Plate Falling Film Evaporator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432037 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Plate Falling Film Evaporator Market Size

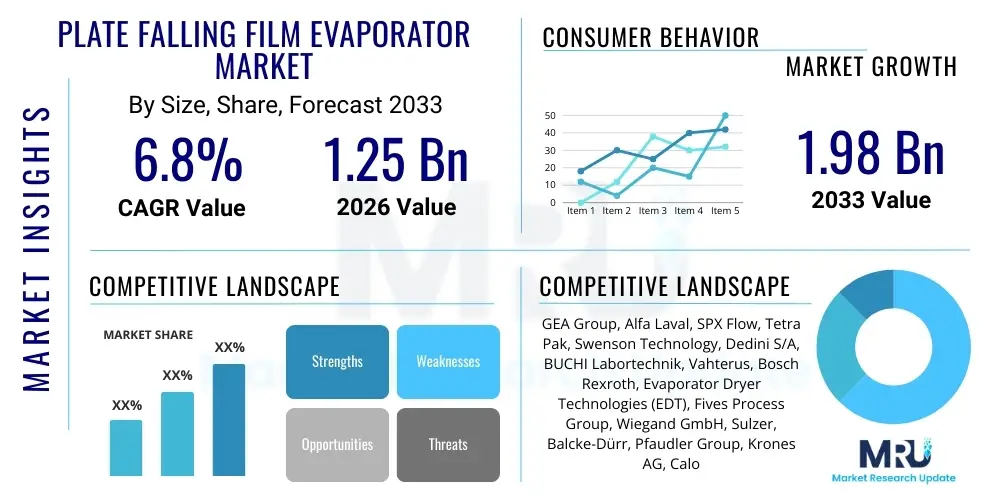

The Plate Falling Film Evaporator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.98 Billion by the end of the forecast period in 2033.

Plate Falling Film Evaporator Market introduction

The Plate Falling Film Evaporator (PFFE) market comprises specialized heat exchange equipment used primarily for the concentration of liquid solutions, particularly those that are sensitive to heat, highly viscous, or prone to foaming. The defining characteristic of PFFE technology is the arrangement of heat transfer surfaces into compact, gasketed plate packs, which facilitate the creation of a thin, turbulent liquid film that "falls" due to gravity. This mechanism ensures rapid evaporation at lower temperatures and shorter residence times, critically important in applications such such as milk concentration, juice processing, and fermentation broth management. The compact design of plate evaporators, contrasting with traditional tubular designs, offers significant advantages in terms of space utilization and maintenance access, driving adoption across diverse industrial landscapes seeking both efficiency and footprint reduction.

PFFEs are extensively utilized across major industrial sectors, including Food and Beverage, Chemical Processing, Pharmaceutical, and Environmental Management (effluent treatment). In the food industry, they are essential for producing high-quality concentrated dairy products, fruit juices, and sugar solutions, preserving thermosensitive components like vitamins and flavor profiles due to reduced thermal stress. For chemical and pharmaceutical sectors, the equipment handles complex crystallization processes and solvent recovery, requiring precise control over temperature gradients and vacuum conditions. Furthermore, the inherent modularity and high heat transfer coefficients achievable through plate technology position PFFEs as a leading solution for modern industrial concentration needs, contributing directly to operational expenditure reduction via optimized energy consumption, especially when integrated with Thermal Vapor Recompression (TVR) or Mechanical Vapor Recompression (MVR) systems.

Driving factors for the global PFFE market include stringent regulatory requirements governing effluent disposal, pushing industries towards Zero Liquid Discharge (ZLD) systems where evaporators are central components for water recovery and waste minimization. Simultaneously, the persistent global demand for sustainable processing technologies is boosting the adoption of highly energy-efficient MVR-integrated PFFEs, which recycle latent heat from the produced vapor. This emphasis on energy conservation, coupled with increasing investments in capacity expansion within the burgeoning Asian manufacturing sector and the pharmaceutical supply chain optimization globally, collectively establishes a robust growth trajectory for the Plate Falling Film Evaporator market through the forecast period 2026–2033.

Plate Falling Film Evaporator Market Executive Summary

The Plate Falling Film Evaporator market is undergoing a significant transformation driven by sustainability mandates and technological integration, primarily shifting towards multi-effect and MVR-enabled systems to achieve maximum operational efficiency and energy savings. Business trends indicate a strong move toward customization and modular solutions, addressing the varying capacity and complexity needs of end-users ranging from large-scale dairy producers to specialized chemical synthesis plants. The growing focus on cleaner production and the optimization of utility consumption has heightened the demand for PFFEs constructed from advanced materials like titanium, especially in highly corrosive environments. Key players are investing heavily in smart factory integration, utilizing sensor technology and predictive analytics to enhance evaporator performance, minimize fouling, and schedule preventative maintenance, thereby maximizing uptime and overall equipment effectiveness (OEE) across different geographic operational zones.

Regionally, the Asia Pacific (APAC) stands out as the primary engine of market growth, fueled by rapid industrialization, burgeoning food processing sectors, and massive investments in wastewater treatment infrastructure, particularly in China and India. While North America and Europe maintain technological leadership and high adoption rates of MVR systems due to high energy costs and strict environmental regulations, the sheer scale of infrastructural development and population growth in APAC is driving volume demand. This regional dynamic is creating substantial opportunities for both established global manufacturers and local fabricators who can offer cost-competitive, high-quality plate evaporator solutions. Furthermore, governmental incentives promoting sustainable manufacturing practices and resource recovery efforts in developed and developing economies alike reinforce the long-term positive outlook for PFFE deployment in various concentration and separation tasks.

Segmentation analysis reveals that multi-effect evaporators remain the dominant segment by type due to their inherently lower steam consumption compared to single-effect units, making them the default choice for large-volume industrial processes. However, the application segment highlights the Food and Beverage industry as the largest consumer, driven by continuous expansion and the need for gentle processing of heat-sensitive products. Simultaneously, the chemical industry is emerging as a high-growth area, requiring robust PFFEs for solvent stripping and concentration of aggressive media, necessitating advancements in plate material science. The interplay between energy efficiency demands (type segmentation) and specific processing requirements (application segmentation) dictates product innovation, focusing on enhanced plate geometries for improved fluid distribution and reduced scale formation, ensuring sustained market expansion throughout the forecast horizon.

AI Impact Analysis on Plate Falling Film Evaporator Market

User queries regarding AI's impact on the Plate Falling Film Evaporator Market predominantly center on predictive maintenance capabilities, energy efficiency optimization, and process parameter control. Users are keen to understand how machine learning algorithms can analyze complex process data—including flow rates, temperature profiles, vacuum levels, and scaling indices—to anticipate equipment failure, minimize unscheduled downtime, and dynamically adjust operation parameters for peak energy efficiency. A recurring theme is the expectation that AI integration will mitigate chronic operational issues like fouling and scaling, which significantly reduce heat transfer coefficients and necessitate costly chemical cleaning cycles. Furthermore, users expect AI to enable seamless integration of PFFEs within larger industrial systems, facilitating holistic resource management and reducing the reliance on manual operator adjustments, thereby enhancing consistency and product quality across batch and continuous processing modes.

- AI-driven Predictive Maintenance: Utilizing sensor data to forecast plate fouling and component wear, minimizing unexpected operational halts.

- Dynamic Process Optimization: Machine learning algorithms adjust vacuum pressure and steam flow rates in real-time to maintain optimal energy consumption (kW/kg of evaporated water).

- Enhanced Fouling Mitigation: AI models predict the onset and severity of scale formation based on input stream properties and temperature history, recommending preventative measures.

- Automated Quality Control: Integrating vision systems and AI analysis to monitor product concentration and color, ensuring consistent output quality without manual sampling delays.

- Supply Chain and Inventory Management: Optimizing the maintenance spares inventory and predicting demand based on fleet performance data across multiple operational sites.

DRO & Impact Forces Of Plate Falling Film Evaporator Market

The Plate Falling Film Evaporator market dynamics are shaped by critical factors including the imperative for energy efficiency and sustainable water management (Drivers), constraints related to high capital investment and technical challenges like fouling (Restraints), and expansive opportunities in emerging industrial sectors like biofuels and specialized chemicals (Opportunities). The core driving force remains the globally accelerating trend towards resource conservation, pushing manufacturers to adopt low-temperature concentration methods, especially in the Food & Beverage and Pharmaceutical industries where product integrity is paramount. However, the complexity associated with cleaning and maintaining large plate packs, coupled with the initial substantial upfront cost of MVR-integrated systems, acts as a significant impediment to widespread adoption, particularly among smaller enterprises or in regions with limited technical expertise for maintenance.

The principal impact forces governing market evolution are technological disruption and stringent regulatory frameworks. Technological advancements focusing on novel plate geometries (e.g., dimpled or corrugated patterns) and advanced surface coatings designed to resist fouling are continuously enhancing operational longevity and efficiency. Simultaneously, global environmental regulations, such as those mandating Zero Liquid Discharge (ZLD) protocols for industrial effluent, create non-negotiable demand for high-performance evaporators capable of separating high-salinity brines and recovering reusable water. The combination of these forces necessitates continuous innovation in materials and system integration (e.g., hybrid systems combining PFFEs with crystallizers or membrane filtration units), thereby raising the barrier to entry for new competitors and accelerating the obsolescence of less efficient traditional evaporation technologies.

Opportunities for growth are abundant in nascent sectors, particularly in the production of plant-based proteins, specialized nutrients, and the rapidly growing biofuels market, where efficient separation and concentration processes are essential for economic viability. The utilization of PFFEs in the extraction and purification of cannabidiol (CBD) and other high-value botanical extracts represents a niche but high-growth application segment. Furthermore, the global push towards circular economy models amplifies the market for PFFEs in waste valorization—recovering valuable by-products from industrial waste streams. Addressing the restraint of high capital cost through innovative financing models or the development of more standardized, lower-capacity modular units will be key to unlocking market potential in diverse geographical settings throughout the forecast period.

Segmentation Analysis

The Plate Falling Film Evaporator market is comprehensively segmented based on its structural and operational characteristics, application scope, and capacity. Key segmentation by type distinguishes between Single-Effect and Multi-Effect Evaporators, reflecting the varying energy recovery mechanisms employed, with multi-effect systems dominating due to their substantial reduction in steam consumption required per unit of evaporation. Further segmentation by material includes Stainless Steel (304/316L) for general and food applications, and specialized materials like Titanium, Hastelloy, or Nickel Alloys used in aggressive chemical environments requiring exceptional corrosion resistance. The market is also segmented by flow configuration—primarily parallel flow, counter-flow, and combined flow—each optimized for different viscosity and temperature sensitivity profiles of the feed liquid, ensuring the selection of equipment is highly tailored to process requirements.

The application segmentation is critical, highlighting the primary end-user industries: Food and Beverage, Chemical and Petrochemical, Pharmaceutical and Biotechnology, and Environmental and Wastewater Treatment. The Food and Beverage sector, encompassing dairy, sugar, and juice concentration, remains the largest segment, driven by global consumption patterns and the necessity for gentle thermal processing. However, the Environmental segment is projected to exhibit the highest CAGR, propelled by mandatory wastewater reduction and ZLD initiatives globally. Capacity segmentation, typically categorized into Small (up to 10 tons/hr), Medium (10 to 50 tons/hr), and Large (over 50 tons/hr) units, illustrates the market fragmentation, catering to both specialized small-batch pharmaceutical operations and high-volume continuous industrial chemical plants.

- By Type:

- Single-Effect Evaporators

- Multi-Effect Evaporators

- Thermal Vapor Recompression (TVR) Systems

- Mechanical Vapor Recompression (MVR) Systems

- By Material:

- Stainless Steel (SS 304, 316L)

- Titanium and High-Nickel Alloys (Hastelloy)

- By Application:

- Food & Beverage (Dairy, Juices, Sugar)

- Chemical & Petrochemical

- Pharmaceutical & Biotechnology

- Environmental & Wastewater Treatment (ZLD)

- Others (Pulp & Paper, Textiles)

- By Capacity:

- Small Scale (up to 10 tons/hr)

- Medium Scale (10 - 50 tons/hr)

- Large Scale (Over 50 tons/hr)

Value Chain Analysis For Plate Falling Film Evaporator Market

The value chain for the Plate Falling Film Evaporator market begins with the Upstream Activities, primarily focusing on the sourcing of high-grade raw materials—chiefly specialized stainless steel (SS 316L being prevalent), titanium, and various alloys crucial for heat exchange surfaces. This phase is characterized by procurement risk management, ensuring material quality (corrosion resistance, weldability), and managing the volatility of global metal prices, which directly impacts manufacturing costs. Following raw material acquisition, the Manufacturing stage involves precision engineering of the heat transfer plates (stamping, pressing, and welding), assembling the plate packs, and integrating peripheral components such as condensers, pumps, valves, and the critical gasket materials, which must be chemically resistant and temperature stable. Manufacturing capabilities, including advanced CNC machining and specialized welding techniques, are key differentiators in this stage, determining the final product's efficiency and longevity.

The Midstream and Distribution channels manage the movement of the finished evaporators from the manufacturer to the end-user. Direct Distribution is common for large, complex, and customized evaporator projects, where the manufacturer provides comprehensive engineering consultation, installation, and commissioning services, often negotiating long-term service contracts. Indirect Distribution utilizes regional distributors and specialized engineering, procurement, and construction (EPC) firms, particularly for standardized or smaller units, leveraging their local presence and familiarity with regional regulatory requirements. The choice of distribution strategy is heavily influenced by the complexity of the equipment and the geographical location of the end-user, with a noticeable shift towards direct engagement for advanced MVR systems requiring specialized integration expertise.

Downstream activities are dominated by Installation, Commissioning, and After-Sales Services, which are integral to the long-term profitability of market participants. Given the complexity and energy-intensive nature of PFFEs, post-installation support, including preventive maintenance, spare parts supply (especially gaskets and plates), and operational optimization consulting, is highly valued by end-users. Potential customers, spanning diverse industrial verticals, rely on the continuous performance and reliability of these evaporators. The long operational lifecycle of PFFEs ensures that the service segment of the value chain represents a stable and recurring revenue stream, making robust global service networks a competitive advantage for leading players in the market.

Plate Falling Film Evaporator Market Potential Customers

Potential customers for Plate Falling Film Evaporators are diverse, spanning multiple regulated and high-volume processing industries that require efficient and gentle thermal separation. The largest segment of buyers resides within the Food and Beverage industry, specifically dairy processors (for milk and whey concentration), fruit juice manufacturers, and sugar refiners, who demand PFFEs for minimizing thermal degradation of their products while achieving high concentration levels. These end-users prioritize hygienic design, ease of cleaning (CIP capability), and systems compliant with FDA and similar regulatory bodies globally. Furthermore, the recent surge in demand for plant-based proteins and functional ingredients also drives adoption among specialized nutraceutical producers requiring precise solvent removal and concentration.

In the Chemical and Pharmaceutical sectors, potential customers include large-scale manufacturers involved in solvent recovery, concentration of reaction by-products, and crystallization processes. Pharmaceutical buyers, particularly, seek evaporators constructed from highly corrosion-resistant materials (e.g., high-nickel alloys) and requiring strict validation procedures (cGMP compliance). These buyers use PFFEs for concentrating active pharmaceutical ingredients (APIs) and managing sterile process streams, where reliable and repeatable performance under vacuum conditions is essential. The demand from this segment is driven by global drug production growth and continuous process optimization efforts aimed at reducing utility costs.

A rapidly expanding customer base is found within the Environmental Sector, comprising municipal and industrial wastewater treatment plants, and companies dedicated to providing Zero Liquid Discharge (ZLD) solutions. These buyers use PFFEs to concentrate industrial effluents and brines, enabling water recycling and minimizing liquid waste volume for disposal. Customers in this area prioritize robust, anti-fouling designs capable of handling highly corrosive or fouling liquids containing high Total Dissolved Solids (TDS). The increasing global scrutiny on industrial water usage and discharge limits is ensuring sustained, high-growth demand from this segment, making environmental service providers and industrial facilities with large wastewater streams key strategic targets for PFFE manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.98 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GEA Group, Alfa Laval, SPX Flow, Tetra Pak, Swenson Technology, Dedini S/A, BUCHI Labortechnik, Vahterus, Bosch Rexroth, Evaporator Dryer Technologies (EDT), Fives Process Group, Wiegand GmbH, Sulzer, Balcke-Dürr, Pfaudler Group, Krones AG, Caloris Engineering, Praj Industries, CMS Evaporator Technologies, ZM Technologies. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plate Falling Film Evaporator Market Key Technology Landscape

The core technology landscape of the Plate Falling Film Evaporator market is rapidly evolving, driven primarily by the integration of energy-saving technologies and advancements in materials science. The most impactful technological trend is the widespread adoption of Mechanical Vapor Recompression (MVR) systems, which use a compressor to increase the pressure and temperature of the generated vapor, recycling it as the heating medium. This eliminates the need for expensive fresh steam, drastically reducing operational costs by up to 80% compared to traditional multi-effect setups. Manufacturers are focusing on developing high-efficiency centrifugal or positive displacement compressors optimized for handling large vapor volumes under vacuum, alongside sophisticated control systems that manage the dynamic equilibrium between evaporation load, compression ratio, and internal pressure drops, ensuring stable and highly economical operation even under fluctuating load conditions.

Material innovation and plate design remain crucial areas of competitive development. Leading manufacturers are continually refining plate geometry—introducing features such as specialized corrugations, grooves, or dimples—designed to enhance liquid distribution, promote high film turbulence for improved heat transfer, and simultaneously reduce the propensity for scaling and fouling. The development of advanced, non-stick, and highly corrosion-resistant coatings, often incorporating ceramic or polymer composites applied to the metallic heat exchange surfaces, is crucial for extending maintenance intervals and operating life, particularly when processing difficult liquids like brines or high-viscosity food products. Furthermore, the use of exotic materials such as Hastelloy or Duplex stainless steel is becoming more common to meet the demanding requirements of high-concentration chemical processes and highly acidic pharmaceutical applications.

The digitalization of PFFE operations, falling under the umbrella of Industry 4.0, is another central technological development. This involves integrating IoT sensors for real-time monitoring of critical process parameters, including plate differential pressure, film thickness indicators, and instantaneous heat transfer coefficients. The data collected powers sophisticated Process Analytical Technology (PAT) and predictive maintenance algorithms, allowing operators to preemptively adjust cleaning cycles or optimize energy input based on the actual performance metrics rather than fixed schedules. This smart integration not only boosts overall efficiency and reliability but also facilitates compliance with stringent regulatory requirements by providing comprehensive, auditable process records, solidifying the PFFE’s role as a high-precision chemical processing unit rather than merely a heat exchanger.

Regional Highlights

Regional dynamics play a crucial role in shaping the Plate Falling Film Evaporator Market, primarily due to differing energy costs, regulatory environments, and the concentration of key end-user industries. North America, characterized by high operational costs and strong environmental consciousness, shows a mature market with a preference for high-efficiency MVR systems. The region's demand is driven by the sophisticated Food and Beverage sector, particularly dairy and nutraceuticals, alongside significant investment in shale oil and gas water management, where ZLD applications for produced water are paramount. European adoption is similarly high, strongly influenced by the EU's strict energy efficiency directives and circular economy initiatives, fostering robust demand for systems that minimize resource consumption and maximize solvent recovery in the chemical and pharmaceutical industries.

The Asia Pacific (APAC) region is forecasted to exhibit the highest growth rate during the 2026–2033 period, transforming it into the largest market globally by volume. This exponential growth is underpinned by rapid industrial expansion, massive investments in infrastructure (including food processing and textile industries), and escalating issues concerning industrial wastewater discharge in rapidly urbanizing areas like China, India, and Southeast Asia. While cost sensitivity remains a factor, the region is increasingly adopting multi-effect and entry-level MVR evaporators to balance upfront investment with long-term operational savings. Government support for indigenous manufacturing and growing pharmaceutical capacity further fuels the demand for standardized, reliable PFFE solutions suitable for high-volume production needs.

- Asia Pacific (APAC): Dominates future growth due to rapid industrialization, large-scale Food & Beverage sector expansion, and increasing regulatory enforcement of industrial wastewater treatment standards (ZLD). Key markets include China, India, and Japan.

- North America: Mature market focused on technological upgrades (MVR adoption) and demanding specialized solutions for high-value applications in pharmaceutical, petrochemical, and produced water management sectors.

- Europe: Driven by stringent environmental policies, high energy costs, and advanced manufacturing standards; strong adoption in chemical recovery and sustainable food processing (e.g., dairy and fermentation).

- Latin America (LATAM): Emerging market with increasing industrial activity, particularly in food processing (sugar, fruit juices) and mining, focusing on cost-effective, durable multi-effect evaporator systems.

- Middle East & Africa (MEA): Growth centered around desalination pre-treatment, chemical production, and significant government-led investments in food security initiatives, requiring robust equipment capable of handling high-salinity water sources.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plate Falling Film Evaporator Market.- GEA Group

- Alfa Laval

- SPX Flow

- Tetra Pak

- Swenson Technology

- Dedini S/A

- BUCHI Labortechnik

- Vahterus

- Bosch Rexroth

- Evaporator Dryer Technologies (EDT)

- Fives Process Group

- Wiegand GmbH

- Sulzer

- Balcke-Dürr

- Pfaudler Group

- Krones AG

- Caloris Engineering

- Praj Industries

- CMS Evaporator Technologies

- ZM Technologies

- Condorchem Envitech

- HPD, LLC (Veolia)

- HRS Heat Exchangers

- GIG Karasek GmbH

- Jindal Water Treatment

- M.A.C. System Inc.

- Okawa Kiko Co., Ltd.

- Zhejiang Aike Chemical Equipment Co., Ltd.

- Saturn Evaporator Technologies

Frequently Asked Questions

Analyze common user questions about the Plate Falling Film Evaporator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary energy saving advantages of using a Plate Falling Film Evaporator (PFFE)?

The primary advantage of PFFEs lies in their high heat transfer efficiency and low holdup volume, which reduces thermal degradation. When integrated with Mechanical Vapor Recompression (MVR) technology, PFFEs can reuse up to 80% of the energy content in the evaporated vapor, drastically cutting operating costs compared to conventional steam-heated systems.

In which industries are Plate Falling Film Evaporators most commonly utilized?

PFFEs are predominantly utilized in the Food and Beverage industry for concentrating heat-sensitive products like dairy, juices, and sugar solutions. They are also essential in the Chemical, Pharmaceutical, and Environmental sectors for solvent recovery, API concentration, and implementing Zero Liquid Discharge (ZLD) systems for industrial wastewater management.

How do Plate Falling Film Evaporators mitigate the risk of fouling or scaling?

Fouling mitigation in PFFEs is achieved through specialized plate geometries that promote turbulent flow and even liquid distribution, minimizing dry spots where scale forms. Furthermore, modern systems incorporate automatic Clean-in-Place (CIP) capabilities and utilize advanced materials or coatings resistant to adhesion, often supported by AI-driven predictive scheduling.

What is the projected Compound Annual Growth Rate (CAGR) for the Plate Falling Film Evaporator market through 2033?

The Plate Falling Film Evaporator market is projected to grow at a robust Compound Annual Growth Rate (CAGR) of 6.8% between the forecast period of 2026 and 2033, driven largely by global regulatory mandates for sustainability and the need for energy-efficient industrial processing.

What distinguishes Plate Falling Film Evaporators from traditional Shell and Tube Evaporators?

PFFEs offer significantly higher compactness and modularity, resulting in a smaller footprint and easier maintenance access compared to Shell and Tube designs. Crucially, PFFEs facilitate lower temperature operation and shorter residence times, making them superior for processing high-value, heat-sensitive, or viscous liquids.

How is environmental regulation influencing the demand for Plate Falling Film Evaporators?

Strict environmental regulations, especially those pertaining to water use and discharge limits, are major growth drivers. PFFEs are a core technology in Zero Liquid Discharge (ZLD) systems, enabling industries to recover up to 98% of process water and minimize the volume of concentrated brine requiring final disposal, ensuring regulatory compliance and resource conservation.

Which geographical region is expected to lead market growth in the coming years?

The Asia Pacific (APAC) region is anticipated to lead the market in terms of volume growth. This is due to massive expansion in manufacturing capabilities, particularly in China and India, coupled with increasing governmental focus on water management infrastructure and food processing capacity.

What are the main types of PFFEs available on the market?

The market primarily offers Single-Effect Evaporators, Multi-Effect Evaporators (which use vapor sequentially across stages), and highly efficient integrated systems utilizing Thermal Vapor Recompression (TVR) or Mechanical Vapor Recompression (MVR) for optimal energy reuse.

Are PFFEs suitable for processing highly viscous liquids?

While PFFEs generally excel with low-to-medium viscosity liquids, specialized plate designs and careful system configuration (e.g., incorporating pre-heaters or optimizing pump systems) allow for the successful concentration of moderately viscous products, provided the film distribution and flow rate are precisely managed to avoid dry-out.

What is the role of digitalization and IoT in modern PFFE systems?

Digitalization involves integrating IoT sensors for real-time data collection on heat transfer rates, pressures, and temperatures. This data feeds into predictive maintenance algorithms and advanced control systems, ensuring dynamic optimization of energy usage, preemptive troubleshooting, and accurate compliance reporting (Industry 4.0 integration).

What determines the choice of material (e.g., Stainless Steel vs. Titanium) for PFFE construction?

Material selection is determined by the corrosivity and temperature of the liquid being processed. Standard stainless steel (SS 316L) is used for benign applications (Food/Dairy). Titanium or high-nickel alloys (Hastelloy) are mandatory for aggressive chemical solutions, high-salinity brines, or processes requiring exceptional resistance to stress corrosion cracking.

How does the initial capital cost of MVR-based PFFEs impact market penetration?

The high initial capital investment required for MVR-integrated PFFEs acts as a restraint, particularly for smaller enterprises. However, this cost is increasingly justified by the substantial and rapid return on investment (ROI) achieved through dramatically reduced steam and energy consumption over the system's operational lifecycle, driving long-term adoption.

What is the difference between MVR and TVR systems in the context of PFFEs?

MVR (Mechanical Vapor Recompression) uses an electrical compressor to increase vapor pressure and temperature for reuse as heating steam, achieving high efficiency. TVR (Thermal Vapor Recompression) uses a steam ejector to mix high-pressure motive steam with generated vapor, offering lower efficiency than MVR but requiring lower initial capital and no complex mechanical parts.

Where do PFFEs fit into the value chain of industrial processing?

PFFEs occupy a critical mid-to-downstream position in the value chain, acting as the primary separation unit that concentrates the target product or recovers water/solvents from the waste stream. Their reliable operation is crucial for subsequent downstream steps like crystallization, drying, or discharge, significantly influencing overall operational efficiency.

What are the opportunities for PFFEs in the emerging biofuels market?

The biofuels market presents significant opportunities as PFFEs are vital for the efficient concentration of fermentation broths, ethanol purification processes, and the recovery of co-products like distillers' dried grains (DDGs). Their energy efficiency aligns perfectly with the economic necessity of optimizing utility consumption in high-volume bio-refineries.

How do competitive strategies of key players influence the PFFE market?

Leading players focus on offering highly customized, modular solutions and integrating advanced digital controls (AI/IoT) to differentiate their offerings. Competitive strategies involve expanding global service networks, emphasizing life-cycle cost savings through MVR technology, and continuous innovation in plate surface metallurgy to reduce fouling and extend operational intervals.

What role does the capacity segment play in PFFE market dynamics?

Capacity segmentation dictates market focus; large-scale units (over 50 tons/hr) cater to high-volume industries like chemical and sugar, prioritizing efficiency and continuous operation. Small and medium units target specialized applications such as pharmaceuticals and high-value nutraceuticals, prioritizing flexibility, hygienic design, and compliance validation.

Is the Plate Falling Film Evaporator technology considered environmentally sustainable?

Yes, PFFE technology, especially when employing MVR, is highly sustainable. It minimizes steam consumption, significantly reduces thermal energy demand, and is central to industrial efforts to achieve Zero Liquid Discharge (ZLD), thereby conserving vast quantities of water and reducing the environmental footprint of industrial processes.

What are the key technical challenges restraining widespread adoption of PFFEs?

Key restraints include the complexity of managing scaling and fouling, which necessitates chemical cleaning and downtime. Furthermore, the specialized engineering expertise required for integrating and maintaining MVR compressors and related vacuum systems poses a technical barrier, particularly for facilities in developing regions.

How does the rise of plant-based foods impact demand for PFFEs?

The growing market for plant-based foods (e.g., oat milk, soy protein isolates) increases demand for PFFEs, as they are ideal for concentrating and purifying these sensitive proteins and extracts under low-temperature, vacuum conditions. This gentle processing preserves the nutritional value and functional properties critical for consumer acceptance.

How is the PFFE market influenced by global supply chain issues?

The market is sensitive to global supply chain issues, particularly concerning the sourcing and price volatility of high-grade stainless steel and specialty alloys (e.g., titanium) used in plate construction. Delays in obtaining specialized components like MVR compressors also impact lead times and project completion schedules for large installations.

What constitutes the Upstream Analysis in the PFFE Value Chain?

Upstream analysis focuses on the procurement of raw materials, primarily high-quality metals (SS 316L, Duplex, Titanium) and specialized gasket materials (e.g., PTFE, EPDM). Managing supplier relationships, ensuring material compliance with hygienic standards, and controlling cost volatility are central upstream activities.

What role does vacuum technology play in PFFE efficiency?

Vacuum technology is essential as it lowers the boiling point of the liquid, enabling evaporation at much lower temperatures. This is vital for processing heat-sensitive materials (like vitamins or dairy products) and significantly enhances the efficiency of MVR and multi-effect systems by maximizing the temperature driving force (T-difference) between stages.

How are PFFEs adapted for pharmaceutical applications?

For pharmaceutical use, PFFEs require specialized features including construction from certified materials (cGMP compliance), highly polished internal surfaces for sterility, complete drainability to prevent cross-contamination, and strict adherence to documentation and validation protocols required for Active Pharmaceutical Ingredient (API) processing.

What makes the PFFE design compact compared to tubular evaporators?

The compact nature of the PFFE stems from the high surface-area-to-volume ratio achieved by stacking numerous corrugated plates in a small frame. This design maximizes the heat transfer area within a minimal footprint, making PFFEs suitable for facilities where space utilization is a premium constraint, such as offshore platforms or urban processing plants.

What is the significance of the Food and Beverage segment for PFFE market revenues?

The Food and Beverage segment accounts for the largest share of market revenue because PFFEs are indispensable for key concentration processes (e.g., milk, sugar, fruit juice). The continuous growth of global food production and the stringent quality standards demanding gentle thermal treatment sustain this segment's leading position.

How does process control optimization utilizing AI benefit PFFE operations?

AI-based process control continuously analyzes real-time data to dynamically adjust parameters like steam pressure and feed flow. This ensures the evaporator operates at the highest possible efficiency point (minimal energy input per kg of water evaporated), optimizing overall throughput and minimizing energy waste across varying load conditions.

What opportunities exist for PFFEs in the Latin American market?

Opportunities in Latin America are strongly linked to the expansion of regional agricultural processing, particularly in the sugar and ethanol industries (Brazil), and increasing investment in mining and municipal water treatment. Demand is characterized by a need for durable, robust systems that can handle large volumes and fluctuating operational conditions.

Why is effective liquid film distribution crucial in PFFE performance?

Effective liquid film distribution is crucial because it maximizes the contact area between the liquid and the heated plate surface, guaranteeing the high heat transfer coefficient necessary for efficient evaporation. Poor distribution can lead to localized dry spots, causing irreversible fouling, thermal degradation of the product, and severe loss of efficiency.

How do technological advancements in plate coatings affect maintenance schedules?

Advanced, low-surface-energy coatings (e.g., fluoropolymers or ceramics) applied to the plates resist the adhesion of dissolved solids and organic matter, significantly delaying the formation of scale and fouling layers. This directly extends the time interval between mandatory Clean-in-Place (CIP) cycles, boosting operational uptime and reducing chemical consumption.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager