Plexiglass Boat Windshields Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439704 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Plexiglass Boat Windshields Market Size

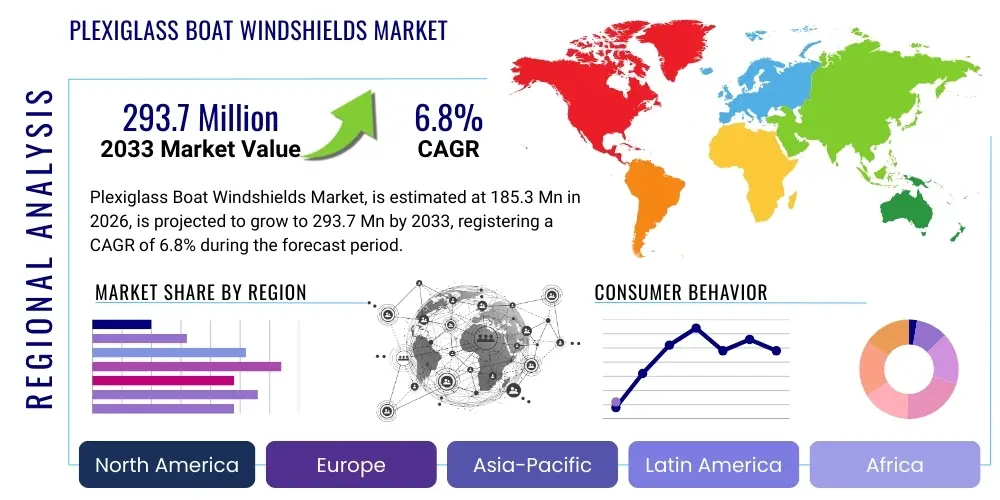

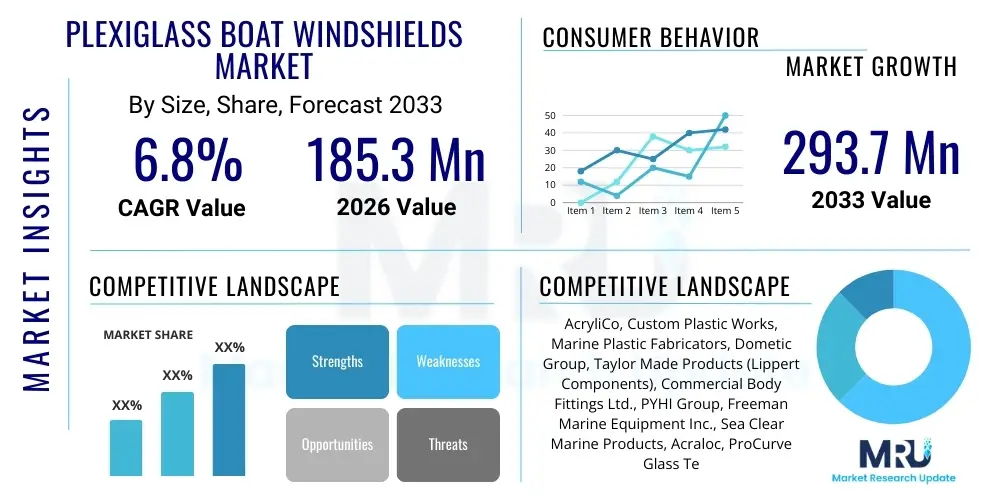

The Plexiglass Boat Windshields Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $185.3 million in 2026 and is projected to reach $293.7 million by the end of the forecast period in 2033.

Plexiglass Boat Windshields Market introduction

The Plexiglass Boat Windshields Market encompasses the manufacturing, distribution, and sales of windshields made from polymethyl methacrylate (PMMA), commonly known as plexiglass or acrylic, specifically designed for marine vessels. These windshields are crucial components, providing protection from wind, spray, and UV radiation while ensuring clear visibility for navigation. Plexiglass is favored in the marine industry due to its superior optical clarity, lightweight nature, impact resistance, and ease of fabrication compared to traditional glass, making it an ideal material for a wide range of boat types from small recreational craft to large yachts.

Major applications for plexiglass boat windshields span across the diverse boating spectrum, including recreational powerboats, sailboats, fishing vessels, pontoon boats, and commercial watercraft. The material's versatility allows for complex curves and custom designs, which are increasingly sought after for both aesthetic appeal and aerodynamic efficiency. These windshields offer significant benefits such as enhanced safety through shatter resistance, improved fuel efficiency due to reduced weight, and longevity aided by UV stability that prevents yellowing and degradation over time. Furthermore, the material's repairability, scratch resistance (when coated), and cost-effectiveness in certain applications contribute to its widespread adoption.

Driving factors for market growth are intricately linked to the overall health of the global marine industry, particularly the robust expansion of recreational boating and marine tourism. Advancements in material science, leading to more durable and scratch-resistant plexiglass formulations, further bolster demand. The growing consumer preference for customizable boat features, coupled with a focus on lightweight construction to optimize performance and fuel economy, also actively propels the adoption of plexiglass solutions. These combined elements underscore the material's strategic importance within the evolving boat manufacturing landscape, driving continuous innovation and market expansion.

Plexiglass Boat Windshields Market Executive Summary

The Plexiglass Boat Windshields Market is experiencing significant momentum, driven by a confluence of evolving business trends and increasing demand across various marine segments. Key business trends indicate a strong shift towards customization and personalization, with boat owners and manufacturers seeking bespoke windshield designs that offer both enhanced functionality and aesthetic integration. There is also a notable emphasis on material innovation, focusing on developing plexiglass formulations with improved scratch resistance, anti-glare properties, and enhanced UV protection to extend product lifespan and maintain optical clarity. Furthermore, sustainability is emerging as a critical consideration, prompting research into recyclable plexiglass options and more energy-efficient manufacturing processes.

Regional trends reveal distinct patterns of growth and demand. North America and Europe, with their well-established recreational boating cultures and significant coastline access, continue to represent major market shares, characterized by a demand for premium, high-performance windshields for luxury yachts and powerboats. The Asia Pacific region is demonstrating the fastest growth, fueled by rising disposable incomes, expanding middle classes, and government initiatives promoting marine tourism and infrastructure development, particularly in coastal countries like China, Australia, and Southeast Asian nations. Latin America and the Middle East and Africa regions are also witnessing nascent growth, driven by increasing investment in tourism and maritime leisure activities, albeit from a smaller base.

Segment trends within the market highlight diversified consumer needs. The recreational boat segment remains the largest end-user, with a consistent demand for both flat and curved windshields across various boat sizes. The yacht segment exhibits a strong preference for complex, custom-molded, and aesthetically integrated plexiglass solutions, often incorporating advanced coatings. The aftermarket segment is growing steadily, driven by the need for replacement windshields due to wear, damage, or the desire for upgrades, offering significant opportunities for independent fabricators and distributors. This comprehensive overview points to a dynamic market poised for sustained expansion, underpinned by innovation and regional economic development.

AI Impact Analysis on Plexiglass Boat Windshields Market

Common user questions regarding AI's impact on the Plexiglass Boat Windshields Market often revolve around how artificial intelligence can optimize design and manufacturing processes, improve material performance, and enhance the overall user experience on boats. Users are keen to understand if AI can lead to more complex and aerodynamic windshield geometries, predict material failures or maintenance needs, or even integrate smart functionalities directly into the windshield itself. There's also curiosity about AI's role in supply chain management for plexiglass raw materials and finished products, and how it might personalize options for boat owners, leading to a highly efficient, responsive, and innovative market landscape.

- AI-driven generative design can accelerate the development of complex, aerodynamic, and aesthetically pleasing windshield shapes, optimizing material usage and structural integrity.

- Predictive analytics powered by AI can forecast material degradation, scratch potential, or UV damage, enabling proactive maintenance and extending windshield lifespan.

- AI-enhanced manufacturing processes, such as robotic cutting and thermoforming, can improve precision, reduce waste, and increase production efficiency for custom windshields.

- Smart windshields integrating AI could feature dynamic tinting based on light conditions, augmented reality overlays for navigation, or sensors for environmental monitoring.

- Supply chain optimization using AI algorithms can manage inventory, predict demand fluctuations, and streamline logistics for raw materials and finished plexiglass products, reducing lead times and costs.

- AI can analyze user preferences and design trends to offer highly personalized customization options, from tint levels to integrated displays, improving customer satisfaction and market responsiveness.

- Quality control can be significantly enhanced through AI-powered visual inspection systems, detecting minute flaws or inconsistencies in plexiglass during production, ensuring superior product quality.

DRO & Impact Forces Of Plexiglass Boat Windshields Market

The Plexiglass Boat Windshields Market is influenced by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces shaping its trajectory. A primary driver is the sustained growth in the global recreational boating industry, fueled by increasing leisure time, disposable incomes, and a cultural shift towards outdoor activities. The inherent advantages of plexiglass, such as its lightweight nature, superior optical clarity, impact resistance, and design flexibility, make it an attractive alternative to traditional glass, further stimulating demand. Additionally, continuous material science advancements are leading to more durable, scratch-resistant, and UV-stable plexiglass formulations, enhancing product performance and consumer confidence.

However, the market faces several notable restraints. Intense competition from alternative materials, particularly tempered glass, which offers higher scratch resistance and rigidity, poses a significant challenge. Fluctuations in raw material prices, specifically for petroleum-derived PMMA, can impact manufacturing costs and profit margins. Furthermore, plexiglass is inherently more prone to scratching than glass, requiring specialized coatings or careful maintenance, which can be a point of concern for some consumers. The initial perception of plexiglass as less premium than glass, despite its functional advantages, also represents a market hurdle that needs to be overcome through effective marketing and education.

Opportunities for growth are abundant, particularly in the realm of advanced customization and integration with smart boat technologies. The increasing demand for bespoke boat designs presents a lucrative avenue for specialized plexiglass fabricators to offer unique shapes, tints, and sizes. The integration of features such as anti-glare coatings, defogging elements, and even augmented reality displays directly into windshields opens new product development possibilities. Furthermore, the expansion of marine tourism and charter services globally creates a consistent demand for new boat construction and aftermarket replacements. The market is also subject to impact forces such as the bargaining power of buyers (boat manufacturers demanding competitive pricing and high quality) and suppliers (raw material providers influencing costs), the potential threat of new entrants due to technological advancements or low barriers to entry for basic fabrication, and the ever-present threat of substitute materials. Competitive rivalry among existing manufacturers drives innovation and efficiency, ultimately benefiting the end-user.

Segmentation Analysis

The Plexiglass Boat Windshields Market is extensively segmented to reflect the diverse needs and applications within the marine industry. This segmentation allows for a granular understanding of market dynamics, consumer preferences, and strategic opportunities across various product types, boat categories, and distribution channels. Analyzing these segments provides critical insights into areas of high growth, emerging trends, and competitive landscapes, enabling stakeholders to tailor their product offerings and market strategies effectively.

- By Boat Type

- Recreational Boats (e.g., Runabouts, Deck Boats, Bowriders, Wakeboard Boats)

- Fishing Boats (e.g., Bass Boats, Center Consoles, Walleye Boats)

- Yachts (e.g., Motor Yachts, Sailing Yachts, Superyachts)

- Commercial Vessels (e.g., Patrol Boats, Workboats, Passenger Ferries)

- Pontoon Boats

- Personal Watercraft (PWC)

- By Product Type

- Flat Windshields

- Curved Windshields (Single Curve, Double Curve)

- Tinted Windshields (Various Shades)

- Coated Windshields (Scratch-resistant, Anti-glare, UV-protected, Hydrophobic)

- Custom/Molded Windshields

- Folding/Walk-Through Windshields

- By Material Thickness

- Less than 1/4 inch (6mm)

- 1/4 inch to 3/8 inch (6mm - 9.5mm)

- More than 3/8 inch (9.5mm)

- By Distribution Channel

- Original Equipment Manufacturers (OEMs)

- Aftermarket (Replacement & Upgrade)

- Specialty Marine Retailers

- Online Retailers

- Distributors/Wholesalers

- Custom Fabricators

Value Chain Analysis For Plexiglass Boat Windshields Market

The value chain for the Plexiglass Boat Windshields Market is a complex network involving several key stages, from raw material sourcing to the end-user. Upstream analysis begins with the suppliers of polymethyl methacrylate (PMMA) resins and sheets, which form the foundational material. These raw material manufacturers are typically large chemical companies that produce acrylic polymers through a sophisticated chemical process. The quality, purity, and availability of these materials directly impact the cost and performance characteristics of the finished windshields. Other upstream suppliers include those providing specialized coatings (e.g., scratch-resistant, UV protective), tints, and hardware components like frames and seals.

The midstream of the value chain involves the manufacturing and fabrication of the actual windshields. This includes processes such as cutting the plexiglass sheets to shape using CNC machinery, thermoforming for curved designs, edge finishing, and the application of various coatings. Manufacturers may specialize in either producing standard windshields for a broad range of boat models or focus on custom, bespoke solutions for high-end yachts or specific OEM requirements. The efficiency and technological sophistication of these manufacturing processes are critical for maintaining competitive pricing, ensuring product quality, and meeting demand for intricate designs.

Downstream analysis covers the distribution channels, which are predominantly split between direct and indirect routes. Direct distribution often involves sales to Original Equipment Manufacturers (OEMs), where plexiglass windshield manufacturers supply directly to boat builders for integration into new vessel constructions. Indirect channels are crucial for the aftermarket segment, encompassing specialty marine retailers, wholesale distributors, online platforms, and independent marine repair shops and custom fabricators. These channels cater to boat owners needing replacement windshields, upgrades, or custom solutions, ensuring widespread availability and service. The effectiveness of these distribution networks is paramount for market penetration and customer reach, linking manufacturers to a diverse base of end-users.

Plexiglass Boat Windshields Market Potential Customers

The potential customers for plexiglass boat windshields are diverse, ranging from large-scale boat manufacturers to individual boat owners seeking upgrades or repairs. Original Equipment Manufacturers (OEMs) form a significant customer base, as they require high volumes of customized or standardized windshields for their new boat models. These manufacturers include producers of recreational powerboats, sailboats, fishing vessels, and luxury yachts, all of whom prioritize factors such as aesthetic integration, durability, weight efficiency, and compliance with marine safety standards in their component sourcing decisions. Strong relationships with OEMs are crucial for sustained, large-volume business in this market.

Beyond new boat construction, a substantial portion of the market caters to the aftermarket. This segment primarily comprises existing boat owners who require replacement windshields due to damage from impact, prolonged exposure to harsh marine environments leading to scratching or hazing, or simply a desire for aesthetic or functional upgrades. These customers are typically reached through marine parts retailers, specialized online stores, and local marine repair and customization shops. Their purchasing decisions are often driven by factors like availability, ease of installation, cost-effectiveness, and the opportunity to enhance their boat's appearance or performance.

Furthermore, commercial marine operators, including charter companies, fishing fleets, and workboat operators, represent another important customer group. While their volume might be lower than recreational boating, their demand for robust, reliable, and often custom-sized windshields for harsh operating conditions is consistent. Marine service providers, independent boat builders specializing in custom projects, and government agencies operating patrol or rescue vessels also contribute to the customer landscape. Each of these customer categories has unique requirements regarding product specifications, durability, and service, necessitating a tailored approach from manufacturers and distributors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $185.3 million |

| Market Forecast in 2033 | $293.7 million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | AcryliCo, Custom Plastic Works, Marine Plastic Fabricators, Dometic Group, Taylor Made Products (Lippert Components), Commercial Body Fittings Ltd., PYHI Group, Freeman Marine Equipment Inc., Sea Clear Marine Products, Acraloc, ProCurve Glass Technology, Spartech LLC, Plaskolite LLC, Cast Acrylics, Bristol Plastic Products Ltd., Marine Parts & Supply, Bayforms, Acrylic Design, Plastics Unlimited, Port Supply (West Marine Pro) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plexiglass Boat Windshields Market Key Technology Landscape

The Plexiglass Boat Windshields Market is underpinned by a dynamic technological landscape, continuously evolving to meet the demands for enhanced performance, aesthetics, and durability. Key manufacturing technologies include advanced polymer extrusion and cast acrylic sheet production, which determine the fundamental quality, optical clarity, and structural integrity of the plexiglass material. Precision CNC (Computer Numerical Control) cutting machines are essential for accurately shaping sheets into complex geometries with minimal material waste, facilitating custom designs and ensuring perfect fits for various boat models. This allows for intricate cutouts, precise edge finishing, and consistent product dimensions across production batches, crucial for both OEM and aftermarket applications.

Thermoforming is another critical technology, particularly for creating curved or three-dimensional windshield designs. This process involves heating plexiglass sheets to a pliable temperature and then molding them over a form or into a vacuum mold to achieve the desired curvature. Advances in thermoforming, including precise temperature control and multi-axis forming capabilities, enable the production of highly complex, aerodynamically efficient, and aesthetically pleasing windshields that were once challenging to achieve. This technology is vital for modern boat designs that emphasize sleek lines and integrated structures, ensuring the windshield seamlessly blends with the vessel's overall appearance.

Furthermore, coating technologies play a pivotal role in enhancing the functional properties of plexiglass boat windshields. Specialized hard coatings are applied to significantly improve scratch resistance, a common concern with acrylics. UV-protective coatings are critical for preventing yellowing and degradation from prolonged sun exposure in marine environments, thereby extending the product's lifespan and maintaining optical clarity. Other advanced coatings include anti-glare, anti-fog, and hydrophobic treatments, which improve visibility and safety under various weather conditions. These technological advancements not only address inherent material limitations but also contribute to the premiumization of plexiglass windshields, offering boat owners superior performance and longevity.

Regional Highlights

The global Plexiglass Boat Windshields Market exhibits distinct regional dynamics driven by varying levels of marine activity, economic development, and consumer preferences. North America stands as a dominant force, particularly due to the robust recreational boating culture in the United States and Canada. The region benefits from extensive coastlines, numerous inland waterways, and a high disposable income among its populace, leading to a strong demand for diverse boat types and, consequently, plexiglass windshields for new builds and extensive aftermarket activity for repairs and upgrades. Significant innovation in marine manufacturing also originates from this region, driving demand for advanced plexiglass solutions.

Europe represents another mature and significant market, with countries like Germany, France, the UK, Italy, and Spain boasting strong shipbuilding industries and a rich tradition of sailing and motor yachting. The demand here is often characterized by a preference for high-quality, custom-engineered windshields for luxury yachts and sophisticated sailing vessels, alongside a steady market for smaller recreational craft. Environmental regulations and a focus on sustainable manufacturing practices also influence material and production choices in this region, pushing for more eco-friendly plexiglass options and efficient processes.

The Asia Pacific (APAC) region is projected to be the fastest-growing market, propelled by rapidly expanding economies in countries such as China, Japan, Australia, and South Korea. Rising disposable incomes, increasing interest in marine tourism, and government investments in coastal infrastructure and recreational facilities are fueling significant growth in boat ownership and shipbuilding. While traditionally a manufacturing hub, APAC is increasingly becoming a major consumer market for marine products, including plexiglass boat windshields, with a strong emphasis on both cost-effectiveness and emerging demand for premium features. Latin America and the Middle East and Africa (MEA) are emerging markets, driven by developing tourism sectors and increasing private wealth, leading to a gradual but steady increase in demand for marine leisure activities and associated components.

- North America: Large established market, high recreational boating participation, strong aftermarket demand, innovation in marine design. Key countries: USA, Canada.

- Europe: Mature market, strong luxury yacht segment, emphasis on quality and custom design, increasing focus on sustainability. Key countries: Germany, UK, Italy, France, Spain.

- Asia Pacific (APAC): Fastest growing market, rising disposable incomes, expanding marine tourism, increasing shipbuilding activity. Key countries: China, Japan, Australia, South Korea.

- Latin America: Emerging market, growing interest in marine leisure, developing tourism infrastructure. Key countries: Brazil, Mexico.

- Middle East and Africa (MEA): Nascent market, driven by luxury tourism investments, development of coastal resorts, growing private yacht ownership. Key countries: UAE, Saudi Arabia, South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plexiglass Boat Windshields Market.- AcryliCo

- Custom Plastic Works

- Marine Plastic Fabricators (MPF)

- Dometic Group

- Taylor Made Products (Lippert Components)

- Commercial Body Fittings Ltd.

- PYHI Group

- Freeman Marine Equipment Inc.

- Sea Clear Marine Products

- Acraloc

- ProCurve Glass Technology

- Spartech LLC

- Plaskolite LLC

- Cast Acrylics

- Bristol Plastic Products Ltd.

- Marine Parts & Supply

- Bayforms

- Acrylic Design

- Plastics Unlimited

- Port Supply (West Marine Pro)

- Sailing Services

- Sea Ray Boats (as an OEM end-user with internal fabrication capabilities)

- Boston Whaler (as an OEM end-user with internal fabrication capabilities)

- Whale Seeker Marine

- Clear View Plastics

Frequently Asked Questions

What are the primary advantages of plexiglass over traditional glass for boat windshields?

Plexiglass (PMMA) offers several key advantages for boat windshields, including significantly lighter weight, which improves fuel efficiency and performance; superior impact resistance, reducing the risk of shattering upon collision; excellent optical clarity for unobstructed views; and greater design flexibility, allowing for complex curves and custom shapes. It also exhibits good UV resistance to prevent yellowing over time and can be more cost-effective for certain applications and custom fabrications.

How durable are plexiglass boat windshields in harsh marine environments?

Plexiglass boat windshields are designed for durability in marine environments, offering good resistance to saltwater, UV radiation, and temperature fluctuations. While naturally more prone to scratching than glass, advancements in hard coatings significantly improve scratch resistance, extending their lifespan. With proper maintenance, including using non-abrasive cleaners and specialized polishes, plexiglass windshields can maintain their clarity and structural integrity for many years, providing reliable performance and protection.

What types of boats commonly use plexiglass windshields?

Plexiglass windshields are widely used across various boat types. They are highly common in recreational boats such as runabouts, bowriders, pontoon boats, and fishing boats due to their lightweight and versatility. Plexiglass is also favored for larger vessels like yachts and commercial vessels, particularly for custom-molded designs that require complex curvatures or specific aesthetic integration. Its adaptability makes it suitable for almost any marine application where visibility, impact resistance, and design flexibility are paramount.

Can existing boat windshields be upgraded to a plexiglass material?

Yes, existing boat windshields can often be upgraded or replaced with plexiglass. This is a common practice in the aftermarket segment, where boat owners may seek to replace damaged glass windshields with a lighter, more impact-resistant plexiglass alternative, or upgrade existing acrylic windshields with newer, coated versions for enhanced scratch resistance and UV protection. Custom fabricators and marine repair shops frequently offer these services, ensuring a precise fit and optimal performance for the specific boat model.

What factors should be considered when choosing a plexiglass boat windshield?

When selecting a plexiglass boat windshield, several factors are crucial. Consider the material thickness, which impacts strength and rigidity, especially for larger boats. Evaluate coating options such as scratch-resistant, anti-glare, or UV-protective treatments to enhance durability and visibility. The design and curvature should match the boat's aesthetics and aerodynamics. Ensure compliance with any relevant marine safety standards. Finally, consider the reputation of the manufacturer or fabricator for quality, fit, and reliable performance in marine conditions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager