Plastic Sealing Washer Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439237 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Plastic Sealing Washer Market Size

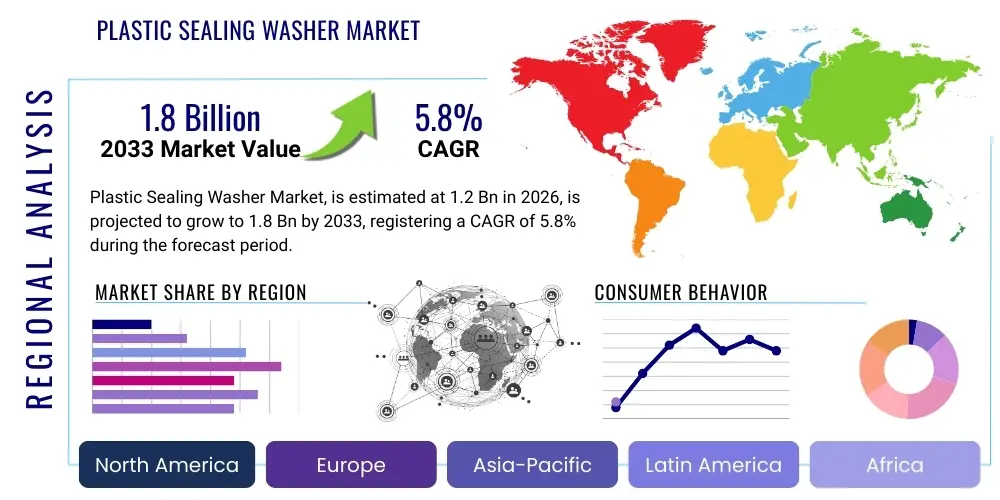

The Plastic Sealing Washer Market is projected to grow at a robust Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is strategically positioned to reach USD 1.8 Billion by the end of the forecast period in 2033. This significant expansion is predominantly catalyzed by the burgeoning demand stemming from a diverse array of end-use industries, most notably the automotive, electronics, and plumbing sectors. In these critical applications, plastic sealing washers are increasingly favored for their intrinsic ability to deliver superior performance characteristics, including exceptional corrosion resistance, reliable electrical insulation, and effective vibration dampening, making them indispensable components in modern industrial design and assembly, especially as global manufacturing output continues its upward trajectory.

The market's upward trajectory is further underpinned by persistent innovations and advancements occurring within the realm of polymer science and material engineering. These developments are consistently leading to the creation of more sophisticated, durable, and high-performance plastic materials that are specifically engineered to withstand increasingly arduous operational environments, including extremes of temperature, aggressive chemical exposure, and intense mechanical stress, thereby broadening the potential application base. Furthermore, the global shift towards lightweighting in various manufacturing processes, driven by efficiency, reduced carbon footprint, and sustainability goals, solidifies the pivotal role of plastic sealing washers. Their inherent lightness, combined with the versatility to be custom-molded into intricate designs, positions them as a preferred choice over traditional metallic alternatives, particularly in the rapidly evolving electric vehicle (EV) segment and advanced aerospace applications, thereby assuring sustained market growth throughout the projected period.

Plastic Sealing Washer Market introduction

Plastic sealing washers represent a class of essential industrial components meticulously engineered to perform critical functions such as establishing tight seals between mating surfaces, mitigating vibrational forces, and providing effective electrical insulation. These versatile washers are fabricated from an expansive spectrum of polymer materials, each possessing a unique profile of physical and chemical properties tailored for specific applications. Common materials include Nylon, revered for its robust mechanical strength, excellent wear resistance, and good chemical resistance; PTFE (Polytetrafluoroethylene), known for its exceptional chemical inertness, high temperature resistance, extremely low coefficient of friction, and superior dielectric strength; HDPE (High-Density Polyethylene), valued for its high strength-to-density ratio, impact resistance, and excellent chemical compatibility; and Polypropylene, recognized for its exceptional chemical resistance, fatigue strength, and good dielectric properties, often used in medical and food-grade applications. The judicious selection of material is paramount, ensuring optimal performance in diverse operating conditions ranging from high-temperature environments to chemically aggressive settings and critical electrical assemblies.

Other significant materials include Polycarbonate, favored for its optical clarity, very high impact resistance, and good dimensional stability, often seen in transparent or impact-prone applications; and PVC (Polyvinyl Chloride), widely utilized for its flexibility, weatherability, and good resistance to oils and chemicals, making it suitable for outdoor and plumbing applications. The applications for plastic sealing washers are remarkably broad and penetrate numerous industrial verticals, underscoring their ubiquity and critical importance. In the automotive industry, they are indispensable in fluid systems like brake lines and fuel injectors, electrical harnesses, and interior assemblies, contributing to leak prevention, enhanced safety, noise reduction, and overall vehicle longevity. Within the electronics sector, these washers serve as vital insulators and spacers, protecting delicate circuit boards, connectors, and sensitive components from electrical interference, short circuits, and physical damage, crucial for reliable device operation in consumer, industrial, and telecommunications equipment. Furthermore, their non-magnetic properties make them ideal for specialized electronic and scientific instrumentation.

The plumbing and HVAC (Heating, Ventilation, and Air Conditioning) industries rely heavily on them to ensure leak-proof connections in water and gas lines, as well as in heating, ventilation, and air conditioning systems, resisting corrosion and scaling in moist environments. Moreover, in general industrial machinery, plastic washers play a crucial role in vibration control, load distribution, friction reduction, and sealing dynamic parts in pumps, motors, gearboxes, and automation equipment, enhancing the longevity and operational reliability of equipment across manufacturing, processing, and heavy machinery operations. The myriad benefits associated with employing plastic sealing washers are significant and compelling. They inherently offer superior corrosion resistance when compared to many metallic counterparts, rendering them ideal for use in moist, outdoor, or chemically reactive environments where metal degradation is a concern. Their exceptional electrical insulation properties prevent current leakage and short circuits, which is critical in electrical and electronic assemblies. Furthermore, plastic washers contribute to noise reduction and component longevity by effectively dampening vibrations and distributing loads, thereby reducing wear and tear, and enhancing the overall performance of mechanical systems. From an economic perspective, plastic washers are often more cost-effective to produce and install, contributing to overall assembly savings and logistical efficiencies. The primary driving factors for the market's sustained expansion include the global surge in manufacturing activities, an escalating demand for lightweight and high-performance components across all sectors, and continuous innovations in polymer technology that unlock new application possibilities and enhance existing product capabilities, ensuring their indispensable role in modern engineering solutions and sustainable design practices.

Plastic Sealing Washer Market Executive Summary

The Plastic Sealing Washer Market is currently undergoing a period of vigorous expansion, primarily propelled by a confluence of accelerating global industrial growth and an increasing imperative for lightweight, durable, and corrosion-resistant components across a multitude of manufacturing and service sectors. Current business trends within this dynamic market highlight a pronounced and strategic shift towards highly customized solutions, where specific material properties and geometries are tailored to meet unique application demands. Concurrently, there is a strong emphasis on the development of advanced, high-performance material formulations that can withstand increasingly harsh operating conditions. Manufacturers are making significant investments in cutting-edge molding technologies, such as multi-shot injection molding and micro-molding, coupled with intensive polymer research. This dual approach aims to meticulously engineer washers that not only fulfill but exceed the stringent and diverse performance specifications required by modern industries. Furthermore, the market is witnessing a trend towards consolidation among smaller players and strategic alliances aimed at leveraging complementary strengths and expanding geographic reach, alongside a growing focus on lean manufacturing principles to enhance operational efficiency.

A pivotal emerging trend significantly influencing the market is the escalating global focus on sustainability and environmental stewardship. This imperative is progressively shaping material selection and production methodologies, fostering accelerated research, development, and adoption of recycled, bio-based, and biodegradable plastics for washer fabrication. This aligns industry practices with stringent global environmental mandates, such as Extended Producer Responsibility (EPR) regulations, and evolving consumer and corporate demand for eco-conscious products and supply chains. Geographically, the Asia-Pacific region steadfastly maintains its position as the dominant market, primarily attributable to its robust and rapidly expanding manufacturing base, which is particularly evident in the automotive, electronics, and burgeoning renewable energy industries. This regional leadership is further reinforced by unprecedented rates of urbanization and extensive infrastructure development projects occurring throughout economic powerhouses like China, India, and Southeast Asian nations, stimulating immense demand for industrial components. Concurrently, North America and Europe command substantial market shares, characterized by their mature industrial economies, stringent quality control frameworks, and a persistent demand for highly specialized and advanced sealing solutions catering to sophisticated engineering requirements, particularly in aerospace, medical, and precision machinery sectors.

These developed regions also demonstrate a strong inclination towards technological innovation and premium product offerings, contributing significantly to market value through high-specification, niche market solutions. The ongoing globalization of manufacturing facilities and supply chains further intertwines regional market dynamics, creating complex interdependencies and diversified growth pathways, with increasing cross-border trade and investment. From a segmentation perspective, the market is witnessing robust and dynamic growth across various material types. Engineering plastics such as Nylon, PTFE, and PEEK are experiencing sustained demand due to their superior mechanical, thermal, and chemical resistance properties, making them indispensable for high-stress and demanding applications requiring extreme precision and durability. Simultaneously, the market is observing increased utilization of commodity plastics like HDPE and Polypropylene for general-purpose and cost-sensitive applications, where their specific benefits provide ample value. Within the application segments, the automotive sector continues to be a primary revenue engine, constantly integrating innovative sealing washer designs into advanced vehicle platforms, including electric vehicles and autonomous systems, to enhance efficiency, safety, and reliability. The plumbing, HVAC, and electronics sectors also remain pivotal contributors, continuously evolving with new technological integrations and design efficiencies that necessitate specialized plastic sealing washers for optimal system performance, enhanced longevity, and compliance with evolving industry standards.

AI Impact Analysis on Plastic Sealing Washer Market

The profound integration of Artificial Intelligence (AI) across the entire spectrum of industrial manufacturing processes is poised to fundamentally reshape the Plastic Sealing Washer Market. This transformative influence will manifest by significantly enhancing various operational facets, including the optimization of production workflows, acceleration of material development cycles, and refinement of complex supply chain dynamics. Common user questions and industry concerns frequently revolve around AI's prospective capabilities to automate intricate design processes, ensuring high precision and efficiency; to rigorously enhance quality control measures through advanced analytical techniques, minimizing human error; to accurately predict the performance longevity and reliability of novel material compositions under varying stress conditions; and to meticulously streamline inventory management systems through intelligent forecasting. The overarching goal behind these inquiries is a collective drive towards achieving unparalleled operational efficiency, substantially reducing material waste, lowering overall production costs, and increasing speed-to-market across the entire value chain for plastic sealing washers, thereby revolutionizing traditional manufacturing paradigms.

Furthermore, stakeholders are keen to understand how AI will strategically influence the customization capabilities essential for addressing highly specialized and niche application requirements, enabling manufacturers to offer more tailored, effective, and rapidly deployable solutions. There is also a strong expectation regarding AI's potential to facilitate advanced predictive maintenance protocols for critical manufacturing equipment, such as injection molding machines and CNC routers. By analyzing real-time sensor data, AI can anticipate potential failures, significantly minimize unscheduled downtime, and extend machinery lifespans, thereby maximizing production throughput and ensuring consistent product quality. The consensus among market participants is that AI will serve as a powerful catalyst for innovation in polymer science, facilitating the rapid exploration, simulation, and synthesis of advanced polymer compounds with precisely tailored properties. This capability is anticipated to provide a substantial competitive advantage, allowing companies to quickly respond to evolving market demands, develop cutting-edge sealing solutions, and maintain market leadership in an increasingly dynamic and technologically driven environment.

Beyond manufacturing and material science, AI is also expected to transform market intelligence and customer engagement within the plastic sealing washer sector. AI-powered analytics can process vast datasets of market trends, customer feedback, and competitive intelligence to identify emerging opportunities, predict demand shifts, and inform strategic business decisions. In customer service and sales, AI-driven chatbots and virtual assistants can provide instant technical support, product recommendations, and order processing, enhancing customer satisfaction and operational efficiency. Moreover, AI can personalize marketing efforts by identifying specific client needs and tailoring product offerings, fostering stronger customer relationships and opening new revenue streams. The ability of AI to synthesize complex information and provide actionable insights will empower manufacturers to make more informed decisions, optimize their market positioning, and proactively address customer requirements in a highly competitive landscape.

- AI-driven generative design tools automate the creation of optimized plastic washer geometries, minimizing material usage, enhancing functional performance, and reducing design cycles.

- Advanced AI-powered predictive analytics monitor manufacturing parameters in real-time, enabling proactive adjustments to reduce defects, optimize energy consumption, and minimize material waste during production.

- Machine learning algorithms accelerate the research and development of novel polymer blends by simulating material properties and predicting performance under various stress conditions, facilitating rapid prototyping and material selection.

- AI-enhanced robotic automation in assembly and inspection processes improves consistency, throughput, and precision, particularly for high-volume or intricate plastic sealing washer types, reducing labor costs and human error.

- Supply chain optimization platforms leveraging AI forecasting capabilities lead to more accurate demand predictions, optimized inventory levels, dynamic routing, and reduced lead times for raw materials and finished products, enhancing logistical efficiency.

- Predictive maintenance systems, integrating AI with sensor data from manufacturing equipment, anticipate potential failures, thereby minimizing unplanned downtime, extending operational lifespans of machinery, and maximizing overall equipment effectiveness (OEE).

- AI analytics contribute significantly to sustainability efforts by identifying opportunities for waste reduction, optimizing recycling processes for plastic scraps, and exploring circular economy models for washer manufacturing, supporting eco-friendly practices.

- Personalized product configurations and customer-specific solutions are enabled by AI analysis of vast datasets on application requirements and performance feedback, leading to highly tailored and superior sealing washer designs, enhancing customer satisfaction and loyalty.

DRO & Impact Forces Of Plastic Sealing Washer Market

The Plastic Sealing Washer Market is propelled by several robust and interconnected drivers, fundamentally rooted in the consistent and unyielding expansion of pivotal end-use industries. The automotive sector, in particular, continues to be a major catalyst, driven by the persistent demand for lightweight components that enhance fuel efficiency and reduce emissions, alongside a growing need for electrically insulating parts in electric vehicles (EVs). Similarly, the electronics and electrical industries require reliable, non-conductive sealing solutions for an ever-increasing array of devices and infrastructure. Furthermore, significant advancements in polymer science and material engineering continue to bolster market growth, leading to the development of high-performance plastics with augmented durability, superior chemical resistance across a wider pH range, and enhanced temperature tolerance, enabling washers to perform effectively in increasingly demanding and aggressive applications. The intrinsic benefits of plastic washers, such as their lightweight nature, exceptional corrosion resistance in moist or chemical environments, and superb electrical insulation properties, continue to drive their adoption over conventional metal alternatives, especially in applications where weight reduction, non-conductivity, or resistance to aggressive chemicals are critical design considerations, thereby solidifying their market position and expanding their application scope globally.

However, the market also contends with notable restraints that pose significant challenges to its growth trajectory and operational stability. The inherent volatility of raw material prices, particularly for petroleum-based polymers, which constitute the foundational components of plastic washers, can unpredictably impact manufacturing costs and subsequently compress profit margins for producers, leading to pricing instability in the market. Furthermore, escalating global environmental concerns surrounding plastic waste, particularly single-use plastics, and the intensifying pressure for sustainable manufacturing practices, present a formidable and growing challenge. This necessitates substantial investment from manufacturers into research and development for eco-friendly alternatives, such as bio-based, recycled, or biodegradable plastics, along with the implementation of robust recycling initiatives and closed-loop systems to mitigate environmental impact and comply with evolving regulatory frameworks. Moreover, stringent and diverse regulatory complexities concerning material standards, product safety, and chemical restrictions (e.g., RoHS, REACH) across different geographical regions also add layers of operational challenge and compliance costs, potentially slowing innovation or market entry for new products.

Despite these restraints, significant opportunities abound within the Plastic Sealing Washer Market, poised to catalyze future growth and innovation. The escalating demand for highly specialized, high-precision washers in niche applications, such as advanced medical devices where biocompatibility, sterilization compatibility, and miniaturization are paramount, and in the aerospace sector which requires ultra-lightweight, high-performance, and radiation-resistant components for critical systems, presents lucrative avenues for market expansion. Moreover, the continuous innovation and development of sustainable materials, including fully recyclable, bio-based, and biodegradable plastics, offer a compelling pathway for market players to differentiate their products, meet evolving environmental regulations, and cater to a growing segment of environmentally conscious consumers and industries. The market's trajectory is profoundly influenced by several interconnected impact forces. These include rapid technological advancements in both molding processes and material science, leading to more efficient production, enhanced customization capabilities, and superior product performance. Stringent and evolving environmental regulations globally exert continuous pressure for greener and more circular solutions. Lastly, overarching global economic conditions, influencing industrial output, infrastructure investment, and consumer spending across developing and developed nations, collectively dictate the pace and direction of market growth, shaping the competitive landscape and strategic priorities of market participants.

Segmentation Analysis

The Plastic Sealing Washer Market is meticulously segmented across various crucial dimensions, encompassing material type, product type, application, and end-use industry. This comprehensive segmentation framework offers an invaluable granular perspective on the intricate market dynamics, identifying specific growth engines, emerging trends, and distinct opportunities within diverse sub-markets. Each defined segment possesses unique characteristics, driven by varying consumer preferences, performance requirements, and technological advancements, allowing for a highly nuanced and targeted analysis of supply and demand patterns. By dissecting the market into these specialized components, stakeholders can gain profound insights into the underlying forces shaping the industry, from the prevalence of specific polymer types and their unique processing requirements to the dominant applications in particular sectors and their corresponding performance criteria, enabling a more precise understanding of market behavior.

Understanding these detailed segmentations is critically important for all market participants, including raw material suppliers, plastic washer manufacturers, distributors, and ultimate end-users. It empowers manufacturers to precisely tailor their product portfolios, optimizing design and production to meet the exacting specifications of niche markets while developing effective go-to-market strategies that resonate with specific customer needs. Furthermore, this analytical approach facilitates more targeted research and development investments, guiding innovation towards areas of highest potential return, such as specialized material formulations for extreme environments, novel manufacturing techniques for miniaturized components, or new product geometries for challenging sealing applications. For investors and strategists, comprehensive segmentation analysis provides a clearer roadmap for identifying untapped market potential, assessing competitive landscapes, understanding market entry barriers, and making informed decisions that align with specific industry verticals and geographical market nuances, ultimately driving sustainable growth, fostering innovation, and securing market leadership in an increasingly complex and competitive global environment.

- By Material Type:

- Nylon: Valued for its high tensile strength, excellent wear and abrasion resistance, good chemical resistance to oils and alkalis, and low friction, often used in automotive and industrial applications.

- PTFE (Teflon): Highly prized for its exceptional chemical inertness, high temperature resistance up to 260°C, extremely low coefficient of friction, superior dielectric strength, and non-stick properties, making it ideal for aggressive chemical environments and high-purity applications.

- HDPE (High-Density Polyethylene): Offers robust chemical resistance, high impact strength, low moisture absorption, and good electrical insulating properties, commonly found in plumbing, outdoor applications, and food contact services due to its non-toxicity.

- Polypropylene (PP): Characterized by excellent chemical resistance to organic solvents and acids, high fatigue resistance, a high melting point, and good dielectric properties, frequently utilized in medical, food-grade, and general industrial applications.

- Polycarbonate: Chosen for its very high impact strength, optical clarity, good dimensional stability, and high heat resistance, suitable for applications requiring transparency and robustness, such as in electronics or specialized machinery.

- PVC (Polyvinyl Chloride): Offers good flexibility (especially in plasticized form), weatherability, excellent resistance to oils, chemicals, and acids, making it a cost-effective choice for plumbing, construction, and general-purpose sealing.

- Others (e.g., Acetal, UHMW-PE, PEEK): Includes a range of specialized high-performance polymers like Acetal (for stiffness and low friction), UHMW-PE (for extreme wear resistance), and PEEK (for outstanding high-temperature and chemical resistance in aerospace and medical applications).

- By Product Type:

- Flat Washers: The most common and versatile type, used for distributing load, preventing pull-through, and providing spacing, applicable across nearly all industries.

- Shoulder Washers: Designed with a shoulder to insulate components, provide spacing, or bear loads against a smaller diameter shaft, often used in electrical and electronic assemblies.

- Sealing Washers (Custom Shapes): Engineered specifically for leak-proof applications, often incorporating unique geometries, molded-in seals, or soft elastic layers to create a hermetic seal against fluids or gases.

- Spacer Washers: Primarily used to maintain precise distances or clearances between components, prevent contact, or adjust alignment within mechanical and electrical assemblies.

- Finishing Washers: Also known as countersunk washers, these provide a clean, aesthetic finish while securely distributing load, often used with flat-head screws in consumer goods and visible applications.

- By Application:

- Sealing: Prevents leakage of fluids, gases, or contaminants between mating surfaces, critical in hydraulic systems, fuel lines, and plumbing.

- Insulation: Electrically or thermally isolates components, protecting sensitive electronics from current flow or heat transfer.

- Vibration Dampening: Reduces noise, fatigue, and wear caused by mechanical vibrations, extending the lifespan of machinery and improving operational comfort.

- Spacing: Maintains precise distances or alignment between parts, crucial for dimensional accuracy in complex assemblies.

- Surface Protection: Prevents scratching, galling, or damage to contact surfaces during assembly or operation, safeguarding finishes and material integrity.

- By End-Use Industry:

- Automotive: Extensive use in engine components, fluid systems (oil, fuel, coolant), electrical wiring, interior assemblies, and chassis, driven by lightweighting, corrosion resistance, and EV electrification.

- Electronics and Electrical: Critical for circuit board mounting, insulation for connectors and terminals, spacing components, and protecting sensitive parts in consumer electronics, industrial controls, and telecommunications.

- Plumbing and HVAC: Essential for creating leak-proof seals in pipes, valves, fittings, pumps, and ventilation systems, resisting water, chemicals, and extreme temperatures.

- Industrial Machinery: Employed in a wide range of equipment including pumps, motors, gearboxes, conveying systems, and automation robotics for vibration control, friction reduction, load distribution, and sealing dynamic parts.

- Aerospace and Defense: Demands high-performance, lightweight, and often custom-engineered plastic washers for aircraft systems, satellites, and military equipment, where reliability under extreme conditions, low weight, and non-conductivity are paramount.

- Medical Devices: Requires biocompatible, sterilizable, and precise plastic washers for surgical instruments, diagnostic equipment, drug delivery systems, and laboratory apparatus, emphasizing material purity and tight tolerances.

- Construction: Utilized in various building applications, including windows, doors, roofing, and structural elements, providing weather sealing, spacing, and corrosion protection.

- Consumer Goods: Incorporated into a vast array of everyday products such as appliances, furniture, toys, and sporting equipment for durability, aesthetic appeal, and cost-effectiveness.

Value Chain Analysis For Plastic Sealing Washer Market

The value chain for the Plastic Sealing Washer Market is an intricate network commencing with the upstream segment, which is predominantly shaped by raw material suppliers. These entities are primarily large petrochemical corporations and specialized polymer manufacturers responsible for the production of a diverse range of plastic resins, including Nylon, PTFE, HDPE, Polypropylene, Polycarbonate, and PVC. These foundational materials are critical inputs, and their quality, consistency, availability, and pricing significantly influence the production costs and ultimate market competitiveness of plastic washers. The upstream segment also encompasses chemical companies that provide essential additives, colorants, reinforcing agents (e.g., glass fibers, carbon fibers), and stabilizers, which are crucial for modifying polymer properties to meet specific application demands such as enhanced UV stability, flame retardancy, increased mechanical strength, or improved electrical properties. Research and development at this initial stage is highly focused on creating innovative polymer formulations, including high-performance engineering plastics and sustainable alternatives like bio-based or recycled polymers, thereby fundamentally impacting the entire downstream chain and product innovation.

Plastic Sealing Washer Market Potential Customers

The Plastic Sealing Washer Market caters to a broad and exceptionally diverse spectrum of potential customers and end-users, encompassing virtually every industrial sector that requires reliable, non-corrosive, electrically insulating, or vibration-dampening components for assembly, operation, and maintenance. Foremost among these is the automotive sector, representing a colossal and consistently growing customer base. Automakers utilize plastic washers extensively in vehicle manufacturing for numerous critical applications, including sealing fluid lines (e.g., fuel lines, brake systems, coolant circuits) to prevent leaks, insulating electrical connections and sensors to ensure system integrity, preventing metal-on-metal contact in chassis and engine components to reduce wear, and dampening vibrations in interior assemblies to enhance occupant comfort and reduce noise. Their lightweight nature also critically contributes to improved fuel efficiency and overall vehicle performance, making them indispensable in both traditional internal combustion engine vehicles and the rapidly expanding electric vehicle (EV) segment, where superior electrical insulation and thermal management are even more critical for battery packs and power electronics.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SKF, igus GmbH, Superior Washer & Gasket Corp., Boker's Inc., Accurate Screw Machine, GBSA Inc., PIC Design, Essentra Components, Sealing Devices Inc., New Process Fibre, NewAge Industries, Plastiques Du Val de Loire, Nyltite Corporation, Federal-Mogul LLC, Trifast plc, Fabory, G&G Manufacturing, PEXCO LLC, Trelleborg AB, Freudenberg Sealing Technologies, Saint-Gobain Performance Plastics, Greenleaf Corporation, WS Hampshire, New England Small Tube Corporation, Plastic Components Inc., Tiodize Co. Inc., Daemar Inc., MISUMI Group Inc., Craftech Industries, PAR Group, C. V. L. Engineering, Caplugs, Polyflon GmbH, Techflex Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plastic Sealing Washer Market Key Technology Landscape

The Plastic Sealing Washer Market's technological landscape is dynamically shaped by continuous advancements in both manufacturing processes and the scientific development of polymer materials, collectively striving for enhanced performance, efficiency, and sustainability. At its core, conventional manufacturing technologies predominantly include highly precise injection molding, which is the cornerstone for high-volume production of complex and intricate washer geometries, offering exceptional repeatability, tight tolerances, and cost-effectiveness for mass market applications. Compression molding is strategically employed for specific high-performance thermoset materials and for fabricating larger, thicker washers that require particular material flow characteristics, high mechanical strength, and excellent thermal stability. Additionally, advanced precision machining techniques, such as Computer Numerical Control (CNC) cutting, laser cutting, and waterjet cutting, are indispensable for producing custom-designed, low-volume specialized washers, ensuring extreme precision, intricate details, and rapid prototyping capabilities required for critical aerospace, medical, and defense applications. These core processes are constantly being refined through increased automation, advanced robotic integration, and the implementation of smart manufacturing principles, including IoT connectivity and real-time data analytics, to achieve higher operational efficiency, reduced cycle times, optimized material utilization, and significantly improved quality control, thereby driving down production costs while elevating product quality and consistency.

Regional Highlights

- North America: This region presents a mature yet highly dynamic market, characterized by significant demand from its well-established automotive, aerospace, and electronics industries. Growth here is primarily driven by stringent quality standards, robust technological innovation, and a strong emphasis on high-performance and specialized materials for critical applications. The presence of leading global manufacturers, coupled with a focus on advanced R&D and specialized, high-value applications, further solidifies its market position, with the United States and Canada being key contributors. The trend towards electric vehicles (EVs) and advanced manufacturing techniques is particularly strong here.

- Europe: A pivotal market with substantial demand originating from its sophisticated automotive, industrial machinery, and construction sectors. Europe is at the forefront of sustainability initiatives, which actively drives the increasing adoption of recycled, bio-based, and environmentally friendly plastic washers, aligning with stringent regional regulations like REACH and RoHS. Countries such as Germany, known for its engineering prowess, France, and the UK are vital contributors, fostering innovation in materials and advanced manufacturing processes, particularly in precision engineering and renewable energy applications.

- Asia Pacific (APAC): Positioned as the fastest-growing region globally, APAC's market expansion is vigorously fueled by rapid industrialization, burgeoning urbanization, and a flourishing manufacturing sector across economic powerhouses like China, India, Japan, and South Korea. The colossal production and consumption of automotive, electronic, and infrastructure components act as major drivers, coupled with increasing foreign direct investment and a burgeoning middle class demanding more manufactured goods. The region serves as a global manufacturing hub, driving both domestic consumption and export demand for plastic sealing washers.

- Latin America: This region represents an emerging market characterized by increasing industrial activity and infrastructure development, particularly notable in the expanding automotive assembly plants and construction projects. Brazil and Mexico stand out as leading markets within the region, where growing foreign investment, expanding domestic manufacturing capabilities, and regional trade agreements are significantly contributing to market expansion and the adoption of modern industrial components, especially in areas related to resource extraction and processing.

- Middle East and Africa (MEA): The MEA region is witnessing a steady surge in demand for plastic sealing washers, largely attributable to ongoing large-scale infrastructure development projects, the substantial presence and expansion of the oil and gas industries requiring robust sealing solutions, and burgeoning manufacturing sectors in diversified economies. The market here is expected to demonstrate consistent growth, driven by economic diversification efforts, increasing industrialization, and foreign investment across key countries like Saudi Arabia, UAE, and South Africa, focusing on advanced industrial applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plastic Sealing Washer Market.- SKF

- igus GmbH

- Superior Washer & Gasket Corp.

- Boker's Inc.

- Accurate Screw Machine

- GBSA Inc.

- PIC Design

- Essentra Components

- Sealing Devices Inc.

- New Process Fibre

- NewAge Industries

- Plastiques Du Val de Loire

- Nyltite Corporation

- Federal-Mogul LLC

- Trifast plc

- Fabory

- G&G Manufacturing

- PEXCO LLC

- Trelleborg AB

- Freudenberg Sealing Technologies

- Saint-Gobain Performance Plastics

- Greenleaf Corporation

- WS Hampshire

- New England Small Tube Corporation

- Plastic Components Inc.

- Tiodize Co. Inc.

- Daemar Inc.

- MISUMI Group Inc.

- Craftech Industries

- PAR Group

- C. V. L. Engineering

- Caplugs

- Polyflon GmbH

- Techflex Inc.

Frequently Asked Questions

What is the projected growth rate for the Plastic Sealing Washer Market and its estimated size by 2033?

The Plastic Sealing Washer Market is projected to grow at a robust Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. It is estimated at USD 1.2 Billion in 2026 and is forecasted to reach USD 1.8 Billion by the end of 2033, primarily driven by increasing industrial demand across automotive, electronics, and plumbing sectors, alongside continuous material innovations.

Which key industries are the primary consumers and significant drivers of demand for plastic sealing washers?

Key industries driving substantial demand include the automotive sector (for lightweighting, electrical insulation in EVs, and fluid sealing), electronics and electrical industries (for component insulation and protection), plumbing and HVAC (for leak-proof sealing in water and gas systems), industrial machinery (for vibration dampening and friction reduction), and the medical devices sector (for biocompatibility and precision in critical applications). These industries highly value the washers' essential sealing, insulating, and vibration-dampening properties.

What are the main advantages of utilizing plastic sealing washers compared to their traditional metal counterparts?

Plastic sealing washers offer numerous distinct advantages, including superior corrosion resistance in diverse and aggressive environments, excellent electrical insulation preventing current leakage, significantly lighter weight contributing to energy efficiency and reduced overall product mass, and often lower manufacturing and installation costs. They are also highly adaptable for custom molding into complex shapes, making them ideal for specialized and precision applications where metal alternatives may be unsuitable due to material limitations or cost.

How is Artificial Intelligence (AI) influencing the Plastic Sealing Washer Market and its manufacturing processes?

AI is profoundly impacting the market by optimizing manufacturing processes through AI-driven predictive analytics, enhancing quality control via advanced defect detection systems, accelerating material research and development for novel polymer formulations, and streamlining supply chain management through intelligent forecasting and logistics optimization. This leads to greater operational efficiency, significant reduction in material waste, and the rapid development of customized, high-performance sealing solutions, thereby transforming traditional production paradigms.

What are the predominant materials used in the production of plastic sealing washers, and what are their key characteristics?

Predominant materials include Nylon (for high strength, wear resistance, and good chemical compatibility), PTFE (Teflon, known for exceptional chemical inertness, high temperature resistance, and low friction), HDPE (High-Density Polyethylene, offering good chemical resistance and impact strength), Polypropylene (PP, valued for chemical and fatigue resistance), Polycarbonate (for very high impact strength and clarity), and PVC (for flexibility, weatherability, and chemical resistance). Each material is selected based on specific application requirements concerning temperature, chemical exposure, mechanical load, and electrical properties.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager