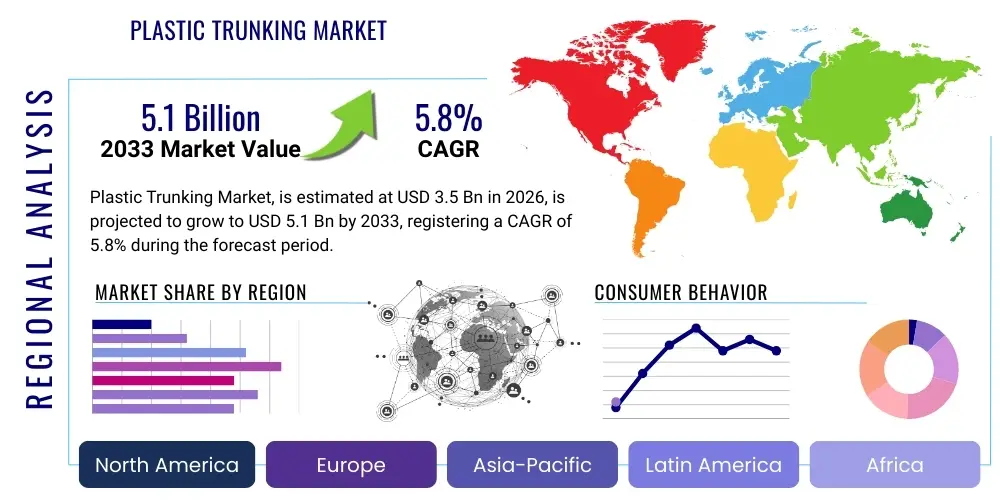

Plastic Trunking Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438630 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Plastic Trunking Market Size

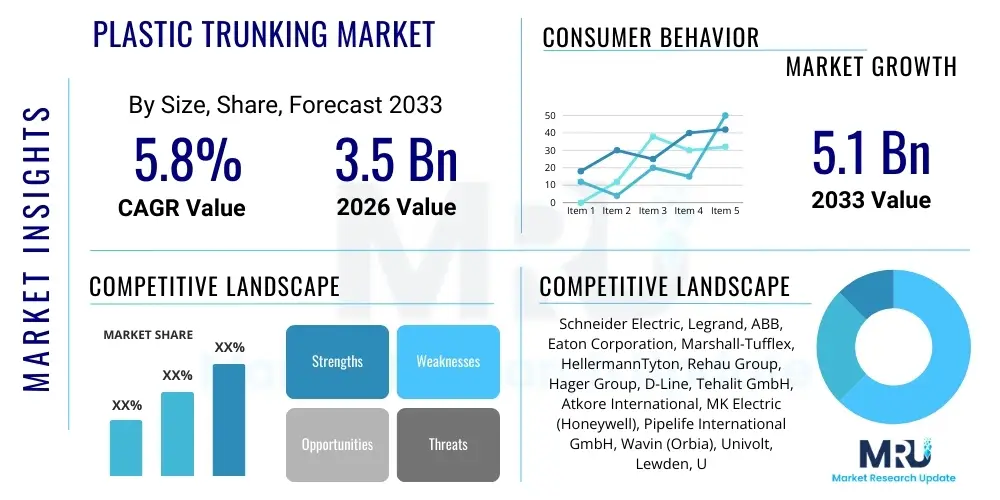

The Plastic Trunking Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.1 Billion by the end of the forecast period in 2033.

Plastic Trunking Market introduction

Plastic trunking, also known as cable management systems, encompasses conduits, ducts, and channels predominantly manufactured from polyvinyl chloride (PVC) or low-smoke zero-halogen (LSZH) materials. These systems are essential components in modern construction and infrastructure projects, designed to protect electrical cables and wires from physical damage, environmental factors, and unauthorized access, while simultaneously ensuring an organized, aesthetically pleasing installation. The primary function involves containing and routing power cables, data lines, and communication wiring within residential, commercial, and industrial environments, supporting efficient electrical distribution networks.

The market growth is fundamentally driven by the accelerated pace of urbanization and industrial development across emerging economies, necessitating robust electrical infrastructure expansion. Furthermore, the global proliferation of smart building technologies, which require complex and extensive network cabling, significantly boosts the demand for high-quality, fire-retardant plastic trunking solutions. Plastic trunking offers considerable advantages over traditional metal conduits, including superior corrosion resistance, lighter weight, ease of installation, and cost-effectiveness, making it the preferred choice for a vast majority of low-voltage and data cabling applications.

Major applications of plastic trunking span the construction sector, including new residential housing, commercial office complexes, hospitals, schools, and expansive industrial facilities such as manufacturing plants and logistics centers. Key benefits driving adoption include compliance with stringent safety standards, particularly concerning fire safety (through LSZH variants), reduced installation time due due to modular designs, and long-term durability. Driving factors such as increased government investment in public infrastructure, coupled with the rapid expansion of data center facilities globally, cement the critical role of plastic trunking in foundational building services.

Plastic Trunking Market Executive Summary

The Plastic Trunking Market exhibits robust growth, underpinned by significant global business trends, including the increasing adoption of pre-fabricated construction methods and a sharp focus on enhanced fire safety compliance, particularly in densely populated urban centers. Manufacturers are increasingly investing in automation and sustainable material production (recycled plastics and halogen-free compounds) to meet regulatory requirements and consumer demand for eco-friendly products. Segment trends indicate a strong shift toward specialized trunking systems designed for demanding applications, such as large-scale data center cable management and integrated solutions for electric vehicle (EV) charging infrastructure, driving premium pricing and technological advancements within the higher-quality product categories.

Regionally, the Asia Pacific (APAC) market leads in terms of volume and growth potential, primarily fueled by massive infrastructure projects in China, India, and Southeast Asian nations, alongside rapid residential construction expansion. North America and Europe, while mature, are characterized by high demand for advanced, aesthetic, and regulatory-compliant solutions, emphasizing LSZH and antimicrobial properties, particularly in healthcare and sensitive commercial settings. These regions drive innovation in design and integration capabilities, ensuring trunking systems can seamlessly incorporate smart building sensors and data transfer capabilities, moving beyond simple cable protection.

Competitive dynamics remain focused on material science efficiency and distribution network optimization. Key market players are concentrating on strategic mergers and acquisitions to expand geographic reach and diversify product portfolios, especially toward modular and customizable trunking solutions that reduce on-site labor costs. The overall market outlook is positive, contingent upon global construction activity remaining stable and continuous technological iterations aimed at improving ease of installation and fire performance metrics.

AI Impact Analysis on Plastic Trunking Market

Common user questions regarding AI's impact on the Plastic Trunking Market typically center on how artificial intelligence can optimize manufacturing efficiency, enhance quality control processes, and transform supply chain logistics. Users are concerned about whether AI-driven design tools can automate the creation of complex, customized trunking configurations for large projects and if AI can improve the prediction of raw material price volatility (such as PVC and stabilizers) to better manage procurement costs. Furthermore, there is significant interest in how AI, integrated with smart building systems, could influence the demand for specific types of trunking, especially regarding predictive maintenance for cable integrity and automated fault detection, demanding more durable and sensor-compatible systems.

AI is fundamentally restructuring the operational landscape of the Plastic Trunking Market, moving manufacturing processes towards greater precision and less waste. AI algorithms are employed in optimizing extrusion parameters, monitoring material consumption in real-time, and detecting subtle defects in the plastic profile that human inspectors might miss. This dramatically improves product consistency and reduces scrap rates, which is crucial given the high volume and relatively low margin nature of many trunking products. The integration of machine learning into Computer-Aided Design (CAD) systems allows for faster prototyping and customization, enabling manufacturers to quickly generate optimized layout plans for complex client specifications, reducing engineering lead times.

In the supply chain, AI tools provide predictive analytics for demand forecasting based on macroeconomic indicators, regional construction permits issued, and seasonal fluctuations. This capability helps manufacturers strategically manage inventory levels, avoiding costly overstock situations while ensuring sufficient supply during peak construction periods. Furthermore, AI-powered logistics systems optimize routing and warehousing for these bulky, yet relatively low-density products, minimizing transportation costs and carbon footprint, aligning with growing corporate sustainability objectives. This comprehensive application of AI streamlines the value chain from raw material acquisition to final installation, enhancing market responsiveness.

- AI optimizes extrusion processes, reducing material waste and improving dimensional accuracy of plastic profiles.

- Machine learning enhances predictive quality control, identifying manufacturing defects instantly during production cycles.

- AI-driven demand forecasting improves inventory management and procurement strategies for raw PVC and additive chemicals.

- Automated design tools use AI to generate complex, project-specific trunking layout configurations rapidly.

- Integration of AI with smart building systems necessitates the development of trunking compatible with embedded sensors and future connectivity needs.

DRO & Impact Forces Of Plastic Trunking Market

The Plastic Trunking Market is primarily driven by global construction and infrastructure spending, particularly the development of commercial and residential real estate, which mandates safe and organized electrical wiring systems. Major drivers include the necessity for compliance with stringent fire safety regulations, promoting the shift towards premium, low-smoke, zero-halogen (LSZH) trunking, and the growing demand for renovation and retrofitting projects in established markets. However, the market faces significant restraints, notably the volatile pricing of petroleum-derived raw materials (PVC resins), which directly impacts production costs and profit margins. Furthermore, intense competition from alternative cable management solutions, such as metal conduits in high-stress industrial environments, and the low-entry barrier for basic trunking manufacturing in certain regions, exert downward pressure on average selling prices. Opportunities lie in developing modular, quick-fit solutions that reduce installation complexity and targeting niche high-growth segments like data center build-outs and renewable energy infrastructure cable routing.

Impact forces currently shaping the market are heavily centered around environmental, social, and governance (ESG) factors. Regulatory impact forces, such as the Restriction of Hazardous Substances (RoHS) directives and localized building codes mandating specific fire resistance ratings, compel innovation in material composition and product certification. Technological impact forces are pushing manufacturers to integrate aesthetic design elements into trunking, particularly for exposed installations in modern offices and residential spaces, moving the product from a purely functional necessity to an architectural element. Economic impact forces, specifically interest rate hikes and global supply chain disruptions, influence the pace of large-scale construction projects, indirectly affecting trunking demand volumes.

The long-term resilience of the market is anchored in the continuous global requirement for electrical system maintenance and upgrades. Despite raw material cost concerns, the inherent benefits of plastic—light weight, corrosion resistance, and simplified cutting/installation—ensure its preferential use in a vast majority of new builds. Strategic manufacturers are mitigating restraints by diversifying their raw material sources and vertically integrating production processes to better control costs, while actively leveraging opportunities in custom color and profile development to differentiate their offerings and capture higher value segments.

Segmentation Analysis

The Plastic Trunking Market is meticulously segmented based on material type, product type, channel type, and application, allowing manufacturers to target specific performance requirements and end-user needs. Segmentation by material is crucial, distinguishing between standard PVC (Polyvinyl Chloride), which dominates volume due to cost-effectiveness, and specialized materials like LSZH (Low Smoke Zero Halogen) and ABS, which cater to safety-critical environments such as hospitals, airports, and data centers where smoke emission and toxic fume generation during a fire must be minimized. Product type segmentation separates systems by form factor, including solid wall trunking for maximum protection, slotted trunking for organized cable routing, and skirting or dado trunking, which integrates aesthetically into interior designs. Application segmentation highlights the divergence in demand between construction sectors, where industrial requirements emphasize durability and corrosion resistance, while commercial and residential sectors prioritize aesthetics and ease of installation, ultimately driving tailored product development and marketing strategies across various geographic regions.

- By Material Type:

- PVC (Polyvinyl Chloride)

- LSZH (Low Smoke Zero Halogen)

- ABS (Acrylonitrile Butadiene Styrene)

- Polypropylene (PP)

- By Product Type:

- Solid Wall Trunking

- Slotted Trunking

- Skirting/Dado Trunking

- Floor Trunking

- Flexible Trunking

- By Channel Type:

- Single Channel

- Multi-Compartment Channel (Dual or Triple)

- By Application:

- Residential

- Commercial (Offices, Retail, Healthcare, Education)

- Industrial (Manufacturing, Power Generation)

- Data Centers and IT Infrastructure

- Transportation and Logistics

Value Chain Analysis For Plastic Trunking Market

The value chain for the Plastic Trunking Market begins with the upstream analysis, focusing on the procurement of primary raw materials, predominantly crude oil derivatives used to manufacture PVC resins, plasticizers, heat stabilizers, and fire-retardant additives. This phase is characterized by intense price sensitivity dictated by global petrochemical commodity markets. Manufacturers then transform these materials using high-precision extrusion and molding processes, relying on sophisticated machinery to achieve the required profiles and dimensions. Efficiency at this stage—minimizing material scrap and optimizing energy consumption—is a primary determinant of final product cost, necessitating significant capital investment in advanced manufacturing technology.

The distribution channel represents a critical midstream link, involving both direct sales to large construction contractors or specialized industrial clients and indirect sales via an extensive network of electrical wholesalers, distributors, and retailers. Indirect distribution dominates the market, leveraging the established infrastructure of electrical suppliers who provide last-mile logistics, inventory holding, and technical support to small and medium-sized installers. Strong distributor relationships are vital for market penetration and timely delivery, given that trunking is often required quickly and in varying volumes across geographically dispersed project sites.

Downstream analysis involves the final installation and end-user consumption. Contractors and professional installers are the primary implementers, seeking products that offer quick installation features, reliability, and regulatory compliance. The ultimate value delivery is realized by the end-users (building owners, facility managers) through safe, organized, and low-maintenance cable management systems that ensure electrical system longevity and easy expansion or modification. Ongoing shifts towards modular, clip-on designs indicate a value chain effort to simplify the downstream installation phase, transferring cost savings to the professional contractor.

Plastic Trunking Market Potential Customers

Potential customers and end-users of plastic trunking are highly diverse, spanning the entire construction ecosystem, categorized primarily by the application environment and necessary compliance level. The largest volume of consumption comes from the Building and Construction sector, where general contractors, electrical installation firms, and HVAC specialists regularly purchase trunking for new builds and refurbishment projects in residential and commercial settings. Residential builders focus on cost-effective, aesthetically subtle solutions, often utilizing skirting or dado trunking to hide wires unobtrusively.

The second major category involves specialized infrastructure and industrial clients, including data center operators, telecommunication providers, and large manufacturing facilities. These customers require highly specialized, heavy-duty, multi-compartment trunking, typically made from LSZH materials, capable of handling large volumes of critical data and power cabling while meeting stringent safety and fire-rating standards. This segment is characterized by high-volume, specification-driven purchases where compliance and product longevity outweigh initial cost considerations.

Finally, institutional and public sector entities, such as governmental bodies, educational campuses, and healthcare providers (hospitals), constitute another key customer base. These sectors are extremely sensitive to public safety and regulatory compliance, necessitating products with superior fire safety credentials and often antimicrobial properties, driving demand for premium, certified trunking systems suitable for sensitive public environments where low smoke toxicity is paramount for occupant safety during emergencies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schneider Electric, Legrand, ABB, Eaton Corporation, Marshall-Tufflex, HellermannTyton, Rehau Group, Hager Group, D-Line, Tehalit GmbH, Atkore International, MK Electric (Honeywell), Pipelife International GmbH, Wavin (Orbia), Univolt, Lewden, Unistrut, Grote & Hartmann, Kabelgo. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plastic Trunking Market Key Technology Landscape

The Plastic Trunking Market's technological landscape is evolving primarily through advancements in material science and manufacturing precision, aiming to enhance product performance, particularly in safety and installation efficiency. A major technological focus involves the development of superior polymer compounds, specifically low-smoke, zero-halogen (LSZH) formulations. These newer generations of LSZH plastics offer improved fire resistance, emit significantly less opaque smoke and corrosive gases when subjected to high temperatures, and are becoming mandatory in numerous international building codes. Manufacturers are continuously refining the additive packages (flame retardants, smoke suppressants) within these compounds to maintain mechanical strength and cost-effectiveness while achieving superior fire safety ratings, such as UL and IEC standards.

Beyond materials, manufacturing technology is seeing significant investment in highly advanced co-extrusion and triple-extrusion lines. These technologies enable the creation of multi-compartment trunking systems with varying material properties across different sections—for example, a rigid PVC base with flexible seals or anti-slip caps—in a single continuous process. This technological leap improves the sealing and organizational capabilities of the trunking, making installations quicker and more reliable. Automation, driven by AI and robotics, is further utilized in the secondary processing stage (cutting, punching, and adding fixing holes) to ensure high precision and consistency across large production batches, catering to the modular construction industry's demands.

Furthermore, product design technologies are focusing on quick-installation mechanisms. Modern trunking features often include snap-on lids, self-adhesive backing, and pre-punched mounting holes, significantly reducing the labor time required on site. The integration of antimicrobial coatings, particularly for trunking used in healthcare and food processing environments, represents a key niche technological specialization. This technological shift, combining material excellence with smart design features, addresses the critical industry needs for safety, speed, and specialization in diverse applications.

Regional Highlights

The global Plastic Trunking Market exhibits distinct dynamics across key geographical regions, driven by varying levels of construction activity, regulatory frameworks, and technological adoption rates. These regional differences necessitate localized product strategies concerning material selection (PVC vs. LSZH), fire compliance, and aesthetic design.

- Asia Pacific (APAC): APAC is the engine of volume growth, characterized by rapid urbanization, massive infrastructure spending (smart cities, high-speed rail), and a booming residential construction sector, particularly in China, India, and Indonesia. While price sensitivity is generally higher, driving demand for standard PVC trunking, the increasing number of hyperscale data centers is significantly accelerating the adoption of premium LSZH and fire-rated solutions. Regulatory bodies are gradually tightening fire safety norms, pushing manufacturers to improve product quality.

- Europe: Europe represents a mature market focused heavily on safety, sustainability, and high aesthetics. Stringent European Union directives (e.g., RoHS, REACH) and national building codes mandate the use of halogen-free and low-smoke materials, especially in public access buildings and commercial spaces. The market thrives on retrofitting projects and sophisticated skirting trunking designs that integrate seamlessly with modern interior architecture, often incorporating antimicrobial features for specialized environments.

- North America (NA): The North American market, dominated by the US and Canada, prioritizes compliance with specific certification standards, notably UL (Underwriters Laboratories) and NFPA (National Fire Protection Association) codes. Demand is driven by commercial facility upgrades, data center expansion, and a strong preference for high-quality, durable materials. The modular construction trend is increasingly influencing product design, favoring pre-assembled and easy-to-install trunking systems to reduce labor costs.

- Middle East and Africa (MEA): Growth in MEA is largely dependent on mega-projects in the GCC nations (Saudi Arabia, UAE), characterized by large-scale commercial and mixed-use developments. Extreme environmental conditions (high heat) necessitate robust and UV-resistant trunking materials. While price sensitivity is present, luxury construction projects drive demand for high-end aesthetic solutions, balanced by regulatory requirements for fire safety in new public infrastructure.

- Latin America (LATAM): This region experiences moderate, yet steady, growth driven by infrastructure investment and housing development in major economies like Brazil and Mexico. The market is highly price-competitive, with standard PVC trunking dominating sales volume. Improving economic stability and increasing foreign direct investment in commercial construction are gradually opening up opportunities for specialized, higher-margin products.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plastic Trunking Market.- Schneider Electric

- Legrand

- ABB

- Eaton Corporation

- Marshall-Tufflex

- HellermannTyton

- Rehau Group

- Hager Group

- D-Line

- Tehalit GmbH (OBO Bettermann Group)

- Atkore International

- MK Electric (Honeywell)

- Pipelife International GmbH

- Wavin (Orbia)

- Univolt

- Lewden

- Unistrut (Atkore International)

- Grote & Hartmann

- Kabelgo

- Tarmac Holdings Limited

Frequently Asked Questions

Analyze common user questions about the Plastic Trunking market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between PVC trunking and LSZH (Low Smoke Zero Halogen) trunking?

PVC trunking is cost-effective and common in standard environments. LSZH trunking is designed for safety-critical areas (hospitals, data centers) because it emits minimal smoke and no toxic halogen gases when exposed to fire, offering superior fire safety compliance.

How do installation time and complexity influence the adoption of modern plastic trunking systems?

Modern plastic trunking is engineered for rapid installation through features like snap-on lids, self-adhesive options, and pre-drilled holes. These design advancements significantly reduce on-site labor costs and time compared to traditional metal conduits, making them highly favored by contractors.

Which regions are driving the highest demand for specialized, aesthetic plastic trunking?

North America and Europe currently exhibit the highest demand for specialized, aesthetic trunking (like skirting and dado profiles). This is driven by high-end commercial office design and residential remodeling projects where cable management must be functional yet architecturally unobtrusive.

What is the main driver of cost volatility in the Plastic Trunking Market?

The main driver of cost volatility is the fluctuating price of petrochemical feedstocks, specifically crude oil and natural gas, which are primary components in the production of PVC resins and other base plastic polymers used in manufacturing trunking systems.

Can plastic trunking be used in industrial environments with high temperatures or chemical exposure?

While standard PVC trunking has limitations, specialized heavy-duty plastic trunking made from specific compounds (like ABS or high-grade polypropylene) offers enhanced chemical resistance and higher temperature thresholds, making them suitable for certain industrial and corrosive environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager