring, and remote diagnostics, improving overall facility efficiency.

Which end-user segment is experiencing the fastest growth in plastic locker adoption?

The Corporate Offices and Industrial segment is exhibiting the fastest growth. This is driven by the need for secure storage of specialized equipment (e.g., PPE) and personal devices in controlled environments, where hygiene and chemical resistance offered by plastic are essential compliance factors.

Are plastic lockers environmentally sustainable?

Yes, modern market trends are heavily focused on sustainability. Many manufacturers utilize recycled plastics (post-consumer or industrial waste) in production. Furthermore, the inherent durability and long lifespan of plastic lockers reduce the frequency of replacements, lowering the overall environmental footprint compared to less durable alternatives.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager