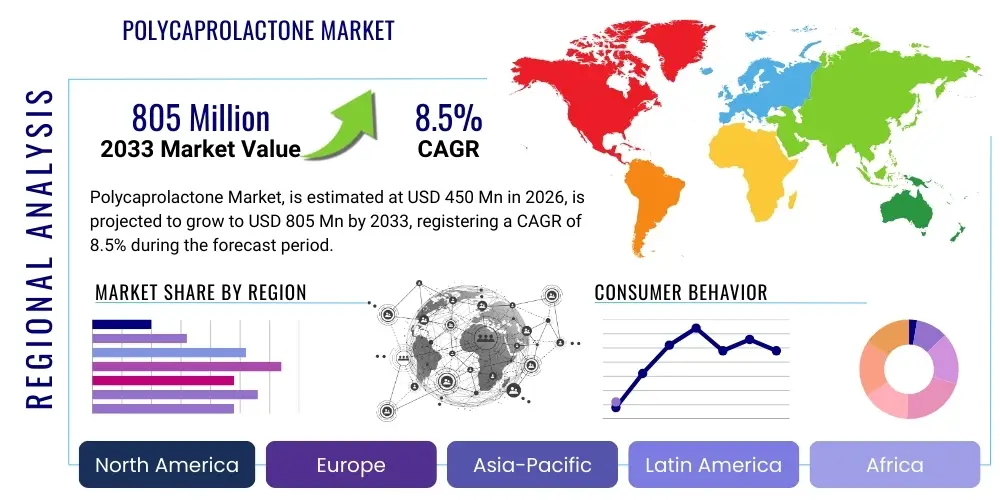

Polycaprolactone Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434881 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Polycaprolactone Market Size

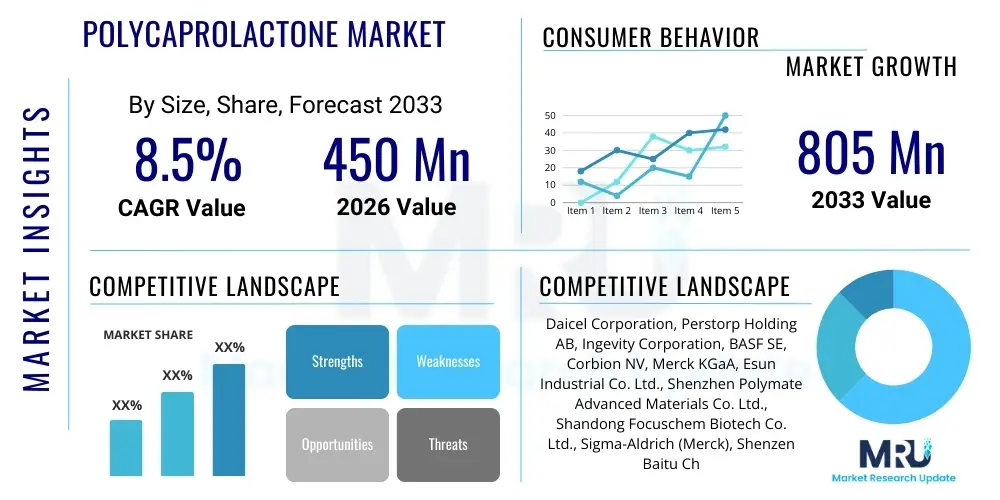

The Polycaprolactone Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 805 Million by the end of the forecast period in 2033. This growth trajectory is significantly underpinned by the increasing global emphasis on sustainable and biodegradable polymer solutions, particularly within high-value applications such as advanced medical devices, controlled drug delivery systems, and environmentally friendly packaging materials. The low melting point, excellent biocompatibility, and superior processability of polycaprolactone (PCL) position it as a critical material enabling innovation across regulated industries, thereby securing its robust financial expansion throughout the forecast period.

Market valuation reflects a dynamic shift away from conventional, non-biodegradable plastics in sectors facing stringent environmental regulations and consumer pressure for greener alternatives. The rising incidence of chronic diseases necessitating implantable medical devices and the continuous development in 3D printing technologies further fuel the demand for PCL, which offers tailored mechanical properties and controlled degradation kinetics. Financial performance indicators suggest sustained investment in R&D aimed at reducing the production costs associated with high-purity PCL grades, which is essential for maximizing market penetration into broader industrial applications beyond specialized niches.

Polycaprolactone Market introduction

The Polycaprolactone (PCL) Market encompasses the manufacturing, distribution, and application of a linear, semicrystalline polyester derived primarily from the ring-opening polymerization of ϵ-caprolactone. PCL is distinguished by its excellent biodegradable nature, low glass transition temperature (around -60 °C), and outstanding compatibility with a wide array of other polymers, making it highly versatile for compounding and blending. Its primary applications span across the biomedical field—including absorbable sutures, temporary scaffolds for tissue engineering, and long-term drug implants—and industrial uses such as specialized thermoplastic polyurethanes (TPUs), hot-melt adhesives, solvent-borne coatings, and environmentally degradable packaging films. The major benefits driving its adoption include non-toxicity, superior biocompatibility with human tissue, and the ability to fully decompose into carbon dioxide and water over a period of 6 to 24 months, satisfying global demands for sustainable materials. Key driving factors include escalating global regulatory mandates concerning plastic waste, rapid advancements in personalized medicine requiring sophisticated biomaterials, and increasing utilization of additive manufacturing (3D printing) technologies where PCL is highly favored due to its low processing temperature and ease of extrusion.

Polycaprolactone Market Executive Summary

The global Polycaprolactone market is poised for significant expansion, driven primarily by robust business trends emphasizing circular economy principles and advanced medical device innovation. Key business trends include strategic collaborations between PCL producers and pharmaceutical companies to develop next-generation controlled release systems, along with substantial capital investments directed towards scaling up production capacity for bio-based PCL variants, aiming to mitigate dependency on petroleum-derived feedstocks. Segment trends indicate the medical application segment maintains the highest growth potential due to ongoing clinical trials validating PCL’s efficacy in regenerative medicine and complex surgical procedures, while the coatings and adhesives segment is expanding rapidly, supported by the demand for high-performance, weather-resistant, and sustainable binding agents in the construction and automotive industries. Regionally, the Asia Pacific (APAC) region is projected to register the fastest growth, fueled by rapid industrialization, increasing healthcare expenditures in emerging economies like China and India, and the establishment of new manufacturing hubs for consumer packaging and medical components, though North America and Europe remain pivotal markets for high-grade PCL due to established R&D infrastructure and strict environmental policies requiring immediate adoption of biodegradable alternatives. This market synthesis underscores a transition towards specialized, performance-driven polymer applications that leverage PCL’s unique thermodynamic and biodegradable properties, assuring sustainable profitability across the value chain.

AI Impact Analysis on Polycaprolactone Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Polycaprolactone market predominantly revolve around three critical areas: optimization of synthesis and production efficiency, acceleration of biomaterial discovery and formulation, and improvement in quality control and regulatory compliance for medical-grade PCL. Users frequently ask how AI can reduce the batch-to-batch variability inherent in ring-opening polymerization processes and whether machine learning (ML) models can accurately predict the degradation kinetics and mechanical lifespan of PCL implants within physiological environments. The key themes summarized from this analysis indicate that users anticipate AI to be transformative, moving PCL manufacturing from empirical experimentation to data-driven predictive modeling. Concerns often center on the initial investment costs required for implementing sophisticated AI/ML platforms, particularly among mid-sized polymer manufacturers, and the need for specialized data scientists capable of handling complex material informatics specific to biodegradable polymers. Expectations are high regarding AI's ability to minimize material waste, optimize energy consumption during high-temperature processing, and significantly hasten the regulatory approval pathway by providing validated, simulated performance data.

- AI-driven material informatics accelerates the discovery of novel PCL copolymers and blends with enhanced properties (e.g., tunable degradation rates, higher tensile strength).

- Machine learning algorithms optimize polymerization reaction parameters (temperature, catalyst concentration, reaction time) to maximize yield and purity, reducing production costs.

- Predictive maintenance and quality control systems using AI analyze sensor data from manufacturing lines to detect anomalies, ensuring consistent high quality for medical and pharmaceutical grades.

- AI simulates the long-term degradation and bioabsorption behavior of PCL scaffolds and drug carriers, significantly speeding up pre-clinical testing phases and regulatory submission timelines.

- Supply chain optimization through AI forecasting improves inventory management for raw materials (ϵ-caprolactone) and finished goods, mitigating geopolitical supply risks.

- Robot process automation (RPA) integrated with AI enhances the efficiency of post-processing techniques such as compounding, granulation, and sterilization of PCL components.

- AI supports the personalized medicine paradigm by rapidly designing and verifying customized PCL geometries for patient-specific implants using 3D printing data.

DRO & Impact Forces Of Polycaprolactone Market

The dynamics of the Polycaprolactone market are shaped by compelling drivers (D), significant restraints (R), and latent opportunities (O), all subjected to powerful external impact forces. Primary drivers include the outstanding biocompatibility and non-toxic nature of PCL, which positions it as a preferred polymer for critical medical applications such as resorbable sutures, drug eluting stents, and temporary tissue scaffolds, alongside the escalating global requirement for sustainable and truly biodegradable packaging solutions to combat environmental pollution. These drivers are bolstered by technological advances in additive manufacturing, where PCL’s low melting point facilitates precise 3D printing of complex structures. However, the market faces considerable restraints, notably the relatively high cost of PCL production compared to commodity polymers like polyethylene (PE) and polypropylene (PP), which limits its widespread adoption in low-margin industrial applications, coupled with competition from other biodegradable polymers such as Polylactic Acid (PLA) and Polyhydroxyalkanoates (PHAs) that sometimes offer superior mechanical rigidity or faster degradation profiles. Opportunities are abundant in the development of novel biomedical applications, including sophisticated controlled drug delivery systems and nerve regeneration conduits, alongside innovation in bio-based or green PCL synthesis, which would significantly reduce reliance on fossil fuels and potentially lower overall production costs. The market is profoundly influenced by regulatory impact forces, specifically the stringent medical device regulations (e.g., FDA approval and EU MDR compliance) which, while increasing market entry barriers, also solidify PCL’s specialized position, and global environmental mandates and Extended Producer Responsibility (EPR) schemes that accelerate demand for PCL in sustainable packaging.

Segmentation Analysis

The Polycaprolactone market segmentation provides a granular view of demand across various product forms, molecular weights, and critical end-user applications, allowing for precise strategic targeting. Segmentation by application reveals the dominance of the biomedical sector, owing to high-value, regulated uses requiring superior material performance, followed closely by the industrial applications encompassing coatings, adhesives, and specialty polyurethanes that leverage PCL’s excellent flexibility and resistance to solvents. The differentiation based on molecular weight—high molecular weight (HMW) typically used for robust medical implants and long-term degradation applications, and low molecular weight (LMW) commonly employed as plasticizers, blending agents, and components in TPUs and coatings—helps manufacturers tailor production capabilities to specific market requirements. Further segmentation includes product form (pellets, resins, powders) which dictates processing techniques and specific utility in compounding or 3D printing. Understanding these segments is crucial for analyzing revenue streams, identifying unmet needs, and prioritizing R&D efforts toward novel PCL derivatives that can bridge performance gaps or offer cost advantages.

- By Application:

- Medical & Healthcare (Sutures, Drug Delivery Systems, Tissue Engineering Scaffolds, Orthopedic Devices)

- Packaging (Biodegradable Films, Food Containers, Specialty Flexible Packaging)

- Coatings & Adhesives (Hot-Melt Adhesives, Solvent-Borne Coatings, Industrial Sealants)

- Footwear & Textile

- 3D Printing & Prototyping

- Others (Composites, Agriculture Films)

- By Manufacturing Process:

- Ring-Opening Polymerization (ROP)

- Polycondensation

- By Molecular Weight:

- Low Molecular Weight PCL (< 20,000 g/mol)

- High Molecular Weight PCL (> 80,000 g/mol)

- By Product Form:

- Pellets

- Resins

- Powders

Value Chain Analysis For Polycaprolactone Market

The Polycaprolactone value chain is intricately structured, beginning with the upstream sourcing of raw materials, progressing through polymerization and compounding, and culminating in highly specialized downstream applications and distribution channels. Upstream analysis focuses predominantly on the sourcing and purification of the monomer, ϵ-caprolactone, which is typically derived from petroleum-based feedstocks, although the increasing emphasis on sustainability is driving investment in fermentation or other bio-based pathways for caprolactone synthesis. Key suppliers in this stage include specialized chemical producers who must maintain extremely high purity standards, particularly for medical and pharmaceutical grades, influencing the final cost and quality of the polymer. The manufacturing stage involves complex ring-opening polymerization (ROP) processes using specific catalysts, a step heavily controlled by major polymer manufacturers who own proprietary technology to achieve desired molecular weights and polydispersity indices.

Downstream analysis covers the transformation of PCL resin into finished products tailored for specific end-users. This involves compounding, blending with other polymers (like PLA or starch), extrusion, or molding processes to create fibers, films, pellets, or customized medical scaffolds. The final consumption is driven by highly regulated industries such as medical device manufacturing and pharmaceuticals, alongside specialized industrial sectors like aerospace coatings and high-end consumer goods packaging. Distribution channels are bifurcated into direct and indirect routes. Direct sales are prevalent for large-volume, highly technical transactions, particularly for medical-grade PCL sold directly to specialized Original Equipment Manufacturers (OEMs) who require detailed technical support and material certification. Indirect distribution relies on global chemical distributors and regional agents, particularly for industrial and lower-volume coating and adhesive applications, ensuring broad market reach and inventory management.

Polycaprolactone Market Potential Customers

The primary potential customers and end-users of Polycaprolactone are highly diversified across industries where biocompatibility, controlled degradation, and excellent processing characteristics are paramount requirements. In the medical sector, potential customers include large multinational Medical Device OEMs specializing in orthopedics, cardiology (stents), and general surgery (sutures), as well as smaller biotech firms developing novel tissue engineering scaffolds and regenerative medicine products, where PCL serves as a foundational bio-resorbable matrix. Pharmaceutical companies constitute another crucial customer base, utilizing PCL for sophisticated controlled-release drug encapsulation and implantable drug delivery systems designed for long-term therapeutic effects. Furthermore, the burgeoning 3D printing industry features specialized service bureaus and material providers who purchase PCL pellets and powders for manufacturing prototypes and final-use components in biomedical and consumer applications, appreciating PCL's ease of extrusion and excellent shape memory properties.

Beyond the healthcare realm, a substantial customer segment exists within the specialized industrial and packaging sectors. Potential customers include major manufacturers of Thermoplastic Polyurethanes (TPUs) for high-performance footwear, automotive components, and protective casings, where PCL enhances flexibility and durability. Leading international coating and adhesive companies purchase low molecular weight PCL for use in hot-melt adhesives, laminating agents, and solvent-borne coatings for marine and construction applications, capitalizing on PCL's strong adhesion to various substrates and weather resistance. Finally, consumer goods and food packaging companies focused on achieving aggressive sustainability targets represent a rapidly growing customer segment, seeking PCL to blend into biodegradable packaging films and compostable rigid containers, thereby offering consumers verifiable eco-friendly alternatives to conventional plastics, often driven by global retail supply chain requirements for ecological compliance.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 805 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Daicel Corporation, Perstorp Holding AB, Ingevity Corporation, BASF SE, Corbion NV, Merck KGaA, Esun Industrial Co. Ltd., Shenzhen Polymate Advanced Materials Co. Ltd., Shandong Focuschem Biotech Co. Ltd., Sigma-Aldrich (Merck), Shenzen Baitu Chemical Co. Ltd., Polysciences Inc., Reagent Chemical Company, DURECT Corporation, Qingdao Ruichang New Material Co. Ltd., PolyNovo Biomaterials Pty Ltd, Wako Pure Chemical Industries Ltd., CAPA Monomer Ltd., NatureWorks LLC (partially competing with derivatives), Evonik Industries AG (specialty grades). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polycaprolactone Market Key Technology Landscape

The technology landscape for the Polycaprolactone market is predominantly centered on optimizing the synthesis of the polymer and enhancing its functionality through advanced processing and compounding methods suitable for high-purity applications. The foundational technology remains Ring-Opening Polymerization (ROP) of the ϵ-caprolactone monomer, which utilizes metallic catalysts (such as tin octoate) or organocatalysts to achieve high molecular weight PCL with low polydispersity—a critical factor for materials used in medical implants where consistent mechanical performance and predictable degradation are non-negotiable requirements. Recent technological advancements focus on developing 'green' synthesis routes, including the use of enzymatic polymerization or bio-based monomers derived from sustainable sources, aiming to reduce the reliance on conventional organometallic catalysts, thereby improving the biocompatibility profile and lowering the environmental impact of the production process, while simultaneously increasing the purity levels necessary for pharmaceutical applications.

Furthermore, significant technological progress is observed in downstream processing and material modification. Continuous manufacturing techniques, such as twin-screw extrusion, are being widely adopted to blend PCL with other polymers (e.g., PLA, PHAs, cellulose) or functional additives (e.g., hydroxyapatite, growth factors) to create specialized composites that exhibit enhanced stiffness, osteoconductivity, or controlled release capabilities. These compounding technologies require stringent process control to prevent thermal degradation of the PCL, which has a relatively low thermal stability. Specialized technologies like electrospinning and microfluidics are essential for creating nanoscale PCL fibers and microparticles, which are crucial for advanced applications in tissue engineering scaffolds, wound dressings, and injectable drug microcapsules, pushing the boundaries of material performance at the biological interface. The evolution of these technologies ensures PCL remains a leading material in the high-performance biodegradable polymer space, meeting the increasingly complex demands of regulated industries.

Regional Highlights

- North America: This region maintains a leading position in terms of value, primarily due to high healthcare expenditure, the presence of major pharmaceutical and medical device manufacturers, and a robust research and development ecosystem that rapidly adopts advanced biomaterials. Strict FDA regulatory standards drive demand for high-purity, well-characterized PCL grades. The U.S. and Canada are significant consumers, particularly within 3D printing for specialized biomedical prototyping and advanced drug delivery research, favoring innovation in PCL copolymers and composites.

- Europe: Driven by highly proactive environmental regulations, particularly the EU’s mandates concerning single-use plastics and packaging waste, Europe demonstrates strong growth in the PCL market for industrial and packaging applications. Countries like Germany, France, and the UK prioritize sustainable polymer alternatives, which benefits PCL adoption in hot-melt adhesives, coatings, and specialized TPU applications. The region also hosts leading chemical producers focusing on bio-based PCL innovations to comply with stringent sustainability objectives like the European Green Deal.

- Asia Pacific (APAC): APAC is expected to exhibit the highest Compound Annual Growth Rate (CAGR) globally, largely fueled by rapid industrialization, expanding domestic healthcare sectors, and a booming consumer goods market requiring functional packaging. China, India, and South Korea are becoming major manufacturing hubs for PCL components, driven by lower production costs and increasing local demand for medical consumables and biodegradable agricultural films. While APAC historically focused on industrial-grade PCL, rising per capita income and healthcare infrastructure development are now accelerating the adoption of high-value medical PCL.

- Latin America (LATAM) and Middle East & Africa (MEA): These regions represent emerging markets characterized by growing urbanization and improving regulatory frameworks concerning environmental standards. While currently smaller in market share, these regions offer significant opportunities, particularly in packaging and specialty coatings, as governments introduce policies to phase out non-degradable plastics. Investment in local compounding facilities and improved distribution networks will be key for future PCL market penetration in MEA and LATAM.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polycaprolactone Market.- Daicel Corporation

- Perstorp Holding AB

- Ingevity Corporation

- BASF SE

- Corbion NV

- Merck KGaA

- Esun Industrial Co. Ltd.

- Shenzhen Polymate Advanced Materials Co. Ltd.

- Shandong Focuschem Biotech Co. Ltd.

- Sigma-Aldrich (Merck)

- Shenzen Baitu Chemical Co. Ltd.

- Polysciences Inc.

- Reagent Chemical Company

- DURECT Corporation

- Qingdao Ruichang New Material Co. Ltd.

- PolyNovo Biomaterials Pty Ltd

- Wako Pure Chemical Industries Ltd.

- CAPA Monomer Ltd.

- Evonik Industries AG

- Mitsubishi Chemical Corporation

Frequently Asked Questions

Analyze common user questions about the Polycaprolactone market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Polycaprolactone (PCL) over other biodegradable polymers like PLA?

PCL possesses several key advantages, primarily its significantly lower glass transition temperature (around -60 °C), which results in high flexibility, superior elasticity, and excellent processability (especially in 3D printing) compared to the brittle nature of Polylactic Acid (PLA). Additionally, PCL is highly compatible with the human body, offering predictable and controlled degradation kinetics, making it the preferred choice for long-term medical implants and tissue engineering scaffolds that require gradual absorption.

How is Polycaprolactone typically synthesized, and are bio-based alternatives available?

PCL is primarily synthesized through the catalytic Ring-Opening Polymerization (ROP) of the cyclic monomer ϵ-caprolactone, usually facilitated by metallic catalysts like tin octoate. While conventional ϵ-caprolactone is derived from petroleum feedstocks, substantial R&D efforts are focused on developing bio-based or 'green' synthesis routes, including enzymatic polymerization and using renewable resources to produce the monomer, aiming to fully eliminate fossil fuel dependence and enhance sustainability.

Which sectors drive the largest demand for high molecular weight PCL?

The largest demand for high molecular weight (HMW) PCL originates from the Medical and Healthcare sector. HMW PCL is essential for manufacturing robust, long-lasting bio-resorbable medical devices, including orthopedic fixation devices, cardiovascular stents, and sustained drug delivery implants. Its high mechanical integrity and slow degradation rate are critical for these structural, regulated applications.

What are the main market restraints impacting PCL adoption in broader industrial applications?

The main restraint is the relatively high production cost of PCL compared to conventional commodity polymers (PE, PP). This cost differential limits its widespread adoption in high-volume, low-margin industrial or general packaging applications. Furthermore, competitive pressure from other cost-effective biodegradable polymers like PLA also acts as a market barrier in specific non-medical sectors.

What role does 3D printing technology play in driving PCL market growth?

3D printing, specifically Fused Deposition Modeling (FDM) and bioprinting, is a significant growth driver. PCL's low melting temperature and excellent flow characteristics make it highly suitable for extrusion-based additive manufacturing. This capability allows researchers and manufacturers to create complex, patient-specific geometries for customized medical implants, drug dosage forms, and intricate tissue scaffolds with high precision, accelerating innovation in personalized medicine.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Bioresorbable Medical Material Market Size Report By Type (Polylactic Acid (PLA), Polyglycolic Acid (PGA), Polysaccharides, Polycaprolactone (PCL), PLGA), By Application (Drug Delivery, Orthopedics, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Polycaprolactone Diol Market Statistics 2025 Analysis By Application (Resins & Coatings, Elastomers, Adhesives, Medical Devices), By Type (400-1000 Molecular Weight, 1000-3000 Molecular Weight, Above 3000 Molecular Weight), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Polycaprolactone Market Statistics 2025 Analysis By Application (Resins & Coatings, Elastomers, Adhesives, Medical Devices), By Type (Double Functional Caprolactone, Tri Functional Caprolactone, High Molar Mass PCL Polymers), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Synthetic Biodegradable Polymer Market Statistics 2025 Analysis By Application (Chemical Industry, Pharmaceutical Industry, Home and Personal Care Industry, Agriculture and Allied Industries), By Type (Aliphatic polymers, Poly glycoside acid (PGA), Polylactic acid (PLA), Polycaprolactone acid (PCL), Polyphosphoesters, Polyanhydrides), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager