Polycarboxylate Water-reducer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435775 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Polycarboxylate Water-reducer Market Size

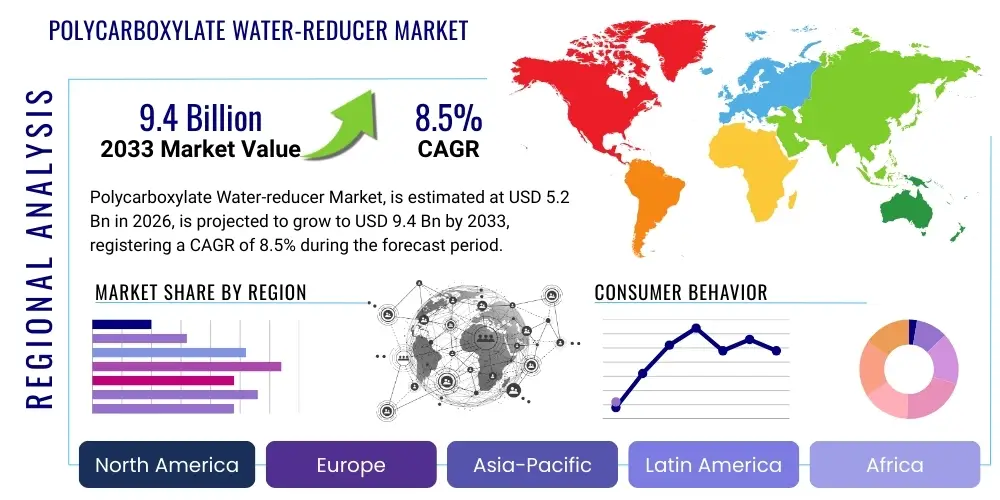

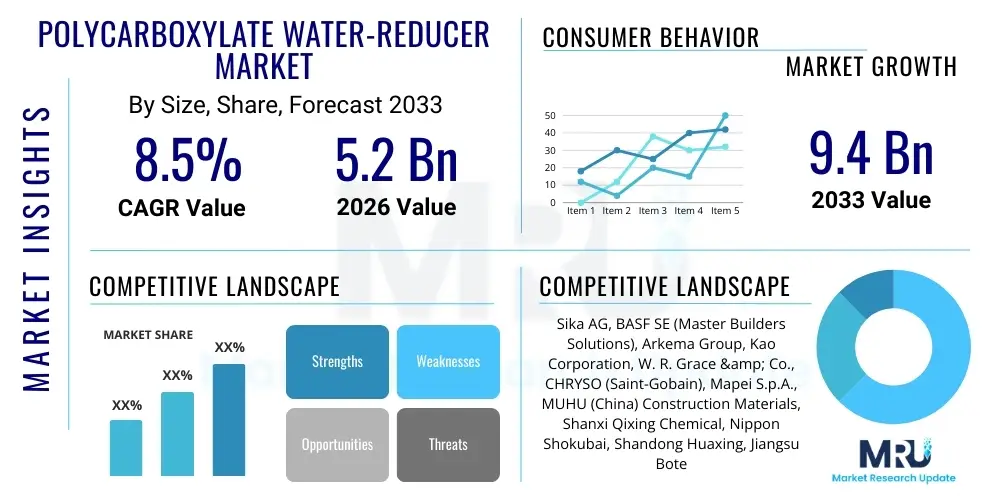

The Polycarboxylate Water-reducer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 5.2 Billion in 2026 and is projected to reach USD 9.4 Billion by the end of the forecast period in 2033.

Polycarboxylate Water-reducer Market introduction

Polycarboxylate water reducers (PCEs), also known as high-performance superplasticizers, represent the cutting edge of chemical admixtures used in concrete production. These polymers are characterized by a highly effective comb-like structure, featuring a backbone chain (typically methacrylate or acrylate) and side chains (polyethylene glycol). This structure provides superior dispersion capabilities, allowing for significant reduction in water content while maintaining or enhancing the workability (slump) of fresh concrete. The primary function of PCEs is to achieve high-early strength, excellent flowability, and increased durability in complex concrete formulations, addressing modern infrastructure demands that conventional lignosulfonate or naphthalene-based superplasticizers often fail to meet. Their adaptability across various cement types and environmental conditions solidifies their pivotal role in the construction industry.

The product’s description centers on its chemical mechanism, which involves steric hindrance and electrostatic repulsion. Unlike older generations that primarily rely on electrostatic forces, PCEs utilize long side chains extending into the surrounding water, creating a physical barrier that prevents cement particles from flocculating. This highly efficient dispersion mechanism results in lower mixing water requirements—often allowing for water reduction rates exceeding 30%—which significantly improves the overall performance and quality of the hardened concrete. Key benefits driving market penetration include enhanced mechanical strength, reduced permeability, minimized shrinkage and cracking, and superior performance stability in low water-to-cement ratio mixtures necessary for high-rise buildings and long-span bridges.

Major applications of Polycarboxylate Water-reducers span critical sectors of civil engineering and construction. They are essential components in ready-mix concrete, precast concrete manufacturing (especially high-performance and self-compacting concrete, SCC), and specialized applications such as tunnel linings, dam construction, and nuclear power containment structures. The increasing global focus on sustainable construction practices further boosts the market, as PCEs enable the incorporation of supplementary cementitious materials (SCMs) like fly ash and slag without compromising concrete strength or workability. Driving factors include rapid urbanization in Asia Pacific, stringent environmental regulations promoting high-durability infrastructure, and continuous innovation in PCE chemical structures leading to tailored performance characteristics for specific project requirements.

Polycarboxylate Water-reducer Market Executive Summary

The Polycarboxylate Water-reducer Market is undergoing robust expansion, fundamentally driven by global infrastructure investment, particularly in emerging economies characterized by rapid urbanization and large-scale construction projects. Key business trends indicate a significant shift towards customized and high-performance PCE formulations designed to meet specific regulatory requirements concerning concrete longevity, freeze-thaw resistance, and corrosion inhibition. Manufacturers are increasingly focusing on vertical integration and strategic mergers and acquisitions to secure raw material supply chains—primarily involving acrylic acid derivatives and polyethers—and to expand specialized product portfolios targeting niche applications such as ultra-high-performance concrete (UHPC) and 3D printed construction materials. Sustainability remains a central commercial theme, with companies prioritizing low-carbon footprint production methods and developing PCEs that maximize the utilization of industrial byproducts in concrete mixes.

Regional trends highlight Asia Pacific (APAC) as the undisputed leader in consumption and growth, primarily due to immense construction activity in China, India, and Southeast Asian nations focused on transportation networks and commercial real estate. North America and Europe, while mature markets, emphasize technological innovation and regulatory compliance, showing strong demand for highly specialized and customized PCE blends that adhere to strict environmental, safety, and performance standards. The Middle East and Africa (MEA) are also emerging as high-growth regions, powered by ambitious mega-projects and diversification efforts away from oil dependence, necessitating durable concrete solutions for extreme arid climates. Market competitiveness is intensifying, with both global chemical giants and specialized regional producers vying for market share through price optimization and technical service superiority.

Segment trends underscore the dominance of the powder form segment in specialized and dry-mix applications, offering advantages in logistics and shelf life, although the liquid form remains paramount in the high-volume ready-mix sector due to ease of handling and dosing. In terms of application, the ready-mix concrete segment accounts for the largest market share, reflecting its ubiquity in general construction. However, the precast concrete segment is projected to exhibit the fastest growth, fueled by the increasing preference for off-site construction methods which demand highly predictable and fast-setting concrete properties enabled by advanced PCE technology. Furthermore, the segmentation by type shows a rising preference for formulations based on specialized side chain chemistry offering superior slump retention and early strength development characteristics, addressing common challenges faced in large pour operations and fast-track construction schedules.

AI Impact Analysis on Polycarboxylate Water-reducer Market

User queries regarding AI's impact on the Polycarboxylate Water-reducer Market primarily revolve around optimizing material composition, predicting concrete performance under varied environmental conditions, and automating quality control during production and application. Key concerns focus on how AI can enhance the formulation efficiency of PCE blends, reducing development cycles and ensuring product consistency across batches. Users are seeking AI-driven solutions for managing complex material interactions, particularly when incorporating diverse supplementary cementitious materials (SCMs), and optimizing dosing rates on site to minimize material waste and labor costs. The expectation is that machine learning (ML) models will be employed to analyze vast datasets of mix designs, rheological properties, and curing conditions, transforming the traditional, often iterative, empirical approach to admixture development into a data-driven science. AI is anticipated to deliver significant improvements in supply chain predictability and risk management for raw materials.

AI's initial application is centered on research and development (R&D), leveraging ML algorithms to screen potential molecular structures and predict their performance characteristics before costly laboratory synthesis. This drastically accelerates the innovation pipeline for next-generation PCEs with enhanced features, such as improved temperature stability or longer slump retention times tailored for specific climates or transportation distances. Furthermore, AI systems can process real-time data from concrete batching plants, adjusting PCE dosage automatically based on minute variations in aggregate moisture content or cement reactivity, thereby guaranteeing optimal concrete workability and reducing human error in the field. This level of precision is critical for high-stakes projects requiring ultra-consistent material quality.

In the commercial domain, AI facilitates market forecasting and demand planning by integrating macroeconomic indicators, regional construction pipeline data, and seasonality trends, allowing manufacturers to optimize inventory and production schedules. Predictive maintenance powered by AI is also being deployed in PCE manufacturing facilities to minimize operational downtime and maintain high levels of quality assurance. Overall, the influence of AI is expected to move the market toward a more digitized, efficient, and precise operational model, enhancing product customization capabilities and contributing significantly to material sustainability by optimizing resource use in concrete production globally. This integration ensures that PCEs remain at the forefront of performance concrete technology.

- Optimization of PCE molecular structure design using generative AI and ML modeling.

- Real-time automated dosing and quality control in concrete batching plants via sensors and AI analytics.

- Predictive analysis of concrete rheology and setting times under variable site conditions.

- Enhanced supply chain forecasting and risk management for raw materials like polyethers and acrylic acid.

- Development of customized, high-performance PCE blends tailored to specific project material compositions.

- Automation of quality assurance testing and data interpretation during PCE manufacturing processes.

- Integration of digital twin technology for simulating the performance of novel PCE formulations.

DRO & Impact Forces Of Polycarboxylate Water-reducer Market

The Polycarboxylate Water-reducer Market is principally driven by the imperative need for high-performance and durable concrete in modern construction, particularly within densely populated urban environments and critical infrastructure projects. Key drivers include massive global investment in infrastructure (roads, bridges, airports, and high-speed rail), rapid urbanization in APAC and MEA regions demanding reliable residential and commercial structures, and stringent regulatory requirements mandating the use of long-lasting, low-permeability concrete to reduce maintenance cycles. The technical superiority of PCEs—offering high water reduction rates and extended slump retention necessary for complex pours and specialized concrete types like self-compacting concrete (SCC)—provides a significant impetus for market growth. Furthermore, environmental drivers, such as the push to utilize high volumes of supplementary cementitious materials (SCMs) to reduce cement's carbon footprint, mandate the use of PCEs to maintain concrete performance metrics, acting as a powerful market force.

Conversely, the market faces notable restraints, primarily concerning the volatility and rising cost of key raw materials, including ethylene oxide and acrylic acid derivatives, which directly impacts production margins and final product pricing. Technical challenges related to compatibility issues between highly customized PCE formulations and specific local cement types, especially those with high alkali content, can hinder broader adoption, requiring intensive, project-specific R&D and calibration. Additionally, the fragmented nature of the construction chemicals market in certain developing regions, coupled with a lack of standardized testing protocols or technical expertise for high-dosage PCE application, poses a barrier to entry for advanced products. Economic instability and slowdowns in large construction sectors due to geopolitical conflicts or global health crises also periodically restrain market expansion by delaying major projects.

Opportunities for market expansion are vast, largely concentrated around the development of specialized, environmentally friendly PCE variants. Significant opportunities exist in formulating multi-functional PCEs that combine water reduction capabilities with other essential concrete properties, such as air entrainment or corrosion inhibition, offering integrated solutions. The growing adoption of precast and modular construction techniques globally presents a high-growth avenue, as these methods rely heavily on the consistent and rapid strength development facilitated by PCEs. Moreover, expanding technical training and service offerings in emerging markets can overcome technical adoption restraints, creating new demand pockets. The push towards 3D printing in construction further opens a lucrative niche for highly specialized, rheology-controlled PCE admixtures capable of meeting the unique demands of layer-by-layer material deposition and rapid setting requirements. Impact forces are strong and predominantly positive, driven by long-term macroeconomic trends favoring durable, smart infrastructure.

Segmentation Analysis

The Polycarboxylate Water-reducer Market is meticulously segmented based on product form, application, and type, providing stakeholders with granular insights into demand patterns and competitive landscapes. The segmentation by form—liquid versus powder—reflects differences in handling, transport logistics, and end-use application suitability. Liquid PCEs dominate the high-volume ready-mix market due to ease of batching and lower cost per application, whereas powder PCEs are essential for specialized dry-mix mortars, grouts, and certain precast applications where stability and extended shelf life are paramount. Understanding this split is crucial for optimizing manufacturing footprints and distribution strategies.

Segmentation by application highlights the immense reliance of key construction sectors on this technology. The ready-mix concrete sector is the largest consumer, reflecting its central role in general building and infrastructure. However, the precast concrete and dry-mix segments are exhibiting accelerated growth due to increased industrialization of construction processes. Type segmentation—focusing on chemistry (e.g., side chain length and density)—allows producers to target specific performance requirements such as high-range water reduction, extended slump retention, or enhanced early-age strength, catering directly to complex engineering needs like those found in bridge construction or specialized civil works requiring high chemical resistance.

The detailed market segmentation is vital for strategic planning, allowing manufacturers to tailor R&D efforts towards high-growth areas such as high-performance concrete (HPC) formulations necessary for nuclear and marine construction, or environmentally focused blends that enhance the effectiveness of non-traditional supplementary cementitious materials. The continuous refinement of PCE chemistry, driven by segment-specific demand, ensures that the product remains technologically relevant and superior to legacy superplasticizer alternatives, thus sustaining its projected robust growth trajectory across all major end-use sectors globally.

- By Form:

- Liquid Polycarboxylate Water-reducer

- Powder Polycarboxylate Water-reducer

- By Type (Chemical Structure):

- PCE based on Methacrylic Acid (MAA)

- PCE based on Acrylic Acid (AA)

- PCE based on Allyl Ether

- By Application:

- Ready-Mix Concrete

- Precast Concrete

- Dry-Mix Mortar

- High-Performance Concrete (HPC)

- Self-Compacting Concrete (SCC)

- Others (Grout, Specialized Repair Mortars)

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, India, Japan, South Korea, Southeast Asia)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East & Africa (GCC Countries, South Africa, Rest of MEA)

Value Chain Analysis For Polycarboxylate Water-reducer Market

The value chain for the Polycarboxylate Water-reducer Market is complex, beginning with the upstream sourcing of crucial petrochemical intermediates. Upstream analysis focuses on key raw materials such as acrylic acid, maleic anhydride, and specialized polyether side chains (e.g., polyethylene glycol monoallyl ether). The cost and supply stability of these materials, which are largely dictated by the petrochemical industry, significantly influence the final pricing and profitability of PCE producers. Major chemical companies specializing in basic and intermediate chemicals constitute the initial supply layer. Price volatility and environmental regulations impacting petrochemical production remain continuous challenges in this stage, necessitating robust contractual agreements and strategic raw material inventory management by PCE manufacturers to mitigate supply risks.

The core manufacturing and formulation stage follows, where raw materials are polymerized and blended into liquid or powder PCE products. This is the value-addition epicenter, where intellectual property and advanced chemical engineering determine product performance. Leading players invest heavily in R&D to develop proprietary PCE structures optimized for specific applications (e.g., high slump retention for hot climates or enhanced early strength for precast factories). Distribution channels are critical for market reach. Direct sales are common for large-volume, high-performance admixture orders involving ready-mix giants or specialized infrastructure projects, allowing for tailored technical support and direct dosage recommendations. Indirect channels, involving regional distributors and specialized construction chemical dealers, facilitate reach into smaller markets and general construction sites, offering localized inventory and quick turnaround times.

Downstream analysis involves the direct interaction with end-users, primarily concrete producers (ready-mix and precast) and construction contractors. The effectiveness of the PCE is proven at this stage through application on site, where performance factors like dosage accuracy, consistency, and compatibility with local cement and aggregates are tested. Post-sale technical support, application training, and troubleshooting are essential components of the value proposition, particularly for sophisticated projects. The efficiency of the distribution network, coupled with high-quality technical service, directly impacts market penetration and customer loyalty, positioning PCEs not just as commodities but as high-value, solution-based construction aids that optimize concrete properties and construction timelines. The movement toward digitized logistics and real-time technical consultation is rapidly optimizing the efficiency of the downstream segment.

Polycarboxylate Water-reducer Market Potential Customers

The primary consumers of Polycarboxylate Water-reducers are professional entities operating within the broader construction and material manufacturing sectors, seeking superior concrete performance and consistency. Ready-mix concrete (RMC) producers represent the largest customer segment globally. RMC companies require high volumes of PCEs to manage workability over long transit times and to meet stringent strength and durability specifications required by commercial, residential, and infrastructural developers. The ability of PCEs to facilitate low water-cement ratios while maintaining adequate slump is indispensable for high-volume, continuous pouring operations, making RMC producers essential and repeat buyers of PCE formulations tailored for various performance needs, including different cement types and temperature ranges.

The second major group consists of precast concrete manufacturers. These customers rely heavily on the rapid early strength development and predictable setting times enabled by high-performance PCEs. Precast elements, such as beams, columns, façade panels, and pipes, are manufactured in controlled factory environments, demanding admixtures that allow for fast demolding and high production throughput. PCEs are critical for achieving the dense, highly durable surfaces and dimensional accuracy required for modular construction and industrialized building systems, offering a compelling value proposition in terms of reduced production cycles and improved product quality control. This segment is characterized by a demand for specialized PCE blends that maximize efficiency within the factory setting.

Other significant potential customers include specialized construction contractors involved in large-scale civil engineering projects (dams, bridges, tunnels, highways) and manufacturers of dry-mix products (tile adhesives, self-leveling compounds, repair mortars). For large civil projects, the requirement for ultra-durable, low-permeability concrete to withstand severe environments (e.g., marine or aggressive chemical exposure) mandates the use of premium PCEs. Manufacturers of dry-mix products utilize powdered PCEs to impart excellent flow, reduced water demand, and enhanced mechanical properties to their specialized cementitious products. Consulting engineers and architects often act as indirect customers, driving demand by specifying PCE usage in project design documents to ensure the longevity and structural integrity of modern buildings and infrastructure.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.2 Billion |

| Market Forecast in 2033 | USD 9.4 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sika AG, BASF SE (Master Builders Solutions), Arkema Group, Kao Corporation, W. R. Grace & Co., CHRYSO (Saint-Gobain), Mapei S.p.A., MUHU (China) Construction Materials, Shanxi Qixing Chemical, Nippon Shokubai, Shandong Huaxing, Jiangsu Bote New Materials, CEMEX, Fosroc International, KZJ New Materials Group, Sakrete, Foshan Dayu Building Materials, Trelleborg Group, GCP Applied Technologies, Borregaard Lignotech |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polycarboxylate Water-reducer Market Key Technology Landscape

The technological landscape of the Polycarboxylate Water-reducer Market is characterized by continuous refinement in polymer synthesis and molecular design aimed at achieving superior concrete performance under increasingly challenging application conditions. The primary technology involves advanced polymerization techniques, such as free-radical polymerization, to control the length, density, and chemical composition of the side chains (polyether macromolecules) attached to the main polymer backbone. Key advancements focus on tuning the side-chain density and length to optimize the steric hindrance effect, which is crucial for achieving high levels of water reduction while ensuring adequate slump retention over extended periods, particularly relevant in hot climates or large infrastructure projects where transit time is significant. Producers are leveraging sophisticated spectroscopic and chromatographic analysis tools to ensure precise control over molecular weight distribution, which directly translates to consistent field performance.

A significant technological focus is directed toward developing tailor-made PCEs that exhibit enhanced compatibility with diverse cement types, particularly those incorporating high volumes of supplementary cementitious materials (SCMs) like fly ash, slag, and calcined clay. Traditional superplasticizers often suffer reduced efficacy when used with certain SCMs; however, modern PCE chemistry overcomes these limitations by adjusting the charge density and adsorption characteristics of the polymer chain. Research is heavily invested in designing hybrid PCE structures that incorporate features of other admixtures, such as viscosity modifiers or set accelerators, creating multi-functional products that simplify the concrete mix design process and enhance overall cost-efficiency. This pursuit of multi-functionality is a defining trend in current market technology, pushing PCEs beyond simple water reduction to full-system performance enhancement.

The shift towards digital construction and smart material management is also profoundly influencing the PCE technology landscape. This includes the development of sensors and digital dosing equipment that integrate directly with batching plant control systems, allowing for real-time monitoring and algorithmic adjustment of PCE dosage based on material properties detected immediately before mixing. Furthermore, nanotechnology is being explored to functionalize PCEs, potentially enhancing particle dispersion at a nanoscale level, leading to even greater improvements in concrete density, strength, and durability. The ongoing technological evolution ensures that PCEs remain integral to innovations like ultra-high-performance concrete (UHPC) and the nascent field of 3D-printed concrete, which requires extremely precise rheological control enabled by cutting-edge admixture chemistry.

Regional Highlights

Asia Pacific (APAC): The APAC region commands the largest share of the Polycarboxylate Water-reducer Market and is projected to exhibit the highest growth rate during the forecast period. This dominance is intrinsically linked to massive, ongoing infrastructure development and unprecedented urbanization across major economies like China, India, and Indonesia. These nations are continuously investing heavily in residential, commercial, and transportation infrastructure, driving immense demand for high-performance concrete. The necessity for reliable construction materials that can withstand diverse and sometimes extreme environmental conditions, coupled with governmental mandates for building durable and sustainable structures, solidifies the requirement for advanced PCE technology. Localized production and strong domestic manufacturing capabilities, particularly in China, also contribute to competitive pricing and rapid product availability, supporting high regional consumption volumes.

- China: Unrivaled market size driven by continuous high-rise construction, extensive highway networks, and large-scale public works.

- India: Rapidly expanding market fueled by national infrastructure initiatives (e.g., Smart Cities Mission) and increasing demand for high-quality residential buildings.

- Southeast Asia (e.g., Vietnam, Indonesia): High growth potential due to fast-paced industrialization and foreign direct investment in manufacturing and logistics infrastructure.

North America: This region is characterized by mature construction markets and a strong focus on high-quality, specialized concrete applications, driven by stringent building codes and the need for rehabilitation of aging infrastructure. The market demand here is less focused on volume growth and more on value, emphasizing customized PCE blends that offer specific functionalities such as corrosion inhibition, improved freeze-thaw resistance, and superior slump retention tailored for complex, large-scale projects. Environmental regulations, particularly those encouraging lower carbon footprints, drive the adoption of PCEs that effectively integrate high dosages of industrial byproducts like fly ash and slag into concrete mixes without compromising structural integrity or longevity. The U.S. remains the primary consumer, supported by significant investment in transportation and energy infrastructure modernization.

- United States: Key driver due to large-scale federal infrastructure spending and high adoption rates of specialized PCEs in high-performance and ultra-high-performance concrete (UHPC).

- Canada: Stable growth fueled by residential construction in urban centers and significant public works projects adapting to severe cold weather conditions, necessitating advanced admixture performance.

Europe: The European market is highly sophisticated, defined by a strong emphasis on sustainability, energy efficiency, and regulatory compliance (e.g., REACH). Demand is primarily generated by renovation and refurbishment projects, coupled with new construction adhering to rigorous standards for material durability and environmental performance. The region shows a strong preference for PCEs used in precast manufacturing and in high-quality self-compacting concrete (SCC), critical for complex architectural and structural designs. Innovation in polymer chemistry and the focus on reducing volatile organic compounds (VOCs) are primary market characteristics, with countries like Germany, France, and the UK leading in the adoption of advanced, eco-friendly PCE formulations.

- Germany: High technological adoption rate, driven by a strong manufacturing base for precast elements and advanced civil engineering.

- United Kingdom: Focus on residential and commercial construction utilizing off-site manufacturing techniques which require high-consistency PCE products.

- Nordic Countries: Specialized demand for PCEs providing enhanced performance in low-temperature casting and superior durability against chemical exposure.

Latin America (LATAM): The LATAM market presents moderate growth potential, influenced heavily by economic stability and government investment cycles in housing and basic infrastructure. Brazil and Mexico are the dominant markets, where PCEs are increasingly replacing older-generation superplasticizers due to rising quality expectations and the demand for faster construction timelines. Challenges include logistical complexities and economic fluctuations, yet long-term urbanization trends continue to support gradual market expansion, particularly in the ready-mix sector where cost-effective performance improvements are highly valued.

- Brazil: Largest market in the region, driven by continuous, though volatile, investment in housing and transportation infrastructure.

- Mexico: Growth supported by expanding industrial construction and modernization of urban centers.

Middle East & Africa (MEA): MEA is a rapidly emerging market characterized by ambitious mega-projects and construction activities designed to diversify regional economies. The critical need for durable concrete that can withstand the region's extreme heat, high temperatures, and aggressive saline environments makes PCEs essential. Demand is surging in the GCC nations (Saudi Arabia, UAE, Qatar) due to large-scale urban development, monumental architectural projects, and essential utility infrastructure. The adoption rate of high-performance and customized PCE formulations is accelerating, driven by the necessity for extended slump retention in hot weather and reduced permeability to combat salt corrosion in coastal areas. Africa is beginning to show nascent growth, driven by infrastructure investment in key economic hubs.

- GCC Countries (Saudi Arabia, UAE): Primary growth engines due to extensive mega-project pipelines and the critical requirement for heat-resistant concrete admixtures.

- South Africa: Key African market, driven by mining and general civil construction, increasingly adopting high-performance concrete solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polycarboxylate Water-reducer Market.- Sika AG

- BASF SE (Master Builders Solutions)

- Arkema Group

- Kao Corporation

- W. R. Grace & Co.

- CHRYSO (Saint-Gobain)

- Mapei S.p.A.

- MUHU (China) Construction Materials

- Shanxi Qixing Chemical

- Nippon Shokubai

- Shandong Huaxing

- Jiangsu Bote New Materials

- CEMEX

- Fosroc International

- KZJ New Materials Group

- Sakrete

- Foshan Dayu Building Materials

- Trelleborg Group

- GCP Applied Technologies

- Borregaard Lignotech

Frequently Asked Questions

Analyze common user questions about the Polycarboxylate Water-reducer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of Polycarboxylate Water-reducers (PCEs) over older superplasticizers?

PCEs utilize a sophisticated comb-like molecular structure that enables dispersion primarily through steric hindrance (physical repulsion), in addition to electrostatic forces. This dual mechanism allows for significantly higher water reduction rates (up to 40%) and superior slump retention without causing rapid setting or excessive air entrainment, making them indispensable for high-performance and self-compacting concrete applications.

How does the volatility of raw material prices impact the Polycarboxylate Water-reducer Market?

Raw material cost fluctuations, particularly in petrochemical intermediates like acrylic acid and ethylene oxide derivatives, directly affect the manufacturing costs and profit margins of PCE producers. High and volatile input costs often necessitate price increases in the final product, potentially challenging adoption in cost-sensitive emerging markets and requiring manufacturers to implement advanced procurement and hedging strategies.

Which application segment drives the highest volume demand for PCEs globally?

The Ready-Mix Concrete (RMC) segment drives the highest volume demand for PCEs. RMC producers require PCEs to ensure consistent workability and high strength development in concrete that must be transported over distance or poured continuously, meeting the stringent performance requirements for general commercial, residential, and large-scale infrastructure projects worldwide.

What role does sustainability play in the development of new PCE formulations?

Sustainability is a core driver. New PCE formulations are engineered to maximize the successful integration of high volumes of Supplementary Cementitious Materials (SCMs) like fly ash and slag into concrete mixes. By ensuring optimal performance with reduced cement content, PCEs directly contribute to lowering the embodied carbon footprint of concrete production, aligning with global green building standards and environmental mandates.

What are the key regional growth engines for the Polycarboxylate Water-reducer Market?

Asia Pacific, especially China and India, represents the most significant growth engine, driven by aggressive urbanization, massive infrastructure projects, and robust residential construction activity. The Middle East is also a rapidly accelerating market, fueled by large-scale government mega-projects requiring specialized PCEs capable of performing optimally under high-temperature and harsh environmental conditions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager