Pleated Membrane Filter Cartridge Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433134 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Pleated Membrane Filter Cartridge Market Size

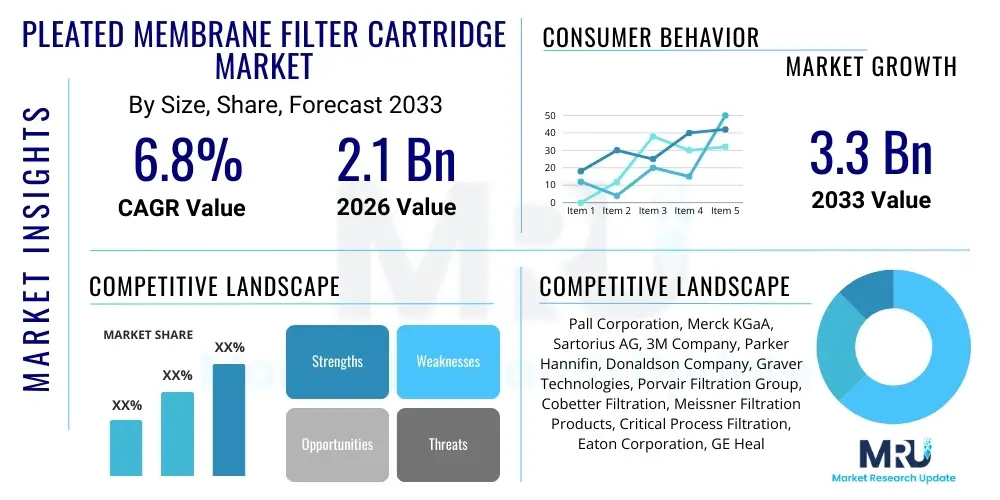

The Pleated Membrane Filter Cartridge Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $2.1 Billion in 2026 and is projected to reach $3.3 Billion by the end of the forecast period in 2033.

Pleated Membrane Filter Cartridge Market introduction

The Pleated Membrane Filter Cartridge Market encompasses advanced separation and purification solutions utilized across sensitive industries such as pharmaceuticals, biotechnology, food and beverage, and microelectronics. These cartridges feature a pleated structure, significantly increasing the surface area of the filtration medium—typically a polymer membrane (e.g., PES, PTFE, PP)—within a compact design. This enhanced surface area provides superior dirt-holding capacity, high flow rates, and extended service life compared to standard depth filters, making them essential for critical fluid processing steps requiring absolute retention ratings and high purity levels.

The product’s primary function is to remove particulates, microorganisms, and colloids from liquids and gases, ensuring product quality and compliance with stringent regulatory standards (like FDA and EMEA requirements). Major applications include sterile filtration, pre-filtration, clarification, and vent filtration. Benefits derived from using pleated membrane cartridges are manifold, including reduced operational costs due to fewer change-outs, improved process efficiency due to high flux rates, and enhanced reliability in maintaining critical contamination control parameters. The specialized nature of these cartridges allows for precise separation based on specific pore sizes, crucial for sensitive applications like vaccine production and ultrapure water generation.

Driving factors for sustained market growth include the escalating global demand for biologics and advanced therapeutic drugs, which mandate ultra-high levels of filtration purity. Furthermore, increasing regulatory scrutiny over water quality and industrial discharge globally compels manufacturers to adopt efficient and reliable filtration technologies. The continuous expansion of the food and beverage sector, coupled with consumer preference for safer and longer-lasting products, reinforces the need for effective microbial control through pleated membrane filtration systems. Technological advancements, such as asymmetric pore structures and novel membrane materials offering enhanced chemical compatibility, further solidify their market position.

Pleated Membrane Filter Cartridge Market Executive Summary

The Pleated Membrane Filter Cartridge Market is characterized by robust growth driven by high-value end-user industries and continuous technological innovation focusing on greater efficiency and selectivity. Business trends indicate a strong move towards single-use (disposable) filtration assemblies, particularly in the biopharmaceutical sector, reducing cleaning validation complexities and enhancing operational flexibility. Key market players are prioritizing expansion through strategic acquisitions and partnerships to broaden their membrane material portfolios and geographic reach, particularly in emerging Asian markets where industrialization and infrastructure development are accelerating. Furthermore, there is an observable trend toward customized filtration solutions designed for specific, challenging fluid characteristics, necessitating collaborative efforts between filter manufacturers and specialized end-users.

Regional trends highlight North America and Europe as established leaders, maintaining dominance due to highly regulated pharmaceutical industries and significant research and development investments in advanced filtration materials. However, the Asia Pacific (APAC) region is poised for the fastest growth, fueled by rapid expansion in domestic drug manufacturing, increasing investments in water treatment infrastructure, and the growing microelectronics sector demanding ultrapure chemicals. In terms of segments, cartridges made from Polyethersulfone (PES) and Polytetrafluoroethylene (PTFE) are witnessing high demand due to their superior flow characteristics and chemical resistance, respectively, crucial for complex biological and solvent applications. Water Treatment and Pharmaceuticals remain the largest and most critical end-user sectors, dictating quality and performance standards across the industry.

The market faces concurrent challenges, notably the high initial investment costs associated with premium membrane technologies and the complexity of validation processes required in highly regulated environments. Nonetheless, opportunities abound in developing more sustainable filtration products, such as those with improved regenerative capabilities or reduced environmental footprints. Successful market strategies involve optimizing supply chains to ensure quick delivery of highly specialized cartridges and leveraging digital tools to provide enhanced technical support and real-time performance monitoring. Overall, the market remains highly competitive, necessitating constant innovation in pore structure, material science, and housing design to maintain a competitive edge.

AI Impact Analysis on Pleated Membrane Filter Cartridge Market

User inquiries regarding the impact of AI on the Pleated Membrane Filter Cartridge Market primarily revolve around predictive maintenance capabilities, optimization of filtration processes, and quality control automation. Users are keen to understand how AI algorithms can analyze complex flow rate, pressure drop, and turbidity data collected from installed cartridge systems to accurately predict filter end-of-life, moving beyond scheduled replacement protocols. Another key theme is the expectation that AI could assist in designing and selecting the optimal cartridge type and pore size for novel or variable fluid streams, leveraging machine learning to correlate fluid characteristics with filtration performance metrics derived from vast historical datasets. The primary concerns often center on data privacy, the cost of integrating smart sensors and AI platforms into legacy infrastructure, and the necessity for highly specialized data scientists to interpret and maintain these complex predictive models within filtration plants.

The application of Artificial Intelligence is revolutionizing process control within the sectors utilizing pleated membrane filters, particularly in large-scale manufacturing environments such as biologics production and ultra-pure water generation. AI systems are increasingly being deployed to monitor real-time process variables, including differential pressure, flow rate stability, and temperature, identifying subtle anomalies that precede cartridge fouling or failure. This capability enables manufacturers to transition from reactive or calendar-based maintenance schedules to highly efficient predictive maintenance strategies. By minimizing unexpected downtime and maximizing the utilization window of each filter, AI integration directly contributes to reduced operational expenditure (OPEX) and improved batch consistency in critical processes.

Furthermore, AI is instrumental in enhancing the quality control and validation stages associated with filtration. Machine learning models can analyze image data from microscopy (post-filtration) or sensor data to verify membrane integrity and filter performance automatically, speeding up quality release times significantly. Looking forward, AI is expected to play a critical role in optimizing the design phase of the cartridges themselves. By simulating fluid dynamics and particle interactions against various membrane pore structures, AI can rapidly iterate and propose novel pleated geometries that offer superior capacity and lower pressure drop, fundamentally accelerating the product development lifecycle for high-performance filtration solutions tailored to specific, highly demanding applications.

- AI enhances predictive maintenance, forecasting cartridge lifespan based on real-time pressure and flow data.

- Machine Learning optimizes process parameters, minimizing fouling rates and maximizing filter efficiency in complex solutions.

- AI aids in automated quality control, analyzing sensor data and imaging for rapid membrane integrity testing.

- Optimization algorithms assist in designing customized pleated structures for specific fluid separation challenges.

- AI-driven data analysis improves inventory management by accurately predicting filter consumption rates.

DRO & Impact Forces Of Pleated Membrane Filter Cartridge Market

The dynamics of the Pleated Membrane Filter Cartridge Market are significantly shaped by a combination of stringent regulatory requirements, technological necessity in key industries, material cost fluctuations, and the pursuit of enhanced process efficiency. Drivers (D) center on the exponential growth of the pharmaceutical and biotechnology sectors, necessitating absolute sterile filtration and high-purity separation in drug formulation and upstream bioprocessing. Restraints (R) primarily involve the high capital expenditure required for installing advanced filtration systems and the associated validation complexities mandated by global health organizations. Opportunities (O) exist in penetrating emerging markets and developing highly selective membranes for specialized applications, such as viral filtration and specific contaminant removal in environmental matrices. These factors converge to create a high-impact market environment where regulatory compliance and product reliability are non-negotiable prerequisites for success.

The core drivers are deeply rooted in global health and safety concerns. The increasing prevalence of chronic diseases and the subsequent need for advanced biopharmaceuticals, including monoclonal antibodies and gene therapies, directly translates into higher demand for validated sterile filtration solutions. Furthermore, global mandates addressing water scarcity and pollution control are accelerating the adoption of high-efficiency pleated filters in municipal and industrial water treatment plants. Innovation in membrane materials, particularly those offering higher chemical compatibility and thermal stability, continually expands the applicability of these cartridges into demanding chemical and microelectronics manufacturing environments, driving market expansion and product premiumization.

Conversely, the market faces constraints related to the lifecycle and disposal of filters. While crucial for purity, the volume of spent cartridges generated, especially in single-use bioprocessing facilities, poses an environmental challenge and increases operational costs related to waste handling. The reliance on advanced polymers for membrane production also exposes the market to volatility in raw material pricing and potential supply chain disruptions. The major impact forces stem from regulatory pressure, forcing continuous innovation in filtration validation standards, and competitive pricing strategies among key global suppliers. Companies that can successfully balance high performance, cost-effectiveness, and sustainability will exert the greatest market impact.

Segmentation Analysis

The Pleated Membrane Filter Cartridge Market is comprehensively segmented based on material type, end-user application, and pore size, reflecting the diverse and highly technical requirements across different industries. Segmentation by material is critical as it determines the chemical compatibility, thermal resistance, and inherent hydrophilicity or hydrophobicity of the filter, directly influencing its suitability for applications ranging from strong acids to sensitive biological buffers. The segmentation by end-user highlights the disproportionate influence of the Pharmaceuticals & Biotechnology sector, which demands the most stringent purity standards, setting a high bar for product quality and validation documentation across the entire market.

Analysis of the segments reveals that Polyethersulfone (PES) filters dominate in high-volume critical applications like sterile filtration due to their inherent hydrophilicity and excellent flow rates. Conversely, Polytetrafluoroethylene (PTFE) filters, known for their universal chemical resistance, are indispensable for filtering aggressive solvents and for gas/vent filtration. Pore size segmentation allows for differentiation between pre-filtration (larger pores, focusing on capacity) and final filtration (sub-micron pores, focusing on absolute retention). Understanding these segments is paramount for manufacturers to tailor their production, marketing, and distribution strategies effectively to meet the varied demands of water purification, chemical processing, and life sciences research.

- Material: Polypropylene (PP), Polytetrafluoroethylene (PTFE), Polyethersulfone (PES), Nylon, Cellulose Acetate, Others.

- End-User: Pharmaceuticals & Biotechnology, Food & Beverage, Water Treatment (Municipal & Industrial), Chemical Processing, Microelectronics, Others.

- Pore Size: 0.1 µm – 0.5 µm (Sterile Filtration), 0.5 µm – 1 µm (Clarification), Above 1 µm (Pre-filtration).

Value Chain Analysis For Pleated Membrane Filter Cartridge Market

The value chain for the Pleated Membrane Filter Cartridge Market begins with upstream activities focused on raw material procurement, primarily specialized polymer resins (like PES, PTFE, and PP) and non-woven support layers. Critical upstream analysis focuses on the select group of sophisticated chemical companies that manufacture these membrane polymers, requiring extremely high purity levels and consistency. The price and availability of these specialty resins heavily influence the production costs and subsequent pricing of the final cartridges. Establishing long-term supply contracts and ensuring material traceability are crucial upstream activities, especially given the stringent requirements for validating materials used in pharmaceutical and food applications.

Midstream activities involve the membrane casting and preparation (often proprietary processes), pleating the membrane material to maximize surface area, assembling the cartridge structure (including end caps and core materials), and performing integrity testing and sterilization (e.g., autoclaving or gamma irradiation). This manufacturing phase demands high levels of automation and quality control to maintain the absolute retention ratings required. Downstream analysis focuses on distribution and final application. Due to the technical nature of the product, distribution often involves specialized distributors or direct sales teams capable of providing technical consultation and application support to end-users.

The distribution channel is typically bifurcated into direct sales for large, strategic end-users (such as global pharmaceutical corporations) where customization and deep technical support are mandatory, and indirect sales through specialized industrial and life science distributors who manage inventory and provide local support to smaller and mid-sized entities. The expertise provided by the sales channel is a key component of the overall value proposition. Direct communication with end-users allows manufacturers to gather critical feedback for product improvement, driving the innovation loop essential for maintaining competitiveness in this technical market.

Pleated Membrane Filter Cartridge Market Potential Customers

Potential customers for pleated membrane filter cartridges are overwhelmingly concentrated in industries requiring precise fluid separation, contamination control, and high standards of regulatory compliance. The primary and largest end-users are pharmaceutical and biotechnology companies, which utilize these cartridges at multiple stages, from media preparation and buffer filtration to final sterile filtration of injectable drugs and biologics. These customers prioritize validation support, documentation traceability, and guaranteed absolute retention ratings above all other factors, making them premium purchasers in the market.

A second major customer segment includes the global water treatment industry—both municipal entities requiring clean drinking water standards and industrial facilities managing process water or wastewater discharge. For these customers, high flow rate, long service life, and excellent dirt-holding capacity are essential metrics, often favoring robust, cost-effective materials like polypropylene. The Food & Beverage sector represents a significant growth area, using cartridges for beer, wine, and bottled water clarification and stabilization, where microbial control is crucial to product integrity and shelf life.

Finally, the microelectronics and chemical processing industries form a niche but highly demanding customer base. Microelectronics fabrication requires ultrapure chemicals and solvents, necessitating specialized PTFE and Nylon membranes capable of removing sub-micron particulates without leaching contaminants. Chemical processors use these cartridges for challenging separations involving aggressive solvents or high-temperature liquids. Overall, the buying decision among these varied end-users is determined by a combination of regulatory adherence, cost-of-ownership (driven by cartridge life), and specific technical compatibility with the fluid being processed.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $2.1 Billion |

| Market Forecast in 2033 | $3.3 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Pall Corporation, Merck KGaA, Sartorius AG, 3M Company, Parker Hannifin, Donaldson Company, Graver Technologies, Porvair Filtration Group, Cobetter Filtration, Meissner Filtration Products, Critical Process Filtration, Eaton Corporation, GE Healthcare, Koch Membrane Systems, Fuji Film, Shanghai Filter Cartridge, Suzhou Naco Filter, Brother Filtration, KLT Filter, Roki Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pleated Membrane Filter Cartridge Market Key Technology Landscape

The key technology landscape of the Pleated Membrane Filter Cartridge Market is defined by continuous advancements in material science and structural engineering aimed at maximizing efficiency and selectivity. A critical technological trend is the development of asymmetric and graded density membranes, where the pore structure transitions from larger pores on the upstream side to smaller pores on the downstream side. This layered structure significantly enhances the dirt-holding capacity and extends the service life of the cartridge by distributing the load across the depth of the filter medium, preventing premature surface blinding and maintaining high flow rates even under high particulate load conditions. Furthermore, innovations in membrane surface modification, such as hydrophilic treatments on typically hydrophobic materials (like PTFE), allow for broader application flexibility without compromising chemical resistance.

Another pivotal technological area involves the mechanics of pleating and sealing. Advanced pleating technologies, often computer-controlled, ensure uniform pleat geometry and maximum membrane utilization within the cartridge housing, preventing flow dead zones and optimizing the hydraulic flow path. Thermal welding and solvent-free bonding techniques are crucial for ensuring the integrity of the cartridge structure, guaranteeing that no adhesives or foreign materials contaminate the filtrate, which is non-negotiable in pharmaceutical and food applications. The integration of advanced sensor technologies, including differential pressure transmitters and conductivity meters built directly into smart housing designs, represents the frontier of operational technology, facilitating real-time monitoring and integration with Industrial Internet of Things (IIoT) platforms.

Current research and development efforts are heavily focused on high-flux membranes, primarily utilizing Polyethersulfone (PES) or Nylon, specifically engineered to operate efficiently under lower differential pressures while achieving stringent sterile grade (0.2 µm) retention. Furthermore, the specialized field of viral filtration necessitates complex multilayer membranes designed with exceptionally fine, consistent pore sizes (typically 20-50 nm) and highly durable materials capable of withstanding aggressive cleaning protocols. These technological breakthroughs are essential for addressing the growing demands of modern biotechnology, where high efficiency, process scalability, and absolute safety are paramount requirements for filtration equipment used in critical drug manufacturing processes.

Regional Highlights

- North America: This region maintains a leading position in the Pleated Membrane Filter Cartridge Market, primarily driven by the colossal presence of the pharmaceutical and biotechnology industries in the United States and Canada. High levels of R&D spending, strict FDA regulations mandating validated filtration protocols, and the rapid adoption of single-use systems in bioprocessing fuel market growth. The region is a key hub for technological innovation and premium product consumption, setting global benchmarks for quality and performance. The advanced nature of the microelectronics sector also contributes significantly to the demand for specialized, high-purity cartridges.

- Europe: Europe represents a mature and highly regulated market, with strong demand stemming from Germany, France, and the UK. The market is propelled by a robust biomanufacturing sector and comprehensive EU water directives that enforce high standards for municipal and industrial water treatment. European manufacturers often focus on sustainability and energy efficiency in their filtration solutions, driving the adoption of high-flux, long-life cartridges. Innovation is strong, particularly in specialized solvent and chemical filtration tailored for the region's advanced chemical sector.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market globally due to accelerated industrialization, massive investments in water infrastructure, and the expansion of domestic pharmaceutical manufacturing, particularly in China and India. Rapid economic growth, rising healthcare spending, and increasing awareness of contamination control drive the need for reliable filtration solutions. The establishment of large-scale water purification projects and the surging microelectronics fabrication industry provide substantial opportunities for market entrants and established global players.

- Latin America (LATAM): Growth in LATAM is steady, primarily concentrated in Brazil and Mexico, driven by foreign direct investment in the food & beverage and pharmaceutical sectors. The demand is focused on balancing quality with cost-effectiveness. Increased urbanization and infrastructure development are creating growing opportunities in industrial water treatment and wastewater management, requiring robust and accessible cartridge solutions.

- Middle East and Africa (MEA): This region is experiencing growth led by large-scale desalination and industrial water reuse projects, particularly in the Gulf Cooperation Council (GCC) countries. The need for potable water and the development of local petrochemical and pharmaceutical production facilities are the primary drivers. The market is highly dependent on international suppliers for high-technology membrane cartridges.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pleated Membrane Filter Cartridge Market.- Pall Corporation (a Danaher Company)

- Merck KGaA

- Sartorius AG

- 3M Company

- Parker Hannifin

- Donaldson Company

- Graver Technologies

- Porvair Filtration Group

- Cobetter Filtration

- Meissner Filtration Products

- Critical Process Filtration

- Eaton Corporation

- GE Healthcare (Part of Cytiva)

- Koch Membrane Systems

- Fuji Film

- Shanghai Filter Cartridge

- Suzhou Naco Filter

- Brother Filtration

- KLT Filter

- Roki Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Pleated Membrane Filter Cartridge market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors primarily drive the growth of the Pleated Membrane Filter Cartridge Market?

Market growth is primarily driven by the rapidly expanding global biopharmaceutical industry, which requires absolute sterile filtration, coupled with increasingly stringent regulatory standards for clean water and high-purity manufacturing processes across the food and microelectronics sectors.

What are the main advantages of using pleated membrane cartridges over standard depth filters?

Pleated membranes offer significantly increased surface area within a compact cartridge, resulting in higher flow rates, superior dirt-holding capacity, longer service life, and guaranteed absolute particle retention ratings, which are critical for precision fluid processing.

Which end-user segment accounts for the highest demand in this market?

The Pharmaceuticals and Biotechnology segment accounts for the highest demand due to the critical nature of sterile filtration and purification processes necessary for the production of vaccines, biologics, and injectable medicines, requiring validated high-performance filtration solutions.

What is the role of materials like PES and PTFE in filter cartridge performance?

Polyethersulfone (PES) is favored for its hydrophilic nature and high flow rates in aqueous solutions, essential for sterile filtration. Polytetrafluoroethylene (PTFE) is used for its broad chemical compatibility and hydrophobicity, making it ideal for filtering aggressive solvents and for gas/vent applications.

How is AI impacting the maintenance and efficiency of filtration systems?

AI is transforming system maintenance by enabling predictive analytics based on real-time sensor data (pressure/flow), allowing operators to forecast filter end-of-life accurately. This minimizes unexpected downtime, optimizes replacement schedules, and enhances overall process efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager