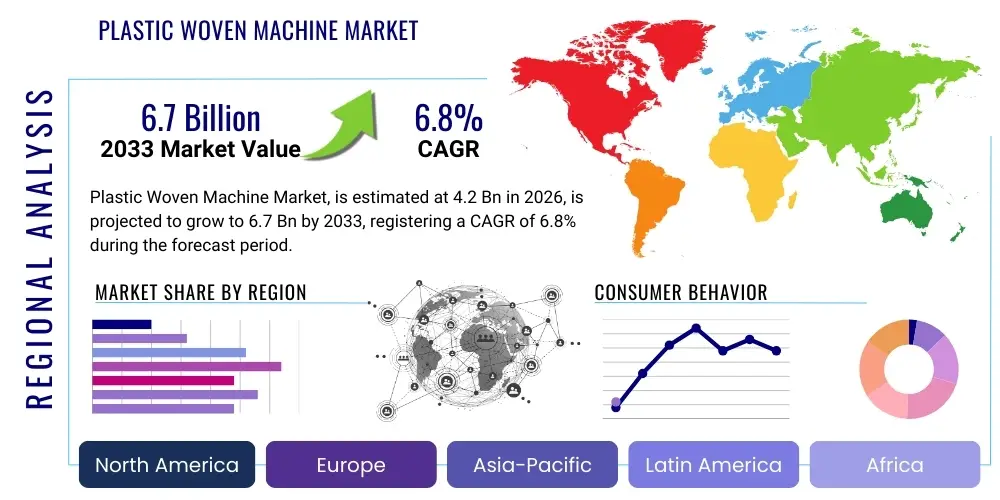

Plastic Woven Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440117 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Plastic Woven Machine Market Size

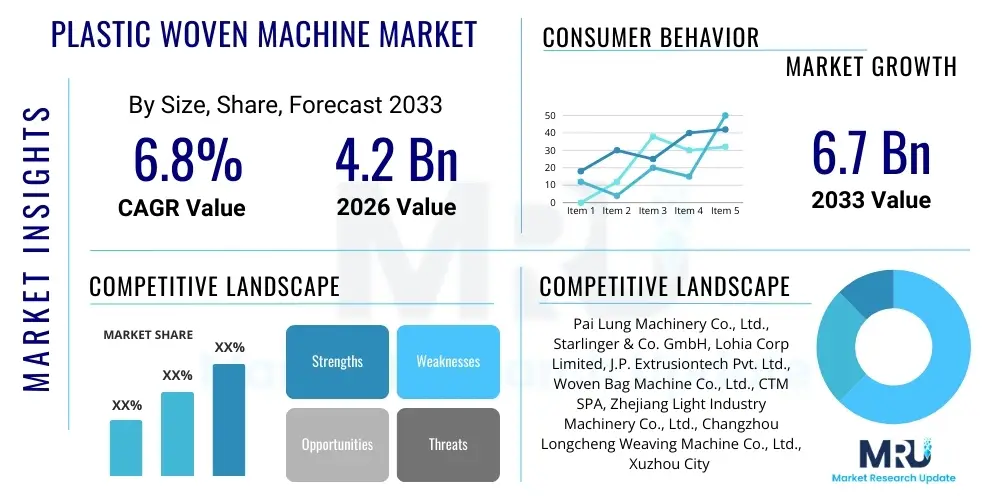

The Plastic Woven Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.2 Billion in 2026 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2033. This growth is underpinned by the increasing global demand for durable and lightweight packaging solutions, coupled with robust expansion in infrastructure development and agricultural applications, particularly across emerging economies. Technological advancements aimed at enhancing machine efficiency, automation, and material versatility are key contributors to this upward trajectory, attracting significant investments in capacity expansion and new product development.

Plastic Woven Machine Market introduction

The Plastic Woven Machine Market encompasses the manufacturing, sales, and servicing of machinery specifically designed for producing woven plastic products from various thermoplastic materials, primarily polypropylene (PP) and high-density polyethylene (HDPE). These machines facilitate the extrusion of plastic granules into tapes or films, which are then stretched, cut, and subsequently woven on specialized looms to create fabrics with high tensile strength and durability. The core function of these machines is to transform raw plastic polymers into versatile woven materials used across a myriad of industries, offering a cost-effective and robust solution for packaging and protection.

Major applications of plastic woven products include industrial packaging like Flexible Intermediate Bulk Containers (FIBCs), woven sacks for grains, cement, and fertilizers, as well as consumer-grade bags. Beyond packaging, they are extensively used in agriculture for tarpaulins, shade nets, and ground covers; in construction for geo-textiles, scaffolding nets, and temporary shelters; and in various industrial applications for protective covers and textile reinforcement. The benefits derived from these machines include high production efficiency, versatility in product size and specification, excellent material utilization, and the ability to produce lightweight yet incredibly strong woven fabrics. These advantages contribute significantly to cost reduction and improved product integrity for end-users.

Driving factors for the Plastic Woven Machine Market primarily include the burgeoning global population and subsequent increase in demand for food and industrial goods, necessitating robust packaging solutions. Rapid urbanization and infrastructure development projects worldwide fuel the need for geo-textiles and construction-related plastic woven materials. Furthermore, the agricultural sector's reliance on protective covers and packaging, combined with the rising trend of automation and energy efficiency in manufacturing processes, continues to propel market expansion. The adaptability of plastic woven products to various custom requirements, alongside ongoing innovation in polymer science, also acts as a significant market stimulant.

Plastic Woven Machine Market Executive Summary

The Plastic Woven Machine Market is experiencing significant momentum, driven by a confluence of favorable business trends, evolving regional dynamics, and increasingly sophisticated segment demands. Business trends indicate a strong shift towards higher automation, greater energy efficiency, and the integration of smart manufacturing principles, often referred to as Industry 4.0. Manufacturers are focusing on developing machines that offer enhanced precision, reduced material waste, and faster production cycles to meet the escalating global demand for plastic woven products across various end-use industries. Furthermore, the market sees a growing emphasis on sustainability, with efforts to develop machines capable of processing recycled plastics and producing lighter-weight, yet equally durable, materials, responding to global environmental pressures and consumer preferences for eco-friendlier solutions. The competitive landscape is characterized by continuous innovation, strategic alliances, and a push for global market penetration, particularly into high-growth regions.

Regionally, Asia Pacific continues to dominate the market, propelled by rapid industrialization, extensive agricultural activities, and burgeoning construction sectors in countries like China, India, and Southeast Asian nations. This region acts as both a major production hub and a significant consumer market for plastic woven products, driving substantial investment in machine acquisition. Europe and North America, while more mature, are focusing on advanced technological integration, premium-grade machinery, and niche applications, with a strong emphasis on automation and energy conservation. Latin America, the Middle East, and Africa are showing promising growth, attributed to increasing infrastructure spending, agricultural modernization, and expanding manufacturing bases, creating new opportunities for market players.

In terms of segments, the market is primarily segmented by machine type, application, and automation level. Circular looms, known for their high output and efficiency in producing tubular fabrics, hold a substantial share. Flat looms cater to specific requirements for specialized woven fabrics, including geotextiles and heavy-duty industrial textiles. The application segment sees packaging continuing to be the largest end-use, followed by construction and agriculture, each demanding specific machine capabilities. The trend towards fully automatic machines, offering minimal human intervention and superior operational efficiency, is gaining traction across all segments, reflecting the broader industry push towards intelligent manufacturing and streamlined production processes. Customization capabilities and machines designed for multi-material processing are also becoming increasingly important differentiators in the market.

AI Impact Analysis on Plastic Woven Machine Market

The integration of Artificial Intelligence (AI) in the Plastic Woven Machine Market is a pivotal area of discussion, with users keenly interested in its potential to revolutionize operational efficiency, product quality, and cost-effectiveness. Common questions revolve around how AI can enhance machine performance, reduce downtime, optimize production parameters, and improve overall process management. There is a strong expectation that AI will move beyond basic automation to offer predictive capabilities for maintenance, intelligent quality control, and adaptive manufacturing, allowing machines to self-adjust to varying conditions or material inputs. Users are also concerned with the practical implementation challenges, the return on investment, and the potential for job displacement, highlighting a desire for AI solutions that are both advanced and user-friendly, providing tangible economic benefits without overly complex integration.

- Predictive Maintenance: AI algorithms analyze real-time sensor data from machines to predict potential failures before they occur, enabling proactive maintenance, significantly reducing unplanned downtime, and extending machine lifespan.

- Optimized Production Parameters: AI systems can continuously monitor and adjust weaving speed, tension, temperature, and other variables to maximize output efficiency, minimize waste, and ensure consistent product quality across different material batches.

- Enhanced Quality Control: Vision-based AI systems detect defects in woven fabrics in real-time with high accuracy, automatically flagging or rejecting flawed products, thereby improving overall quality assurance and reducing manual inspection efforts.

- Automated Design and Pattern Generation: AI tools can assist in rapidly prototyping new woven patterns or optimizing existing designs for specific material properties and application requirements, accelerating product development cycles.

- Supply Chain Optimization: AI can forecast demand, manage inventory levels for raw materials and finished goods, and optimize logistics for the delivery of woven products, leading to more efficient resource allocation and reduced holding costs.

- Energy Consumption Management: AI systems can identify inefficiencies in machine operation and suggest adjustments to reduce energy consumption, contributing to lower operational costs and a more sustainable manufacturing process.

- Worker Augmentation and Training: AI-powered interfaces can provide real-time operational guidance to machine operators, assist in troubleshooting, and offer virtual training modules, improving skill levels and operational safety.

DRO & Impact Forces Of Plastic Woven Machine Market

The Plastic Woven Machine Market is profoundly shaped by a dynamic interplay of Drivers, Restraints, Opportunities, and a variety of Impact Forces. Key drivers include the exponential growth in the global packaging industry, which necessitates high volumes of cost-effective and durable woven sacks and FIBCs. The burgeoning construction sector, particularly in developing economies, fuels demand for geotextiles and construction-related plastic woven fabrics. Furthermore, the increasing adoption of modern agricultural practices relies heavily on plastic woven materials for protective covers and packaging. Technological advancements leading to more efficient, automated, and versatile weaving machinery also act as a significant driver, enabling manufacturers to meet diverse market needs with improved productivity and reduced operational costs. The demand for lightweight and strong materials across various industries continues to push innovation and adoption.

Conversely, the market faces several notable restraints. High initial capital investment required for purchasing advanced plastic woven machines can be a barrier for small and medium-sized enterprises (SMEs), particularly in regions with limited access to financing. Volatile raw material prices, primarily for polypropylene and high-density polyethylene, directly impact production costs and profit margins, creating market uncertainty. Environmental regulations and growing public pressure regarding plastic waste present challenges, pushing manufacturers to invest in more sustainable technologies or face potential restrictions. Intense competition from alternative packaging and material solutions, such as paper, jute, and non-woven fabrics, also exerts downward pressure on market growth. Additionally, the need for skilled labor to operate and maintain sophisticated machinery can be a bottleneck in certain regions.

Opportunities within the market are abundant and diverse. Emerging economies offer vast untapped potential due to their rapidly expanding industrial bases, infrastructure projects, and agricultural modernization initiatives, presenting new markets for machine manufacturers. Significant opportunities lie in research and development focused on sustainable and biodegradable plastic materials, enabling the production of eco-friendly woven products that align with global environmental goals. The increasing trend towards customization and specialized product requirements across various industries provides an avenue for manufacturers to offer bespoke machine solutions. Furthermore, the integration of advanced technologies such as Industry 4.0, IoT, and AI into weaving machinery presents opportunities for enhanced automation, predictive maintenance, and optimized production, leading to higher efficiency and competitiveness. Expansion into non-traditional applications for plastic woven fabrics, such as in medical textiles or specialized filtration, also represents a growth frontier. These factors collectively contribute to a complex yet promising market landscape.

Segmentation Analysis

The Plastic Woven Machine Market is comprehensively segmented to provide a granular understanding of its diverse components, allowing for targeted analysis and strategic planning. These segmentations are critical for identifying specific market niches, understanding end-user preferences, and recognizing key technological and application trends. The primary axes of segmentation typically include machine type, application, end-use industry, and automation level, each revealing distinct market dynamics and growth potentials. This detailed breakdown enables market participants to tailor their product offerings and marketing strategies effectively, addressing the unique requirements of various customer groups and operational environments across the globe.

- By Machine Type:

- Circular Looms: Widely used for producing tubular fabrics like sacks, tarpaulins, and FIBCs, known for high speed and efficiency.

- Flat Looms: Employed for weaving flat fabrics, often for specialized applications such as geotextiles, industrial fabrics, and heavy-duty covers.

- Extrusion Lines: Machines responsible for converting plastic granules into tapes or filaments, crucial for feeding the weaving process.

- Winding Machines: Essential for spooling the extruded tapes onto bobbins for the weaving process and winding finished woven fabric rolls.

- By Application:

- Packaging: The largest segment, including woven sacks for agricultural products, cement, chemicals, and FIBCs for bulk materials.

- Construction: Geotextiles for soil stabilization, erosion control, scaffolding nets, and temporary shelters.

- Agriculture: Tarpaulins, shade nets, ground covers, and crop protection fabrics.

- Geotextiles: Specialized fabrics for civil engineering applications.

- Industrial Textiles: Conveyor belts, filter fabrics, protective covers, and other technical textiles.

- By End-Use Industry:

- Bags & Sacks Manufacturers: Companies producing various types of plastic woven bags.

- Tarpaulin Producers: Manufacturers specializing in waterproof and durable covers.

- FIBC Manufacturers: Companies focused on producing bulk bags for industrial goods.

- Geo-synthetic Producers: Businesses creating materials for civil engineering applications.

- Agro-textile Manufacturers: Firms making products for agricultural use.

- By Automation Level:

- Manual Machines: Basic operation with significant human intervention.

- Semi-Automatic Machines: Incorporate some automated functions, but still require operator involvement.

- Automatic Machines: Highly automated, requiring minimal human supervision, offering high efficiency and precision.

Value Chain Analysis For Plastic Woven Machine Market

The value chain for the Plastic Woven Machine Market is a complex ecosystem involving several sequential stages, from raw material sourcing to the final distribution of both the machinery and the woven plastic products themselves. Understanding this chain provides insights into cost structures, areas for value addition, and potential points of collaboration or competition. Upstream analysis focuses on the procurement and processing of fundamental components and raw materials essential for machine manufacturing. This primarily involves sourcing high-quality metals, electronic components, precision engineering parts, and specialized software required for constructing the sophisticated mechanical and electrical systems of weaving machines. Suppliers in this segment play a crucial role in determining the quality, reliability, and technological capability of the final machinery. Any disruptions or price fluctuations in this upstream segment can have a ripple effect throughout the entire value chain, impacting production costs and delivery timelines for plastic woven machine manufacturers.

Downstream analysis in the value chain pertains to the distribution, sales, and post-sales support of the plastic woven machines, as well as the manufacturing and sale of the woven plastic products themselves. Once the machines are manufactured, they are distributed through a network of agents, distributors, and direct sales channels to end-user manufacturers. These end-users, primarily producers of woven sacks, FIBCs, tarpaulins, and geotextiles, then use these machines to create their final products. The efficiency and quality of the downstream segment are vital for market penetration and customer satisfaction. This also includes the servicing, maintenance, and spare parts supply for the machines, which significantly contributes to their operational lifespan and the overall value proposition. The effectiveness of this downstream support directly influences the productivity and profitability of the customers using these machines.

Distribution channels in this market are diverse, encompassing both direct and indirect approaches. Direct channels involve machine manufacturers selling directly to large-scale end-users or through their own dedicated sales teams, allowing for closer customer relationships and bespoke solutions. Indirect channels utilize a network of regional distributors, agents, and value-added resellers who often provide local support, installation services, and market insights. These indirect partners are particularly crucial in reaching smaller enterprises or penetrating geographically distant markets. The choice of distribution channel often depends on the manufacturer's global reach, the specific market characteristics, and the level of technical support required. Effective management of these distribution networks is paramount for ensuring market access, prompt delivery, and comprehensive after-sales service, all of which contribute significantly to the overall customer experience and brand loyalty within the highly competitive plastic woven machine market.

Plastic Woven Machine Market Potential Customers

The potential customers for plastic woven machines are a diverse group of manufacturing entities across various industrial sectors, all seeking efficient and reliable means to produce woven plastic fabrics and products. These end-users are primarily driven by the need for durable, cost-effective, and versatile packaging, protective materials, and specialized industrial textiles. The core segment of buyers includes companies engaged in the production of packaging materials, such as woven sacks for commodities like cement, grains, fertilizers, and sugar. These manufacturers rely on plastic woven machines for their high-volume production capabilities, ensuring consistency and strength in their packaging solutions to protect contents during storage and transport. Their purchasing decisions are heavily influenced by machine output, material efficiency, and the ability to handle various types of plastic tapes effectively.

Beyond traditional packaging, another significant segment of potential customers comprises manufacturers of Flexible Intermediate Bulk Containers (FIBCs), often referred to as bulk bags or jumbo bags. These companies require specialized weaving machines capable of producing large, heavy-duty fabrics with robust seams and reinforcement to safely contain and transport tons of dry, flowable materials. The demand for FIBCs is growing across industries like chemicals, pharmaceuticals, food, and mining, making FIBC manufacturers key buyers of advanced plastic woven machinery. Furthermore, the construction and civil engineering sectors represent a substantial customer base, with companies producing geotextiles for soil stabilization, erosion control, and filtration applications. These buyers seek machines that can weave strong, durable, and sometimes permeable fabrics to meet stringent engineering specifications, contributing to the longevity and stability of infrastructure projects.

The agricultural sector also forms a crucial group of potential customers, including companies that produce tarpaulins, shade nets, ground covers, and other agro-textiles for crop protection, storage, and water conservation. These manufacturers look for machines that can deliver high-quality, UV-resistant, and weather-durable woven plastics essential for agricultural longevity and productivity. Industrial textile producers, encompassing manufacturers of protective covers, filter fabrics, and specialized technical textiles for various industries, further expand the customer spectrum. Their needs often involve machines capable of high precision, flexibility in material handling, and the ability to produce fabrics with specific performance characteristics. Ultimately, any manufacturing entity that requires high-strength, lightweight, and versatile woven plastic materials for their product offerings represents a direct potential customer for plastic woven machine manufacturers, driving ongoing demand and technological innovation in the market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.2 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Pai Lung Machinery Co., Ltd., Starlinger & Co. GmbH, Lohia Corp Limited, J.P. Extrusiontech Pvt. Ltd., Woven Bag Machine Co., Ltd., CTM SPA, Zhejiang Light Industry Machinery Co., Ltd., Changzhou Longcheng Weaving Machine Co., Ltd., Xuzhou City Xuri Textile Machinery Co., Ltd., Shandong Jinhu Machinery Manufacturing Co., Ltd., Fuzhou Fuxing Industrial Co., Ltd., Nantong Huahong Weaving Machine Co., Ltd., SML Maschinengesellschaft mbH, Norson Power-Mac Equipment Co., Ltd., Taiwan Textile Machine Co., Ltd., GPM Plastic Machinery GmbH, Techtex Engineering (India) Pvt. Ltd., Suzhou Huashun Machinery Co., Ltd., Shaanxi Jinchi Textile Machinery Co., Ltd., Qingdao Wuxiao Group Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plastic Woven Machine Market Key Technology Landscape

The Plastic Woven Machine Market is continuously evolving, driven by significant advancements in technology aimed at enhancing efficiency, precision, and sustainability. A cornerstone of this technological landscape is the widespread adoption of advanced control systems, prominently featuring Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs). These systems provide operators with intuitive control over machine parameters, enabling precise adjustments of weaving patterns, speeds, and tension, which are critical for producing high-quality and consistent woven fabrics. The integration of PLCs allows for complex automation sequences, while HMIs offer real-time monitoring and diagnostic capabilities, significantly improving operational efficiency and reducing the likelihood of errors.

Another crucial technological development is the implementation of servo motors and drives across various machine components. These high-precision motors offer superior control over movement and speed, which is vital for critical functions such as tape feeding, shedding, and take-up. Servo technology ensures highly accurate positioning and synchronization, leading to reduced material waste, higher weaving speeds, and the ability to produce more intricate patterns with greater reliability. This directly contributes to higher productivity and better product quality. Furthermore, the industry is witnessing a strong trend towards energy-efficient designs, incorporating features like direct drive systems and optimized motor controls to minimize power consumption, aligning with global environmental objectives and reducing operational costs for manufacturers.

The advent of Industry 4.0 principles and the Internet of Things (IoT) is also profoundly impacting the plastic woven machine market. IoT sensors are integrated into machines to collect vast amounts of data on performance, material consumption, and maintenance requirements in real-time. This data can then be analyzed to identify inefficiencies, predict potential failures (predictive maintenance), and optimize production schedules. Real-time monitoring systems provide immediate feedback to operators and management, allowing for swift corrective actions and continuous process improvement. Additionally, the development of precision winding systems and automatic bobbin changers further enhances automation and reduces manual labor, leading to increased uptime and overall production throughput. The continuous pursuit of smart manufacturing solutions, coupled with innovations in material handling and processing, defines the progressive technological landscape of this market.

Regional Highlights

- Asia Pacific: This region is the undisputed leader in the Plastic Woven Machine Market, driven by rapid industrialization, robust growth in packaging, agriculture, and infrastructure sectors, particularly in China, India, and Southeast Asian countries. The presence of numerous local manufacturers and a large consumer base for woven plastic products further solidifies its dominance, leading to continuous investments in advanced machinery and production capacity expansion.

- Europe: Characterized by a focus on high-quality, automated, and energy-efficient machines, the European market for plastic woven machines emphasizes precision engineering and sustainability. Countries like Germany and Italy are key players in manufacturing advanced machinery, catering to specialized industrial and technical textile applications, while stringent environmental regulations are driving innovation towards more eco-friendly solutions.

- North America: The North American market is driven by demand for advanced automation, smart manufacturing solutions, and premium-grade plastic woven products, particularly in industrial packaging and construction. Investments in R&D and integration of AI and IoT technologies are prominent, with a strong emphasis on operational efficiency and labor cost reduction.

- Latin America: This region is experiencing steady growth in the plastic woven machine market, fueled by increasing agricultural output, expanding construction activities, and a growing consumer goods sector. Countries such as Brazil and Mexico are emerging as significant markets, with a rising demand for both basic and semi-automatic weaving machinery to support their industrial growth.

- Middle East and Africa (MEA): The MEA region presents significant growth potential, primarily due to ongoing infrastructure development projects, modernization of agricultural practices, and increasing demand for packaging solutions. Investments in manufacturing capabilities, particularly in countries like Saudi Arabia, UAE, and South Africa, are creating new opportunities for plastic woven machine suppliers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plastic Woven Machine Market.- Starlinger & Co. GmbH

- Lohia Corp Limited

- Pai Lung Machinery Co., Ltd.

- J.P. Extrusiontech Pvt. Ltd.

- Woven Bag Machine Co., Ltd.

- CTM SPA

- Zhejiang Light Industry Machinery Co., Ltd.

- Changzhou Longcheng Weaving Machine Co., Ltd.

- Xuzhou City Xuri Textile Machinery Co., Ltd.

- Shandong Jinhu Machinery Manufacturing Co., Ltd.

- Fuzhou Fuxing Industrial Co., Ltd.

- Nantong Huahong Weaving Machine Co., Ltd.

- SML Maschinengesellschaft mbH

- Norson Power-Mac Equipment Co., Ltd.

- Taiwan Textile Machine Co., Ltd.

- GPM Plastic Machinery GmbH

- Techtex Engineering (India) Pvt. Ltd.

- Suzhou Huashun Machinery Co., Ltd.

- Shaanxi Jinchi Textile Machinery Co., Ltd.

- Qingdao Wuxiao Group Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Plastic Woven Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a plastic woven machine?

A plastic woven machine primarily extrudes plastic granules into tapes, which are then woven into durable fabrics for packaging, construction, agriculture, and industrial applications. It transforms raw polymers into strong, lightweight woven materials.

Which factors are driving the growth of the plastic woven machine market?

Key drivers include the expanding global packaging industry, increasing demand for durable materials in construction and agriculture, rapid urbanization, infrastructure development, and technological advancements enhancing machine efficiency and automation.

How is AI impacting the plastic woven machine market?

AI is transforming the market through predictive maintenance, optimizing production parameters, enhancing real-time quality control, automating design processes, and improving overall supply chain efficiency, leading to higher productivity and reduced waste.

What are the main types of plastic woven machines?

The main types include circular looms for tubular fabrics, flat looms for specialized flat fabrics, extrusion lines for tape production, and winding machines for bobbin preparation and fabric collection.

Which regions are key contributors to the plastic woven machine market?

Asia Pacific is the dominant region due to industrialization and strong end-user demand. Europe and North America focus on advanced, automated solutions, while Latin America and MEA show promising growth driven by infrastructure and agricultural expansion.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager