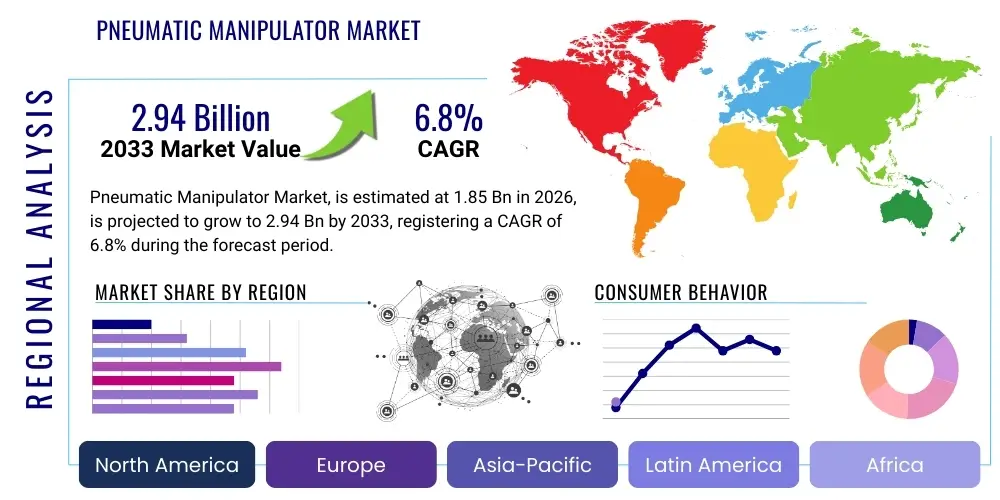

Pneumatic Manipulator Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439231 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Pneumatic Manipulator Market Size

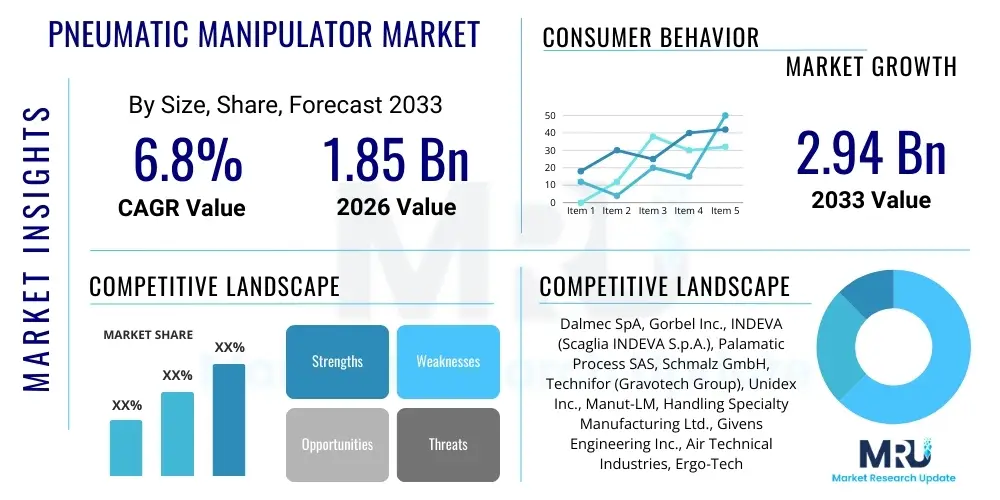

The Pneumatic Manipulator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.85 billion in 2026 and is projected to reach USD 2.94 billion by the end of the forecast period in 2033.

Pneumatic Manipulator Market introduction

Pneumatic manipulators represent a crucial class of industrial equipment designed to facilitate the lifting, moving, and positioning of heavy or awkward objects with precision and ease. These systems operate using compressed air to power their various movements, offering a robust and reliable solution for material handling in diverse manufacturing and assembly environments. The core functionality revolves around balancing loads, making objects feel virtually weightless to the operator, thereby significantly reducing physical strain and enhancing workplace safety and ergonomics. Their mechanical advantage and intuitive controls allow for complex maneuvers that would be strenuous or impossible with manual labor alone, transforming operational efficiency across numerous industries.

The product description encompasses a range of designs, from column-mounted and overhead rail-mounted systems to mobile and articulated arm configurations, each tailored to specific application requirements and spatial constraints. Key components include an air cylinder, control valves, a robust arm structure, end effectors (such as grippers, hooks, or suction cups adapted to the load), and an intuitive control interface, often a handle with integrated buttons or triggers. Major applications span industries like automotive for engine assembly, aerospace for component placement, food and beverage for packaging and palletizing, pharmaceuticals for sterile material transfer, and general manufacturing for machine tending and part manipulation. These versatile tools are indispensable for tasks requiring repetitive lifting, precise alignment, and safe handling of sensitive or heavy components, contributing significantly to streamlined production processes.

The benefits derived from adopting pneumatic manipulators are multifaceted, primarily centered on enhanced productivity, improved operator safety, and superior ergonomic performance. By minimizing manual handling of heavy loads, these manipulators drastically reduce the risk of musculoskeletal injuries, fatigue, and workplace accidents, fostering a safer working environment. Furthermore, their ability to precisely position components improves product quality and reduces rework, while accelerating task completion times contributes directly to higher throughput and operational efficiency. The driving factors for market growth include the increasing global emphasis on industrial automation, the imperative for improved workplace safety standards, the rising demand for ergonomic solutions in manufacturing, and the continuous need for higher productivity and quality control in diverse industrial sectors facing labor shortages and stringent regulatory compliance.

Pneumatic Manipulator Market Executive Summary

The pneumatic manipulator market is currently undergoing a significant transformation, propelled by evolving industrial demands and technological advancements. Business trends indicate a strong move towards integrated solutions, where manipulators are not standalone units but rather components within larger automated systems, often featuring advanced sensors for precise feedback and intelligent control interfaces. There is a growing demand for customized manipulators tailored to specific industry needs, particularly for handling delicate or uniquely shaped products, which drives innovation in end-effector design and programming flexibility. The emphasis on operational efficiency and lean manufacturing principles continues to fuel investments in these systems, as companies seek to optimize material flow and reduce non-value-added activities, positioning pneumatic manipulators as critical enablers for modern production strategies.

Regional trends reveal a robust growth trajectory in emerging economies, particularly in the Asia Pacific region, driven by rapid industrialization, expanding manufacturing bases, and increasing adoption of automation technologies in countries like China, India, and Southeast Asian nations. North America and Europe, while representing more mature markets, are experiencing growth fueled by the replacement of aging equipment, a renewed focus on advanced ergonomics, and the integration of manipulators into Industry 4.0 frameworks. These regions are prioritizing solutions that enhance human-robot collaboration and address skilled labor shortages. Latin America and the Middle East & Africa also show promising growth potential as industrial infrastructure develops and businesses seek cost-effective yet efficient material handling solutions to boost local manufacturing capabilities and competitiveness.

Segmentation trends highlight a diverse market responding to specific industrial requirements. By type, articulated arm manipulators dominate due to their flexibility and reach, while parallel arm and vertical lift systems cater to specialized applications. Application-wise, machine tending, assembly, welding, and packaging are critical segments experiencing high growth, demanding manipulators with varying payload capacities and precision levels. Industry segments such as automotive, aerospace, electronics, and food & beverage continue to be major consumers, each driving specific requirements for speed, hygiene, or robust handling. The evolution of end-effector technologies, including vacuum grippers, magnetic lifters, and mechanical clamps, further refines market segmentation, allowing manipulators to handle an ever-broader range of materials and products, thereby expanding their overall market reach and utility.

AI Impact Analysis on Pneumatic Manipulator Market

The integration of Artificial Intelligence (AI) is set to revolutionize the pneumatic manipulator market by significantly enhancing their capabilities, efficiency, and adaptability, addressing key user concerns regarding operational rigidity and complexity. Users frequently inquire about how AI can make manipulators more autonomous, how it can simplify programming, and whether it can improve predictive maintenance to reduce downtime. There is also considerable interest in AI's role in enabling more seamless human-robot collaboration and its potential to allow manipulators to adapt to dynamic environments or handle varied tasks without extensive manual reprogramming. The overarching theme is a desire for smarter, more versatile, and easier-to-manage material handling solutions that can integrate effectively into advanced manufacturing ecosystems.

AI's influence is expected to transform pneumatic manipulators from relatively simple, programmable devices into intelligent, self-optimizing systems. For instance, AI-driven vision systems will enable manipulators to identify, locate, and pick up objects with greater accuracy and flexibility, even in unstructured environments, reducing the need for precise fixturing. Machine learning algorithms will allow manipulators to learn optimal movement paths and grasp forces through repetitive tasks, continuously refining their performance for maximum efficiency and energy consumption. This adaptive learning capability will be crucial for handling varying product types or complex assembly sequences without constant human intervention, thereby significantly boosting productivity and operational agility in dynamic production settings.

Furthermore, AI will play a pivotal role in predictive maintenance, analyzing sensor data from manipulator components to foresee potential failures before they occur, enabling proactive servicing and minimizing costly downtime. Natural language processing could simplify the programming interface, allowing operators to issue commands or define tasks using conversational language rather than complex code, making the technology more accessible to a wider range of users. The development of AI-enhanced safety protocols will also facilitate closer human-robot collaboration, ensuring that manipulators can operate safely alongside human workers by recognizing and responding to human presence and intent. These advancements collectively promise a new generation of pneumatic manipulators that are not only more capable but also more intuitive, reliable, and integral to the smart factory paradigm.

- Enhanced adaptive control and task flexibility through machine learning.

- Predictive maintenance capabilities reducing downtime and optimizing service schedules.

- Smarter vision systems for improved object recognition and handling in unstructured environments.

- Simplified programming and human-machine interface via natural language processing.

- Real-time optimization of movement paths and energy consumption.

- Improved human-robot collaboration and safety protocols through AI-driven situational awareness.

- Autonomous error detection and recovery mechanisms.

- Integration with broader IoT and smart factory ecosystems for centralized control and data analysis.

DRO & Impact Forces Of Pneumatic Manipulator Market

The pneumatic manipulator market is significantly shaped by a dynamic interplay of drivers, restraints, and opportunities, alongside various impact forces that influence its growth trajectory. Key drivers include the escalating demand for industrial automation across manufacturing sectors seeking to boost productivity, reduce labor costs, and improve operational consistency. The increasing global focus on workplace safety and ergonomics further propels market expansion, as businesses prioritize solutions that mitigate risks associated with manual handling of heavy or awkward loads. Furthermore, the inherent versatility and cost-effectiveness of pneumatic systems, coupled with their robust performance in demanding industrial environments, make them an attractive choice for various material handling applications, from assembly to packaging, thereby reinforcing their market position.

However, the market also faces notable restraints. The relatively high initial capital expenditure required for purchasing and integrating pneumatic manipulator systems can be a deterrent for small and medium-sized enterprises (SMEs) with limited budgets. The complexity of integrating these systems into existing production lines, along with the need for specialized training for operators and maintenance personnel, poses additional challenges. Furthermore, competition from alternative material handling technologies, such as electric manipulators or advanced robotics, which offer higher precision or greater payload capacities in certain niche applications, can restrict market growth. The ongoing maintenance requirements and the reliance on a steady supply of compressed air, which can be energy-intensive, also represent operational considerations that act as restraints for some potential adopters.

Despite these challenges, significant opportunities abound for the pneumatic manipulator market. The growing trend towards customization and specialized solutions, particularly for niche applications requiring precise handling of unique components, presents a fertile ground for innovation and market differentiation. Expanding into emerging markets, where industrialization is accelerating and automation adoption is on the rise, offers substantial growth potential. Moreover, the integration of advanced technologies like AI, IoT, and improved sensor systems promises to enhance the intelligence, flexibility, and connectivity of pneumatic manipulators, thereby opening new application possibilities and increasing their value proposition. The impact forces affecting this market include the bargaining power of buyers, driven by their diverse needs and choices, and the bargaining power of suppliers, influenced by component availability and technological leadership. The threat of new entrants, while moderate due to capital requirements and technical expertise, exists, as does the threat of substitute products, primarily from electric manipulators and collaborative robots. Competitive rivalry among existing players remains intense, leading to continuous product innovation and aggressive market strategies.

Segmentation Analysis

The pneumatic manipulator market is segmented comprehensively to address the diverse needs and applications across various industrial landscapes. This segmentation allows for a granular understanding of market dynamics, growth drivers, and specific opportunities within different product types, payload capacities, end-user industries, and regional adoption patterns. Analyzing these segments provides critical insights into purchasing behaviors, technological preferences, and the evolving demands of both established and nascent markets, facilitating targeted product development and strategic market entry for manufacturers and solution providers. Each segment represents a distinct customer base with unique requirements for precision, speed, safety, and operational environment, necessitating tailored manipulator designs and functionalities.

- By Type

- Articulated Arm Manipulators

- Parallel Arm Manipulators

- Vertical Lift Manipulators

- Column Mounted Manipulators

- Overhead Rail Mounted Manipulators

- Mobile Manipulators

- Cable Manipulators

- By Payload Capacity

- Light Duty (Up to 50 kg)

- Medium Duty (51 kg - 250 kg)

- Heavy Duty (Above 250 kg)

- By Application

- Machine Tending

- Assembly and Disassembly

- Welding and Fabrication

- Packaging and Palletizing

- Material Transfer and Loading

- Pick and Place Operations

- Testing and Inspection

- Foundry and Forging

- By End-User Industry

- Automotive

- Aerospace and Defense

- Electronics and Semiconductors

- Food and Beverage

- Pharmaceuticals and Healthcare

- Logistics and Warehousing

- General Manufacturing

- Chemical and Petrochemical

- Metalworking

- Plastics and Rubber

- By Operating Mode

- Manual Control

- Semi-Automatic Control

- Automated Control

- By End Effector

- Grippers (Internal, External, Parallel, Angular)

- Vacuum Lifters

- Hooks and Clamps

- Magnetic Lifters

- Specialized Tooling

- By Geographic Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Pneumatic Manipulator Market

The value chain for the pneumatic manipulator market begins with a robust upstream segment, encompassing the suppliers of raw materials and core components essential for manipulator manufacturing. This includes providers of high-grade metals like aluminum and steel for structural components, as well as specialized plastics and composites for lighter-weight parts. Crucially, the upstream segment also involves manufacturers of pneumatic components such as cylinders, valves, pressure regulators, air preparation units, and sensors, which form the functional heart of these manipulators. The quality, cost, and availability of these foundational elements directly impact the production efficiency and final performance of the manipulators, making strong supplier relationships and supply chain management paramount for manufacturers.

Moving further down the value chain, the manufacturing phase involves the design, assembly, and testing of the complete pneumatic manipulator systems. This stage often incorporates advanced engineering processes, quality control measures, and customization capabilities to meet specific client requirements. Following manufacturing, the distribution channel plays a critical role in bringing the products to market. This involves both direct sales, where manufacturers engage directly with large industrial clients or implement customized solutions, and indirect channels, which leverage a network of distributors, system integrators, and original equipment manufacturers (OEMs). Distributors often provide localized sales, technical support, and after-sales services, acting as vital intermediaries between manufacturers and a diverse customer base, particularly for standardized products.

The downstream analysis primarily focuses on the end-users and the after-sales services that ensure long-term operational efficiency. End-users, spanning various industries like automotive, aerospace, and food & beverage, integrate these manipulators into their production lines for tasks such as material handling, assembly, and machine tending. System integrators are often crucial here, designing and installing complete automation solutions that incorporate manipulators. After-sales support, including maintenance, spare parts supply, training, and troubleshooting, forms a significant part of the value proposition, ensuring customer satisfaction and repeat business. The effectiveness of the entire value chain hinges on seamless coordination, technological innovation, and a clear understanding of customer needs from raw material sourcing to post-installation support, emphasizing the critical role of both direct sales channels for complex projects and indirect channels for broader market penetration.

Pneumatic Manipulator Market Potential Customers

Potential customers for pneumatic manipulators span a wide array of industrial sectors, each seeking to enhance operational efficiency, improve worker safety, and streamline material handling processes. The primary end-users are manufacturing and assembly plants that frequently deal with repetitive lifting, precise positioning, or handling of heavy or delicate components. These facilities often contend with ergonomic challenges and the need to maintain consistent production quality. Industries such as automotive, aerospace, and electronics manufacturing represent significant customer bases due to their reliance on precise component assembly, heavy part transfer, and stringent quality control standards, making pneumatic manipulators indispensable tools for optimizing their production lines and reducing manual labor-related injuries.

Beyond traditional manufacturing, the food and beverage industry constitutes a growing segment of potential customers. Here, pneumatic manipulators are crucial for tasks such as packaging, palletizing, and handling raw materials, often requiring systems designed for hygiene and washdown environments. Similarly, the pharmaceutical and healthcare sectors utilize these manipulators for sterile material transfer, precision assembly of medical devices, and ergonomic handling within cleanroom conditions. These industries prioritize contamination control and precise, repeatable motions, which pneumatic systems can reliably provide. The logistics and warehousing sector also presents a burgeoning market as companies increasingly automate their distribution centers for faster, safer, and more efficient movement of goods, especially within order fulfillment and palletizing operations.

Furthermore, the heavy machinery and metalworking industries are key adopters, employing pneumatic manipulators for tasks like machine tending, forging, casting, and transferring large, heavy parts around the workshop, significantly reducing physical strain on operators. The general manufacturing sector, encompassing a vast array of small to large-scale production facilities, consistently seeks versatile material handling solutions to adapt to diverse product lines and production volumes. Even emerging sectors focused on renewable energy component manufacturing, such as wind turbine blades or solar panels, are becoming significant potential customers, requiring robust and precise manipulators for handling large, unwieldy, and often delicate components during assembly and transportation. This broad customer base underscores the widespread applicability and critical value pneumatic manipulators provide across the industrial spectrum, driven by an overarching need for enhanced productivity and safety.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.94 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dalmec SpA, Gorbel Inc., INDEVA (Scaglia INDEVA S.p.A.), Palamatic Process SAS, Schmalz GmbH, Technifor (Gravotech Group), Unidex Inc., Manut-LM, Handling Specialty Manufacturing Ltd., Givens Engineering Inc., Air Technical Industries, Ergo-Tech, J.D. Neuhaus GmbH & Co. KG, Ingersoll Rand, Cleveland Crane & Engineering, ATLA S.r.l., Dongguan Chansin Mechanical & Electrical Equipment Co., Ltd., Shenyang Machine Tool Group Co., Ltd., Fuji Yusoki Kogyo Co., Ltd., Yaskawa Electric Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pneumatic Manipulator Market Key Technology Landscape

The pneumatic manipulator market is driven by a sophisticated blend of mature and emerging technologies that collectively enhance their functionality, precision, and integration capabilities within modern industrial environments. At the core are advanced pneumatic cylinder designs, which are increasingly engineered for higher efficiency, durability, and precise motion control, often incorporating low-friction seals and integrated damping systems. Complementing these are a variety of precision control valves, including proportional valves, which allow for fine-tuned speed and force regulation, moving beyond simple on/off pneumatic actuation. These fundamental pneumatic components are constantly being refined to offer greater energy efficiency and extended operational lifespans, contributing to the overall cost-effectiveness and reliability of the manipulators.

Beyond the core pneumatic components, sensor technology plays a pivotal role in the modern manipulator landscape. Integrated sensors, such as position sensors, pressure sensors, and force sensors, provide real-time feedback to the control system, enabling precise positioning, collision avoidance, and adaptive force application, which is crucial for handling delicate materials. Human-Machine Interface (HMI) solutions, ranging from intuitive joysticks and touchscreens to ergonomic handles with integrated controls, are critical for ease of operation and enhancing the operator experience, making complex tasks more accessible and reducing the learning curve. These interfaces are often designed to be highly customizable, allowing operators to program specific movements or switch between different operating modes quickly and efficiently, optimizing workflow and reducing setup times.

Furthermore, the technology landscape is expanding to include advanced materials and connectivity solutions. Lightweight yet strong composite materials are increasingly used in manipulator arm construction to reduce inertia, improve speed, and enhance overall energy efficiency. End effectors are evolving with modular designs and quick-change mechanisms, allowing manipulators to adapt to a wider variety of tasks and products. The advent of Industry 4.0 and the Internet of Things (IoT) is driving the integration of manipulators with networked control systems, enabling remote monitoring, diagnostic capabilities, and predictive maintenance. This connectivity facilitates seamless data exchange with other automation equipment and enterprise resource planning (ERP) systems, leading to optimized production processes, enhanced resource allocation, and a more intelligent manufacturing ecosystem that pushes the boundaries of traditional material handling solutions.

Regional Highlights

- North America: A mature market characterized by high adoption of automation, stringent safety regulations, and a focus on advanced ergonomics. Key countries like the United States and Canada are leading in integrating pneumatic manipulators into sophisticated manufacturing and aerospace applications, driven by labor cost reduction and quality control imperatives. The region also sees significant investment in R&D for next-generation, AI-enabled manipulators.

- Europe: A significant market with strong demand from the automotive, machinery, and food & beverage industries, particularly in Germany, Italy, and France. Emphasis on energy efficiency, precise control, and robust safety standards propels market growth. The region benefits from a well-established industrial base and a proactive approach to adopting Industry 4.0 principles, driving innovation in manipulator design and application.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, expanding manufacturing sectors, and increasing foreign direct investment in countries like China, India, Japan, and South Korea. The automotive, electronics, and general manufacturing industries are key drivers, seeking cost-effective and efficient material handling solutions to meet surging production demands and improve competitiveness on a global scale. Government initiatives promoting smart manufacturing further boost adoption.

- Latin America: An emerging market experiencing steady growth, particularly in Mexico and Brazil, driven by expanding automotive production, mining, and food processing industries. Increasing investments in industrial infrastructure and a rising focus on improving workplace safety and productivity contribute to the adoption of pneumatic manipulators. The region represents significant untapped potential as manufacturing capabilities continue to develop.

- Middle East and Africa (MEA): A developing market with nascent but growing demand, primarily in the UAE, Saudi Arabia, and South Africa. Growth is spurred by diversification efforts away from oil and gas, leading to investments in manufacturing, logistics, and infrastructure development. As industrialization gains momentum, there is an increasing need for automated material handling solutions to enhance efficiency and reduce reliance on manual labor.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pneumatic Manipulator Market.- Dalmec SpA

- Gorbel Inc.

- INDEVA (Scaglia INDEVA S.p.A.)

- Palamatic Process SAS

- Schmalz GmbH

- Technifor (Gravotech Group)

- Unidex Inc.

- Manut-LM

- Handling Specialty Manufacturing Ltd.

- Givens Engineering Inc.

- Air Technical Industries

- Ergo-Tech

- J.D. Neuhaus GmbH & Co. KG

- Ingersoll Rand

- Cleveland Crane & Engineering

- ATLA S.r.l.

- Dongguan Chansin Mechanical & Electrical Equipment Co., Ltd.

- Shenyang Machine Tool Group Co., Ltd.

- Fuji Yusoki Kogyo Co., Ltd.

- Yaskawa Electric Corporation

Frequently Asked Questions

Analyze common user questions about the Pneumatic Manipulator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a pneumatic manipulator and how does it work?

A pneumatic manipulator is an industrial device that uses compressed air to assist operators in lifting, moving, and positioning heavy or awkward objects with precision. It works by balancing the load through air pressure, making the object feel weightless, and allowing the operator to guide it effortlessly and safely using ergonomic controls, thereby enhancing productivity and reducing physical strain.

Which industries primarily benefit from using pneumatic manipulators?

Pneumatic manipulators offer significant benefits across various industries, including automotive for assembly and component handling, aerospace for precision placement, food and beverage for packaging and palletizing, pharmaceuticals for sterile transfers, and general manufacturing for machine tending and heavy part manipulation, all seeking improved safety, ergonomics, and efficiency.

What are the main advantages of pneumatic manipulators over other material handling systems?

Key advantages include superior ergonomics and safety by reducing manual lifting strain, high precision for delicate tasks, inherent safety in hazardous environments due to air power, versatility across various load types and environments, and often a lower maintenance profile compared to complex robotic systems, leading to enhanced productivity and reduced workplace injuries.

How is AI impacting the future development of pneumatic manipulators?

AI is transforming pneumatic manipulators by enabling features like adaptive control for dynamic tasks, predictive maintenance to minimize downtime, smarter vision systems for better object recognition, and simplified programming via natural language processing. These advancements contribute to more autonomous, efficient, and user-friendly systems capable of seamless human-robot collaboration in evolving smart factory environments.

What factors should be considered when choosing a pneumatic manipulator for a specific application?

When selecting a pneumatic manipulator, critical factors include the required payload capacity, reach and range of motion, type of end effector needed for the specific object, operational environment (e.g., cleanroom, hazardous area), desired level of precision and speed, integration with existing systems, ergonomic requirements for operators, and overall budget for initial investment and ongoing maintenance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager