Poly Ethylene Decking Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432476 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Poly Ethylene Decking Market Size

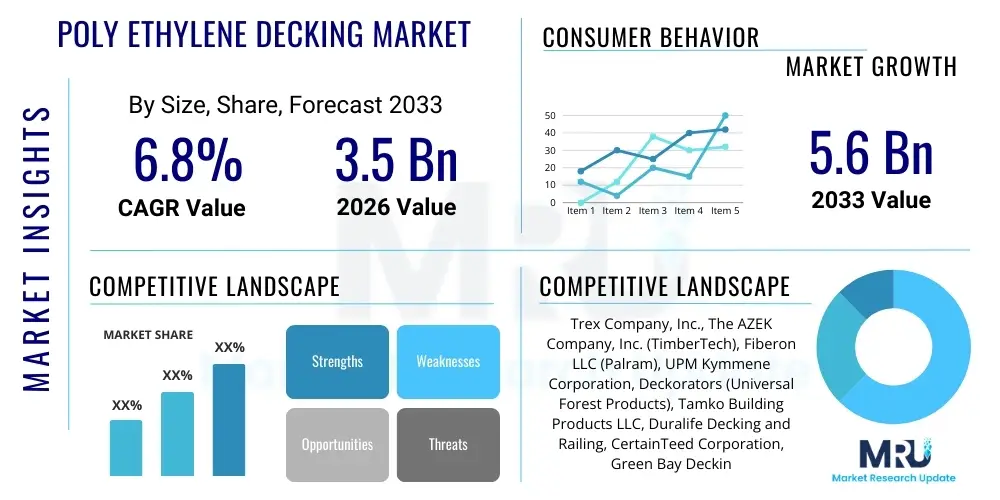

The Poly Ethylene Decking Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.6 Billion by the end of the forecast period in 2033.

Poly Ethylene Decking Market introduction

The Poly Ethylene (PE) Decking Market encompasses the manufacturing and distribution of decking materials primarily composed of polyethylene polymers, often combined with wood fibers or fillers to create composite decking products. These materials are highly valued in construction and remodeling due to their exceptional durability, resistance to moisture, rot, and insects, and low maintenance requirements compared to traditional wood decking. Polyethylene composite decking specifically uses high-density polyethylene (HDPE) or low-density polyethylene (LDPE) as the binding agent, offering a resilient surface that retains its aesthetic appeal for decades, making it a sustainable and cost-effective alternative for outdoor living spaces.

Major applications of PE decking span both residential and commercial sectors. In residential settings, it is extensively used for patios, balconies, pool surrounds, and garden walkways, driven by consumer demand for long-lasting, aesthetically pleasing, and environmentally friendly outdoor solutions. Commercially, PE decking finds application in high-traffic areas such as resorts, marinas, boardwalks, public parks, and outdoor dining facilities, where resistance to wear and tear and stringent safety standards are paramount. The inherent characteristics of PE, including its recyclability and the ability to mimic the look and feel of natural wood without the associated maintenance burden, fuel its increasing adoption globally.

Driving factors for this market include the global trend toward sustainable building materials, increased investment in home improvement projects, and regulatory pressures favoring fire-retardant and long-lasting construction products. The benefits of PE decking—such as UV resistance, color retention, splinter-free surfaces, and ease of installation—solidify its position as a premium choice in the outdoor construction materials segment. Furthermore, continuous product innovation, particularly in capping technology and surface finishes, enhances product performance and broadens the design possibilities available to architects and homeowners.

Poly Ethylene Decking Market Executive Summary

The Poly Ethylene Decking Market demonstrates robust growth, primarily fueled by shifting consumer preferences towards durable, low-maintenance, and eco-friendly construction materials. Current business trends indicate a strong focus on circular economy principles, leading manufacturers to increase the utilization of recycled polyethylene content in their composite formulations, thereby appealing to environmentally conscious consumers and reducing raw material costs. Technological advancements in co-extrusion and capping processes are enabling the production of boards with superior scratch and stain resistance, effectively narrowing the performance gap between premium PE composites and traditional materials. The market is highly competitive, characterized by strategic mergers, acquisitions, and extensive distribution network expansions aimed at optimizing supply chain efficiency and reaching underserved geographies.

Regional trends highlight North America as the dominant market, driven by established DIY culture, high disposable incomes, and widespread residential renovation activity. However, the Asia Pacific region is poised for the fastest growth, primarily due to rapid urbanization, increasing infrastructural spending, and the rising adoption of Western-style outdoor living concepts in emerging economies like China and India. Europe shows steady growth, propelled by strict environmental regulations and high demand for durable, weather-resistant materials suitable for variable climate conditions. Pricing sensitivity remains a key factor, particularly in developing regions, prompting manufacturers to optimize production processes to achieve cost competitiveness while maintaining product quality.

Segment trends reveal that the Residential application segment holds the largest market share, though the Commercial segment is exhibiting faster expansion due to large-scale infrastructure and hospitality projects requiring materials with longevity and minimal upkeep. Within the product type segmentation, capped composite decking is rapidly gaining traction over uncapped variants, offering superior protection against fading and mold, justifying a higher price point. HDPE remains the preferred raw material due to its superior strength-to-density ratio and widespread availability, dominating the raw material category used in high-performance PE decking formulations.

AI Impact Analysis on Poly Ethylene Decking Market

User queries regarding the impact of Artificial Intelligence (AI) on the Poly Ethylene Decking Market frequently center around three core themes: optimization of manufacturing processes, predictive maintenance for machinery, and leveraging advanced analytics for supply chain resilience and customer behavior forecasting. Users are keenly interested in how AI can minimize material waste during the extrusion process, particularly concerning complex composite formulations where achieving consistent texture and color is critical. Furthermore, there are significant inquiries about AI-driven customer service platforms and design tools (like AI configurators) that simplify the visualization and selection process for homeowners, thereby enhancing the buying experience and accelerating sales cycles. The overarching expectation is that AI will drive efficiency, reduce production costs, and provide a competitive edge in product customization and market responsiveness.

AI's application extends fundamentally to optimizing raw material blending and quality control. Machine learning algorithms can analyze data streams from sensors embedded in mixers and extruders, predicting potential defects based on real-time temperature, pressure, and flow rates. This enables proactive adjustments, significantly reducing the incidence of flawed boards and minimizing scrap material, which is critical given the high cost of polymer inputs. By implementing AI-powered vision systems on production lines, manufacturers can automate the inspection of finished products, ensuring consistent quality in terms of dimension, texture, and color matching, far surpassing the speed and accuracy achievable by manual inspection methods.

In the realm of strategy and sales, AI is transforming demand forecasting and inventory management. Analyzing vast datasets, including historical sales figures, seasonal weather patterns, regional housing starts, and marketing campaign performance, AI models generate highly accurate predictions of future demand. This predictive capability allows PE decking companies to optimize inventory levels, minimizing storage costs and mitigating the risk of stockouts during peak renovation seasons. Moreover, AI aids in targeted marketing by identifying specific customer segments most likely to purchase high-end composite decking, thereby maximizing the return on investment for advertising spend and streamlining the market penetration strategy.

- AI-driven optimization of extrusion parameters leading to reduced material waste and improved color consistency.

- Predictive maintenance analytics for manufacturing equipment, minimizing unplanned downtime and maximizing operational efficiency.

- Enhanced quality control through AI vision systems for automated, high-speed defect detection in finished decking boards.

- Machine learning models for highly accurate demand forecasting, optimizing inventory management and supply chain planning.

- AI-powered design configurators and visualization tools improving the residential customer experience and accelerating purchasing decisions.

- Optimization of raw material sourcing and blend ratios based on real-time polymer market price and quality fluctuations.

- Automated analysis of competitor pricing and product features to inform dynamic pricing strategies and market positioning.

DRO & Impact Forces Of Poly Ethylene Decking Market

The Poly Ethylene Decking Market is shaped by a confluence of strong drivers rooted in sustainability and consumer convenience, offset by restraints related to initial cost and raw material volatility, yet poised for significant expansion through innovation and penetration into emerging markets. The primary driver is the growing consumer preference for low-maintenance, high-durability materials that offer a superior lifespan compared to traditional treated lumber, thereby reducing long-term ownership costs. This is synergized by strong regulatory support for green building initiatives, which favors composite materials utilizing recycled plastics, further enhancing the market's environmental appeal. However, the initial capital expenditure for PE decking remains substantially higher than wood, posing a significant restraint, particularly in price-sensitive markets. Furthermore, the market is exposed to price volatility in petroleum-derived polymers (polyethylene), which directly impacts production costs and profit margins for manufacturers.

Opportunities in this market are abundant, particularly through technological innovation and geographic expansion. The development of advanced capping technologies that provide exceptional fade and stain resistance opens new avenues for premium product differentiation and justifies higher selling prices. Moreover, capitalizing on the increasing construction activity in fast-growing regions like Southeast Asia and Latin America represents a substantial untapped opportunity. The market is also finding opportunities in non-traditional applications, such as specialized marine environments and modular construction units, where the material's resistance to moisture and harsh conditions is highly advantageous.

Impact forces currently influencing the market include the stringent regulatory environment in developed economies requiring fire resistance and low volatile organic compound (VOC) emissions, pushing companies toward safer, higher-quality formulations. Economic impact forces, such as fluctuating interest rates and inflation, influence housing starts and renovation budgets, creating cyclical demand patterns that necessitate flexible manufacturing and inventory strategies. Technological impact forces, driven by competitors seeking innovative ways to improve the aesthetics of PE decking (e.g., highly realistic wood grain embossing), continually raise the bar for product quality and visual fidelity, ensuring constant evolutionary pressure on existing product lines. These interacting forces collectively determine the competitive intensity and overall growth trajectory of the PE decking sector.

Segmentation Analysis

The Poly Ethylene Decking Market is analyzed across various parameters, including material type, product profile, application, and distribution channel, providing a granular view of market dynamics and consumer preferences. Understanding these segments is crucial for manufacturers to tailor their production, pricing, and marketing strategies effectively. The segmentation by application clearly differentiates demand between the high-volume residential sector, which is driven by DIY and home renovation trends, and the commercial sector, which focuses on performance specifications suchability as load-bearing capacity and regulatory compliance for public spaces. Material type segmentation reveals the dominance of high-density polyethylene (HDPE) due to its superior mechanical properties, although combinations involving LDPE are used for specific flexibility requirements.

- By Type:

- Capped Composite Decking

- Uncapped Composite Decking

- By Profile:

- Solid Profile

- Hollow Profile

- By Application:

- Residential (Patios, Balconies, Pool Areas)

- Commercial (Marinas, Boardwalks, Hospitality, Public Parks)

- By Raw Material:

- High-Density Polyethylene (HDPE)

- Low-Density Polyethylene (LDPE)

- Mixed Recycled PE

- By Distribution Channel:

- Direct Sales (Contractors, Builders)

- Indirect Sales (Retailers, Home Centers, Online)

Value Chain Analysis For Poly Ethylene Decking Market

The value chain for the Poly Ethylene Decking Market begins with the upstream sourcing of critical raw materials, primarily virgin and recycled polyethylene pellets, wood fibers or fillers (such as rice hulls or cellulose), and performance-enhancing additives (UV stabilizers, color pigments, and coupling agents). Upstream analysis is critical, as the cost and consistency of recycled PE streams directly influence the final product cost and sustainability credentials. Manufacturers must establish robust relationships with petrochemical suppliers and plastic recyclers to ensure a steady, high-quality input supply. Fluctuations in crude oil prices, therefore, have a ripple effect throughout the entire value chain, impacting the competitiveness of PE decking relative to wood and PVC alternatives.

The core manufacturing process involves compounding and extrusion. Polyethylene and fillers are blended under precise conditions and then extruded through specialized dies to form the decking board profiles (solid or hollow). Capping, or co-extrusion, is a vital secondary manufacturing step for premium products, where a protective polymer layer is bonded to the core to enhance resistance against weathering, staining, and scratching. Operational efficiency and energy management in these sophisticated processing stages are key determinants of overall profitability. Quality control checkpoints are mandatory post-extrusion to ensure dimensional stability, structural integrity, and color matching across batches.

Downstream analysis focuses on distribution and installation. The distribution channel is bifurcated into direct sales, involving large commercial contractors and builders purchasing high volumes directly from the manufacturer, and indirect sales, which utilize extensive networks of home improvement retailers (Home Depot, Lowe's), specialized lumberyards, and online platforms. The choice of channel depends heavily on the target segment; residential customers typically rely on indirect channels, while commercial projects favor direct sourcing for bulk discounts and technical support. Effective logistics, ensuring timely and cost-efficient delivery of bulky decking materials, forms the final link before professional installation or DIY application by the end-user. The installer or contractor often serves as the final influential point, recommending specific brands based on ease of use and perceived long-term value.

Poly Ethylene Decking Market Potential Customers

The primary customers for Poly Ethylene Decking materials are segmented based on project size, purchasing volume, and specific application needs, falling broadly into residential consumers and commercial entities. Residential homeowners undertaking renovation or new construction projects represent the largest volume segment, driven by the desire to upgrade outdoor living spaces with durable, aesthetically pleasing, and maintenance-free materials. This group often seeks materials that are easy to install (DIY friendly) and offer a strong warranty, prioritizing long-term value over initial cost savings associated with traditional wood products. Targeted marketing towards this segment frequently emphasizes lifestyle benefits, sustainability, and low upkeep.

The secondary, yet rapidly growing, customer base consists of professional commercial buyers, including real estate developers, hospitality groups (hotels, resorts), government entities (public parks, boardwalks), and marine construction firms (marinas, docks). These customers require PE decking that meets rigorous performance standards concerning fire safety, slip resistance, load-bearing capacity, and compliance with local building codes. Their purchasing decisions are heavily influenced by specification sheets, material certifications, and the manufacturer's ability to supply large, consistent volumes on tight construction timelines. The marine sector, in particular, highly values the material's unparalleled resistance to salt water and UV degradation.

A third crucial customer group includes professional contractors and builders who act as intermediaries and specifiers. While not the ultimate end-users, their recommendations significantly influence brand choice among homeowners and small-scale commercial developers. Maintaining strong relationships with this group through product training, incentive programs, and reliable supply chain support is paramount for market penetration. The adoption of PE decking by modular home builders is also increasing, recognizing the material's consistency and speed of installation in off-site construction processes, further diversifying the customer landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.6 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Trex Company, Inc., The AZEK Company, Inc. (TimberTech), Fiberon LLC (Palram), UPM Kymmene Corporation, Deckorators (Universal Forest Products), Tamko Building Products LLC, Duralife Decking and Railing, CertainTeed Corporation, Green Bay Decking LLC, Advanced Environmental Recycling Technologies (AERT), Fortress Building Products, WPC Decking (China), Nanjing Jufeng WPC Technology Co., Ltd., Woodway UK Ltd., and Genova Products. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Poly Ethylene Decking Market Key Technology Landscape

The Poly Ethylene Decking market is characterized by significant technological intensity, primarily centered on enhancing material durability, visual appeal, and sustainability through advanced manufacturing techniques. The foundational technology is co-extrusion, or "capping," which involves simultaneously extruding the composite core (wood fiber and polyethylene mixture) with a protective, all-polymer shell. This capstock technology is crucial for preventing mold growth, resisting UV degradation, and offering superior scratch and stain resistance, effectively addressing the primary drawbacks of older, uncapped composite materials. Continuous innovation in capstock formulations, utilizing specialized additives and higher-performance polymers, allows manufacturers to offer extended warranties and maintain aesthetic integrity over decades of exposure to harsh climates.

Another critical area of technological advancement lies in surface finish and aesthetic replication. Manufacturers are employing high-definition digital printing and advanced embossing techniques to mimic the look and texture of exotic hardwoods with remarkable realism, making PE decking visually indistinguishable from premium lumber. This involves developing sophisticated tooling and using proprietary processes to create deep, non-repeating wood grain patterns, satisfying consumer demand for natural aesthetics combined with composite performance. Furthermore, specialized color pigmentation technologies are being developed to ensure long-term color retention, particularly in dark or highly saturated colors that are prone to fading under intense sunlight.

The integration of recycled material processing technology is also key, impacting both the supply chain and environmental positioning. Companies are investing in advanced sorting and cleaning technologies for recycled plastics to ensure the consistency and purity of the PE used in the decking core. Furthermore, ongoing R&D focuses on developing superior coupling agents that enhance the chemical bond between the wood fibers (a hydrophilic material) and the polyethylene polymer (a hydrophobic material). A stronger, more stable interface reduces water absorption, minimizes thermal expansion/contraction, and enhances the overall structural integrity and lifespan of the composite board, solidifying the market's technological edge.

Regional Highlights

Geographic analysis reveals diverse market penetration and growth drivers across major global regions, reflecting variations in construction practices, climate, and economic maturity.

- North America (United States, Canada): This region dominates the global market, largely due to high levels of consumer awareness, significant expenditure on residential remodeling (driven by the robust housing market), and the widespread acceptance of composite decking as a superior, low-maintenance alternative to wood. Favorable climatic conditions across many states necessitate highly durable materials resistant to extreme temperature fluctuations. The U.S. remains the innovation hub, home to major market leaders pushing advancements in capped technology and aesthetic design.

- Europe (Germany, UK, France): Characterized by stringent environmental regulations and a strong emphasis on sustainability, the European market shows steady, mature growth. Demand is concentrated in Western and Northern European countries where consumers prioritize long-term investment in high-quality outdoor materials. The focus here is often on materials with verified low environmental footprints and specific fire-rating certifications required for dense urban and multi-story residential constructions.

- Asia Pacific (China, Japan, Australia, India): Projected to be the fastest-growing market, APAC is witnessing surging demand driven by rapid urbanization, increasing disposable incomes, and the adoption of Western-style architectural designs featuring extensive outdoor spaces (balconies, rooftop gardens). China is a massive manufacturing base and a growing domestic market, while Australia shows high uptake due to its harsh weather conditions (intense UV exposure) favoring the durability of PE composites.

- Latin America (Brazil, Mexico): This emerging region offers high growth potential, particularly in urban coastal areas where moisture resistance and resistance to insects are critical material specifications. Market penetration is currently lower compared to North America, but increasing construction investments in hospitality and high-end residential communities are driving future demand. Price sensitivity remains a key factor influencing purchasing decisions.

- Middle East and Africa (MEA): Growth in MEA is highly localized and project-driven, focused mainly on large commercial developments, such as resorts, marinas, and public parks in the Gulf Cooperation Council (GCC) countries. Extreme heat and intense UV radiation necessitate specialized, high-performance PE decking formulations that can withstand these environmental stresses without degradation, often requiring customized solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Poly Ethylene Decking Market.- Trex Company, Inc.

- The AZEK Company, Inc. (TimberTech)

- Fiberon LLC (Palram)

- UPM Kymmene Corporation

- Deckorators (Universal Forest Products)

- Tamko Building Products LLC

- Duralife Decking and Railing

- CertainTeed Corporation

- Green Bay Decking LLC

- Advanced Environmental Recycling Technologies (AERT)

- Fortress Building Products

- WPC Decking (China)

- Nanjing Jufeng WPC Technology Co., Ltd.

- Woodway UK Ltd.

- Genova Products

- Envision Building Products LLC

- Foshan MexyTech Co., Ltd.

- California Redwood Association (Offering composite alternatives)

- Geocel Corporation (Associated products)

- Barrette Outdoor Living, Inc. (Similar outdoor solutions)

Frequently Asked Questions

Analyze common user questions about the Poly Ethylene Decking market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Poly Ethylene (PE) Decking and how does it compare to traditional wood?

PE Decking is a type of composite material made primarily from recycled polyethylene plastic and wood fibers. Unlike traditional wood, PE decking requires minimal maintenance (no staining or sealing), resists rot, insects, and splintering, and typically lasts much longer, offering superior durability and a strong warranty against weathering and fading due to its protective outer shell (capstock).

Is Poly Ethylene Decking considered an environmentally friendly or sustainable material?

Yes, PE decking is highly sustainable. Most leading manufacturers incorporate significant amounts of recycled content, including reclaimed plastic bags and wood scrap, diverting waste from landfills. The product's extremely long lifespan further contributes to sustainability by reducing the need for frequent replacement, aligning with circular economy principles favored by global environmental standards.

What factors contribute to the higher initial cost of PE composite decking?

The initial cost is higher primarily due to the complex, high-technology manufacturing processes, specifically the co-extrusion capping required for superior performance, and the cost of high-grade, often recycled, raw polymer materials and specialized additives. However, this higher upfront investment is often offset by dramatically lower long-term maintenance costs and the extended product life, offering better value over time.

What is the most important technological development currently driving the PE decking market?

The most important technological development is advanced Capped Composite technology. This involves bonding a protective, all-polymer outer layer (capstock) to the wood-plastic core, significantly enhancing resistance to scratching, staining, fading from UV exposure, and moisture absorption, thereby dramatically improving the aesthetic retention and overall structural integrity of the decking board.

Which geographical region exhibits the strongest growth potential for PE decking?

The Asia Pacific (APAC) region, specifically emerging economies like China and India, demonstrates the strongest growth potential. This growth is fueled by rapid urbanization, substantial investment in infrastructure, increasing disposable incomes, and the growing adoption of durable, low-maintenance building materials for new residential and commercial developments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager