Plastics Coating Window Screen Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439273 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Plastics Coating Window Screen Market Size

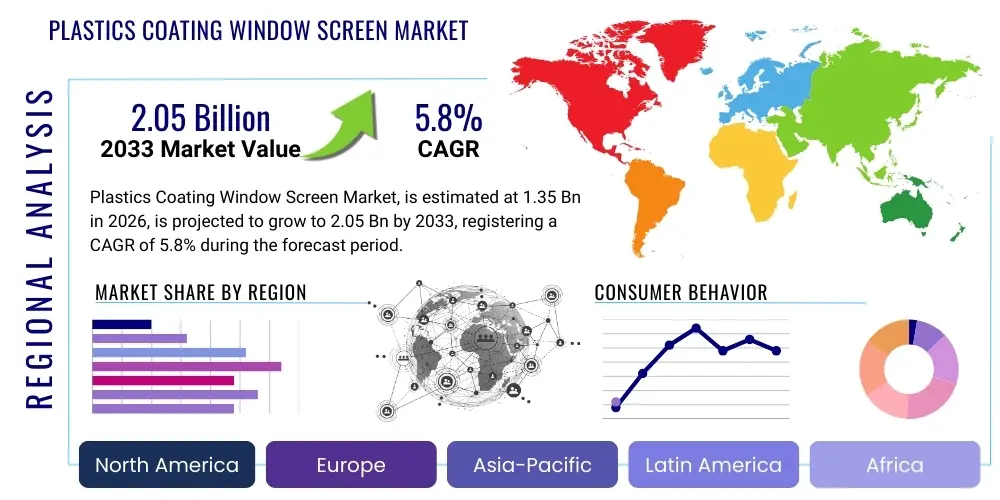

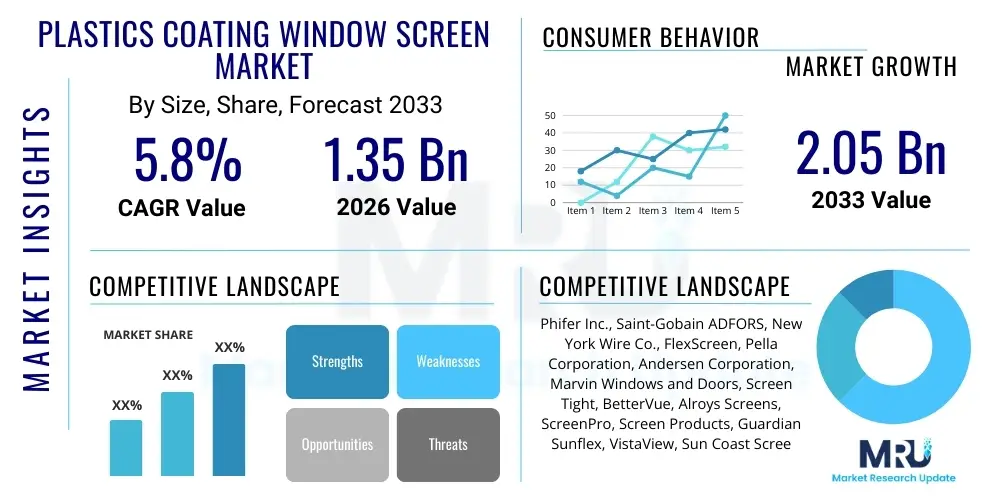

The Plastics Coating Window Screen Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.35 Billion in 2026 and is projected to reach USD 2.05 Billion by the end of the forecast period in 2033. This growth is underpinned by increasing construction activities worldwide, a heightened focus on energy efficiency in residential and commercial buildings, and rising consumer awareness regarding the benefits of durable, low-maintenance, and insect-repellent window screen solutions.

The market expansion is also driven by technological advancements in polymer science and coating techniques, leading to the development of screens with enhanced properties such as UV resistance, anti-microbial features, and improved airflow. Developing economies, particularly in Asia Pacific and Latin America, are expected to contribute significantly to market growth due to rapid urbanization, increasing disposable incomes, and the widespread adoption of modern building materials. Furthermore, the demand for versatile screening solutions in various applications, including pet-resistant screens and fine-mesh options for allergen protection, continues to fuel market momentum.

Plastics Coating Window Screen Market introduction

The Plastics Coating Window Screen Market encompasses the manufacturing, distribution, and sale of window screens featuring a core mesh material, typically fiberglass or polyester, coated with various plastic polymers such as PVC, vinyl, or acrylic. These coatings significantly enhance the screen's durability, weather resistance, and aesthetic appeal, offering superior performance compared to traditional uncoated metal or plain fiber screens. The market addresses a crucial need for effective insect barriers, improved ventilation, and a layer of privacy while allowing natural light penetration in diverse environments.

Key products within this market range from standard insect screens for residential windows and doors to specialized applications like pet-resistant screens, solar screens designed to reduce heat gain, and industrial-grade screens for specific filtration or protection purposes. The plastic coating process provides a smooth, uniform surface that resists corrosion, fraying, and general wear and tear, contributing to a longer lifespan and reduced maintenance requirements for end-users. This technological advantage positions plastics coating window screens as a preferred choice for modern architectural and construction projects.

Major applications for plastics coating window screens span across residential buildings, commercial establishments, industrial facilities, and even agricultural structures, where they protect against pests while facilitating air circulation. The market's growth is primarily driven by escalating construction spending, particularly in emerging economies, increasing public health awareness regarding insect-borne diseases, and a growing consumer preference for energy-efficient and aesthetically pleasing building components. Benefits such as enhanced durability, superior weather resistance, UV protection, and ease of cleaning are significant factors propelling their adoption.

Plastics Coating Window Screen Market Executive Summary

The Plastics Coating Window Screen Market is experiencing robust growth, propelled by global urbanization, a surge in residential and commercial construction, and an increasing focus on sustainable and low-maintenance building materials. Business trends indicate a strong inclination towards product innovation, with manufacturers investing in advanced polymer formulations to offer screens with enhanced features like increased tensile strength, better airflow, and specialized functionalities such as anti-glare or self-cleaning properties. The market is also witnessing a shift towards customized and aesthetically diverse solutions to meet evolving consumer preferences and architectural demands.

Regionally, the Asia Pacific continues to dominate the market, driven by rapid infrastructure development and a burgeoning middle-class population seeking modern home improvement solutions. North America and Europe demonstrate mature market characteristics, focusing on premium products, smart home integration, and sustainable manufacturing practices. Latin America and the Middle East and Africa regions are emerging as high-potential markets, fueled by economic development and growing construction sectors. These regional dynamics contribute to a diverse competitive landscape, encouraging global and local players to adapt their strategies to specific market needs.

In terms of segmentation, the market observes significant trends across material types, coating formulations, mesh sizes, and end-use applications. Fiberglass mesh with PVC coating remains a dominant segment due to its cost-effectiveness and versatility, though polyester and other advanced polymer blends are gaining traction for their superior strength and durability. The residential sector maintains its largest share, but commercial and industrial applications are demonstrating accelerated growth, driven by stringent safety regulations and the need for specialized screening solutions. The increasing adoption of e-commerce platforms also represents a crucial trend in the distribution landscape, enhancing market accessibility for a wider consumer base.

AI Impact Analysis on Plastics Coating Window Screen Market

The integration of Artificial Intelligence (AI) within the Plastics Coating Window Screen Market is poised to revolutionize various facets, from manufacturing efficiency to demand forecasting and customer experience. Common user inquiries often center on how AI can streamline production, improve product quality, and personalize offerings. There's significant interest in AI's role in optimizing material usage, reducing waste, and developing next-generation screen materials with enhanced properties. Users are also keen to understand how AI can assist in predicting market trends and managing supply chain complexities, ultimately leading to more sustainable and cost-effective operations across the industry value chain.

- AI-driven predictive maintenance for manufacturing machinery, reducing downtime and optimizing production schedules.

- Enhanced quality control through AI-powered visual inspection systems, identifying defects in mesh and coating with greater accuracy and speed.

- Optimization of polymer blending and coating formulations using AI algorithms to achieve desired properties like UV resistance, flexibility, and durability.

- AI-enabled demand forecasting and inventory management, leading to reduced overstocking and improved supply chain responsiveness.

- Personalized product recommendations and configuration tools for consumers, leveraging AI to match screen specifications with individual needs and architectural styles.

- Development of smart, responsive window screens with AI integration for environmental sensing and automated adjustments.

- Improved energy efficiency modeling for buildings by simulating screen performance under various conditions, guided by AI.

- Automated material sourcing and supplier management through AI, identifying optimal procurement strategies and ensuring supply chain resilience.

DRO & Impact Forces Of Plastics Coating Window Screen Market

The Plastics Coating Window Screen Market is influenced by a complex interplay of Drivers, Restraints, Opportunities, and broader Impact Forces that shape its trajectory. Key drivers include accelerating urbanization, particularly in developing nations, leading to extensive construction of residential and commercial infrastructures. Coupled with this is a heightened global awareness regarding the necessity of protection against insect-borne diseases, compelling consumers to invest in effective screening solutions. Furthermore, the continuous demand for energy-efficient building materials and low-maintenance home improvement products significantly propels market growth, as plastics coated screens offer superior durability and thermal performance compared to conventional alternatives. The rising disposable incomes in emerging economies also contribute to increased consumer spending on quality home renovations and new constructions.

However, the market faces several notable restraints. The volatility in raw material prices, particularly for polymers and fiberglass, directly impacts manufacturing costs and profit margins, creating financial pressure on market players. Intense competition from both established manufacturers and local players, alongside the availability of substitute products such as aluminum, stainless steel, or even advanced glass solutions, poses a challenge to market share and pricing power. Environmental regulations concerning plastic production and waste management also present hurdles, necessitating investment in eco-friendly materials and sustainable manufacturing processes, which can increase operational costs in the short term.

Despite these restraints, significant opportunities abound. The integration of plastics coating window screens into smart home ecosystems, offering automated functionalities and connectivity, presents a lucrative avenue for innovation and market expansion. The increasing focus on sustainable and recyclable materials offers a chance for manufacturers to differentiate their products and appeal to environmentally conscious consumers. Furthermore, penetrating untapped emerging markets with tailored, cost-effective solutions and leveraging customization trends to offer bespoke screen designs can unlock substantial growth potential. Impact forces such as the bargaining power of buyers, driven by increased product availability and online comparison tools, and the bargaining power of suppliers, influenced by raw material monopolies, continually reshape market dynamics. The threat of new entrants remains moderate due to capital intensity, while the threat of substitutes is present but mitigated by the unique benefits of plastic-coated screens. Competitive rivalry is high, pushing companies towards continuous innovation and strategic pricing.

Segmentation Analysis

The Plastics Coating Window Screen Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation helps in identifying key growth areas, understanding consumer preferences, and formulating targeted market strategies. The market is typically broken down by material type, the specific coating applied, the mesh size of the screen, the end-use application, and the distribution channel through which products reach consumers. Each segment exhibits distinct characteristics and contributes uniquely to the overall market landscape, reflecting the varied demands across different regions and industries.

Understanding these segments allows stakeholders to tailor their product development, marketing efforts, and supply chain strategies to optimize market penetration and profitability. For instance, the demand for fine mesh screens might be higher in regions prone to small insects, while pet-resistant coatings would appeal more to homeowners with pets. The interplay between these segments defines the competitive environment and highlights opportunities for niche market development and product differentiation. This granular analysis is crucial for navigating the complexities of the global plastics coating window screen market effectively.

- By Material Type:

- Fiberglass

- Polyester

- Other Polymers (e.g., Polyethylene, Polypropylene)

- By Coating Type:

- PVC (Polyvinyl Chloride)

- Vinyl

- Acrylic

- Polyurethane

- Specialty Coatings (e.g., Anti-microbial, Self-cleaning)

- By Mesh Size:

- Standard Mesh (e.g., 18x16)

- Fine Mesh (e.g., 20x20, 20x30)

- Ultra-fine Mesh (e.g., No-See-Um mesh)

- Heavy Duty/Pet Screen Mesh

- By Application:

- Residential

- Windows

- Doors (Patio, Entry)

- Porches/Patios

- Commercial

- Offices

- Hotels/Resorts

- Restaurants

- Healthcare Facilities

- Industrial

- Agricultural

- Automotive

- Residential

- By Distribution Channel:

- Online Retail

- Offline Retail (e.g., Hardware Stores, Home Improvement Chains)

- Wholesalers/Distributors

- Direct Sales/OEM

Value Chain Analysis For Plastics Coating Window Screen Market

The value chain for the Plastics Coating Window Screen Market begins with the upstream activities focused on raw material procurement and initial processing. This segment involves suppliers of polymer resins such as PVC, polyester, and other specialty plastics, as well as manufacturers of fiberglass yarn or other textile fibers that form the core mesh. These raw material providers are crucial, as the quality and cost of their offerings directly impact the final product's performance and market competitiveness. Key upstream activities also include the initial extrusion or weaving processes that convert raw materials into basic mesh structures, setting the stage for subsequent coating and finishing operations.

Midstream activities primarily involve the core manufacturing processes, where the woven or extruded mesh undergoes the plastic coating application. This stage includes sophisticated techniques like dip coating, spray coating, or calendering, which meticulously apply a uniform layer of plastic polymer to the mesh, followed by curing and finishing. Manufacturers in this part of the chain also handle cutting, packaging, and assembly of the finished screen products. Downstream activities focus on bringing the finished products to the end-users, involving a complex network of distribution channels including wholesalers, retailers, and direct sales. Retailers, such as large home improvement chains, specialized hardware stores, and burgeoning online platforms, play a vital role in consumer access.

The distribution channels for plastics coating window screens are diverse, encompassing both direct and indirect routes. Direct distribution involves sales to original equipment manufacturers (OEMs) who integrate these screens into their window and door products, or direct sales to large construction projects and industrial clients. Indirect channels are more prevalent for consumer markets, utilizing wholesalers who manage bulk distribution to various retail outlets and specialized distributors catering to specific regions or market segments. The growing prominence of e-commerce platforms has also created a significant direct-to-consumer pathway, offering convenience and broader product availability, while intensifying competition among traditional brick-and-mortar retailers. This integrated value chain ensures efficient production, widespread availability, and effective delivery of high-quality plastics coating window screens to a global customer base.

Plastics Coating Window Screen Market Potential Customers

The Plastics Coating Window Screen Market serves a broad spectrum of potential customers, primarily driven by the universal need for insect protection, ventilation, and enhanced property aesthetics and energy efficiency. The largest segment of end-users comprises residential homeowners, who seek durable and low-maintenance solutions for their windows, doors, and screened enclosures such as patios and pergolas. This demographic values ease of installation, longevity, aesthetic appeal that complements their home architecture, and the protective benefits against insects and sometimes even harmful UV rays. New home builders and renovation contractors are also significant customers, integrating these screens into their construction projects to meet modern building standards and consumer expectations for quality and comfort.

Beyond the residential sector, commercial establishments represent a substantial customer base. Hotels, resorts, restaurants, healthcare facilities, and educational institutions require robust and hygienic screening solutions to maintain comfortable environments, comply with health regulations, and enhance the overall experience for occupants and guests. These commercial clients often prioritize durability, fire resistance, and easy cleaning, alongside effective insect control. Industrial facilities also utilize plastics coating window screens for specific applications where dust control, debris protection, or basic insect barriers are necessary in manufacturing or storage areas, often requiring custom sizing and robust materials capable of withstanding harsh conditions.

Furthermore, the agricultural sector, including greenhouses and livestock enclosures, increasingly adopts these screens for pest management and controlled ventilation, optimizing growing conditions and animal welfare. Architects and interior designers are influential potential customers as they specify materials for new constructions and renovations, often seeking innovative and aesthetically pleasing screen solutions that align with their design vision. The diverse needs across these end-user categories necessitate a versatile product range and tailored marketing approaches from manufacturers and distributors within the Plastics Coating Window Screen Market, highlighting the extensive potential for market penetration and growth across various economic sectors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.35 Billion |

| Market Forecast in 2033 | USD 2.05 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Phifer Inc., Saint-Gobain ADFORS, New York Wire Co., FlexScreen, Pella Corporation, Andersen Corporation, Marvin Windows and Doors, Screen Tight, BetterVue, Alroys Screens, ScreenPro, Screen Products, Guardian Sunflex, VistaView, Sun Coast Screens, Metro Screenworks, Quality Screen Company, Advanced Screenworks, Apex Screens, Fenestration Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plastics Coating Window Screen Market Key Technology Landscape

The Plastics Coating Window Screen Market is significantly shaped by a dynamic technology landscape that encompasses advancements in material science, manufacturing processes, and coating applications. At the core, the technology revolves around the meticulous production of the mesh and its subsequent polymer coating. Modern extrusion and weaving technologies are critical for creating highly uniform and structurally stable fiberglass or polyester mesh foundations, ensuring consistent pore size, tensile strength, and overall durability. Innovations in fiber manufacturing allow for thinner yet stronger strands, contributing to improved visibility and airflow without compromising on insect protection.

A crucial aspect of the technological landscape is the development and application of advanced plastic coatings. Techniques such as dip coating, spray coating, and calendering are continuously refined to ensure optimal adhesion, uniform thickness, and desired surface properties of the polymer layer. Research and development efforts are concentrated on enhancing coating formulations, moving beyond traditional PVC and vinyl to include advanced acrylics, polyurethanes, and specialty blends that offer superior UV resistance, anti-microbial properties, self-cleaning capabilities, and even increased fire retardancy. Nanotechnology is also emerging as a frontier, enabling the incorporation of nanoparticles into coatings to impart novel functionalities like enhanced hydrophobicity or improved photocatalytic self-cleaning actions.

Furthermore, the integration of automation and quality control systems within the manufacturing process is paramount. Robotic systems are increasingly being used for precision coating and handling, minimizing human error and maximizing production efficiency. Advanced sensor technologies and imaging systems are employed for real-time defect detection, ensuring that only high-quality, perfectly coated screens reach the market. These technological innovations collectively drive product differentiation, improve performance characteristics, and contribute to the market's ability to meet the evolving demands for more durable, functional, and aesthetically pleasing window screen solutions across various applications.

Regional Highlights

- North America: Characterized by a mature market with high demand for premium, durable, and energy-efficient screening solutions. Innovation in smart screen integration and customization options is prevalent, driven by a strong focus on home improvement and renovation activities. The region also sees a significant adoption of pet-resistant and ultra-fine mesh screens.

- Europe: Emphasizes sustainability, eco-friendly materials, and compliance with stringent environmental regulations. Demand is robust for screens that contribute to energy conservation and offer advanced features like anti-pollen and self-cleaning coatings. Germany, France, and the UK are key markets.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid urbanization, massive infrastructure development, and a burgeoning middle-class population. Countries like China, India, and Southeast Asian nations are witnessing an explosion in residential and commercial construction, driving high demand for cost-effective yet durable plastics coating window screens.

- Latin America: Exhibiting steady growth, propelled by increasing disposable incomes, improving living standards, and a growing awareness of health and hygiene, leading to greater adoption of insect protection solutions in residential and commercial sectors. Brazil and Mexico are significant contributors to regional market expansion.

- Middle East and Africa (MEA): Emerging market with increasing investments in construction and tourism infrastructure. The demand for robust, weather-resistant screens is on the rise, particularly in regions with harsh climates and a need for effective insect barriers. Government initiatives for smart cities and sustainable development also contribute to market potential.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plastics Coating Window Screen Market.- Phifer Inc.

- Saint-Gobain ADFORS

- New York Wire Co.

- FlexScreen

- Pella Corporation

- Andersen Corporation

- Marvin Windows and Doors

- Screen Tight

- BetterVue

- Alroys Screens

- ScreenPro

- Screen Products

- Guardian Sunflex

- VistaView

- Sun Coast Screens

- Metro Screenworks

- Quality Screen Company

- Advanced Screenworks

- Apex Screens

- Fenestration Group

Frequently Asked Questions

Analyze common user questions about the Plastics Coating Window Screen market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of plastics coating window screens?

Plastics coating window screens offer superior durability, enhanced weather resistance, and effective protection against insects. They are generally low-maintenance, resist corrosion and fraying, and can provide UV protection, contributing to better indoor comfort and longer product lifespan compared to traditional uncoated options.

How durable are these screens compared to traditional options?

Plastics coating window screens, especially those with PVC or vinyl coatings, are significantly more durable than traditional aluminum or plain fiberglass screens. The coating protects the underlying mesh from environmental damage, corrosion, and fraying, making them more resistant to wear and tear, pet damage, and harsh weather conditions, thereby extending their service life.

What drives the growth of the plastics coating window screen market?

Market growth is primarily driven by global urbanization and increasing construction activities, rising consumer awareness of insect-borne diseases, and a growing demand for energy-efficient, low-maintenance, and aesthetically pleasing building materials. Technological advancements in polymer coatings also enhance product performance and appeal.

Are there environmentally friendly options available in this market?

Yes, manufacturers are increasingly developing environmentally friendly plastics coating window screens. This includes using recycled content in the mesh or coating materials, offering screens made from more sustainable polymers, and implementing greener manufacturing processes to reduce the environmental footprint of these products.

How does the coating material impact screen performance and cost?

The type of plastic coating significantly impacts screen performance and cost. PVC coatings are generally cost-effective and offer good durability and weather resistance. Vinyl provides similar benefits with enhanced flexibility. More advanced coatings like acrylics or polyurethanes might offer superior UV resistance, specialized anti-microbial properties, or enhanced aesthetic finishes, often at a higher price point.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager