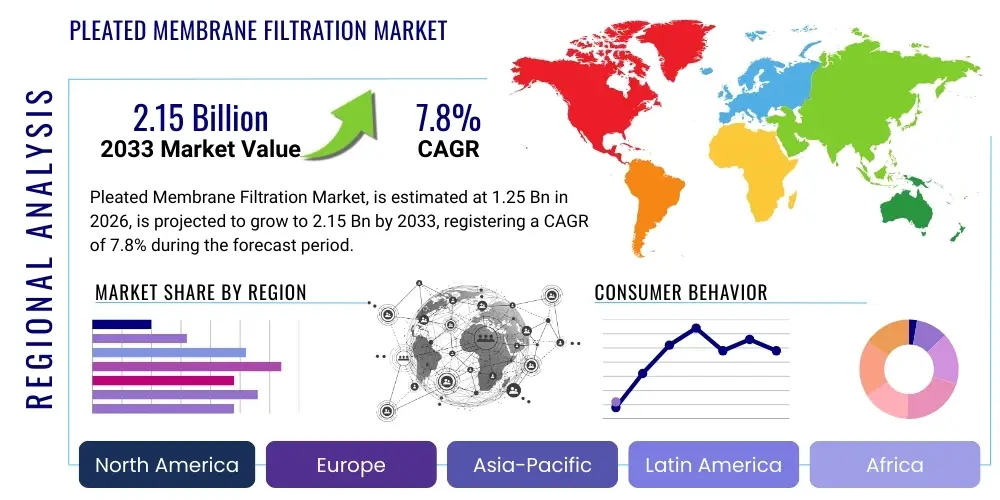

Pleated Membrane Filtration Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439481 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Pleated Membrane Filtration Market Size

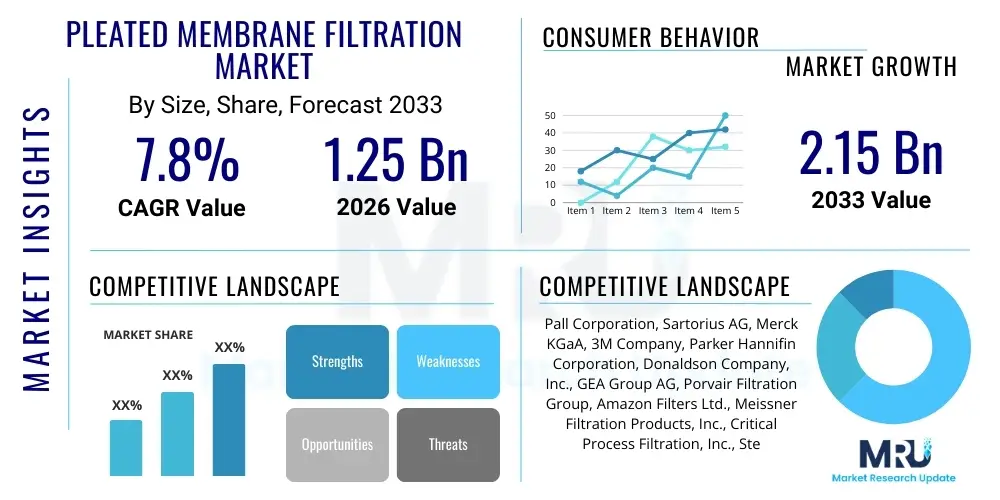

The Pleated Membrane Filtration Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 2.15 Billion by the end of the forecast period in 2033.

Pleated Membrane Filtration Market introduction

Pleated membrane filtration represents a highly efficient and sophisticated separation technology essential for achieving stringent purity standards across diverse industries. This filtration method ingeniously utilizes membranes structured with numerous folds, or pleats, to significantly increase the effective surface area available for filtration within a remarkably compact cartridge housing. This innovative design not only maximizes the contaminant-holding capacity but also ensures high flow rates, making these filters exceptionally effective for removing a broad spectrum of impurities, ranging from microscopic particles and suspended solids to bacteria, viruses, and other undesirable microorganisms from various fluid streams. The operational principle relies on passing a fluid under pressure through the semi-permeable membrane, which selectively allows the purified liquid to pass through while physically retaining contaminants based on their size and the membrane's precisely controlled pore structure.

The versatility and efficacy of pleated membrane filters underpin their widespread adoption across critical sectors. In the realm of water and wastewater treatment, they are indispensable for producing potable water, ensuring industrial process water quality, and achieving compliance with strict environmental discharge regulations. For the burgeoning food and beverage industry, these filters play a pivotal role in the clarification of beverages like beer, wine, and juices, microbiological stabilization, and ensuring the sterility of liquid food products, thereby enhancing product quality, safety, and extending shelf-life. Within pharmaceuticals and biotechnology, pleated membranes are fundamental for terminal sterilization of injectables, purification of biological active ingredients, filtration of cell culture media, and the production of ultra-pure water for laboratory and manufacturing processes, adhering to highly rigorous regulatory standards such as cGMP (current Good Manufacturing Practice).

The inherent advantages of pleated membrane filtration systems are a significant driving force behind their market growth. These include their capacity for exceptionally high flow rates, which translates to reduced processing times and enhanced operational efficiency. The extended service life, attributable to the vastly increased surface area for particle capture, minimizes the frequency of filter changes, leading to considerable cost savings in terms of consumables and labor. Furthermore, their robust construction and material compatibility with a wide range of chemicals and temperatures ensure reliable performance in demanding industrial environments. The market's expansion is further propelled by an escalating global demand for clean water resources, the continuous tightening of environmental regulations worldwide, accelerated industrialization in emerging economies, and persistent advancements in membrane science and module design, all of which underscore the indispensable nature of this critical filtration technology in modern industrial landscapes.

Pleated Membrane Filtration Market Executive Summary

The Pleated Membrane Filtration Market is currently undergoing dynamic growth, propelled by a confluence of factors including increasing global demand for high-purity fluids, escalating industrial output, and the pervasive tightening of environmental and health regulations across jurisdictions. A key business trend shaping the market is the relentless pursuit of product innovation, where manufacturers are heavily investing in research and development to engineer next-generation membrane materials featuring enhanced anti-fouling properties, superior chemical resistance, and improved mechanical strength. This innovation extends to modular designs that offer greater ease of installation, reduced footprint, and optimized operational efficiency. Furthermore, strategic consolidations, including mergers and acquisitions, are becoming increasingly common as companies aim to broaden their technology portfolios, expand their geographic footprint, and leverage synergistic capabilities to capture greater market share, especially in specialized and high-value application segments such as biopharmaceutical processing and advanced industrial fluid separation.

From a regional perspective, the market exhibits varied growth patterns and maturity levels. The Asia Pacific (APAC) region stands out as a primary growth engine, experiencing exponential demand fueled by rapid industrial expansion, significant investments in new manufacturing infrastructure, and burgeoning urban populations requiring access to clean water. Countries like China, India, and various Southeast Asian nations are at the forefront of this growth, driven by both domestic industrial development and increasing environmental consciousness. Conversely, North America and Europe, while representing more mature markets, continue to demonstrate robust demand sustained by stringent regulatory landscapes that necessitate high-purity filtration, alongside ongoing efforts in process optimization, resource recovery, and the adoption of advanced filtration solutions in their well-established pharmaceutical, chemical, and food & beverage industries. These regions also lead in the adoption of cutting-edge technologies and sustainable practices.

Segmentation analysis reveals distinct trends influencing market dynamics. The liquid filtration segment, encompassing critical applications in water and wastewater treatment, pharmaceuticals, and food & beverage, remains the largest and most dominant due to universal requirements for fluid purification and sterilization. However, the gas filtration segment is exhibiting accelerated growth, driven by increasing demands for clean air in manufacturing processes, the need for high-purity gases in semiconductor and electronics fabrication, and medical applications. There is a discernible trend towards finer filtration capabilities, enabling the removal of increasingly smaller particles and contaminants, alongside a growing emphasis on automated and smart filtration systems that leverage IoT (Internet of Things) and data analytics for real-time monitoring, predictive maintenance, and optimized performance. This shift reflects a broader industry imperative for enhanced operational reliability, reduced manual intervention, and improved cost-effectiveness throughout the filtration lifecycle.

AI Impact Analysis on Pleated Membrane Filtration Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Pleated Membrane Filtration Market frequently center on its potential to revolutionize operational paradigms, enhance predictive capabilities, and drive efficiency improvements. Key themes that emerge from these inquiries include how AI can be leveraged to minimize instances of human error in complex filtration processes, substantially reduce costly downtime through proactive interventions, optimize the lifespan of expensive membranes, and elevate overall filtration performance by deriving actionable insights from vast datasets. Users are particularly keen to understand the practical integration of AI with existing filtration infrastructure, seeking clarity on how these advanced technologies can confer a tangible competitive advantage. This often encompasses concerns about the initial investment required for AI implementation, the crucial aspects of data security and intellectual property protection, and the imperative for upskilling or recruiting specialized personnel capable of managing and interpreting AI-driven solutions within highly regulated and critical industrial environments, thereby ensuring a smooth and effective transition.

The pervasive integration of AI and machine learning algorithms within the industrial sector promises to instigate profound transformative changes within the pleated membrane filtration domain. AI can dramatically enhance process control by continuously analyzing voluminous real-time data streams emanating from an array of sensors monitoring critical operational parameters such as transmembrane pressure, volumetric flow rates, permeate quality indicators (e.g., turbidity, conductivity), and chemical dosing levels. This constant data assimilation allows AI systems to dynamically adjust filtration parameters, optimizing operating conditions to prevent premature membrane fouling, ensure consistent permeate quality, and maximize flux rates. This capability extends powerfully into the realm of predictive analytics, where sophisticated AI algorithms are trained to recognize subtle patterns and anomalies in operational data, enabling them to accurately forecast potential equipment malfunctions or anticipate the onset of membrane degradation far in advance. Such foresight facilitates highly proactive maintenance scheduling, thereby significantly minimizing the occurrence of costly, unscheduled downtime and extending the functional life of filtration assets.

Beyond the immediate operational enhancements, AI also holds immense potential for accelerating innovation in the design and material science of pleated membranes. By employing advanced simulation and optimization algorithms, AI can rapidly analyze various material compositions, pore structures, and pleating geometries to predict their performance characteristics under different operating conditions. This capability allows engineers to virtually test and refine countless design iterations, dramatically shortening the research and development cycles required to create membranes with enhanced permeability, selectivity, anti-fouling properties, and durability for specific applications. Furthermore, AI-powered vision systems and analytical tools can be deployed to streamline and automate rigorous quality control processes throughout the manufacturing phase. These systems ensure consistent product output, detect microscopic defects, and verify adherence to stringent industry standards and regulatory compliance requirements, thereby reinforcing the market's trajectory towards unparalleled precision, reliability, and ultimately, a superior return on investment for end-users.

- Enhanced predictive maintenance and early fault detection for filtration systems, leading to minimized operational downtime and reduced maintenance costs.

- Real-time process optimization through AI-driven dynamic adjustment of operational parameters based on continuous sensor data.

- Improved product quality and batch consistency via AI-powered monitoring and anomaly detection in filtration output.

- Accelerated research and development for novel membrane materials and optimized pleating designs through AI-powered simulations and material informatics.

- Automated monitoring and control of membrane fouling, leading to extended membrane lifespan and reduced cleaning frequency.

- Data-driven insights for efficient resource management, including optimized energy consumption, water usage, and chemical dosing in cleaning cycles.

- Enhanced operational safety through AI's ability to identify and flag potential risks or deviations from safe operating limits.

DRO & Impact Forces Of Pleated Membrane Filtration Market

The Pleated Membrane Filtration Market is dynamically shaped by a sophisticated interplay of forces, encompassing prominent drivers, inherent restraints, emerging opportunities, and broader impactful forces that collectively dictate its growth trajectory and evolutionary path. A primary driver propelling significant market expansion is the escalating global demand for high-purity water, which is critical across municipal water supplies, a vast array of industrial processes, and residential consumption, intensified by a rapidly expanding global population and pervasive industrialization. Concurrently, the increasing stringency of environmental regulations worldwide, particularly concerning wastewater discharge limits and air quality standards, compels industries to adopt advanced and highly efficient filtration technologies like pleated membranes to ensure compliance and mitigate ecological footprints. Furthermore, the robust and continuous growth observed in the pharmaceutical, biotechnology, and food & beverage industries, all of which rely intrinsically on sterile and precise filtration for product safety, quality assurance, and regulatory adherence, serves as a monumental impetus for the sustained demand for pleated membrane solutions.

Despite these powerful drivers, the market navigates several notable restraints that pose challenges to its unhindered growth. One significant impediment is the substantial initial capital investment required for the procurement and installation of sophisticated pleated membrane filtration systems, particularly for large-scale industrial or municipal applications. This considerable upfront cost can act as a significant barrier to entry or adoption for smaller enterprises, nascent industries in developing regions, or those operating with limited capital budgets. Another pervasive technical challenge is membrane fouling, a phenomenon where accumulated particulates, organic matter, or biological films on the membrane surface lead to a progressive reduction in flux, increased operational pressure, and diminished filtration efficiency. While ongoing research aims to mitigate fouling, its persistent nature necessitates frequent cleaning cycles, increased chemical usage, and often premature membrane replacement, all contributing to elevated operational expenditures and potential downtime, which can deter widespread adoption in certain cost-sensitive applications.

Conversely, the market is replete with substantial opportunities that promise future growth and innovation. These include the continuous and accelerated development of novel membrane materials, such as advanced polymers, ceramic composites, and hybrid membranes, which are engineered to exhibit superior permeability, enhanced selectivity for specific contaminants, and significantly improved anti-fouling properties. Such material innovations not only promise extended membrane lifespan but also open avenues for more efficient and cost-effective separation processes. The expansion into highly specialized and niche applications, such as the recovery of valuable materials from industrial waste streams, highly specific separations in fine chemical synthesis, and the growing demand for decentralized, point-of-use water treatment solutions, presents new and lucrative market segments. Moreover, the accelerating industrial and urban development in burgeoning economies across the Asia Pacific, Latin America, and Africa regions offers vast untapped potential for new installations and substantial market penetration, as these regions prioritize infrastructure development, industrial growth, and increasingly focus on addressing pressing environmental and public health concerns related to water and air quality.

Broader impact forces are consistently reshaping the market landscape. Rapid technological advancements in membrane science, including breakthroughs in membrane fabrication techniques, module design, and system integration, are perpetually refining the efficiency, durability, and cost-effectiveness of pleated membrane filters. A heightened and intensifying global focus on environmental protection, sustainability initiatives, and the circular economy principles further amplify the demand for highly efficient, energy-saving, and waste-reducing filtration solutions. Additionally, macroeconomic conditions, geopolitical shifts affecting industrial growth, and the varying degrees of regulatory enforcement across different regions can indirectly but significantly influence market dynamics. The growing awareness among industries and municipalities about the critical long-term benefits of implementing high-efficiency filtration, encompassing not only compliance with regulations but also reduced operational costs, enhanced product quality, and improved public health outcomes, collectively acts as a formidable impact force driving sustained market evolution, fostering innovation, and ensuring the continued indispensable role of pleated membrane filtration in modern society.

Segmentation Analysis

The Pleated Membrane Filtration Market is meticulously segmented across various critical dimensions to offer a granular and insightful understanding of its intricate structure and underlying dynamics. This comprehensive segmentation allows market participants, from manufacturers and distributors to end-users and investors, to identify specific growth engines, understand varying customer needs, and pinpoint strategic opportunities within the diverse ecosystem. Each segment is characterized by unique technical specifications, application requirements, and market drivers, reflecting the wide spectrum of operational challenges and purity standards addressed by pleated membrane technology. Analyzing these segments is paramount for developing targeted product portfolios, tailoring marketing strategies, optimizing supply chains, and making informed investment decisions that align with the specific demands and trends of different industrial and commercial applications.

The classification by material type is crucial as it dictates the chemical compatibility, thermal stability, pore size range, and overall performance characteristics of the membrane, enabling selection based on fluid properties and operating conditions. Segmentation by filtration type (Microfiltration, Ultrafiltration, Nanofiltration) categorizes products based on their pore size and the types of contaminants they are designed to remove, addressing needs from macro-particulate removal to the separation of viruses and dissolved solids. Furthermore, segmenting by application highlights the primary end-use industries, showcasing how varied sectors like water treatment, pharmaceuticals, food & beverage, and chemical processing leverage these filters for distinct purposes. This detailed breakdown ensures that market analysis is not only comprehensive but also highly actionable, providing a robust framework for strategic planning and competitive positioning within the evolving landscape of pleated membrane filtration.

- By Material: This segment classifies membranes based on the polymer or material composition, which dictates their chemical resistance, thermal stability, pore structure, and application suitability.

- Polypropylene (PP): Widely used for general filtration due to excellent chemical resistance and low cost.

- Polyethersulfone (PES): Known for high flow rates, low protein binding, and broad chemical compatibility, often used in biopharmaceuticals.

- Polytetrafluoroethylene (PTFE): Offers superior chemical resistance and high-temperature stability, ideal for aggressive chemicals and gas filtration.

- Nylon: Utilized for broad chemical compatibility and good mechanical strength, suitable for various aqueous and solvent-based applications.

- Cellulose Acetate (CA): Provides low protein binding and hydrophilic properties, commonly used in laboratory and pharmaceutical applications.

- Others (e.g., Polyvinylidene Fluoride (PVDF), Regenerated Cellulose): Include specialized materials for specific applications requiring unique properties like higher temperature resistance or specific solvent compatibility.

- By Type: Categorizes filters by their effective pore size and the size of particles or molecules they are designed to retain.

- Microfiltration (MF): Typically removes particles ranging from 0.1 to 10 micrometers, including bacteria and suspended solids.

- Ultrafiltration (UF): Filters particles between 0.01 and 0.1 micrometers, effective for removing viruses, proteins, and macromolecules.

- Nanofiltration (NF): Targets smaller particles, ranging from 0.001 to 0.01 micrometers, for removal of multivalent ions, pesticides, and organic macromolecules.

- By Application: This segment highlights the primary industries and uses where pleated membrane filtration is critically employed.

- Water & Wastewater Treatment: For purification, desalination pre-treatment, and effluent polishing in municipal and industrial settings.

- Food & Beverage: Essential for clarification, sterilization, and cold stabilization of beverages, dairy products, and liquid food.

- Pharmaceutical & Biotechnology: Critical for sterile filtration, cell culture media preparation, vaccine production, and API purification.

- Chemical & Petrochemical: Used for solvent recovery, catalyst retention, product clarification, and separation of chemical intermediates.

- Oil & Gas: Employed in produced water treatment, injection water filtration, and refining processes to remove solids and impurities.

- Power Generation: For boiler feed water treatment, condensate polishing, and cooling water filtration to prevent scaling and corrosion.

- Others (e.g., Electronics, Automotive, Laboratories): Includes ultra-pure water production for semiconductor manufacturing, paint preparation, and general laboratory filtration.

- By End-Use Industry: Focuses on the type of organizational entities that are the ultimate consumers of these filtration products.

- Industrial: Large-scale manufacturing plants, processing facilities, and utilities requiring robust and high-capacity filtration.

- Commercial: Smaller businesses, institutions, and service providers (e.g., hospitals, hotels, breweries) with specific filtration needs.

- Residential: Point-of-entry or point-of-use filtration systems for household water purification.

- By Flow Configuration: Differentiates filtration methods based on how the fluid flows relative to the membrane surface.

- Cross-Flow Filtration: Fluid flows tangentially across the membrane surface, minimizing cake formation and allowing continuous operation.

- Dead-End Filtration: Fluid flows perpendicularly through the membrane, collecting retained particles on the surface, typical for batch processes.

Value Chain Analysis For Pleated Membrane Filtration Market

The value chain for the Pleated Membrane Filtration Market is a multi-tiered and complex ecosystem, commencing with the upstream segment dominated by specialized raw material suppliers. These suppliers are pivotal in providing high-performance polymers such as polypropylene, polyethersulfone, PTFE, nylon, and PVDF, which constitute the fundamental building blocks for membrane fabrication. The quality, consistency, and innovative properties of these base polymers directly influence the final membrane’s filtration efficiency, chemical compatibility, and mechanical durability. In addition to polymers, this upstream segment also includes providers of non-woven support fabrics, end-caps, O-rings, and other structural components necessary for assembling robust pleated cartridges, alongside suppliers of advanced coatings or chemicals used for membrane surface modification (e.g., hydrophilic treatments, anti-fouling agents). The stringent quality control and technical expertise within this foundational stage are paramount, as any deficiency can propagate downstream, affecting the performance and longevity of the ultimate filtration product.

Moving further along the value chain, the manufacturing segment encompasses the sophisticated processes of membrane sheet production, precision pleating, and the intricate assembly of filter cartridges. Membrane manufacturers leverage advanced extrusion, casting, or phase inversion techniques to create membranes with precisely controlled pore sizes and structures. This is followed by automated pleating processes that carefully fold the membrane material into its characteristic pleated configuration, maximizing surface area. Subsequent steps involve thermal or ultrasonic welding and sealing techniques to secure the pleated pack within a durable housing, ensuring no bypass leakage occurs. This stage demands exceptional engineering precision, stringent quality assurance protocols, and often sterile manufacturing environments (especially for pharmaceutical-grade filters) to guarantee product integrity and performance. Innovation at this stage often focuses on optimizing pleating density, improving housing materials, and integrating smart features like embedded sensors, which contribute significantly to the filter's overall efficiency, reliability, and cost-effectiveness.

The distribution and downstream segments are critical for delivering the finished pleated membrane filters to end-users. Distribution channels typically bifurcate into direct and indirect routes. Direct distribution involves manufacturers engaging their own sales forces and technical support teams to serve large industrial clients, often involving complex, customized solutions, system integration, and long-term service contracts. This approach allows for deep customer relationships, tailored product offerings, and direct feedback loops crucial for continuous improvement. Indirect distribution, conversely, relies on an extensive network of specialized distributors, wholesalers, and value-added resellers. These partners play a vital role in reaching a broader customer base, including small-to-medium enterprises, geographically dispersed markets, and customers requiring standard off-the-shelf products. They provide logistical efficiency, local inventory, and frontline technical support, enhancing market penetration and accessibility. The final stage of the value chain involves the end-users—ranging from municipal waterworks and global pharmaceutical giants to local breweries and electronics manufacturers—who integrate these filters into their critical processes for purification, separation, and sterilization, thereby achieving their desired operational and quality objectives. Effective after-sales service and technical support from both direct and indirect channels are crucial for ensuring optimal product performance, facilitating troubleshooting, and securing sustained customer loyalty in this competitive market.

Pleated Membrane Filtration Market Potential Customers

The Pleated Membrane Filtration Market serves an incredibly broad and diverse clientele, encompassing a wide array of industries and institutions that necessitate stringent fluid purification, precise separation, or robust sterilization processes. These potential customers, acting as the ultimate end-users or buyers, are organizations whose operational integrity, product quality, public safety compliance, or environmental stewardship depend critically on effective filtration solutions. The pervasive utility of pleated membrane filters means that the customer spectrum ranges from expansive multinational corporations with complex, large-scale processing needs to highly specialized small and medium-sized enterprises (SMEs) operating in niche markets, each presenting unique requirements concerning flow rates, target contaminants, chemical compatibility, and adherence to specific regulatory frameworks. Understanding the distinct needs of each customer segment is paramount for market players to develop tailored product offerings and provide specialized technical support.

Prominent customer segments include municipal water treatment facilities and industrial wastewater treatment plants, which utilize pleated membranes for producing safe potable water, conditioning process water for various manufacturing operations, and ensuring effluent quality meets stringent discharge regulations. These entities often require high-capacity, robust, and reliable filtration systems capable of handling large volumes and diverse contaminant loads. The pharmaceutical and biotechnology industries represent a high-value customer base, where pleated membranes are indispensable for sterile filtration of injectables, purification of active pharmaceutical ingredients (APIs), filtration of cell culture media, and the production of ultra-pure water for critical laboratory and manufacturing processes. Compliance with cGMP standards and ensuring product integrity and patient safety are non-negotiable for these customers. Similarly, the food and beverage sector extensively employs these filters for critical applications such as beer and wine clarification, juice filtration, dairy product processing, and ensuring the microbiological stability of liquid foodstuffs to extend shelf life and maintain consistent taste and quality.

Furthermore, chemical and petrochemical plants are significant buyers, deploying pleated membrane filters for applications like catalyst recovery, solvent purification, clarification of intermediates, and the separation of desired chemical products from reaction mixtures, all of which are vital for process efficiency and product purity. The oil and gas sector utilizes these membranes for filtering injection water to prevent reservoir damage, treating produced water prior to discharge or reuse, and protecting sensitive downstream equipment from particulate contamination in refining operations. Beyond these major industries, other significant potential customers include electronics manufacturers that demand ultra-pure water for semiconductor fabrication to prevent microscopic defects, power generation facilities for critical boiler feed water treatment to prevent scaling and corrosion, and a variety of general industrial applications requiring particle removal from hydraulic fluids, coolants, and compressed air. The indispensable nature of high-efficiency filtration across these diverse sectors underpins the consistent and growing demand from this broad range of potential customers, driving continuous innovation and market expansion for pleated membrane technologies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 2.15 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Pall Corporation, Sartorius AG, Merck KGaA, 3M Company, Parker Hannifin Corporation, Donaldson Company, Inc., GEA Group AG, Porvair Filtration Group, Amazon Filters Ltd., Meissner Filtration Products, Inc., Critical Process Filtration, Inc., Sterlitech Corporation, Alfa Laval, Pentair plc, Evoqua Water Technologies LLC, Veolia Water Technologies, Suez, Koch Separation Solutions, Cobetter Filtration Equipment Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pleated Membrane Filtration Market Key Technology Landscape

The technological landscape of the Pleated Membrane Filtration Market is characterized by relentless innovation, driven by an imperative to enhance filtration efficiency, prolong membrane lifespan, reduce operational costs, and meet increasingly stringent regulatory and performance demands. A paramount area of focus is the continuous development of advanced membrane materials. Researchers are actively exploring novel polymeric compounds such as modified polyethersulfone (PES), polyvinylidene fluoride (PVDF), and even ceramic or metallic membranes that offer superior chemical and thermal resistance, enhanced mechanical strength, and more precisely controlled pore size distributions. The integration of nanotechnology is a burgeoning field, leading to the development of mixed-matrix membranes incorporating nanomaterials like carbon nanotubes, graphene oxide, or metal-organic frameworks (MOFs) to impart advanced properties such as improved anti-fouling characteristics, higher flux rates, and enhanced selectivity for specific contaminants, effectively addressing persistent challenges like biofouling and inorganic scaling that plague conventional membranes.

Beyond the fundamental material science, significant technological advancements are continually being made in membrane module design and the sophistication of manufacturing processes. Optimization of pleating patterns, geometry, and packing density is crucial for maximizing the effective filtration area within a given cartridge footprint, leading to higher flow rates and significantly improved dirt-holding capacities. Innovations in automated manufacturing techniques, including advanced ultrasonic welding, precise thermal bonding, and innovative sealing methods, ensure the structural integrity of the filter cartridges and critically prevent bypass leakage, which is paramount for maintaining filtration efficiency and product purity. Furthermore, the development and application of advanced anti-fouling coatings and innovative surface modification technologies are key areas of R&D. These solutions chemically or physically alter the membrane surface to reduce the adhesion of foulants, thereby dramatically extending membrane operational life, minimizing the frequency and intensity of cleaning-in-place (CIP) cycles, and consequently reducing associated downtime and chemical consumption.

Another pivotal aspect of the evolving technology landscape is the increasing integration of smart filtration systems, heavily influenced by the principles of Industry 4.0 and the Industrial Internet of Things (IIoT). This involves embedding sophisticated sensors, implementing advanced automation, and integrating digital control systems to enable real-time monitoring of critical filtration parameters such as pressure drop, flow rates, temperature, and permeate quality. These intelligent systems leverage data analytics and machine learning algorithms to provide predictive maintenance alerts, optimize backwashing and cleaning cycles, and offer comprehensive data for process analytics and optimization. Energy efficiency is also a major driver of technological development, with ongoing efforts focused on designing filtration systems that operate at lower transmembrane pressures or with reduced energy consumption for pumping, aeration, and cleaning operations. These integrated and intelligent systems not only enhance operational reliability, efficiency, and safety but also contribute significantly to a more sustainable, cost-effective, and environmentally responsible filtration process, aligning perfectly with broader industry trends towards smart manufacturing, resource optimization, and sustainable environmental stewardship.

Regional Highlights

- North America: This region represents a mature yet continuously evolving market, characterized by highly stringent regulatory frameworks governing water quality, industrial emissions, and pharmaceutical manufacturing, which consistently drive the demand for high-performance and compliant filtration solutions. The presence of a robust pharmaceutical and biotechnology sector, along with significant investments in research and development and a strong emphasis on technological innovation, ensures a sustained and early adoption of advanced pleated membrane technologies. The market in North America also benefits from a profound focus on sustainability, resource recovery, and environmental protection initiatives, spurring demand for eco-friendly, energy-efficient, and highly reliable filtration systems capable of meeting complex industrial demands and contributing to circular economy principles. Major players often engage in strategic partnerships and acquisitions to expand their market reach and technological capabilities.

- Europe: Europe stands as another well-established and technologically advanced market for pleated membrane filtration, with a strong emphasis on environmental protection, particularly concerning water and wastewater treatment, and a leading global position in pharmaceutical, food & beverage, and chemical manufacturing. Countries like Germany, France, the UK, and Italy are significant contributors to market revenue, driven by a culture of technological advancement, proactive environmental policies, and a strong impetus towards adopting state-of-the-art filtration solutions for both industrial and municipal applications. The region's focus on sustainable development and adherence to strict EU directives propel continuous innovation in membrane materials and system designs, favoring solutions that offer high efficiency, energy savings, and minimal environmental impact.

- Asia Pacific (APAC): Positioned as the fastest-growing region in the pleated membrane filtration market, APAC's expansion is fundamentally propelled by rapid industrialization, burgeoning urbanization, and a colossal population base, particularly across economic powerhouses like China, India, Japan, South Korea, and Southeast Asian nations. The escalating demand for clean water resources due to population growth and industrial expansion, coupled with expanding manufacturing capabilities in key sectors suchs as pharmaceuticals, food processing, chemicals, and electronics, represents a colossal market opportunity. Governments in the region are making substantial investments in water infrastructure, pollution control, and industrial upgrading, which directly fuel the adoption of advanced filtration technologies to address critical environmental concerns and ensure public health.

- Latin America: This region is experiencing steady and consistent growth in the pleated membrane filtration market, primarily driven by increasing investments in industrial and municipal water and wastewater treatment infrastructure, particularly in economically developing countries such as Brazil, Mexico, Argentina, and Chile. The expansion of resource-intensive industries like mining, agriculture, food and beverage processing, and chemical manufacturing further contributes significantly to the demand for efficient and reliable filtration solutions. Economic development initiatives, coupled with a growing awareness of pressing water scarcity issues and the need for improved public health standards, are stimulating the widespread adoption of pleated membrane systems for various purification and separation applications across both industrial and commercial sectors.

- Middle East and Africa (MEA): Emerging as a critically significant market, the MEA region is characterized by severe water scarcity challenges, which necessitate substantial investments in advanced water treatment technologies, including large-scale desalination and wastewater reuse projects. The substantial growth of the region's oil and gas sector, coupled with ongoing industrial development, urbanization, and a rapidly increasing population, is fueling a strong demand for high-efficiency filtration solutions for process water, produced water, and municipal supplies. Governments across the Gulf Cooperation Council (GCC) countries and parts of Africa are prioritizing water security and industrial diversification, leading to increased adoption of pleated membrane systems for diverse applications, including potable water production, industrial process purification, and environmental compliance.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pleated Membrane Filtration Market.- Pall Corporation

- Sartorius AG

- Merck KGaA

- 3M Company

- Parker Hannifin Corporation

- Donaldson Company, Inc.

- GEA Group AG

- Porvair Filtration Group

- Amazon Filters Ltd.

- Meissner Filtration Products, Inc.

- Critical Process Filtration, Inc.

- Sterlitech Corporation

- Alfa Laval

- Pentair plc

- Evoqua Water Technologies LLC

- Veolia Water Technologies

- Suez

- Koch Separation Solutions

- Cobetter Filtration Equipment Co., Ltd.

- Kumera Corporation

Frequently Asked Questions

What is pleated membrane filtration?

Pleated membrane filtration is an advanced fluid separation technology that utilizes a filter membrane meticulously folded into a series of pleats within a compact cartridge. This unique design significantly increases the effective surface area for filtration, allowing for higher flow rates, extended filter life, and superior dirt-holding capacity compared to flat sheet or depth filters. It is highly effective for removing particles, microorganisms, and other contaminants from various liquids and gases, ensuring high-purity output for critical industrial and commercial applications.

What are the main applications of pleated membrane filters?

The primary applications for pleated membrane filters are widespread and critical across numerous industries. These include water and wastewater treatment for purification, disinfection, and effluent compliance; the food and beverage industry for clarification, sterile filtration, and extending product shelf-life; pharmaceutical and biotechnology sectors for critical sterile filtration of injectables, cell culture media, and API purification; chemical and petrochemical processing for solvent recovery and product clarification; and the oil and gas industry for produced water treatment and protection of sensitive equipment. Their versatility makes them indispensable for achieving stringent purity standards.

What are the key benefits of using pleated membranes in industrial processes?

The key benefits of employing pleated membranes in industrial processes are substantial, contributing significantly to operational efficiency and cost-effectiveness. These advantages include exceptionally high flow rates, which lead to reduced processing times and increased throughput; an extended operational lifespan due to their large surface area for contaminant retention, resulting in fewer filter change-outs and lower labor costs; superior dirt-holding capacity; and robust construction that ensures consistent, reliable performance even in demanding environments. Ultimately, these features lead to enhanced product quality, reduced downtime, and lower overall total cost of ownership.

How does pleated membrane filtration contribute to sustainability and environmental protection?

Pleated membrane filtration contributes significantly to sustainability and environmental protection by enabling more efficient resource utilization and pollution control. In water treatment, it facilitates the production of clean potable water, aids in wastewater reuse, and ensures compliant discharge, thereby conserving freshwater resources and protecting ecosystems. Its high efficiency reduces the need for chemical additives in purification processes and minimizes waste volumes, supporting circular economy principles. By removing pollutants effectively, it helps industries meet strict environmental regulations, reducing their ecological footprint and fostering more sustainable operational practices across various sectors.

What is the future outlook for innovation in pleated membrane filtration technology?

The future outlook for innovation in pleated membrane filtration technology is highly promising, driven by continuous advancements in materials science, module design, and smart systems integration. Key areas of innovation include the development of next-generation membrane materials with enhanced anti-fouling properties, greater chemical resistance, and improved selectivity. There will be increased focus on optimizing pleating geometries and integrating nanotechnology for superior performance. Furthermore, the adoption of AI, IoT, and automation will lead to more intelligent, energy-efficient, and self-optimizing filtration systems capable of real-time monitoring and predictive maintenance, ensuring even greater operational reliability and cost-effectiveness.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager