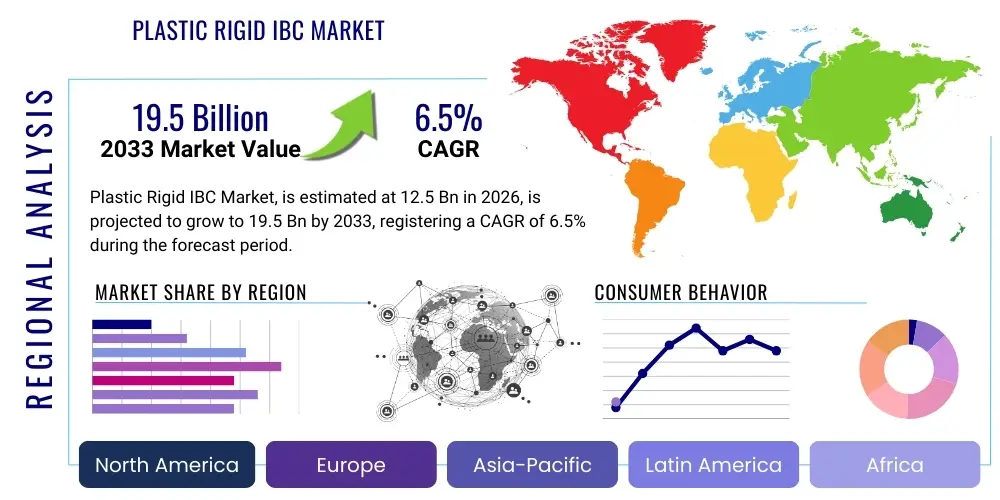

Plastic Rigid IBC Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439550 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Plastic Rigid IBC Market Size

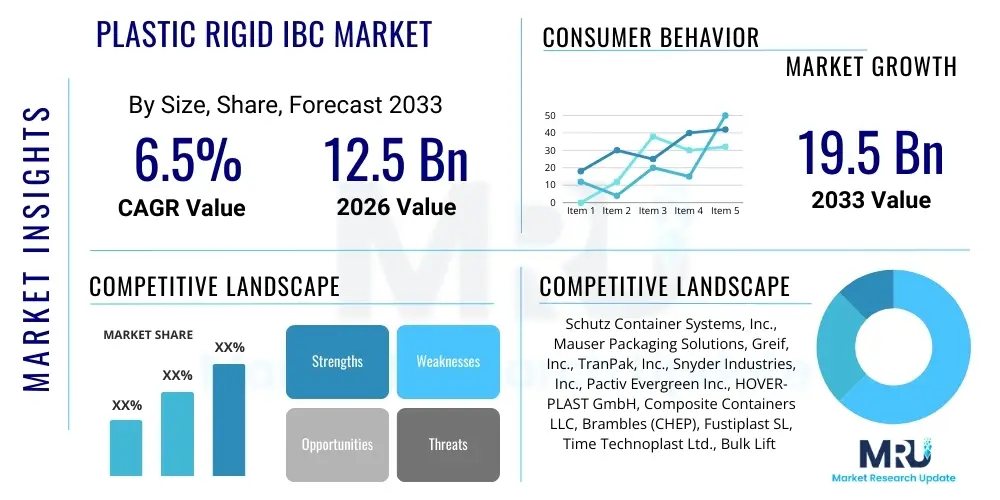

The Plastic Rigid IBC Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 12.5 Billion in 2026 and is projected to reach USD 19.5 Billion by the end of the forecast period in 2033.

Plastic Rigid IBC Market introduction

The Plastic Rigid IBC (Intermediate Bulk Container) market encompasses the production, distribution, and utilization of robust, reusable plastic containers designed for the safe and efficient transportation and storage of bulk liquids, granular materials, and powders. These containers typically range in capacity from 500 to 1,250 liters, offering a versatile alternative to traditional drums and smaller packaging formats. Their inherent design emphasizes durability, stackability, and ease of handling, making them indispensable across a multitude of industrial sectors.

Major applications for plastic rigid IBCs span the chemical industry for acids, solvents, and resins; the food and beverage sector for syrups, edible oils, and concentrates; the pharmaceutical industry for active pharmaceutical ingredients and excipients; and other sectors such as paints, coatings, lubricants, and agricultural chemicals. The robust construction, often from high-density polyethylene (HDPE), ensures chemical resistance, UV protection, and structural integrity, crucial for maintaining product quality and safety during transit and storage. Their design often includes a galvanized steel cage for added protection and forklift accessibility.

The primary benefits driving the adoption of plastic rigid IBCs include enhanced logistical efficiency, significant cost savings through reduced labor and material handling requirements, and superior product protection compared to traditional drums. Their cubical shape optimizes storage space in warehouses and shipping containers, leading to reduced transportation costs. Furthermore, the reusability aspect of these containers aligns with growing sustainability initiatives, minimizing packaging waste and supporting circular economy principles within various supply chains. These advantages collectively position plastic rigid IBCs as a preferred choice for bulk material handling across diverse global industries.

Plastic Rigid IBC Market Executive Summary

The Plastic Rigid IBC market is currently experiencing robust growth, primarily fueled by the expanding manufacturing output across key end-use industries and the persistent demand for efficient, sustainable, and cost-effective bulk packaging solutions. Business trends indicate a strong focus on innovation, with manufacturers investing in advanced material formulations to enhance container durability, chemical resistance, and barrier properties, alongside the integration of smart technologies like IoT for tracking and monitoring. Supply chain resilience and optimization remain critical, driving adoption for their logistical advantages.

Regionally, the market exhibits dynamic growth, with Asia Pacific emerging as a dominant force due to rapid industrialization, increasing consumption in the chemical and food processing sectors, and burgeoning e-commerce activities requiring efficient logistics. North America and Europe, while mature markets, continue to demonstrate steady demand, driven by stringent regulatory frameworks promoting safe handling of hazardous materials and a strong emphasis on sustainability, fostering the adoption of reusable IBCs. Latin America and the Middle East & Africa are also showing promising growth, attributed to developing industrial bases and infrastructure improvements.

Segmentation trends highlight a growing preference for specific volume capacities tailored to particular applications, with 1000-liter IBCs remaining a standard. The demand for reconditioned and recycled plastic IBCs is also on the rise, aligning with global efforts toward environmental stewardship and cost optimization. End-use industry segments, particularly chemicals and food & beverages, are driving significant volume, alongside a steady increase in pharmaceutical and industrial applications. This diversification across applications and a renewed focus on product lifecycle management underscore the market's adaptive and forward-looking nature.

AI Impact Analysis on Plastic Rigid IBC Market

The integration of Artificial Intelligence (AI) into the Plastic Rigid IBC market is poised to revolutionize various operational aspects, addressing common user questions related to supply chain efficiency, predictive maintenance, demand forecasting, and inventory management. Users are primarily concerned with how AI can minimize operational costs, enhance product integrity during transit, and contribute to more sustainable and transparent supply chains. There is a strong expectation that AI will optimize logistics, reduce waste, and provide real-time insights, ultimately leading to more intelligent and adaptive bulk packaging solutions. This transformation is anticipated to lead to significant operational improvements and open new avenues for service offerings.

- Supply Chain Optimization: AI algorithms can analyze vast datasets to optimize routing, load consolidation, and warehousing strategies for IBCs, significantly reducing transportation costs and delivery times.

- Predictive Maintenance: AI-driven sensors embedded in smart IBCs can monitor container integrity, potential leaks, or structural weaknesses, predicting maintenance needs before failures occur, extending asset life and ensuring safety.

- Demand Forecasting: Advanced AI models can analyze historical sales data, seasonal trends, and external factors to accurately predict future demand for specific IBC types, optimizing inventory levels and reducing stockouts or overstocking.

- Automated Logistics and Tracking: AI combined with IoT and RFID technologies enables real-time tracking of IBCs throughout their lifecycle, providing visibility into location, status, and environmental conditions (temperature, humidity), crucial for sensitive contents.

- Quality Control and Inspection: AI-powered vision systems can automate the inspection of IBCs for damage, cleanliness, and proper assembly, ensuring compliance with safety and quality standards more efficiently than manual processes.

- Sustainability and Recycling Management: AI can help manage the lifecycle of reusable IBCs, optimizing collection, cleaning, and refurbishment processes, thereby enhancing circular economy initiatives and reducing environmental impact.

- Customization and Design Optimization: AI can analyze performance data and user requirements to suggest optimal IBC designs, material choices, and features, leading to more tailored and efficient packaging solutions.

DRO & Impact Forces Of Plastic Rigid IBC Market

The Plastic Rigid IBC market is shaped by a confluence of influential factors, encompassing strong growth drivers, inherent restraints, and compelling opportunities that together determine its trajectory and competitive landscape. A primary driver is the burgeoning demand from end-use industries such as chemicals, food and beverages, and pharmaceuticals, which are continually expanding production capacities and seeking efficient bulk packaging. The inherent benefits of plastic rigid IBCs, including their stackability, reusability, and robust construction, directly contribute to improved logistical efficiency and reduced operational costs across these sectors. Furthermore, the global shift towards more sustainable packaging solutions, driven by environmental regulations and corporate responsibility initiatives, strongly favors reusable IBCs over single-use alternatives, propelling market expansion.

However, the market is not without its restraints. Significant among these is the volatility of raw material prices, particularly for high-density polyethylene (HDPE), which directly impacts manufacturing costs and profit margins. Intense competition from alternative bulk packaging solutions, such as metal IBCs, drums, and flexitanks, also poses a challenge, requiring continuous innovation and differentiation from plastic IBC manufacturers. Additionally, the initial capital investment required for purchasing reusable IBCs, coupled with the logistics and costs associated with cleaning, maintenance, and return freight in a closed-loop system, can sometimes deter smaller businesses or those with less integrated supply chains from widespread adoption.

Despite these challenges, substantial opportunities exist for growth and innovation. Emerging markets, especially in Asia Pacific and Latin America, present vast untapped potential due to their rapid industrialization and developing logistical infrastructures. Technological advancements, such as the integration of IoT sensors for smart IBCs, offer new avenues for real-time tracking, condition monitoring, and enhanced supply chain visibility, adding significant value. Moreover, the increasing focus on advanced recycling technologies and the development of IBCs made from recycled plastics or bio-based materials will open doors for manufacturers to meet evolving sustainability mandates and capture new market segments. Strategic partnerships and customization services to cater to specific industry needs further amplify these opportunities, positioning the market for continued evolution.

Segmentation Analysis

The Plastic Rigid IBC market is comprehensively segmented to provide granular insights into its diverse components, allowing for a detailed understanding of market dynamics, consumer preferences, and growth opportunities. This segmentation enables manufacturers, distributors, and end-users to identify specific niches and tailor strategies for optimal market penetration. The key segments analyze the market based on material type, volume capacity, end-use industry, and product type, each revealing distinct trends and demand patterns across different regions and applications.

- By Material Type:

- High-Density Polyethylene (HDPE)

- Low-Density Polyethylene (LDPE)

- Polypropylene (PP)

- Others (e.g., composite materials, recycled plastics)

- By Volume Capacity:

- Up to 500 Liters

- 501 - 1,000 Liters

- 1,001 - 1,250 Liters

- Above 1,250 Liters

- By End-Use Industry:

- Chemicals & Industrial Oils

- Food & Beverages

- Pharmaceuticals & Healthcare

- Paints, Coatings, & Adhesives

- Agriculture & Fertilizers

- Others (e.g., cosmetics, detergents)

- By Product Type:

- New IBCs

- Reconditioned IBCs

- Recycled Content IBCs

Value Chain Analysis For Plastic Rigid IBC Market

The value chain for the Plastic Rigid IBC market is a complex network of interconnected activities, commencing from the sourcing of raw materials to the final delivery and lifecycle management of the product. Upstream analysis focuses on the critical suppliers of primary raw materials, predominantly various grades of plastics like High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), and Polypropylene (PP), along with steel for cages and pallets. These raw material suppliers hold significant power, as their pricing and supply stability directly impact the manufacturing costs and lead times for IBC producers. Innovation in material science, such as the development of barrier plastics or recycled content polymers, also originates at this stage, influencing the performance and sustainability profile of the final IBC product. Efficient sourcing and strong supplier relationships are paramount for manufacturers to maintain competitive pricing and consistent production.

Midstream activities involve the core manufacturing processes of plastic rigid IBCs, which include blow molding, rotational molding, or injection molding techniques to form the inner bottle, followed by the assembly of steel cages, pallets (often steel, wood, or plastic), and ancillary components like valves, caps, and gaskets. Manufacturers in this segment focus on design optimization for strength, stackability, and ease of use, adherence to international standards for hazardous materials transport (e.g., UN ratings), and quality control. The efficiency of manufacturing operations, economies of scale, and investment in advanced production technologies are key differentiators here. Beyond new IBC production, the value chain also includes specialized services for the reconditioning and recycling of used IBCs, extending their lifecycle and contributing to circular economy objectives.

Downstream analysis primarily concerns the distribution channels and end-users. Plastic rigid IBCs are distributed through a mix of direct sales channels, where manufacturers sell directly to large industrial clients, and indirect channels, which involve a network of distributors, wholesalers, and logistics providers. These intermediaries play a crucial role in reaching a broader customer base, offering localized support, inventory management, and sometimes value-added services like cleaning and repair. The choice of distribution channel often depends on the customer's size, geographic location, and specific requirements. Ultimately, the end-users are the diverse range of industries—chemicals, food & beverage, pharmaceuticals, agriculture, etc.—that utilize these containers for storage and transport. The effectiveness of the value chain is measured by its ability to deliver quality IBCs to these end-users efficiently, safely, and cost-effectively, considering the entire product lifecycle including return and recycling.

Plastic Rigid IBC Market Potential Customers

The Plastic Rigid IBC market serves a broad and diverse range of industries, all requiring robust and efficient solutions for the bulk handling and transportation of their products. The primary potential customers are enterprises operating within sectors that frequently deal with large volumes of liquids, semi-solids, or granular materials. These include multinational corporations, mid-sized companies, and even smaller businesses that prioritize safety, cost-efficiency, and logistical optimization in their supply chains. The decision to adopt plastic rigid IBCs is often driven by the need to consolidate shipments, reduce packaging waste, comply with regulatory standards, and improve material handling processes within their facilities.

Key segments of end-user/buyers include the chemical and petrochemical industries, which rely heavily on IBCs for storing and transporting various hazardous and non-hazardous chemicals, solvents, resins, and industrial oils. The pharmaceutical and healthcare sectors are also significant consumers, utilizing IBCs for active pharmaceutical ingredients (APIs), excipients, and other bulk intermediates where stringent cleanliness and contamination control are critical. In the food and beverage industry, customers include manufacturers of edible oils, syrups, fruit concentrates, dairy products, and alcoholic beverages, seeking hygienic and efficient bulk packaging solutions that preserve product quality.

Beyond these core industries, other substantial customer bases include manufacturers of paints, coatings, and adhesives; agricultural businesses for fertilizers, pesticides, and seeds; and various industrial applications requiring the bulk transport of lubricants, cleaning agents, and other specialized fluids. Furthermore, the growing demand for reconditioned and recycled IBCs also creates a distinct customer segment focused on cost-effectiveness and sustainability, often including companies that have a robust reverse logistics infrastructure. Ultimately, any industry seeking to optimize its bulk material handling, reduce its environmental footprint, and enhance supply chain security represents a potential customer for plastic rigid IBCs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 12.5 Billion |

| Market Forecast in 2033 | USD 19.5 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schutz Container Systems, Inc., Mauser Packaging Solutions, Greif, Inc., TranPak, Inc., Snyder Industries, Inc., Pactiv Evergreen Inc., HOVER-PLAST GmbH, Composite Containers LLC, Brambles (CHEP), Fustiplast SL, Time Technoplast Ltd., Bulk Lift International, LLC, Denios US, WERIT Kunststoffwerke W. Schneider GmbH & Co. KG, Custom Metalcraft, Inc., Con-Tech International, Inc., Dura-Pack, LLC, Plymouth Foam, Inc., LC Packaging International BV, DS Smith Plc |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plastic Rigid IBC Market Key Technology Landscape

The Plastic Rigid IBC market is underpinned by a dynamic technological landscape that continuously evolves to meet increasing demands for durability, safety, efficiency, and sustainability. A fundamental technology is advanced plastic molding techniques, primarily blow molding and rotational molding, which are crucial for manufacturing the robust inner bottle of the IBC. Blow molding, particularly extrusion blow molding, is widely used for producing high-density polyethylene (HDPE) containers due to its efficiency in creating hollow, seamless structures with excellent strength-to-weight ratios. Rotational molding is employed for larger or more complex designs, offering uniform wall thickness and stress-free parts, ideal for specific industrial applications.

Beyond basic molding, material science plays a critical role. Manufacturers are increasingly adopting co-extrusion technologies to create multi-layer plastic bottles with enhanced barrier properties, protecting sensitive contents from oxygen, moisture, and UV light, which is particularly vital for food, pharmaceutical, and specialty chemical applications. The development of specialized polymer grades, including those with improved chemical resistance, impact strength, or flame retardant properties, further expands the applicability of plastic rigid IBCs to a wider range of challenging substances. Recycled content plastics and bio-based polymers are also gaining traction, driven by sustainability mandates and circular economy initiatives, pushing innovation in compounding and processing technologies.

Furthermore, the integration of smart technologies is transforming the functionality of plastic rigid IBCs. This includes the incorporation of Internet of Things (IoT) sensors, RFID tags, and QR codes for real-time tracking, temperature monitoring, pressure sensing, and fill-level measurement. These technologies enable unprecedented supply chain visibility, predictive maintenance capabilities, and enhanced security for valuable or sensitive contents. Automation in manufacturing processes, from robotic handling to automated quality inspection systems, also contributes to higher production efficiency, consistency, and reduced labor costs. The convergence of advanced materials, manufacturing processes, and digital technologies is setting new benchmarks for performance and intelligence in the plastic rigid IBC market.

Regional Highlights

- North America: This region represents a mature yet continually growing market for Plastic Rigid IBCs, driven by robust industrial activities in the chemical, food processing, and pharmaceutical sectors. Strict regulatory frameworks for safe handling and transportation of hazardous materials mandate the use of certified containers, favoring high-quality IBCs. The emphasis on supply chain efficiency and the strong presence of key market players also contribute significantly to market stability and growth in countries like the United States and Canada.

- Europe: Europe stands as a key market, characterized by stringent environmental regulations and a strong push towards sustainable packaging solutions. The demand for reusable plastic rigid IBCs is high due to circular economy initiatives and corporate sustainability goals. Germany, France, and the UK are prominent consumers, with significant chemical, pharmaceutical, and food and beverage industries. Innovation in smart IBCs and advanced recycling technologies is also a noticeable trend across the European Union.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by rapid industrialization, expanding manufacturing bases, and increasing disposable incomes leading to higher consumption across diverse sectors. Countries like China, India, Japan, and Southeast Asian nations are experiencing burgeoning demand for efficient bulk packaging solutions in chemicals, agriculture, and especially the fast-growing food and beverage industry. Government initiatives supporting manufacturing and infrastructure development further propel market expansion.

- Latin America: This region exhibits promising growth potential, driven by the expansion of its industrial base, particularly in chemicals, agriculture, and mining. Countries such as Brazil, Mexico, and Argentina are witnessing increased investment in manufacturing and logistics infrastructure, leading to a higher adoption rate of plastic rigid IBCs. The rising demand for efficient and safe packaging in the face of developing regulatory landscapes supports market growth.

- Middle East and Africa (MEA): The MEA region is emerging as a significant market, primarily due to expanding oil and gas industries, chemical manufacturing, and increasing investments in food processing and agriculture. The need for durable and reliable containers for challenging environmental conditions, coupled with growing industrialization, is driving the adoption of plastic rigid IBCs. Infrastructure development and economic diversification efforts are key market stimulants.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plastic Rigid IBC Market.- Schutz Container Systems, Inc.

- Mauser Packaging Solutions

- Greif, Inc.

- TranPak, Inc.

- Snyder Industries, Inc.

- Pactiv Evergreen Inc.

- HOVER-PLAST GmbH

- Composite Containers LLC

- Brambles (CHEP)

- Fustiplast SL

- Time Technoplast Ltd.

- Bulk Lift International, LLC

- Denios US

- WERIT Kunststoffwerke W. Schneider GmbH & Co. KG

- Custom Metalcraft, Inc.

- Con-Tech International, Inc.

- Dura-Pack, LLC

- Plymouth Foam, Inc.

- LC Packaging International BV

- DS Smith Plc

Frequently Asked Questions

Analyze common user questions about the Plastic Rigid IBC market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using plastic rigid IBCs over traditional drums?

Plastic rigid IBCs offer superior logistical efficiency through stackability and optimized space utilization, significant cost savings in material handling and transportation, enhanced product protection due to robust construction, and greater sustainability through reusability, leading to reduced packaging waste compared to multiple drums.

Which industries are the largest consumers of plastic rigid IBCs?

The largest consumers of plastic rigid IBCs are typically the chemical and petrochemical industries, followed closely by the food and beverage sector, and the pharmaceutical and healthcare industries. These sectors require efficient, safe, and often compliant solutions for bulk liquid and granular material handling.

How do plastic rigid IBCs contribute to sustainability?

Plastic rigid IBCs significantly contribute to sustainability by being reusable for multiple cycles, drastically reducing the demand for new packaging materials and minimizing landfill waste. Their design also often allows for efficient cleaning and reconditioning, further extending their lifespan and supporting circular economy principles.

What role does technology play in the evolution of the plastic rigid IBC market?

Technology plays a crucial role through advanced molding techniques, specialized material developments (e.g., barrier plastics, recycled content), and the integration of smart features like IoT sensors and RFID tags. These innovations enhance container durability, safety, traceability, and overall supply chain efficiency, driving market evolution.

What are the main factors driving the growth of the Plastic Rigid IBC market?

Key growth drivers include the increasing demand from expanding end-use industries, a global emphasis on efficient logistics and supply chain optimization, growing awareness and mandates for sustainable and reusable packaging solutions, and the cost-effectiveness and operational benefits offered by IBCs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Plastic Rigid IBC Market Size Report By Type (HDPE, LDPE, LLDPE, PP, By Capacity, Up to 500 Liters, 501-1000 Liters, 1001-2000 Liters, Above 2000 Liters), By Application (Industrial Chemicals, Petroleum & Lubricants, Paints, Inks & Dyes, Food & beverages, Building & Construction, Pharmaceuticals), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Plastic Rigid IBC Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Linear Low-Density Polyethylene (LLDPE), Low-Density Polyethylene (LDPE), High-Density Polyethylene (HDPE), Polyvinyl Chloride (PVC), Others), By Application (Petroleum and Lubricants, Industrial Chemicals, Paints, Inks and Dyes, Food and Beverages, Pharmaceuticals, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager