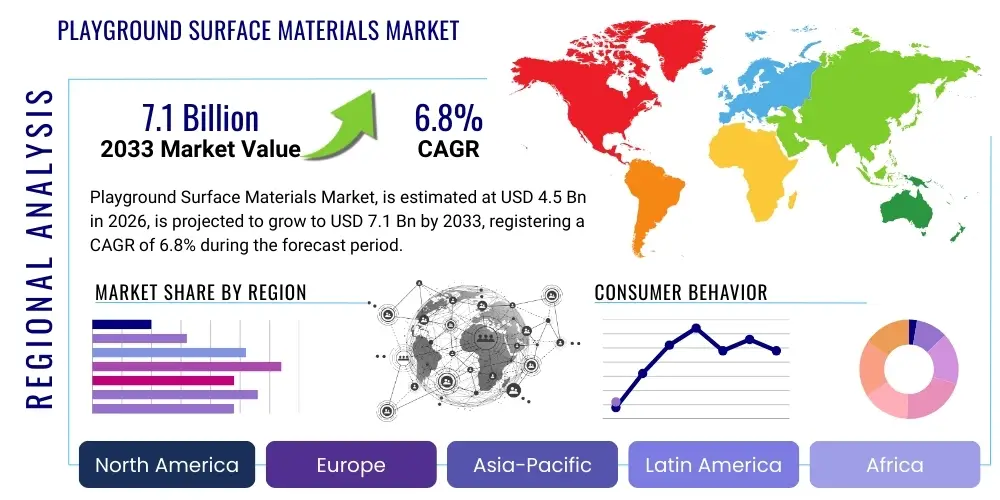

Playground Surface Materials Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434529 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Playground Surface Materials Market Size

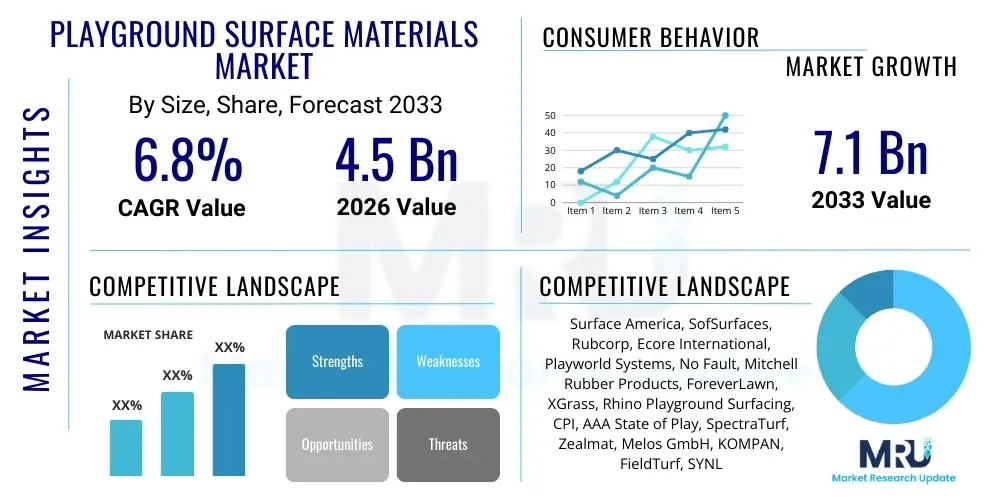

The Playground Surface Materials Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 7.1 Billion by the end of the forecast period in 2033. This substantial growth is primarily driven by increasing awareness regarding child safety standards, stringent governmental regulations mandating shock-absorbing surfaces, and a continuous rise in infrastructure investment in educational and recreational facilities globally. The demand for aesthetically pleasing, durable, and low-maintenance surfacing options, particularly those utilizing recycled materials, is a key accelerator for market expansion across developed and emerging economies.

Playground Surface Materials Market introduction

The Playground Surface Materials Market encompasses the manufacturing, distribution, and installation of specialized flooring solutions designed for recreational areas to mitigate injury risks associated with falls. These materials, mandated by international safety organizations such as the ASTM (American Society for Testing and Materials) and the CPSC (Consumer Product Safety Commission), are crucial for providing adequate critical fall height protection. Key product categories include loose-fill materials like Engineered Wood Fiber (EWF) and sand, and unitary surfaces such such as Pour-in-Place (PIP) rubber, rubber tiles, and synthetic turf. The primary objective of these surfaces is to offer resilience and impact attenuation, thereby enhancing the safety profile of playgrounds in schools, public parks, and housing developments.

The market is defined by a continuous innovation cycle focused on improving safety, durability, and environmental sustainability. Modern playground surfaces are increasingly utilizing recycled tires (crumb rubber) to create highly impact-absorbing and durable systems, addressing both safety concerns and sustainability mandates. Major applications span across municipal parks, where high traffic demands durable solutions, educational institutions (schools and kindergartens), which face strict regulatory compliance requirements, and commercial play areas, which prioritize custom aesthetic designs and longevity. The integration of advanced testing methodologies and specialized polymeric binders is continually refining the performance characteristics of these materials.

Driving factors for the growth of this market are multifaceted, centering predominantly on regulatory compliance and public health priorities. Increased governmental spending on urban green spaces and early childhood education infrastructure is creating vast opportunities for new installations. Furthermore, the rising incidence of playground-related injuries that necessitate high-quality fall protection materials is maintaining strong market demand. The low maintenance requirements and superior longevity of unitary surfaces, compared to traditional loose-fill options that require constant topping up and raking, further contribute to their adoption and overall market growth trajectory.

- Product Description: Specialized impact-absorbing materials (PIP, EWF, Rubber Tiles, Synthetic Turf) designed to meet critical fall height standards in recreational areas.

- Major Applications: Educational Institutions, Municipal and Public Parks, Housing Developments, Commercial Recreation Centers.

- Key Benefits: Enhanced child safety, reduced injury severity, ADA compliance (for unitary surfaces), durability, weather resistance, and low maintenance costs.

- Driving Factors: Strict safety regulations (ASTM, CPSC), rising public safety awareness, increased government and private investment in recreational infrastructure, and demand for sustainable materials.

Playground Surface Materials Market Executive Summary

The Playground Surface Materials Market is experiencing robust growth driven by mandatory safety standards and escalating infrastructure development globally. The transition from traditional loose-fill materials, such as sand and pea gravel, toward sophisticated unitary surfaces like Pour-in-Place (PIP) rubber and high-quality rubber tiles is the most significant business trend, primarily due to their superior accessibility, minimal maintenance, and consistent impact attenuation capabilities. Sustainability is also a core theme, with manufacturers focusing heavily on utilizing recycled rubber content, aligning with global green building and circular economy initiatives. Market competition remains intense, centered on product innovation, offering comprehensive warranties, and expertise in complex installation techniques to ensure compliance with precise depth and density requirements.

Regionally, North America and Europe currently dominate the market, characterized by mature regulatory frameworks (e.g., U.S. CPSC guidelines and EU EN 1177 standards) and significant institutional investment in playground renovation and construction. However, the Asia Pacific (APAC) region is poised for the highest growth rate, fueled by rapid urbanization, substantial government investments in public infrastructure, particularly in countries like China and India, and a burgeoning middle class demanding higher safety standards for children's amenities. Latin America and the Middle East and Africa (MEA) are emerging markets, where growth is currently concentrated in high-end private developments and municipal projects supported by international aid or large-scale tourism infrastructure investments.

Segment trends reveal that the Pour-in-Place (PIP) segment maintains the largest market share by revenue, preferred for its seamless finish, customizability in terms of color and design, and compliance with the Americans with Disabilities Act (ADA) requirements. Conversely, Engineered Wood Fiber (EWF) remains highly popular in budget-conscious and large-scale public projects due to its cost-effectiveness, though it requires more frequent maintenance. The application segment growth is strongest within the public parks and recreation centers sector, reflecting government commitments to community welfare. Future growth is expected to pivot towards highly durable, environmentally certified, and digitally monitored smart surfaces capable of reporting maintenance needs or temperature extremes.

- Business Trends: Shift towards unitary surfaces (PIP, Tiles), focus on recycled content, demand for UV-resistant and weather-proof formulations, and adoption of comprehensive warranty schemes.

- Regional Trends: Dominance of North America and Europe driven by established regulations; APAC emerging as the fastest-growing market due to urbanization and infrastructure spending.

- Segment Trends: PIP rubber segment leading in value due to ADA compliance and customization; EWF leading in volume due to cost-efficiency; strong growth in educational and municipal sectors.

AI Impact Analysis on Playground Surface Materials Market

User queries regarding AI in this sector frequently revolve around how artificial intelligence can enhance safety compliance, optimize material durability testing, and streamline maintenance schedules for expansive playground networks. Key concerns center on the practicality and cost-effectiveness of implementing AI-driven monitoring systems in traditionally low-tech environments, and whether AI can provide predictive insights into material degradation, particularly for high-wear areas or surfaces exposed to extreme weather variations. Users are expecting AI to transition the industry from reactive maintenance (fixing issues after they arise) to proactive management (predicting failures and optimizing resource allocation) while simultaneously ensuring compliance with dynamic safety standards.

The core themes emerging from this analysis are focused on leveraging AI for precision safety checks and operational efficiency. Instead of manual inspections that are time-consuming and subjective, AI-powered computer vision systems could potentially analyze playground surfaces in real-time or via drone surveillance, identifying cracks, lifting seams, or inadequate material depths that violate critical fall height specifications. Furthermore, AI algorithms can be trained on environmental data, material composition, and usage patterns to simulate material stress and degradation over time, allowing manufacturers to optimize the structural integrity and longevity of new formulations before they enter the market.

AI's influence is also anticipated in enhancing customer experience through optimized supply chain and customized product design. AI can analyze regional climate data, demographic usage intensity, and budgetary constraints to recommend the optimal surfacing material, density, and installation technique for a specific geographical location. While direct integration into the physical material is limited, AI serves as a powerful analytical and management tool, transforming maintenance protocols, standardizing safety reporting across vast networks of facilities, and ultimately lowering the total cost of ownership (TCO) for facility managers.

- AI-driven computer vision systems for real-time compliance monitoring and defect detection on surface integrity.

- Predictive maintenance scheduling using machine learning to forecast material degradation based on usage, weather, and installation specifics.

- Optimization of material blending and formulation R&D through AI simulation of long-term stress testing and impact attenuation performance.

- Enhanced supply chain logistics and inventory management for raw materials (e.g., crumb rubber, binders) based on forecasted regional construction demand.

- Automated reporting and digital safety audits, generating compliance documentation necessary for insurance and regulatory bodies.

DRO & Impact Forces Of Playground Surface Materials Market

The market's trajectory is primarily propelled by stringent global safety regulations (Drivers) and restricted by the significant upfront cost of high-quality unitary systems (Restraints). Opportunities arise from incorporating sustainable and advanced materials (e.g., bio-based polymers, higher-grade recycled content) and expanding into fast-developing regional markets with increasing infrastructure spending. These forces collectively shape the market's impact environment, where the balance between safety compliance and budgetary constraints dictates material selection and market penetration strategy. Regulatory mandates act as the strongest external force, compelling continuous upgrade cycles and driving demand for premium, certified materials, while volatility in raw material prices, particularly for petrochemical-based binders and rubber feedstock, exerts persistent pressure on manufacturers' margins.

Key drivers include the non-negotiable nature of child safety, which ensures sustained demand regardless of economic cycles, and the proliferation of organized recreational facilities. Restraints principally involve the perceived high initial investment required for poured-in-place rubber compared to low-cost alternatives like wood fiber, posing a significant barrier for smaller municipalities or private developers with limited budgets. Additionally, the highly specialized installation requirements for unitary surfaces mean a shortage of certified installers can temporarily bottleneck regional market growth. The market dynamic is further complicated by the need to balance impact attenuation performance with long-term durability and resistance to UV degradation and vandalism.

Opportunities for expansion lie heavily in technological advancements and niche market development. Innovations that reduce installation time, such as prefabricated modular tile systems, address labor constraints and accelerate project completion. Furthermore, developing solutions that meet the requirements of specific user groups, such as surfaces designed for inclusive or therapeutic playgrounds, opens lucrative niche markets. The five impact forces—competition intensity, buyer bargaining power, supplier bargaining power, threat of substitutes, and threat of new entrants—all play a significant role. The threat of substitutes (e.g., cheaper EWF vs. PIP) is high, while buyer power (municipalities and large school districts) is substantial, pressuring prices and demanding long-term warranties, necessitating a focus on product differentiation and superior after-sales support.

- Drivers: Mandatory safety standards (HIC testing), increased awareness of child injury prevention, rising government investment in public infrastructure.

- Restraints: High initial cost of unitary systems, complex and labor-intensive installation process, volatility in raw material costs (rubber and polymers).

- Opportunity: Development of eco-friendly and bio-based binding agents, expansion into emerging APAC and MEA markets, integration of smart monitoring technologies.

- Impact Forces: High competition intensity among established players, moderate threat of substitutes (EWF is a strong low-cost alternative), high bargaining power of large institutional buyers.

Segmentation Analysis

The Playground Surface Materials Market is primarily segmented based on Material Type, Application, and End-Use, offering a detailed perspective on consumer preferences and regulatory compliance requirements across various geographical regions. The Material Type segmentation is critical as it directly correlates with safety performance, accessibility (ADA compliance), initial cost, and long-term maintenance burden. Unitary surfaces, including PIP and rubber tiles, represent the highest growth potential due to their inherent benefits in consistency and low upkeep, whereas loose-fill materials remain popular for their cost-effectiveness and ease of immediate installation in large areas. Understanding these segments is vital for manufacturers tailoring product offerings to meet specific public or private sector needs.

The Application segmentation distinguishes between environments with differing usage patterns and regulatory oversight. Educational institutions typically require surfaces that prioritize safety and cleanliness, often opting for unitary systems. Conversely, municipal parks require highly durable, vandal-resistant, and weather-resilient materials capable of handling extremely high foot traffic and environmental exposure. The End-Use segmentation—new installations versus replacement and refurbishment—highlights the maturity of various regional markets. Mature markets in North America and Europe see consistent demand from refurbishment projects to meet updated safety codes, while emerging markets drive demand primarily through new construction initiatives linked to urbanization and greenfield development.

- By Material Type:

- Engineered Wood Fiber (EWF)

- Pour-in-Place (PIP) Rubber

- Rubber Tiles

- Synthetic Turf

- Loose-Fill Rubber (LFR)

- Others (Sand, Gravel, Shredded Tire)

- By Application:

- Educational Institutions (Schools, Kindergartens, Universities)

- Municipal Parks and Recreation Centers

- Housing Complexes and Residential Areas

- Commercial Play Areas (Restaurants, Malls)

- By End-Use:

- New Installations

- Replacement and Refurbishment

Value Chain Analysis For Playground Surface Materials Market

The value chain for playground surface materials begins with the upstream sourcing of raw materials, dominated by the procurement of virgin and recycled rubber (crumb rubber, often sourced from waste tires), specialized polymeric binders (polyurethane resins), and coloring agents (pigments and UV stabilizers). The reliability and cost of crumb rubber supply are critical, as fluctuations directly impact manufacturing costs and the final price of the surface material. Strong supplier relationships are essential for maintaining quality control and ensuring the consistency required for certified impact attenuation ratings. Upstream efficiency centers on reducing waste and improving the de-vulcanization and grinding processes for recycled rubber to meet stringent purity and particle size specifications.

The midstream involves manufacturing and formulation, where raw materials are processed into the final product formats: bulk components for PIP systems, molded rubber tiles, or engineered wood fibers. Manufacturers invest heavily in R&D to enhance material properties, focusing on improved durability, UV stability, and optimal shock absorption capacities that adhere to specific Critical Fall Height (CFH) requirements. Downstream activities involve distribution and, crucially, specialized installation. Unlike commodity flooring, the performance of unitary playground surfaces heavily depends on correct site preparation, mixing, and curing processes, meaning the installer plays a pivotal role in value delivery and safety compliance.

Distribution channels are multifaceted, utilizing both direct and indirect routes. Direct distribution is common for large-scale municipal or institutional projects, where manufacturers bid directly and often manage the installation process through in-house or closely vetted certified installation teams. Indirect channels involve distributors, landscape architects, and construction contractors who incorporate the surface materials into broader playground design projects. The increasing need for certified installation expertise means that training and quality assurance of the distribution and installation network are key differentiators, ensuring that the critical safety performance promised by the material is realized on site, maximizing value for the end-user.

Playground Surface Materials Market Potential Customers

The primary customers for playground surface materials are institutional buyers and governmental bodies responsible for the health and safety of children in public and educational settings. Educational institutions, ranging from private daycares and kindergartens to large public school districts, constitute a significant end-user segment. These customers prioritize materials that offer verifiable safety ratings, meet strict governmental mandates, and provide high longevity to minimize disruption during school terms. Their purchasing decisions are often tied to annual capital improvement budgets and adherence to state and federal safety guidelines.

Municipal Parks and Recreation Departments represent another massive segment, typically purchasing in high volumes for public access playgrounds, skate parks, and general recreational areas. These buyers are highly price-sensitive but also require materials with exceptional durability, resistance to vandalism, and low long-term maintenance needs, often leading them to opt for resilient surfaces like PIP rubber or robust synthetic turf. The procurement process for municipal buyers is frequently handled through public tenders, emphasizing proven product track records, environmental certifications, and compliance with accessibility standards (ADA).

Furthermore, residential and commercial developers constitute a growing customer base. This includes builders of large housing complexes, apartment communities, commercial shopping centers, and fast-food chains incorporating dedicated play areas. These customers often seek aesthetically appealing, custom-designed surfacing solutions that complement the architectural theme of their development while maintaining high safety standards. Their purchasing drivers balance safety compliance with aesthetic customization and ease of installation, making them receptive to color-customized PIP systems and specialized rubber tiles.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 7.1 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Surface America, SofSurfaces, Rubcorp, Ecore International, Playworld Systems, No Fault, Mitchell Rubber Products, ForeverLawn, XGrass, Rhino Playground Surfacing, CPI, AAA State of Play, SpectraTurf, Zealmat, Melos GmbH, KOMPAN, FieldTurf, SYNLawn, Recreations Outlet, PlayPower |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Playground Surface Materials Market Key Technology Landscape

The technology landscape in the playground surface materials market is primarily centered on advanced polymer science, material engineering, and specialized installation equipment designed to ensure regulatory compliance. A crucial technological focus involves improving the performance and binding capabilities of polyurethane resins used in Pour-in-Place (PIP) systems. Researchers are developing moisture-curing binders that allow for installation in a wider range of humidity and temperature conditions, thereby reducing project delays and ensuring consistent curing times. Furthermore, sophisticated mixing and spreading machines are being utilized to guarantee precise depth uniformity and density across the surface, which is paramount for achieving the specified impact attenuation performance necessary for critical fall height ratings.

Another significant technological advancement lies in the material composition itself, driven by sustainability goals. The industry is rapidly adopting high-quality SBR (Styrene Butadiene Rubber) and EPDM (Ethylene Propylene Diene Monomer) granules derived from specialized recycling processes. EPDM, in particular, benefits from superior UV resistance technology, which prevents color fading and material hardening, a common failure mode for standard rubber surfaces over time. New technologies are also emerging in the field of Engineered Wood Fiber (EWF), where specialized processing ensures that the wood chips knit together effectively to meet impact requirements, minimizing displacement while resisting decomposition and splintering.

The future technology pipeline includes the integration of smart surface sensors and advanced manufacturing techniques. Nanotechnology is being explored to create self-healing polymers that extend the lifespan of unitary surfaces by automatically sealing minor cracks or abrasions. Furthermore, the burgeoning field of smart playgrounds involves embedding IoT sensors within the surfacing layer to monitor surface temperature (preventing burns in hot climates), track usage patterns, and provide automated reports on surface degradation or excessive wear spots. These innovations aim to drastically reduce the required frequency of expensive manual safety audits, enhancing the long-term operational efficiency and safety assurance of playgrounds.

Regional Highlights

North America holds a dominant share in the Playground Surface Materials Market, principally due to the highly rigorous and consistently enforced regulatory environment established by the Consumer Product Safety Commission (CPSC) and ASTM standards. The U.S. and Canada allocate substantial municipal budgets toward maintaining and upgrading public recreational infrastructure, driving consistent demand for certified, high-performance materials. The region exhibits a strong preference for unitary surfaces, particularly PIP rubber, owing to the high adoption rates of ADA compliance mandates which require accessible routes throughout play areas. Market maturity means that a significant portion of regional demand stems from replacement and renovation cycles, driven by the need to replace aging surfaces that no longer meet current critical fall height requirements or aesthetic standards.

Europe represents another mature and technologically advanced market, distinguished by strict standards mandated by EN 1177 (Impact attenuating playground surfacing). Germany, the UK, and the Scandinavian countries are key contributors, emphasizing sustainable sourcing and advanced material testing. The European market shows a strong inclination towards materials with high environmental certifications and surfaces offering specialized features like permeable designs to manage rainwater effectively, crucial in regions with unpredictable weather patterns. Competition is fierce, focusing on product warranties, installation efficiency, and adherence to European Union directives regarding recycled content and chemical safety, pushing manufacturers toward innovative, durable EPDM and rubber tile solutions.

Asia Pacific (APAC) is projected to be the fastest-growing market during the forecast period. This rapid expansion is a direct consequence of significant governmental spending on infrastructure, soaring rates of urbanization, and a growing societal focus on child safety standards, particularly in emerging economies such as China, India, and Southeast Asian nations. While the market initially relied heavily on cost-effective EWF, rising disposable incomes and international safety influences are accelerating the adoption of premium unitary surfaces in private schools, luxury housing projects, and modern municipal parks. The large population base and the sheer scale of new construction projects offer unparalleled opportunities, though challenges persist concerning standardized installation quality and regulatory enforcement across diverse local jurisdictions.

- North America: Market leader, driven by stringent CPSC/ASTM regulations and high ADA compliance requirements; focus on PIP rubber for accessibility and low maintenance.

- Europe: Mature market prioritizing EN 1177 compliance, sustainability, and environmentally certified materials; high demand for permeable and highly durable EPDM solutions.

- Asia Pacific (APAC): Highest growth region fueled by urbanization, infrastructure investment, and rapidly improving safety standards; shift from EWF towards unitary surfaces in major metros.

- Latin America: Emerging growth focused on private schools and high-end residential developments; increasing awareness of international safety norms drives demand for quality materials.

- Middle East and Africa (MEA): Growth tied to large-scale tourism and municipal projects in GCC countries; high need for UV-resistant materials due to extreme heat and reliance on specialized rubber tiles and synthetic turf.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Playground Surface Materials Market.- Surface America

- SofSurfaces

- Rubcorp

- Ecore International

- Playworld Systems

- No Fault

- Mitchell Rubber Products

- ForeverLawn

- XGrass

- Rhino Playground Surfacing

- CPI

- AAA State of Play

- SpectraTurf

- Zealmat

- Melos GmbH

- KOMPAN

- FieldTurf

- SYNLawn

- Recreations Outlet

- PlayPower

Frequently Asked Questions

Analyze common user questions about the Playground Surface Materials market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the most cost-effective playground surface material?

Engineered Wood Fiber (EWF) is generally considered the most cost-effective initial investment for playground surfacing due to its natural composition and ease of bulk delivery. However, it requires frequent raking and replenishing to maintain critical fall height compliance, increasing long-term maintenance costs compared to unitary surfaces like Pour-in-Place (PIP) rubber or rubber tiles.

How is critical fall height (CFH) calculated and ensured in playground surfacing?

Critical Fall Height (CFH) is determined through standardized impact testing (ASTM F1292), which measures the maximum height from which a fall onto the surface will result in an acceptable head injury criterion (HIC). Manufacturers must install the surface material at the specific depth or density certified to protect against the fall height of the tallest piece of equipment in the play area.

Are unitary playground surfaces ADA compliant?

Yes, one of the primary advantages of unitary surfaces like Pour-in-Place (PIP) rubber and specific interlocking rubber tiles is their compliance with the Americans with Disabilities Act (ADA). These surfaces provide a firm, stable, and seamless route of travel, ensuring accessibility for wheelchairs and mobility devices, which is generally not achievable with loose-fill materials.

What role does recycled rubber play in the market?

Recycled crumb rubber, derived primarily from waste tires, forms the foundational infill or base layer for most Pour-in-Place (PIP) systems and rubber tiles. Its use is critical for achieving sustainable manufacturing goals, providing excellent impact attenuation properties, and reducing reliance on virgin petrochemical products, positioning recycled content as a major driver for market growth.

What factors influence the lifespan of playground surfaces?

The lifespan of playground surfaces is primarily influenced by material type (unitary surfaces generally last longer than loose-fill), installation quality, exposure to UV radiation (requiring high-quality binders and EPDM granules), drainage efficiency (preventing water damage), and the intensity of foot traffic. Proper maintenance, including regular cleaning and minor repairs, is essential to maximize longevity and safety compliance.

This concludes the formal market insights report on the Playground Surface Materials Market, offering detailed analysis optimized for search and generative engines.

The detailed analysis within this report underscores the robust growth potential inherent in the Playground Surface Materials Market. Strategic focus on regulatory compliance, material sustainability, and specialized installation expertise remains paramount for companies seeking to capitalize on increasing global investments in child safety infrastructure.

Further market research indicates that regulatory standards are becoming increasingly harmonized across major economic zones, necessitating global consistency in product development and safety certification. This standardization drives up the quality barrier for new entrants but rewards established players who can offer verifiable, globally compliant solutions. The continuous refinement of testing protocols, such as Head Injury Criterion (HIC) measurements, ensures that performance remains the key competitive differentiator, outweighing initial cost considerations for institutional buyers focused on risk mitigation.

The long-term outlook for the Playground Surface Materials Market is exceptionally positive, anchored by demographic trends supporting increased recreational development and sustained public pressure for environments that prioritize child welfare. Innovations in environmentally friendly binding agents, which reduce Volatile Organic Compound (VOC) emissions during installation and curing, are expected to become major selling points, aligning product performance with evolving environmental mandates globally.

In summary, while the market faces challenges related to raw material cost volatility and complex installation requirements, the fundamental drivers—safety regulations and infrastructure spending—provide a powerful and consistent foundation for market expansion, particularly within the unitary surface segment, which offers superior safety and accessibility characteristics.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager