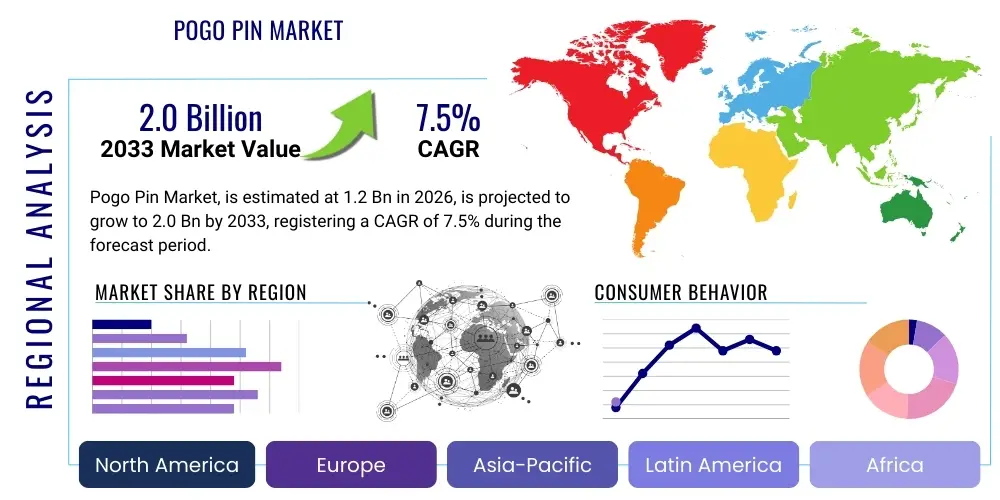

Pogo Pin Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440257 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Pogo Pin Market Size

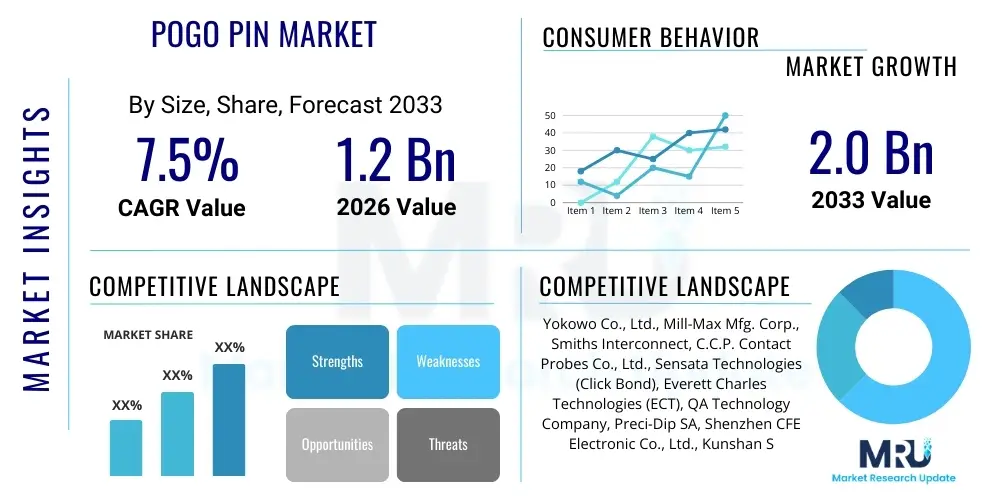

The Pogo Pin Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 2.0 Billion by the end of the forecast period in 2033.

Pogo Pin Market introduction

The Pogo Pin market encompasses a specialized segment within the broader electrical connector industry, focusing on spring-loaded contact pins designed for robust and reliable electrical connections. These pins, characterized by their unique spring-loaded mechanism, are crucial components in a vast array of electronic devices, providing a flexible and durable interface that can withstand repeated mating cycles and environmental stresses. Their intrinsic design allows for consistent contact force, minimizing signal loss and ensuring stable electrical performance even in demanding applications. The market's growth is inherently tied to the relentless pace of technological innovation, particularly in sectors requiring compact, high-performance, and resilient connectivity solutions.

Pogo pins are essentially miniature plunger-style connectors consisting of a barrel, a spring, and a plunger (or probe). The internal spring provides the necessary force to maintain constant contact pressure against a mating surface, making them ideal for applications that require quick disconnects, blind mating, or shock and vibration resistance. They offer significant advantages over traditional fixed connectors, including superior durability, a higher number of mating cycles, and excellent tolerance for misalignment, which simplifies assembly and enhances product reliability. The product range is diverse, featuring various designs optimized for current capacity, operating frequency, form factor, and environmental robustness, catering to a broad spectrum of industry needs from high-precision medical instruments to ruggedized industrial equipment.

Major applications for Pogo Pins span across consumer electronics, automotive systems, medical devices, industrial automation, and test & measurement equipment. In consumer electronics, they are indispensable for charging ports, data transfer, and modular accessories in smartphones, wearables, and laptops due to their small footprint and reliability. The automotive industry utilizes them for advanced driver-assistance systems (ADAS), infotainment, and electric vehicle (EV) charging interfaces, where high current and vibration resistance are paramount. Benefits such as space efficiency, high reliability, ease of connection, and resistance to environmental factors like dust and moisture further drive their adoption. Key driving factors propelling this market include the global trend towards device miniaturization, the proliferation of Internet of Things (IoT) devices, the rollout of 5G technology, and the expanding electric vehicle ecosystem, all of which necessitate advanced, high-density, and dependable connectivity solutions.

Pogo Pin Market Executive Summary

The Pogo Pin market is experiencing dynamic growth, propelled by robust business trends centered on technological advancements, increasing demand for miniaturized electronic devices, and the expanding scope of IoT applications. Manufacturers are focusing on developing high-performance pins capable of handling higher current densities and data rates, while also enhancing their durability and environmental resistance. Customization and specialized solutions for niche applications, such as medical implants and aerospace systems, represent significant business avenues. There is also a notable trend towards automation in the manufacturing processes of pogo pins, aimed at improving precision, reducing costs, and increasing production efficiency to meet escalating global demand, particularly from rapidly evolving consumer electronics and automotive sectors.

Regional trends indicate that the Asia Pacific continues to dominate the Pogo Pin market, primarily due to its established manufacturing hub for consumer electronics and a burgeoning automotive industry, particularly in countries like China, South Korea, Japan, and Taiwan. This region benefits from a robust supply chain and a large base of skilled labor, alongside a high rate of adoption of advanced electronic devices. North America and Europe, while possessing mature markets, are characterized by high innovation, significant investments in research and development, and a strong focus on high-reliability applications in sectors such as medical, aerospace, and industrial automation. Emerging economies in Latin America, the Middle East, and Africa are showing promising growth, driven by increasing industrialization, infrastructure development, and growing consumer purchasing power leading to higher demand for electronic devices.

Segmentation trends within the Pogo Pin market highlight the dominance of applications in consumer electronics, which continues to be the largest segment owing to the widespread use of smartphones, tablets, and wearables. However, the automotive segment is poised for the most rapid growth, fueled by the increasing electrification of vehicles, advanced infotainment systems, and the proliferation of ADAS functionalities that rely on robust connectivity. The medical sector also represents a stable and growing segment, driven by the demand for portable, wearable, and implantable medical devices that require compact and highly reliable connectors. Furthermore, there is an increasing demand for high-current and high-frequency pogo pins across various industrial and telecommunication applications, reflecting the market's continuous evolution towards more specialized and performance-oriented solutions.

AI Impact Analysis on Pogo Pin Market

Artificial Intelligence (AI) is poised to fundamentally transform various facets of the Pogo Pin market, from initial design and manufacturing processes to quality assurance and predictive maintenance. Common user questions related to AI's impact often revolve around how AI can enhance the performance and reliability of pogo pins, whether AI can automate their complex production, and how the proliferation of AI-powered devices will influence overall market demand. The consensus among industry stakeholders and technical experts is that AI offers significant opportunities for optimization, efficiency gains, and the creation of new market opportunities. This includes leveraging AI for rapid prototyping and material selection, optimizing manufacturing parameters, improving inspection accuracy, and enabling smart monitoring of connector health in deployed systems.

One of the key themes emerging from discussions on AI's influence is its potential to significantly reduce the design cycle time for pogo pins. Traditional design processes often involve extensive manual iterations and physical prototyping. AI-driven simulation and generative design tools can explore a vast array of design parameters—such as spring constant, plunger geometry, and material composition—to identify optimal configurations for specific performance criteria, like contact resistance, current capacity, and mating cycles. This not only accelerates product development but also allows for the creation of more sophisticated and application-specific pogo pin designs that might be too complex for conventional methods. Furthermore, AI algorithms can predict performance under various operating conditions, enabling engineers to refine designs for enhanced reliability and longevity, addressing concerns about durability and failure rates in critical applications.

Beyond design, AI's impact extends profoundly into the manufacturing and quality control stages. The intricate nature of pogo pin production, involving precise machining, spring coiling, and plating, presents an ideal scenario for AI-driven automation and optimization. Machine learning models can analyze real-time sensor data from production lines to identify anomalies, predict equipment failures, and fine-tune process parameters for improved yield and consistent product quality. In quality assurance, AI-powered vision systems can perform high-speed, high-accuracy inspection of microscopic features, detecting defects that might be missed by human operators or traditional automated systems. This level of precision is critical for maintaining the high reliability standards demanded by industries like automotive and medical. Moreover, the increasing integration of AI into end-user devices, from smart wearables to autonomous vehicles, directly drives the demand for more advanced, reliable, and compact pogo pins, creating a synergistic relationship where AI both optimizes the production of pogo pins and expands their application landscape.

- AI-driven generative design optimizes Pogo Pin geometry and material selection for enhanced performance and miniaturization.

- Predictive analytics enables proactive maintenance of manufacturing equipment, reducing downtime and improving production efficiency.

- AI-powered vision systems enhance quality control through high-precision, automated inspection of microscopic pin features, ensuring reliability.

- Machine learning algorithms optimize manufacturing parameters, leading to higher yield rates and consistent product quality.

- AI facilitates the development of smart pogo pins with embedded sensors for real-time performance monitoring and fault detection.

- Increased demand for advanced pogo pins in AI-enabled devices across consumer electronics, automotive, and industrial sectors.

- AI-assisted simulation accelerates prototyping and validation, significantly shortening the product development cycle.

DRO & Impact Forces Of Pogo Pin Market

The Pogo Pin market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively form the Impact Forces shaping its trajectory. A primary driver is the pervasive trend of device miniaturization across virtually all electronic sectors, from consumer gadgets to sophisticated medical implants. As devices shrink, the demand for compact, high-density, and reliable connectors like pogo pins escalates, as they offer superior space-saving characteristics compared to traditional connectors. Coupled with this is the explosive growth of the Internet of Things (IoT) and the rapid global deployment of 5G technology, both requiring seamless, high-speed, and robust connectivity for a multitude of sensors, modules, and communication devices. The expansion of the electric vehicle (EV) market further fuels demand, as pogo pins are increasingly utilized in charging interfaces, battery management systems, and various vehicle electronics due to their high current capacity and vibration resistance.

Despite these powerful drivers, the Pogo Pin market faces several significant restraints. The manufacturing of pogo pins demands extremely high precision and intricate engineering, particularly for micro-pins and high-performance variants, which can lead to elevated production costs. This often results in intense cost competition, especially from manufacturers in regions with lower labor costs, putting pressure on profit margins. Furthermore, the market must contend with the continuous evolution of alternative connectivity solutions, including advanced wireless technologies, optical connectors, and other forms of mechanical connectors, which could potentially displace pogo pins in certain applications. Fluctuations in the cost of raw materials, such as brass, beryllium copper, and precious metal plating materials (e.g., gold), also pose a challenge, impacting manufacturing expenses and overall pricing strategies within the industry.

However, substantial opportunities exist for market expansion and innovation. The burgeoning fields of medical wearables and advanced robotics present lucrative prospects, as these applications require highly reliable, durable, and often customized connectivity solutions that pogo pins are uniquely positioned to provide. The aerospace and defense sector, with its stringent requirements for performance under extreme conditions, also represents a premium market for specialized pogo pins. Additionally, the development of pogo pins capable of handling high-frequency signals and integrating advanced features like embedded sensors opens new avenues for sophisticated applications in telecommunications and test & measurement. The ability to offer highly customized solutions tailored to specific client needs, from unique form factors to enhanced environmental sealing, further solidifies the market's growth potential by addressing niche but high-value demands. These impact forces collectively dictate the strategic decisions and innovative directions for players within the Pogo Pin market.

Segmentation Analysis

The Pogo Pin market is meticulously segmented to provide a granular understanding of its diverse landscape, reflecting varied product characteristics, application requirements, and end-user demands. This comprehensive segmentation allows market participants to identify key growth areas, tailor product development strategies, and optimize market entry approaches. The market is primarily analyzed across several critical dimensions including product type, specific application, the end-use industry, pin diameter, and plating material, each revealing distinct market dynamics and competitive intensities. The demand for specific pogo pin attributes, such as high current capacity or miniaturized form factors, often varies significantly across these segments, necessitating a customized approach from manufacturers and suppliers.

Segmentation by product type typically differentiates between standard pogo pins designed for general-purpose connectivity, high-current pogo pins engineered for power delivery in demanding applications like electric vehicles, and switch pogo pins that incorporate a mechanical switch function for detection or control. The application-based segmentation highlights their utility in board-to-board connections within complex electronic assemblies, battery contacts in portable devices, RF/antenna connections for wireless communication, and as critical components in test probes for quality assurance. Each application demands specific performance parameters from the pogo pins, such as low contact resistance for power, excellent signal integrity for RF, or a high cycle life for test probes, driving specialized manufacturing processes and material choices.

Further segmentation by end-use industry provides crucial insights into the primary consumers of pogo pin technology. Consumer electronics remain a dominant segment, encompassing smartphones, tablets, laptops, and wearables, driven by massive production volumes and continuous innovation in device design. The automotive sector is rapidly expanding, fueled by advancements in electric vehicles, autonomous driving systems, and sophisticated infotainment. Industrial applications, medical devices, aerospace & defense, and telecommunications also represent significant segments, each characterized by unique reliability, regulatory, and performance requirements. Understanding these distinct segments is vital for strategic market planning, enabling companies to focus their resources on the most promising and profitable areas within the evolving Pogo Pin market.

- By Type

- Standard Pogo Pin

- High Current Pogo Pin

- Switch Pogo Pin

- By Application

- Board-to-Board Connectors

- Battery Connectors

- RF/Antenna Connectors

- Test Probes

- Data Transfer Connectors

- By End-Use Industry

- Consumer Electronics

- Automotive

- Industrial

- Medical

- Aerospace & Defense

- Telecommunications

- Test & Measurement

- By Pin Diameter

- Less than 1.0mm

- 1.0mm - 2.0mm

- Greater than 2.0mm

- By Plating Material

- Gold

- Nickel

- Palladium

- Rhodium

Value Chain Analysis For Pogo Pin Market

The value chain for the Pogo Pin market is a complex ecosystem involving multiple stages, from raw material sourcing to final product distribution and end-user applications. At the upstream end, the chain begins with the procurement of specialized raw materials, primarily including brass, beryllium copper, and stainless steel for the barrel and plunger components, as well as various alloys for the springs. Additionally, precious metals like gold, nickel, and palladium are crucial for plating, ensuring low contact resistance and corrosion protection. Suppliers in this segment focus on providing high-quality, consistent materials that meet the stringent specifications required for precision machining and electrical conductivity, impacting the overall performance and cost efficiency of the final product. The quality and availability of these materials are foundational to the manufacturing process, with disruptions or price volatility directly affecting downstream operations and market stability.

Moving downstream, the core of the value chain involves the specialized manufacturing processes undertaken by pogo pin producers. This includes high-precision CNC machining for creating the intricate components (barrel, plunger), advanced spring manufacturing, and sophisticated plating processes. Manufacturers often invest heavily in automation and quality control systems to ensure the micro-level accuracy and consistent performance demanded by diverse applications. Following manufacturing, these components are assembled into finished pogo pins or integrated into connector modules. Distribution channels play a critical role in bridging the gap between manufacturers and end-users. Direct distribution is common for large-volume orders and customized solutions, where manufacturers work closely with Original Equipment Manufacturers (OEMs) in sectors like consumer electronics and automotive. This direct engagement allows for tailored technical support, specialized product development, and strong client relationships.

Indirect distribution, on the other hand, involves a network of distributors, resellers, and online platforms, which serve smaller businesses, offer a wider range of standard products, and provide local market access. These indirect channels are crucial for reaching a broader customer base and serving diverse industrial and test & measurement applications that might require lower volumes or off-the-shelf components. Furthermore, the value chain extends into after-sales support, technical consulting, and continuous innovation, driven by feedback from end-users. The effective management of this entire value chain, from securing reliable raw material supplies to efficient distribution and responsive customer service, is paramount for companies seeking to maintain competitiveness and capitalize on emerging market opportunities within the dynamic Pogo Pin industry.

Pogo Pin Market Potential Customers

The potential customers for Pogo Pins represent a diverse array of industries and applications, all requiring reliable, compact, and high-performance electrical connectors. These end-users, or buyers of the product, are primarily Original Equipment Manufacturers (OEMs) who integrate pogo pins into their final products, as well as companies specializing in test and measurement equipment. The market's customer base is characterized by a strong demand for precision, durability, and customization, reflecting the critical role pogo pins play in ensuring the functionality and longevity of their respective electronic systems. Understanding the specific needs and design cycles of these various customer segments is crucial for pogo pin manufacturers to effectively penetrate and expand their market presence.

A significant portion of potential customers comes from the consumer electronics sector, including major manufacturers of smartphones, tablets, smartwatches, laptops, and various wearable devices. These companies continuously seek ultra-miniaturized, high-density pogo pins for charging ports, data transfer interfaces, and modular accessories, driven by consumer demand for sleeker designs and enhanced functionality. The automotive industry is another rapidly growing customer segment, with OEMs utilizing pogo pins in electric vehicle (EV) charging connectors, infotainment systems, advanced driver-assistance systems (ADAS), and battery management units. Their requirements are particularly stringent, focusing on high current capability, vibration resistance, and long-term reliability under harsh environmental conditions, making specialized pogo pin solutions highly desirable.

Beyond consumer and automotive, the medical device industry represents a high-value customer base for pogo pins, especially for portable diagnostics, wearable health monitors, and even implantable devices where reliability, biocompatibility, and compactness are paramount. Industrial automation and robotics manufacturers are also key buyers, requiring robust pogo pins for docking stations, modular tool changers, and sensor connections in demanding factory environments. Furthermore, companies in the aerospace and defense sectors, along with those specializing in telecommunications infrastructure and test & measurement equipment, consistently seek high-performance, custom pogo pin solutions that can withstand extreme conditions and deliver exceptional electrical performance. Each of these customer groups drives unique demands, ranging from specific plating materials to advanced mechanical designs, highlighting the market's need for versatile and application-specific connector solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 2.0 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Yokowo Co., Ltd., Mill-Max Mfg. Corp., Smiths Interconnect, C.C.P. Contact Probes Co., Ltd., Sensata Technologies (Click Bond), Everett Charles Technologies (ECT), QA Technology Company, Preci-Dip SA, Shenzhen CFE Electronic Co., Ltd., Kunshan SVL Electric Co., Ltd., Harwin Plc, TE Connectivity, Amphenol Corporation, Würth Elektronik GmbH & Co. KG, JAE Electronics, Inc., Hirose Electric Co., Ltd., Samtec, Inc., ODU GmbH & Co. KG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pogo Pin Market Key Technology Landscape

The Pogo Pin market's technological landscape is defined by continuous innovation aimed at enhancing performance, miniaturization, durability, and cost-effectiveness. Central to this evolution are advanced manufacturing techniques such as ultra-precision CNC machining, which is crucial for producing the intricate geometries of plungers and barrels with micron-level tolerances. These machining capabilities enable the creation of increasingly smaller pogo pins without compromising mechanical integrity or electrical performance, directly addressing the industry's drive towards device miniaturization. Alongside this, sophisticated micro-fabrication processes are being developed to create novel pin designs and integrate features that enhance functionality, such as multi-point contacts for improved signal integrity or integrated environmental sealing for harsh conditions. The ongoing refinement of these manufacturing processes ensures that pogo pins can meet the exacting demands of high-density electronic assemblies and specialized applications.

Material science plays another pivotal role, particularly in the development of advanced alloys for springs and contact elements. Research into materials with superior electrical conductivity, enhanced mechanical strength, fatigue resistance, and temperature stability is paramount. Beryllium copper, music wire, and stainless steel are common spring materials, but continuous innovation seeks new alloys that offer better elasticity and longer cycle life under extreme conditions. Furthermore, advanced plating technologies, including Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD), are critical for applying durable, low-resistance, and corrosion-resistant coatings such as gold, nickel, and palladium. These plating processes are essential for maintaining stable contact resistance over thousands of mating cycles and in challenging environments, significantly impacting the long-term reliability and performance of pogo pins.

The broader technology landscape also includes the increasing automation in assembly lines and the deployment of sophisticated testing equipment. Automated assembly systems enhance production efficiency and consistency, reducing human error and enabling the mass production of high-quality pogo pins. Advanced testing equipment, including electrical performance testers, mechanical durability testers, and environmental chambers, is vital for ensuring that pogo pins meet rigorous industry standards and application-specific requirements. Moreover, emerging trends involve the integration of high-speed data transmission capabilities into pogo pin designs, addressing the demand for higher bandwidth in devices. Future advancements are expected to focus on smart pogo pins with embedded diagnostic features, enabling real-time monitoring of connection integrity and predictive maintenance, further solidifying their role as critical components in next-generation electronic systems.

Regional Highlights

- Asia Pacific (APAC): Dominates the Pogo Pin market due to its robust manufacturing infrastructure for consumer electronics and a burgeoning automotive industry, especially in China, South Korea, Japan, and Taiwan. The region benefits from a large consumer base, rapid industrialization, and significant investments in 5G and IoT technologies, driving high demand for compact and reliable connectors. APAC also serves as a key production hub, with numerous manufacturers supporting global supply chains.

- North America: Characterized by high innovation and significant R&D investments, particularly in aerospace & defense, medical devices, and high-end industrial applications. The demand here is driven by a focus on high-reliability, customized, and technologically advanced pogo pin solutions. The region's strong push towards electric vehicles and advanced computing also contributes to market growth.

- Europe: A mature market with strong demand from the automotive (especially electric vehicles), industrial automation, and medical technology sectors. European countries like Germany, France, and the UK emphasize stringent quality standards and precision engineering, leading to a demand for high-performance and durable pogo pins. Investments in smart factories and Industry 4.0 initiatives further bolster demand.

- Latin America: An emerging market experiencing growth due to increasing industrialization, infrastructure development, and rising disposable incomes. Demand for consumer electronics and automotive components is steadily growing, creating opportunities for pogo pin manufacturers. However, market penetration is still lower compared to other regions.

- Middle East and Africa (MEA): Shows gradual growth driven by expanding telecommunications infrastructure, increasing adoption of consumer electronics, and developing industrial sectors. Investments in smart city projects and digitalization initiatives are expected to fuel future demand for connectivity solutions, including pogo pins.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pogo Pin Market.- Yokowo Co., Ltd.

- Mill-Max Mfg. Corp.

- Smiths Interconnect

- C.C.P. Contact Probes Co., Ltd.

- Sensata Technologies (Click Bond)

- Everett Charles Technologies (ECT)

- QA Technology Company

- Preci-Dip SA

- Shenzhen CFE Electronic Co., Ltd.

- Kunshan SVL Electric Co., Ltd.

- Harwin Plc

- TE Connectivity

- Amphenol Corporation

- Würth Elektronik GmbH & Co. KG

- JAE Electronics, Inc.

- Hirose Electric Co., Ltd.

- Samtec, Inc.

- ODU GmbH & Co. KG

Frequently Asked Questions

Analyze common user questions about the Pogo Pin market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are Pogo Pins and how do they function?

Pogo Pins are spring-loaded electrical connectors comprising a barrel, spring, and plunger, designed to create a reliable and temporary electrical connection. They function by compressing the internal spring, allowing the plunger to make contact with a mating surface, providing constant contact force and accommodating misalignment. Their primary use is in applications requiring repeated connections, shock/vibration resistance, or blind mating, ensuring stable electrical performance.

What are the primary applications of Pogo Pins across various industries?

Pogo Pins find primary applications across diverse industries including consumer electronics (smartphones, wearables, laptops for charging/data), automotive (EV charging, ADAS, infotainment), medical devices (wearable monitors, diagnostics), industrial automation (robotics, control systems), and test & measurement equipment (test probes, fixtures). Their versatility stems from their compact size, high reliability, and ability to handle various electrical requirements.

What are the key advantages of Pogo Pins compared to traditional electrical connectors?

Key advantages of Pogo Pins over traditional connectors include superior durability and a significantly higher number of mating cycles, excellent resistance to shock and vibration, tolerance for misalignment during connection, and their space-saving design crucial for miniaturized devices. They also offer consistent low contact resistance, ensuring stable signal integrity and power transmission, and can be designed for environmental protection.

How do Pogo Pins contribute to the ongoing trend of device miniaturization?

Pogo Pins contribute significantly to device miniaturization due to their compact form factor and ability to provide high-density interconnections in a small footprint. Their vertical compression mechanism allows for closer component placement and multi-directional mating options, reducing the overall size and weight of electronic devices. This makes them indispensable for slim designs in smartphones, wearables, and other portable electronics.

What technological advancements are currently shaping the Pogo Pin market?

Technological advancements shaping the Pogo Pin market include ultra-precision machining for smaller pin diameters, advanced material science for improved spring alloys and plating, enhanced plating technologies (PVD, CVD) for durability and conductivity, and the development of high-frequency and high-current pogo pins. Additionally, automation in manufacturing and the potential for AI-driven design optimization and quality control are significant trends.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager