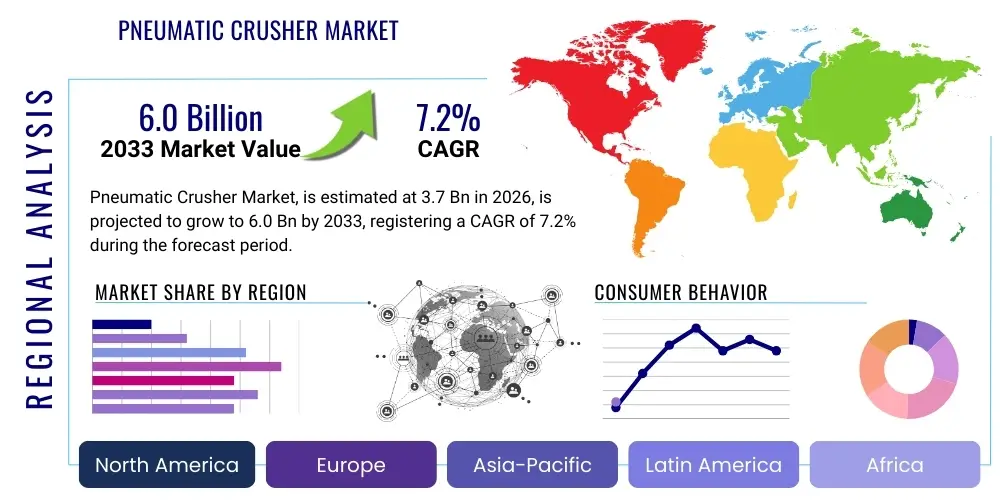

Pneumatic Crusher Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439333 | Date : Jan, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Pneumatic Crusher Market Size

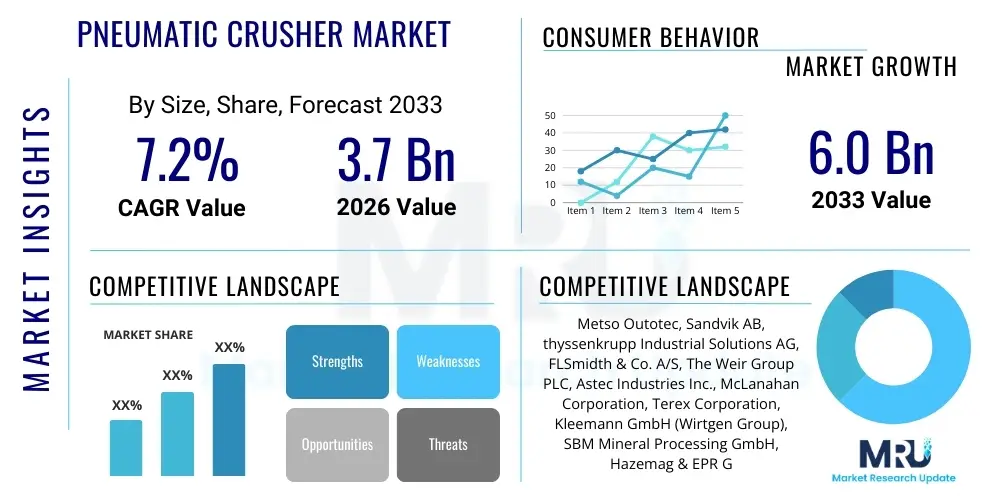

The Pneumatic Crusher Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2026 and 2033. The market is estimated at USD 3.7 Billion in 2026 and is projected to reach USD 6.0 Billion by the end of the forecast period in 2033.

Pneumatic Crusher Market introduction

The pneumatic crusher market encompasses machinery that utilizes compressed air to generate the force required for breaking down various materials into smaller, manageable pieces. These crushers are integral to industries demanding precise and efficient material reduction, offering a versatile solution for processing rocks, minerals, concrete, and recycled materials. Unlike hydraulic or mechanical crushers, pneumatic systems often provide specific advantages in terms of control, operational safety, and maintenance requirements, leveraging the power of air pressure to deliver impactful crushing actions. The underlying principle involves the conversion of pneumatic energy into mechanical force, driving crushing elements such as jaws, cones, or impact plates to disintegrate feed material.

Pneumatic crushers are employed across a broad spectrum of applications, primarily in the construction, mining, demolition, and recycling sectors. In construction, they are vital for preparing aggregates for concrete and asphalt, as well as for site clearance and demolition projects where precise material sizing is crucial. The mining industry relies on these crushers for primary, secondary, and tertiary crushing of ores and minerals, optimizing downstream processing. Furthermore, their application in recycling facilities for crushing concrete, asphalt, and other construction and demolition waste contributes significantly to sustainable resource management and waste reduction efforts. The adaptability of pneumatic crushing technology allows for deployment in both stationary plant configurations and mobile setups, catering to diverse operational scales and site requirements.

The market's growth is predominantly driven by increasing global infrastructure development, rapid urbanization, and a surging demand for aggregates and recycled materials. Benefits such as enhanced operational efficiency, reduced dust emissions, and improved safety due to less complex mechanical systems are further accelerating adoption. The precision offered by pneumatic controls allows for finer adjustments in particle size, which is a critical advantage in applications requiring specific material characteristics. Additionally, the continuous emphasis on environmental sustainability and the circular economy further bolsters the demand for efficient crushing solutions that facilitate material recycling and resource recovery, positioning pneumatic crushers as a key technology in modern industrial processes.

Pneumatic Crusher Market Executive Summary

The pneumatic crusher market is experiencing robust growth, propelled by significant business trends that prioritize operational efficiency, automation, and environmental responsibility. Key among these trends is the increasing integration of smart technologies, including IoT and AI, to enhance crusher performance, enable predictive maintenance, and optimize energy consumption. There is a strong movement towards modular and mobile crushing solutions that offer flexibility and reduce transportation costs, particularly beneficial for temporary or remote project sites. Furthermore, the market is witnessing a surge in demand for crushers capable of handling diverse materials, driven by the expansion of recycling initiatives and the need for versatile processing equipment across industries. Strategic alliances, mergers, and acquisitions are also prominent, as companies seek to expand their product portfolios and geographical reach.

Regional trends indicate that Asia Pacific continues to be a dominant force in the market, primarily fueled by massive infrastructure development projects, rapid urbanization, and an expanding mining sector in countries like China, India, and Southeast Asian nations. North America and Europe, while more mature markets, are characterized by a strong emphasis on replacing aging machinery with advanced, more efficient, and environmentally compliant pneumatic crushers. These regions also lead in the adoption of automation and digitalization within crushing operations. Latin America and the Middle East and Africa regions are showing promising growth, driven by investments in mining, oil & gas infrastructure, and large-scale construction projects, albeit with varying levels of technological adoption and market maturity.

Segmentation trends highlight distinct dynamics across different types of pneumatic crushers, mobility options, and applications. The stationary crusher segment remains foundational for large-scale, long-term operations, while the mobile crusher segment is experiencing accelerated growth due to its versatility and cost-effectiveness for various construction and demolition projects. By application, the construction and aggregates sectors represent the largest share, with significant demand also emanating from the mining and recycling industries. There's a growing preference for crushers that offer higher throughput and energy efficiency, coupled with advanced features for remote monitoring and control. Manufacturers are increasingly focusing on developing application-specific crushing solutions and offering comprehensive aftermarket services to meet evolving customer needs and maintain competitive advantage.

AI Impact Analysis on Pneumatic Crusher Market

User inquiries regarding AI's impact on the pneumatic crusher market consistently revolve around themes of operational efficiency, predictive maintenance, automation, safety enhancements, and data-driven decision-making. Users are keen to understand how AI can reduce downtime, optimize throughput, improve material quality consistency, and contribute to more sustainable crushing practices. Concerns also include the initial investment costs, the complexity of integrating AI systems with existing machinery, and the need for skilled personnel to manage and interpret AI-generated insights. Expectations are high for AI to revolutionize the sector by enabling smarter, more autonomous, and ultimately more profitable crushing operations, moving beyond traditional reactive maintenance to proactive, data-informed management of assets.

- AI-driven predictive maintenance scheduling reduces unexpected breakdowns and extends equipment lifespan by analyzing sensor data for early fault detection.

- Optimized crusher settings and throughput achieved through real-time data analysis and machine learning algorithms, maximizing productivity and energy efficiency.

- Enhanced operational safety through AI-powered monitoring of equipment performance and environmental conditions, identifying potential hazards before they escalate.

- Improved material quality control and consistent output size through AI-assisted adjustments to crushing parameters based on material feedback.

- Automation of routine tasks and remote operation capabilities through AI and robotics integration, reducing the need for manual intervention in hazardous environments.

- Data analytics platforms leveraging AI for comprehensive performance insights, enabling strategic planning and continuous process improvement across crushing operations.

DRO & Impact Forces Of Pneumatic Crusher Market

The pneumatic crusher market is profoundly shaped by a confluence of driving factors, restraining elements, and emerging opportunities, all interacting to create a dynamic landscape. Key drivers include the relentless pace of global infrastructure development, particularly in emerging economies, which necessitates vast quantities of aggregates and processed materials. Urbanization trends further amplify the demand for construction materials, directly fueling the need for efficient crushing equipment. The mining industry's continuous quest for higher productivity and lower operational costs also significantly boosts the adoption of advanced crushing solutions. Furthermore, a growing emphasis on recycling construction and demolition waste, driven by environmental regulations and resource scarcity, creates a substantial market for pneumatic crushers capable of processing diverse recycled materials. Technological advancements leading to more energy-efficient and automated crushing systems also act as a strong impetus for market expansion.

However, the market faces several significant restraints that can impede its growth trajectory. The high initial capital investment required for pneumatic crushing equipment can be a barrier for smaller enterprises or those in regions with limited financial resources. Operational costs, including energy consumption and maintenance of specialized pneumatic components, can also be considerable. Stringent environmental regulations concerning noise pollution, dust emissions, and waste management necessitate costly compliance measures and may restrict operational flexibility. The shortage of skilled labor proficient in operating and maintaining sophisticated crushing machinery poses another challenge. Economic uncertainties and fluctuations in commodity prices, particularly in the mining sector, can also lead to delayed investments in new equipment, thereby restraining market growth.

Despite these challenges, numerous opportunities exist for market expansion and innovation. The increasing adoption of smart crushing solutions, integrating IoT, AI, and automation, presents avenues for enhanced efficiency, remote monitoring, and predictive maintenance. Emerging markets, with their ongoing industrialization and infrastructure projects, offer substantial untapped potential. The demand for customized crushing solutions tailored to specific material types and processing requirements is on the rise. Furthermore, the expansion of aftermarket services, including parts supply, maintenance contracts, and equipment upgrades, represents a stable revenue stream for manufacturers. Focus on sustainable crushing practices, such as improved energy efficiency and enhanced recycling capabilities, aligns with global environmental goals and opens new market segments for innovative pneumatic crusher technologies, promising a robust future for the market despite its inherent challenges.

Segmentation Analysis

The pneumatic crusher market is extensively segmented to reflect the diverse applications, operational requirements, and technological variations within the industry. Understanding these segments is crucial for market participants to identify niche opportunities, tailor product offerings, and develop targeted marketing strategies. The primary segmentation categories typically include classification by type of crusher, its mobility, the specific application it serves, the end-user industry, and the stage of crushing in the overall material processing chain. Each segment exhibits unique growth drivers, competitive landscapes, and technological preferences, indicating a highly variegated market structure that caters to a wide array of industrial needs. This multi-faceted segmentation allows for a granular analysis of market dynamics, enabling stakeholders to make informed decisions and optimize their investments in the pneumatic crushing sector.

- By Type

- Jaw Crusher (Pneumatic-assisted)

- Cone Crusher (Pneumatic-assisted)

- Impact Crusher (Pneumatic-assisted)

- Hammer Crusher (Pneumatic-assisted)

- Roll Crusher (Pneumatic-assisted)

- Gyratory Crusher (Pneumatic-assisted)

- By Mobility

- Stationary Crusher

- Mobile Crusher

- Portable Crusher

- By Application

- Mining

- Construction (Road Construction, Building Construction)

- Demolition

- Recycling (C&D Waste, Concrete, Asphalt)

- Aggregates Production

- Mineral Processing

- Other Industrial Applications

- By End-User

- Mining Companies

- Construction Companies

- Aggregate Producers

- Demolition Contractors

- Recycling Facilities

- Government & Municipalities

- By Crushing Stage

- Primary Crushing

- Secondary Crushing

- Tertiary Crushing

- Quaternary Crushing

Value Chain Analysis For Pneumatic Crusher Market

The value chain for the pneumatic crusher market begins with the upstream analysis, which focuses on the sourcing and supply of raw materials and essential components. This stage involves suppliers of high-grade steel alloys for crushing jaws and wear parts, specialized manufacturers of pneumatic cylinders, valves, compressors, and control systems, as well as providers of electrical components and sophisticated automation hardware and software. The quality and reliability of these upstream inputs directly influence the performance, durability, and cost-effectiveness of the final crushing machinery. Strong relationships with technologically advanced and reliable component suppliers are crucial for manufacturers to maintain competitive product offerings and ensure consistent production quality, forming the foundational layer of the entire value chain.

Moving further along the value chain, the manufacturing stage involves the design, assembly, and testing of the pneumatic crushing units, often incorporating advanced engineering techniques and quality control measures. Following manufacturing, the distribution channel plays a pivotal role in connecting these complex machines with the end-users. Distribution can occur through several avenues: direct sales from the manufacturer to large industrial clients, which allows for customized solutions and strong customer relationships; indirect sales via a network of authorized distributors and dealers, who provide regional market access, sales support, and often local maintenance services; and to a lesser extent, through online platforms for parts or smaller components. This network ensures broad market penetration and efficient delivery of equipment to diverse geographical locations and customer segments.

The downstream analysis primarily encompasses the end-users and the critical aftermarket services that support the longevity and operational efficiency of pneumatic crushers. End-users, including mining companies, construction firms, and recycling facilities, leverage these machines for their specific material processing needs. Post-purchase support, comprising installation, commissioning, routine maintenance, spare parts supply, and repair services, is a significant part of the downstream value chain. These services are vital for minimizing downtime, maximizing productivity, and extending the operational life of the equipment. Both direct sales channels often involve manufacturers providing these services directly, while indirect channels rely heavily on the capabilities of distributors and local service providers, highlighting the importance of a well-integrated and responsive service network to sustain customer satisfaction and market loyalty.

Pneumatic Crusher Market Potential Customers

The pneumatic crusher market serves a diverse array of end-users and buyers, spanning multiple heavy industries where material reduction is a fundamental operational requirement. Primary potential customers include large-scale mining companies involved in the extraction and processing of metallic and non-metallic minerals, where pneumatic crushers are crucial for preparing raw ores for further beneficiation. These companies often require robust, high-capacity crushers capable of handling extremely abrasive materials and operating continuously in demanding environments. The drive for efficiency and automation in mining operations makes advanced pneumatic crushers an attractive investment, offering improved throughput and reduced operational costs in the long term for preparing ores and aggregates for various industrial applications.

Another significant segment of potential customers comprises construction companies and aggregate producers. These entities rely on pneumatic crushers for the production of various aggregate sizes used in concrete, asphalt, road bases, and other construction materials. Urbanization and ongoing infrastructure development projects globally, from residential buildings to highways and bridges, consistently generate a substantial demand for aggregates, directly driving the need for efficient crushing equipment. Within this sector, the demand for both stationary plants for large-scale, long-term aggregate production and mobile or portable crushers for on-site processing at smaller or temporary construction sites is particularly pronounced, reflecting the varied operational scales and specific requirements of the construction industry.

Furthermore, demolition contractors and recycling facilities represent a rapidly growing customer base for pneumatic crushers. As environmental regulations tighten and the circular economy gains traction, there is an increasing imperative to recycle construction and demolition (C&D) waste, such as concrete, asphalt, bricks, and masonry. Pneumatic crushers offer effective solutions for breaking down these waste materials into reusable aggregates, reducing landfill burden and generating new revenue streams. Government and municipal bodies undertaking infrastructure upgrades or managing public waste also emerge as potential buyers, often through contractors, seeking sustainable and efficient methods for material processing and resource recovery. This diverse customer landscape underscores the broad applicability and integral role of pneumatic crushers across essential global industries.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.7 Billion |

| Market Forecast in 2033 | USD 6.0 Billion |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Metso Outotec, Sandvik AB, thyssenkrupp Industrial Solutions AG, FLSmidth & Co. A/S, The Weir Group PLC, Astec Industries Inc., McLanahan Corporation, Terex Corporation, Kleemann GmbH (Wirtgen Group), SBM Mineral Processing GmbH, Hazemag & EPR GmbH, Stedman Machine Company, Cedarapids (Terex), Telsmith (Astec), Lippmann-Milwaukee Inc., Eagle Crusher Company Inc., Chengdu Dahongli Machinery, Zhengzhou Liming Heavy Industry, Fives Group, Baioni Crushing Plants SpA |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pneumatic Crusher Market Key Technology Landscape

The pneumatic crusher market is undergoing a significant technological transformation, driven by the relentless pursuit of efficiency, automation, and sustainability. A cornerstone of this evolution is the integration of advanced sensor technology, which allows for real-time monitoring of various operational parameters such as pressure, temperature, vibration, and material flow. These sensors provide critical data streams that are essential for optimizing performance, preventing breakdowns, and ensuring consistent output quality. Furthermore, the development of more sophisticated pneumatic control systems, leveraging precise valve technology and advanced feedback loops, enhances the responsiveness and adaptability of crushers to varying material characteristics, leading to superior crushing efficiency and reduced energy consumption.

The rise of the Internet of Things (IoT) is profoundly impacting the pneumatic crusher landscape, enabling remote monitoring and control of crushing operations from anywhere in the world. This connectivity facilitates proactive management, diagnostics, and even over-the-air software updates, significantly improving operational uptime and reducing the need for on-site physical inspections. Complementing IoT, Artificial Intelligence (AI) and Machine Learning (ML) algorithms are being deployed to analyze the vast amounts of data collected by sensors, enabling predictive maintenance, optimizing crushing parameters for different materials, and forecasting future performance trends. These AI-powered insights contribute to substantial gains in productivity, energy efficiency, and overall operational intelligence, marking a significant departure from traditional, less adaptive crushing methods.

Beyond digital technologies, advancements in material science are playing a crucial role in enhancing the durability and lifespan of pneumatic crusher components, particularly wear parts like jaw plates, cone liners, and impactors. The development of new alloys and composite materials with superior hardness and abrasion resistance minimizes downtime associated with component replacement, thereby improving overall operational economics. Furthermore, a growing emphasis on environmental responsibility is driving innovations in dust suppression systems and noise reduction technologies, making pneumatic crushers more compliant with stringent environmental regulations. The incorporation of energy-efficient motors and hydraulic systems, even in predominantly pneumatic setups, further underscores the industry's commitment to reducing the carbon footprint and promoting sustainable crushing practices, making the technological landscape vibrant and forward-looking.

Regional Highlights

- North America: Characterized by a mature market with a strong emphasis on automation, efficiency, and compliance with stringent environmental regulations. Demand is driven by infrastructure upgrades, a robust recycling sector, and the replacement of aging machinery with technologically advanced pneumatic crushers, particularly in the US and Canada.

- Europe: A region focused on sustainable practices, high technological adoption, and strict environmental standards. Growth is fueled by strong recycling initiatives, the modernization of existing infrastructure, and significant R&D investments in advanced crushing technologies. Germany, the UK, and France are key contributors, prioritizing energy efficiency and reduced emissions.

- Asia Pacific (APAC): The largest and fastest-growing market, propelled by extensive infrastructure development projects, rapid urbanization, and expanding mining activities in countries like China, India, and Southeast Asian nations. High demand for new equipment, coupled with increasing investments in smart crushing solutions, defines this dynamic region.

- Latin America: Experiencing growth largely due to significant investments in the mining sector, particularly in countries rich in mineral resources such as Brazil, Chile, and Peru. Infrastructure development and a burgeoning construction industry also contribute to the demand for pneumatic crushing equipment, though market maturity varies across nations.

- Middle East & Africa (MEA): Emerging as a promising market with substantial growth driven by large-scale construction projects, oil & gas infrastructure development, and increasing mining activities, especially in Saudi Arabia, UAE, and South Africa. There is a growing adoption of modern crushing technologies to meet the demands of rapid industrialization and urbanization.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pneumatic Crusher Market.- Metso Outotec

- Sandvik AB

- thyssenkrupp Industrial Solutions AG

- FLSmidth & Co. A/S

- The Weir Group PLC

- Astec Industries Inc.

- McLanahan Corporation

- Terex Corporation

- Kleemann GmbH (Wirtgen Group)

- SBM Mineral Processing GmbH

- Hazemag & EPR GmbH

- Stedman Machine Company

- Cedarapids (Terex)

- Telsmith (Astec)

- Lippmann-Milwaukee Inc.

- Eagle Crusher Company Inc.

- Chengdu Dahongli Machinery

- Zhengzhou Liming Heavy Industry

- Fives Group

- Baioni Crushing Plants SpA

Frequently Asked Questions

Analyze common user questions about the Pneumatic Crusher market and generate a concise list of summarized FAQs reflecting key topics and concerns.What defines a pneumatic crusher and its primary function?

A pneumatic crusher is a type of material processing machine that utilizes compressed air to generate the force necessary for breaking down rocks, minerals, concrete, and other materials into smaller pieces. Its primary function is to achieve efficient and precise size reduction across various industrial applications, offering advantages in control and operational safety.

What are the main advantages of using pneumatic crushers over other types?

Pneumatic crushers offer several key advantages, including enhanced operational control and precision in particle sizing, often leading to more consistent output. They can provide improved safety due to less complex mechanical systems and contribute to reduced dust emissions. Their robust design often ensures reliability in demanding environments, making them suitable for specialized applications.

In which major industries are pneumatic crushers most commonly utilized?

Pneumatic crushers are predominantly utilized in the mining industry for ore processing, the construction sector for aggregate production and site preparation, and the demolition and recycling industries for processing concrete, asphalt, and construction and demolition (C&D) waste. Their versatility allows for application in various material reduction tasks across these heavy industries.

How does technological advancement, particularly AI, impact the pneumatic crusher market?

Technological advancements, especially AI and IoT, significantly impact the pneumatic crusher market by enabling predictive maintenance, optimizing crusher settings for maximum efficiency, and enhancing operational safety through real-time monitoring. AI-driven insights improve material quality control, automate routine tasks, and facilitate data-driven decision-making, leading to higher productivity and reduced downtime.

What are the key market trends shaping the future of pneumatic crushers?

The future of pneumatic crushers is shaped by key trends such as increasing adoption of smart crushing solutions (AI, IoT), a growing demand for mobile and modular equipment, heightened focus on sustainable and energy-efficient operations, and the expansion of the recycling industry. These trends are driving innovation towards more automated, precise, and environmentally friendly crushing technologies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager