Polishing Grinding Robot Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440470 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Polishing Grinding Robot Market Size

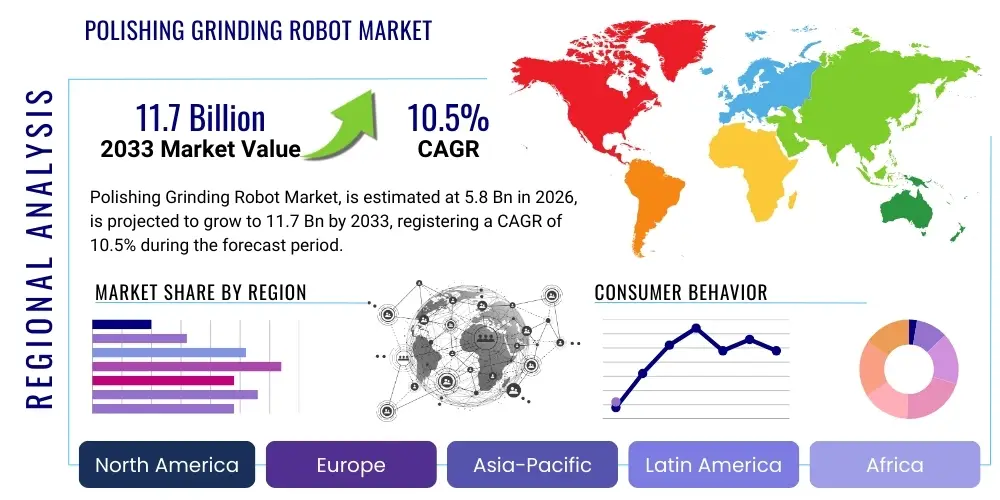

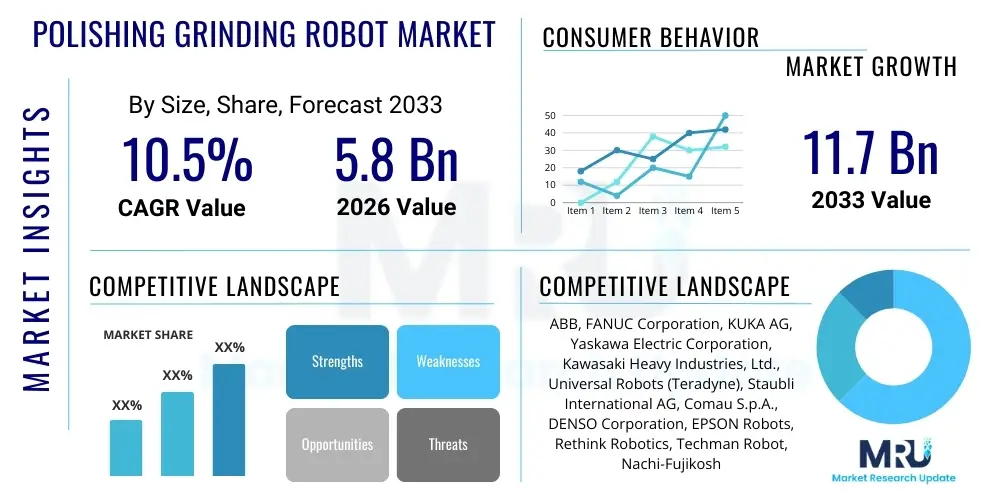

The Polishing Grinding Robot Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2026 and 2033. The market is estimated at USD 5.8 Billion in 2026 and is projected to reach USD 11.7 Billion by the end of the forecast period in 2033. This substantial growth is primarily driven by the increasing demand for automation in manufacturing processes, the pursuit of higher precision and consistency in finishing operations, and the ongoing integration of advanced robotics into diverse industrial applications. The market expansion reflects a global industrial shift towards enhancing productivity, reducing labor costs, and achieving superior product quality, particularly in sectors requiring intricate surface treatment and material removal.

Polishing Grinding Robot Market introduction

The Polishing Grinding Robot Market encompasses the industrial landscape dedicated to the design, manufacturing, and deployment of robotic systems specifically engineered for surface finishing operations such as polishing, grinding, deburring, and sanding. These sophisticated machines integrate robotic arms with specialized end-effectors, vision systems, and advanced control software to automate tasks traditionally performed manually, often involving strenuous, repetitive, or hazardous conditions. The primary product description involves multi-axis robotic manipulators equipped with abrasive tools, capable of executing complex motion paths with high accuracy and repeatability, adapting to various material properties and geometries. Major applications span across critical industries including automotive for bodywork finishing, electronics for component polishing, aerospace for turbine blade grinding, medical for orthopedic implant finishing, and general manufacturing for tool deburring and surface preparation. The inherent benefits of these robotic systems include significantly improved product quality consistency, enhanced operational efficiency through faster cycle times, reduced labor costs, increased worker safety by minimizing exposure to hazardous environments, and the ability to process intricate parts with unparalleled precision. Key driving factors propelling market growth include the relentless pursuit of automation across global manufacturing sectors, the imperative for higher quality surface finishes to meet stringent industry standards, rising labor costs and shortages in skilled manual labor, and continuous technological advancements in robotics, artificial intelligence, and material science, making these systems more versatile and accessible to a wider range of industries seeking to optimize their production lines and gain a competitive edge.

Polishing Grinding Robot Market Executive Summary

The Polishing Grinding Robot Market is poised for robust expansion, driven by transformative business trends, dynamic regional market shifts, and evolving segmentation demands. Global business trends indicate a strong inclination towards intelligent automation and Industry 4.0 integration, where polishing and grinding robots play a crucial role in smart factories aiming for autonomous production and data-driven optimization. Companies are increasingly investing in these robots to mitigate challenges such as labor scarcity, inconsistent product quality from manual processes, and the need for higher production throughputs. From a regional perspective, Asia Pacific continues to dominate the market due to its vast manufacturing base, particularly in automotive and electronics, alongside supportive government initiatives for industrial automation. North America and Europe also exhibit significant growth, propelled by the adoption of advanced robotics in high-value manufacturing and precision engineering sectors, coupled with substantial investments in research and development. Latin America and the Middle East & Africa regions are emerging markets, demonstrating steady growth as industrialization accelerates and awareness of robotic benefits increases. Segment-wise, the market is seeing a strong demand for collaborative robots due to their flexibility and ease of integration, while application segments like aerospace and medical devices are driving demand for highly precise and specialized grinding robots. The trend towards customized robotic solutions, integrating advanced sensors and AI-powered vision systems for adaptive polishing and grinding, is also profoundly shaping the market's trajectory. Overall, the executive summary underscores a market characterized by continuous innovation, strategic partnerships, and a global pivot towards automated, high-precision manufacturing solutions to meet the escalating demands for quality, efficiency, and safety in modern industrial environments.

AI Impact Analysis on Polishing Grinding Robot Market

The integration of Artificial Intelligence (AI) is fundamentally transforming the Polishing Grinding Robot Market, addressing key concerns and elevating user expectations regarding precision, adaptability, and operational intelligence. Users are keenly interested in how AI can overcome the inherent challenges of traditional robotic polishing, such as the difficulty in handling variations in part geometry, material inconsistencies, and the extensive programming required for complex tasks. The primary expectation revolves around AI's ability to enable robots to learn from experience, adapt to unstructured environments, and achieve superior surface finish quality with minimal human intervention. Key themes emerging from this analysis include the potential for AI to enhance real-time decision-making, optimize tool paths dynamically, and provide advanced anomaly detection during the grinding and polishing processes. There is significant anticipation that AI will democratize access to advanced automation, making sophisticated finishing processes more accessible and easier to implement for a broader range of manufacturers, especially those dealing with high-mix, low-volume production or intricate, variable components. Furthermore, concerns about the initial investment costs and the complexity of integrating AI-powered systems are being balanced by the long-term benefits of increased efficiency, reduced material waste, and the ability to achieve unprecedented levels of precision and consistency, ultimately driving down overall operational expenditures and enhancing competitive advantage.

- Enhanced Adaptive Control: AI algorithms allow polishing and grinding robots to detect variations in material properties, surface imperfections, and part geometry in real-time, dynamically adjusting pressure, speed, and tool angles for optimal results, thereby improving consistency and reducing rework.

- Optimized Tool Path Generation: Machine learning enables robots to learn from successful polishing and grinding operations, generating more efficient and precise tool paths autonomously, reducing programming time and improving overall cycle efficiency for complex surfaces.

- Improved Vision System Integration: AI-powered vision systems provide superior object recognition, defect detection, and precise localization of workpieces, enhancing the robot's ability to target specific areas for grinding or polishing and ensuring high-quality finishes.

- Predictive Maintenance and Anomaly Detection: AI algorithms analyze operational data from robot sensors to predict potential equipment failures, schedule proactive maintenance, and detect anomalies during the polishing and grinding process, minimizing downtime and optimizing robot longevity.

- Increased Autonomy and Reduced Human Intervention: Advanced AI allows robots to make more autonomous decisions, handle greater variability in tasks, and perform sophisticated finishing operations with less direct human oversight, freeing up skilled labor for more complex tasks.

- Rapid Process Optimization: AI facilitates quicker setup times and process optimization for new parts or materials by leveraging historical data and simulation, significantly accelerating the deployment of new production lines or product variations.

- Collaborative Robotics Enhancement: AI enhances the safety and efficiency of collaborative polishing and grinding robots by improving their ability to perceive and respond to human presence, enabling seamless human-robot collaboration in shared workspaces.

DRO & Impact Forces Of Polishing Grinding Robot Market

The Polishing Grinding Robot Market is influenced by a complex interplay of drivers, restraints, and opportunities, collectively shaped by various impact forces that dictate its growth trajectory and competitive landscape. The primary drivers stem from the global manufacturing sector's relentless pursuit of enhanced automation, the critical need for superior surface finish quality in high-precision industries, and the increasing pressure to reduce operational costs associated with manual labor. These robots offer a compelling solution to labor shortages and the demand for consistent, repeatable processes, significantly boosting productivity and material utilization. However, the market faces notable restraints, particularly the high initial capital investment required for these sophisticated robotic systems, which can be a barrier for small and medium-sized enterprises (SMEs). The technical complexity involved in programming, integrating, and maintaining these robots also presents a challenge, demanding specialized expertise. Opportunities within this market are abundant, driven by continuous innovation in AI and machine learning, which enable greater adaptability and autonomy in robotic operations, along with the growing demand for customized solutions tailored to specific industrial needs. The expansion into new application areas, such as additive manufacturing post-processing and advanced materials, further amplifies market potential. Impact forces such as rapid technological advancements in robotics and sensor technology are continually lowering costs and improving capabilities, while stringent regulatory standards for product quality and worker safety compel industries to adopt automated solutions. Global economic conditions, trade policies, and geopolitical stability also play a significant role, influencing industrial investment cycles and the overall demand for automation technologies. The convergence of these factors creates a dynamic environment where innovation and strategic market penetration are key to sustained growth and competitive advantage for participants in the polishing grinding robot market.

Segmentation Analysis

The Polishing Grinding Robot Market is extensively segmented to reflect the diverse applications, technological variations, and end-user requirements across the global industrial landscape. Understanding these segments is crucial for market players to tailor their strategies, product development, and sales initiatives to specific demand pockets. The market can be broadly categorized based on the type of robot, the specific application or industry it serves, the end-user enterprise size, and the components that constitute the robotic system. Each segment presents unique growth dynamics, technological preferences, and competitive intensities, contributing differently to the overall market trajectory. For instance, the demand for fixed robots might be strong in large-scale, repetitive manufacturing lines, while mobile or collaborative robots gain traction in flexible production environments requiring human-robot interaction or movement between workstations. Similarly, the requirements for robots in the automotive industry, which demands high throughput and consistency, will differ significantly from those in the aerospace sector, where ultra-precision and specialized material handling are paramount. This granular segmentation allows for a comprehensive analysis of market trends, identification of high-growth areas, and development of targeted solutions that address the specific needs and challenges of various industrial stakeholders, ultimately driving the evolution and expansion of the polishing grinding robot market. As industries continue to automate and optimize their production processes, the nuances within these segments will become even more pronounced, necessitating agile and adaptable market offerings.

- By Type

- Fixed Robots

- Mobile Robots

- Collaborative Robots

- By Application

- Automotive

- Electronics

- Aerospace

- Medical

- General Manufacturing

- Other Applications (e.g., Jewelry, Furniture)

- By End-Use

- Small & Medium Enterprises (SMEs)

- Large Enterprises

- By Component

- Robotic Arm

- End-Effectors (Grinders, Polishers, Sanders, Deburring Tools)

- Vision Systems

- Controllers & Software

- Sensors & Force Feedback Systems

Value Chain Analysis For Polishing Grinding Robot Market

The value chain for the Polishing Grinding Robot Market is a multi-tiered structure encompassing various stages from raw material procurement to end-user deployment and post-sales support, illustrating the flow of value creation and distribution. At the upstream analysis stage, it involves the sourcing of critical components such as high-performance metals for robotic arms, precision motors, advanced sensors, complex electronic circuits, and sophisticated control software from specialized suppliers. These suppliers form the foundational layer, providing the technological building blocks that enable the functionality and precision of the robots. Manufacturers then assemble these components, integrate complex mechanical and electronic systems, and develop proprietary algorithms for motion control and surface finishing. This manufacturing phase is critical for ensuring the quality, durability, and performance characteristics of the robots, often involving rigorous testing and quality control procedures. The downstream analysis focuses on the distribution and implementation of these robotic systems. This includes original equipment manufacturers (OEMs) who produce the robots, often selling them directly or through a network of distributors and integrators. These integrators play a vital role in customizing solutions, installing robots on client sites, and ensuring seamless integration with existing production lines. The distribution channels can be both direct, involving sales teams engaging directly with large industrial clients, and indirect, leveraging value-added resellers (VARs) and system integrators who provide tailored solutions and local support. Post-sales services, including maintenance, training, and software updates, form another crucial part of the downstream value chain, ensuring customer satisfaction and long-term operational efficiency. The efficient functioning of this entire chain, from raw material procurement to post-implementation support, is essential for the sustained growth and competitive health of the polishing grinding robot market, emphasizing collaboration and specialized expertise at each stage to deliver comprehensive solutions to end-users.

Polishing Grinding Robot Market Potential Customers

The potential customers for Polishing Grinding Robots represent a broad spectrum of industries and enterprises that prioritize high-precision surface finishing, automation, and operational efficiency in their manufacturing processes. These end-users or buyers are primarily industrial entities seeking to improve product quality, reduce labor costs, increase throughput, and enhance worker safety. The automotive industry stands as a major consumer, utilizing these robots for tasks such as body panel finishing, deburring engine components, and polishing interior parts, where consistent surface quality is paramount for aesthetics and performance. The electronics sector employs these robots for precision polishing of components like semiconductor wafers, smartphone casings, and circuit boards, requiring microscopic accuracy to ensure functionality and durability. Aerospace manufacturers are also significant customers, relying on grinding robots for shaping and finishing turbine blades, structural components, and landing gear with extreme precision to meet stringent safety and performance standards. In the medical industry, polishing and grinding robots are indispensable for creating smooth, biocompatible surfaces on orthopedic implants, surgical instruments, and prosthetics, where surface integrity directly impacts patient outcomes. Furthermore, the general manufacturing sector, encompassing diverse areas from metal fabrication and tool making to consumer goods production, leverages these robots for a wide array of deburring, sanding, and surface preparation tasks. The growing adoption by small and medium-sized enterprises (SMEs) due to increasing robot affordability and ease of integration, alongside continued investment by large enterprises in advanced automation, underscores the expansive and continuously evolving customer base for polishing grinding robots. These customers share a common goal: to achieve superior product quality and operational excellence through advanced robotic automation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.8 Billion |

| Market Forecast in 2033 | USD 11.7 Billion |

| Growth Rate | 10.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB, FANUC Corporation, KUKA AG, Yaskawa Electric Corporation, Kawasaki Heavy Industries, Ltd., Universal Robots (Teradyne), Staubli International AG, Comau S.p.A., DENSO Corporation, EPSON Robots, Rethink Robotics, Techman Robot, Nachi-Fujikoshi Corp., Mitsubishi Electric Corporation, Genesis Systems Group, Robotiq, Schunk GmbH & Co. KG, UR Robotics, Shibaura Machine Co., Ltd., Hyundai Robotics |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polishing Grinding Robot Market Key Technology Landscape

The Polishing Grinding Robot Market is defined by a dynamic and continuously evolving technology landscape, where innovation in several key areas drives enhanced performance, versatility, and accessibility. At its core, the technology involves advanced robotic manipulators, typically articulated arms with multiple degrees of freedom, designed for precision movement and heavy payload capacity. These robotic arms are integrated with highly specialized end-effectors, which are the actual grinding, polishing, deburring, or sanding tools. The innovation in end-effector technology includes specialized abrasive materials, force-compliant tools, and quick-change systems, allowing robots to adapt to various surface finishes and materials efficiently. Crucial to their operation are sophisticated vision systems, often leveraging 2D and 3D cameras combined with advanced image processing algorithms, which enable robots to accurately locate parts, inspect surface quality, and adapt their paths to irregular geometries or surface imperfections. Furthermore, force feedback systems and tactile sensors are increasingly vital, providing real-time data on contact force and pressure, allowing robots to maintain optimal contact with the workpiece and prevent over-grinding or under-polishing, thereby ensuring consistent quality. The intelligence layer is powered by advanced control software, which orchestrates complex motion planning, collision avoidance, and adaptive process control. This software often incorporates elements of artificial intelligence and machine learning to enable self-optimization, pattern recognition, and predictive maintenance. The emergence of collaborative robotics (cobots) is another significant technological trend, making these systems safer and easier to integrate into existing human-centric workspaces. Moreover, the integration of IoT (Internet of Things) for data collection and cloud-based analytics allows for remote monitoring, performance optimization, and fleet management of robotic systems. These technological advancements collectively contribute to making polishing and grinding robots more intelligent, flexible, and capable of addressing the complex demands of modern manufacturing, pushing the boundaries of what automated surface finishing can achieve in terms of precision, efficiency, and adaptability.

Regional Highlights

The global Polishing Grinding Robot Market exhibits distinct regional dynamics, influenced by varying levels of industrialization, technological adoption rates, labor costs, and government initiatives. Each region presents a unique set of drivers and opportunities, contributing differently to the overall market growth and competitive landscape. Understanding these regional specificities is crucial for market players to develop localized strategies and maximize their market penetration. For instance, countries with established manufacturing bases and high labor costs often lead in robot adoption, seeking efficiency and quality improvements. Conversely, emerging economies with rapid industrialization are increasingly investing in automation to build competitive manufacturing capabilities. These regional differences highlight the diverse market maturity levels and the potential for growth across different geographical segments, reflecting the global imperative for enhanced productivity and superior product quality through advanced robotic solutions.

- Asia Pacific (APAC): The Asia Pacific region stands as the largest and fastest-growing market for polishing grinding robots, primarily driven by its robust manufacturing sector, particularly in countries like China, Japan, South Korea, and India. China's "Made in China 2025" initiative and South Korea's advanced robotics industries are significant accelerators. The region benefits from increasing investments in automotive, electronics, and general manufacturing industries, coupled with a growing demand for high-quality finished products and rising labor costs that necessitate automation.

- North America: North America represents a mature market with a strong emphasis on advanced manufacturing and innovation. The United States and Canada are leading the adoption of polishing grinding robots, especially in aerospace, automotive, and medical device manufacturing, driven by the need for high-precision, high-quality finishes and efforts to reshore manufacturing processes. Investments in AI and collaborative robotics further bolster market growth in this region.

- Europe: Europe is another significant market, characterized by stringent quality standards and a highly automated industrial landscape, particularly in Germany, Italy, and France. The automotive, aerospace, and general manufacturing sectors are key adopters, with a strong focus on Industry 4.0 integration and sustainable manufacturing practices. High labor costs and a strong research and development ecosystem propel the demand for sophisticated polishing and grinding robot solutions.

- Latin America: The Latin American market is an emerging region for polishing grinding robots, showing steady growth driven by increasing industrialization and foreign direct investment in manufacturing facilities, particularly in Brazil and Mexico. The automotive industry is a primary driver, with a growing need for automation to enhance production efficiency and meet global quality standards. Awareness and adoption of robotic technologies are progressively increasing.

- Middle East and Africa (MEA): The MEA region is at an nascent stage but demonstrates significant potential, with increasing investments in manufacturing diversification projects, particularly in countries like Saudi Arabia and UAE. The adoption of polishing grinding robots is driven by efforts to modernize industrial infrastructure, reduce reliance on manual labor, and enhance productivity in sectors such as metal fabrication and automotive components. Government visions for economic diversification play a crucial role in promoting industrial automation.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polishing Grinding Robot Market.- ABB

- FANUC Corporation

- KUKA AG

- Yaskawa Electric Corporation

- Kawasaki Heavy Industries, Ltd.

- Universal Robots (Teradyne)

- Staubli International AG

- Comau S.p.A.

- DENSO Corporation

- EPSON Robots

- Rethink Robotics

- Techman Robot

- Nachi-Fujikoshi Corp.

- Mitsubishi Electric Corporation

- Genesis Systems Group

- Robotiq

- Schunk GmbH & Co. KG

- UR Robotics

- Shibaura Machine Co., Ltd.

- Hyundai Robotics

Frequently Asked Questions

What is a polishing grinding robot and how does it benefit manufacturing?

A polishing grinding robot is an industrial robotic system designed for automated surface finishing tasks like polishing, grinding, deburring, and sanding. It enhances manufacturing by improving product quality consistency, increasing operational efficiency, reducing labor costs, ensuring worker safety, and achieving high precision on complex parts.

What are the primary industries adopting polishing grinding robots?

The primary industries adopting these robots include automotive for bodywork and component finishing, electronics for precision polishing, aerospace for turbine blade and structural component grinding, medical for implant and instrument finishing, and general manufacturing for various deburring and surface preparation tasks.

How does AI impact the performance of polishing grinding robots?

AI significantly impacts performance by enabling adaptive control for real-time adjustments to material variations, optimizing tool paths for efficiency, enhancing vision systems for defect detection, facilitating predictive maintenance, and increasing overall robot autonomy for complex finishing operations.

What are the key drivers and restraints for the Polishing Grinding Robot Market?

Key drivers include the increasing demand for automation, need for high-precision surface finishes, and rising labor costs. Restraints typically involve the high initial capital investment required and the technical complexity associated with integration and programming.

Which geographical region leads the market for polishing grinding robots?

The Asia Pacific region currently leads the market for polishing grinding robots, driven by its extensive manufacturing base, particularly in countries like China, Japan, and South Korea, coupled with significant investments in industrial automation and increasing demand for quality finished products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager