Polycrystalline Diamond Tool Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438434 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Polycrystalline Diamond Tool Market Size

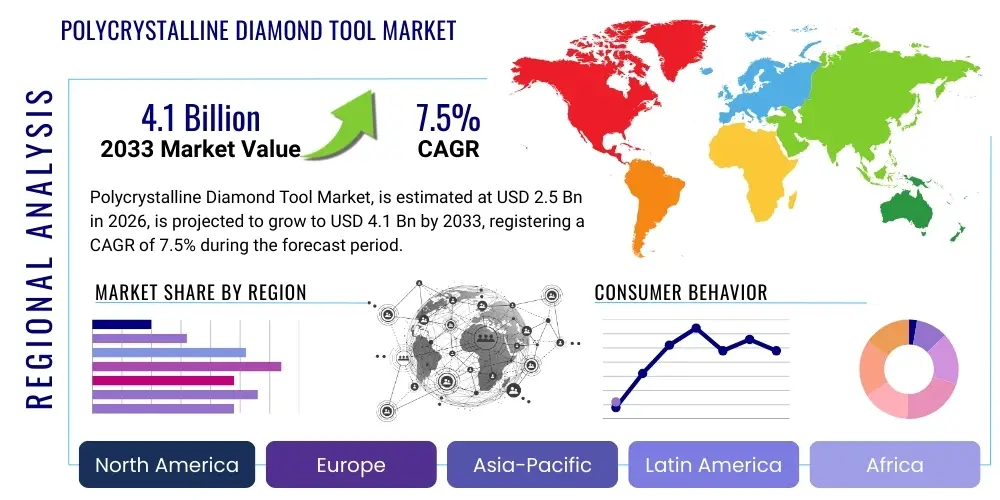

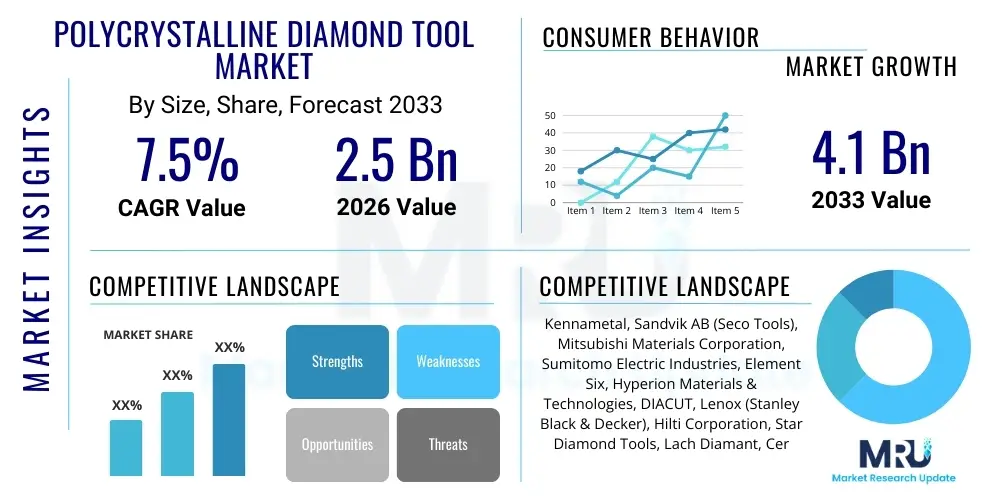

The Polycrystalline Diamond Tool Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 2.5 Billion in 2026 and is projected to reach USD 4.1 Billion by the end of the forecast period in 2033.

Polycrystalline Diamond Tool Market introduction

The Polycrystalline Diamond (PCD) Tool Market encompasses highly advanced cutting tools fabricated by sintering selected diamond particles with a metal binder, typically cobalt, under extremely high pressure and temperature conditions. This process yields a material possessing exceptional hardness, wear resistance, and thermal conductivity, positioning PCD tools as essential components in the precision machining of non-ferrous materials such as aluminum alloys, composites, carbides, and specialized ceramics. These tools, including inserts, drills, reamers, and end mills, are defined by their superior longevity and ability to maintain tight tolerances and high surface finish quality, significantly reducing machine downtime and overall manufacturing costs compared to traditional cemented carbide tools. The market’s resilience is intrinsically linked to the demand for lightweight, fuel-efficient materials across key industrial sectors, notably automotive, aerospace, and electronics manufacturing, where the complexities of modern engineering require cutting solutions that can handle increasingly challenging materials.

The primary applications driving the adoption of PCD tools are concentrated in industries requiring high-volume, high-precision machining operations. In the automotive sector, PCD tools are crucial for manufacturing engine components, brake rotors, and transmission parts made from hypoeutectic and hypereutectic aluminum silicon alloys. Similarly, the aerospace industry utilizes PCD for machining lightweight carbon fiber reinforced polymer (CFRP) composites and high-strength aluminum alloys used in airframe structures and engine assemblies, where component integrity and reliability are paramount. Beyond traditional manufacturing, the market benefits substantially from expansion in the consumer electronics sector, particularly in the production of precision parts for smartphones and tablets, which frequently employ aluminum casings and specialized substrate materials that demand ultra-hard tooling for efficient processing.

Key benefits driving market growth include enhanced operational efficiency due to faster cutting speeds and feed rates permissible with PCD tools, coupled with their drastically extended tool life, which minimizes replacement frequency. This combination translates directly into lower cost-per-part manufacturing and higher throughput, making the investment in PCD technology highly justifiable for large-scale production facilities. Furthermore, the rising focus on sustainable manufacturing practices favors PCD tools, as their durability reduces material waste associated with frequent tool changes and maintenance. The market’s driving factors are therefore centered around technological advancements in tool geometry, the introduction of innovative multi-tip and full-face PCD formats, and the continuous need for lightweighting in critical transport industries globally.

Polycrystalline Diamond Tool Market Executive Summary

The Polycrystalline Diamond Tool market is experiencing robust growth fueled primarily by global shifts towards lightweight materials adoption, particularly in the electric vehicle (EV) and aerospace sectors. Business trends indicate a strong focus on advanced manufacturing processes such as additive manufacturing (AM) for tool substrates, allowing for complex geometries and optimized cooling channels, thereby enhancing PCD tool performance and longevity. Major market players are strategically investing in capacity expansion and vertical integration—especially in high-pressure, high-temperature (HPHT) synthesis capabilities—to secure raw material supply and maintain quality control. Furthermore, the integration of Industry 4.0 principles, including sensor-equipped smart tools and predictive maintenance software, is becoming a crucial differentiator, optimizing tool utilization and minimizing unexpected failures on the shop floor.

Regionally, Asia Pacific (APAC) stands out as the dominant growth engine, driven by massive manufacturing expansions in China, India, and Southeast Asian nations, particularly within the automotive, electronics, and construction equipment sectors. North America and Europe maintain significant market shares, characterized by high adoption rates of advanced, customized PCD tooling required for demanding aerospace and medical device applications, reflecting a preference for high-quality, high-tolerance machining solutions. Emerging economies in Latin America and MEA are showing increasing potential as localized industrialization efforts gain momentum, requiring precision tools for newly established automotive and oil & gas infrastructure projects. The competitive landscape globally is marked by intense rivalry between multinational corporations offering full tooling solutions and specialized regional players focusing on bespoke PCD inserts and refurbishment services.

Segmentation trends highlight the increasing demand for PCD inserts, which represent the largest segment by product type, owing to their versatility and ease of replacement in standard tool holders. The demand for PCD drills and reamers is also escalating rapidly, propelled by the complex hole-making requirements in stacked composite materials prevalent in the aerospace industry. By application, the automotive sector remains the primary consumer, although the aerospace and defense segment commands a premium due to the ultra-high precision and stringent material requirements involved. Future segment growth is anticipated to accelerate within specialized areas such as woodworking and medical implant manufacturing, demonstrating the expanding scope of materials that benefit from the superior hardness of polycrystalline diamond.

AI Impact Analysis on Polycrystalline Diamond Tool Market

User queries regarding the impact of Artificial Intelligence (AI) on the Polycrystalline Diamond Tool Market frequently center on predictive tool life modeling, optimization of machining parameters, and quality assurance during tool manufacturing and application. Users are keen to understand how AI-driven analytics can prevent catastrophic tool failure, improve the utilization rate of expensive PCD assets, and ultimately reduce the cost of ownership. Key concerns revolve around data infrastructure requirements, the accuracy of machine learning models applied to complex wear patterns, and the integration of AI tools with existing Computer Numerical Control (CNC) and manufacturing execution systems (MES). The prevailing expectation is that AI will transition tool maintenance from a reactive or scheduled process to a truly predictive and prescriptive one, thereby maximizing the economic benefits inherent in PCD technology.

AI's primary influence is observed in enhancing the efficacy and efficiency of PCD tool usage across the entire lifecycle. During the manufacturing stage, AI is used to optimize the HPHT sintering process, ensuring minimal structural defects and consistent diamond layer integrity by analyzing sensor data related to pressure, temperature ramps, and cooling cycles. In the operational phase, machine learning algorithms analyze high-frequency sensory data (vibration, acoustic emission, spindle power consumption) collected from the CNC machine to accurately predict the remaining useful life (RUL) of the PCD tool, enabling just-in-time replacement and reducing scrap rates caused by worn tools. Furthermore, AI assists in automated quality inspection of the finished PCD cutting edges using computer vision, ensuring that precise micro-geometries are achieved before deployment.

The long-term impact of AI involves the creation of self-optimizing machining cells where parameters such as feed rate, depth of cut, and spindle speed are dynamically adjusted in real-time based on the instantaneous wear state of the PCD tool and the variability of the workpiece material. This prescriptive approach significantly enhances material removal rates while preserving surface finish and extending tool longevity far beyond what standard programming can achieve. AI-driven simulation tools are also crucial in the design phase, allowing manufacturers to model complex thermal and mechanical stresses on novel PCD geometries, accelerating product development cycles and customizing tools for niche applications.

- AI enables real-time monitoring and predictive maintenance, drastically extending Polycrystalline Diamond tool life.

- Machine learning optimizes CNC machining parameters (feed, speed) based on dynamic tool wear patterns.

- Computer vision and AI streamline quality control during PCD manufacturing, detecting micro-defects in cutting edges.

- AI algorithms analyze manufacturing data to improve the consistency and quality of the HPHT sintering process.

- Smart PCD tools equipped with integrated sensors transmit data for enhanced operational analytics and process control.

- Data-driven simulations accelerate the design and prototyping of novel PCD tool geometries for complex materials.

DRO & Impact Forces Of Polycrystalline Diamond Tool Market

The Polycrystalline Diamond Tool Market is fundamentally driven by the relentless pursuit of high-efficiency machining necessary for modern lightweight materials, yet it is constrained by high initial capital investment and the complexity of the manufacturing process. Key opportunities stem from the electrification of the automotive sector and the expansion of composite usage in aerospace, creating specialized and non-negotiable demands for superior hard tooling. These market forces collectively shape the competitive environment, where technological superiority and robust supply chain management dictate market position. The overarching impact force is the necessity for energy efficiency and sustainability in manufacturing, demanding tools that last longer and enable faster processing with minimal waste.

Major market drivers include the explosive growth of electric vehicle production globally, which relies heavily on precision machining of aluminum alloy components (e.g., motor housings, battery casings) that rapidly wear out conventional carbide tools. The concurrent expansion of the aerospace industry, marked by rising demand for new aircraft built with complex composite and stacked materials (CFRP, titanium), necessitates the extreme durability and precision offered by PCD tools. Additionally, the increasing complexity and miniaturization of components in the electronics and medical device industries mandate tooling capable of handling micro-precision features and ultra-hard materials without compromising structural integrity or surface finish quality. These factors generate consistent, non-cyclical demand for specialized PCD solutions.

However, significant restraints temper the market’s expansion potential. The initial cost of PCD tools is substantially higher than traditional carbide alternatives, often creating an adoption barrier for small and medium-sized enterprises (SMEs) despite the proven long-term cost benefits. Furthermore, the specialized manufacturing required for PCD tools—involving sophisticated HPHT presses and highly skilled technicians—limits the number of reliable global suppliers. Opportunities arise primarily from the growing demand for tool refurbishment and regrinding services, maximizing the lifespan of the costly assets, and the development of cost-effective PCD grades suitable for less demanding applications. The impact forces are thus heavily weighted by the total cost of ownership (TCO) calculation for manufacturers, balancing the high initial cost against exceptional operational performance.

Segmentation Analysis

The Polycrystalline Diamond Tool Market is segmented comprehensively across product type, application, and material substrate, providing a granular view of demand dynamics across industrial verticals. Analyzing these segments is crucial for understanding current market concentration and forecasting future growth trajectories based on technological shifts and material science advancements. The market structure reflects the varied needs of precision engineering sectors, ranging from large-scale automotive manufacturing demanding standardized inserts to highly specialized aerospace operations requiring bespoke, complex PCD cutting geometries. The differentiation between segments is increasingly driven by the composition of the PCD layer, including diamond content, binder material, and the thickness of the diamond layer, which determines the tool's performance envelope for specific workpiece materials.

The primary segmentation by product type typically categorizes tools into PCD Inserts, End Mills, Reamers, Drills, and others (including specialized woodworking cutters and form tools). PCD inserts consistently command the largest share due to their standardized form factor, suitability for turning and milling operations, and high versatility in different tool holders. Growth is accelerating in the Drills and Reamers segment, directly correlating with the increasing usage of composite stacking and multi-material structures in high-value applications, where precise hole making is paramount. By application, the automotive segment dominates volume demand, driven by mass production requirements for aluminum engine blocks and transmission components, while the aerospace sector contributes significantly to revenue due to the high average selling price (ASP) of specialized, custom-engineered tooling solutions required for advanced composites and superalloys.

Segmentation by material substrate, often classifying tools based on the type of material they are designed to cut, such as Non-ferrous Metals (Aluminum, Copper), Composites (CFRP, GFRP), Woodworking Materials, and Hard Materials (Carbides, Ceramics), further refines market analysis. The fastest growth is observed in tools designed for Composites and Lightweight Alloys, reflecting global material substitution trends aimed at achieving improved fuel economy and higher performance characteristics in transportation industries. This demand necessitates continuous innovation in PCD grades, particularly those optimized for managing chip evacuation and minimizing delamination when machining anisotropic composite structures. Understanding these granular segmentations is vital for manufacturers to tailor their R&R (research and development) efforts and distribution strategies effectively.

- Product Type:

- PCD Inserts (Turning and Milling)

- PCD Drills and Reamers

- PCD End Mills

- PCD Boring Tools

- PCD Special Tools (Form Tools, Engraving Tools)

- Application:

- Automotive Industry

- Aerospace and Defense

- Electronics and Consumer Goods

- Machinery and Equipment Manufacturing

- Woodworking

- Medical Devices

- Manufacturing Process:

- Brazed PCD Tools

- Laser-Welded PCD Tools

- Solid PCD Veins

- Material Substrate:

- Aluminum Alloys and Non-ferrous Metals

- Composites (CFRP, GFRP)

- Carbide and Ceramics

- Wood and Wood-based Materials

Value Chain Analysis For Polycrystalline Diamond Tool Market

The Polycrystalline Diamond Tool market value chain is characterized by high technological barriers at the upstream level and intensive distribution requirements downstream to serve a globally dispersed industrial client base. The upstream segment is highly concentrated, involving specialized manufacturers who synthesize industrial diamonds under extreme pressure and temperature conditions, subsequently bonding them to a tungsten carbide substrate. This initial synthesis step is capital-intensive and critical, as the quality and grade of the synthesized PCD material directly determine the performance and cost of the final cutting tool. Key players in this phase focus on controlling crystal size, binder content (usually cobalt), and layer thickness to produce distinct PCD grades optimized for specific applications, such as fine-grained material for precision finishing or coarse-grained material for rough machining.

Midstream activities involve tool manufacturing and fabrication, which includes processes such as laser cutting, electrical discharge machining (EDM), and high-precision grinding and polishing necessary to create the final complex geometry of the cutting tool from the PCD blank. This stage adds substantial value through proprietary design, geometric optimization, and bonding techniques (e.g., brazing or laser welding) to ensure the diamond tip remains securely attached to the tool body under high mechanical and thermal stress. Companies often invest heavily in advanced manufacturing equipment and quality inspection systems to ensure micron-level accuracy, recognizing that defects in geometry directly translate into premature tool failure and poor surface finish on the workpiece.

The downstream segment, encompassing distribution and end-user engagement, involves both direct sales channels, particularly for large automotive and aerospace OEMs requiring bespoke solutions and technical support, and indirect channels through specialized industrial distributors and tooling service providers. Indirect channels are crucial for reaching smaller job shops and general manufacturing clients. A vital component of the downstream value chain is the provision of tool management services, including inventory control, reconditioning (re-grinding and polishing) of worn PCD tools, and application engineering support. The efficiency of the distribution network and the quality of post-sale services significantly influence customer loyalty and repeat business within this high-value tooling market.

Polycrystalline Diamond Tool Market Potential Customers

Potential customers for Polycrystalline Diamond Tools are primarily large-scale manufacturing enterprises and precision engineering firms that handle high volumes of abrasive, non-ferrous, and composite materials where tool wear is a critical cost factor. The automotive industry represents the largest single end-user segment, particularly Original Equipment Manufacturers (OEMs) and their Tier 1 suppliers involved in powertrain components, chassis parts, and body structures utilizing aluminum, magnesium, and specific composite grades. The ongoing shift toward Electric Vehicles (EVs) is generating heightened demand, as EV production relies even more heavily on complex aluminum machining for battery housings, motor casings, and thermal management systems, materials that demand the superior edge retention of PCD.

The aerospace and defense sector constitutes another high-value customer base, characterized by stringent quality requirements and the use of advanced, difficult-to-machine materials like Carbon Fiber Reinforced Polymers (CFRP), Glass Fiber Reinforced Polymers (GFRP), and specific lightweight alloys. Aerospace manufacturers (e.g., airframe builders and engine component specialists) are high-volume consumers of PCD drills, reamers, and specialized trimming cutters designed to prevent material delamination and ensure component integrity in critical applications. Furthermore, the electronics industry, specifically companies involved in the production of high-end consumer devices, also represents a growing segment, utilizing PCD tools for the high-precision machining of aluminum and ceramic components used in smartphone and laptop casings, demanding ultra-fine finishes and high throughput.

Beyond these major segments, the woodworking industry, particularly manufacturers of high-density particleboard and MDF, utilizes PCD tools for long-lasting routers and saw blades due to the abrasive nature of the raw materials. Additionally, the medical device sector, specializing in instruments and orthopedic implants made from difficult-to-machine ceramics and specialized plastics, relies on PCD tools for precise, defect-free surface generation. These diverse end-user applications highlight that any industry prioritizing production efficiency, component precision, and managing abrasive wear on tooling represents a core potential customer for Polycrystalline Diamond solutions, justifying the higher initial investment through exceptional operational life.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.5 Billion |

| Market Forecast in 2033 | USD 4.1 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kennametal, Sandvik AB (Seco Tools), Mitsubishi Materials Corporation, Sumitomo Electric Industries, Element Six, Hyperion Materials & Technologies, DIACUT, Lenox (Stanley Black & Decker), Hilti Corporation, Star Diamond Tools, Lach Diamant, Ceratizit Group, Tungaloy Corporation, Mapal, Kyocera Corporation, Asahi Diamond Industrial Co., Ltd., De Beers Industrial Diamonds, US Synthetic, Nanjing Wanan Industrial Co., Ltd., Worldia. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polycrystalline Diamond Tool Market Key Technology Landscape

The technology landscape of the Polycrystalline Diamond Tool market is dominated by advancements in material synthesis, tool fabrication, and application optimization through digital integration. The core technology remains the High-Pressure High-Temperature (HPHT) synthesis method, which bonds micron-sized diamond particles onto a carbide substrate using a metallic binder (typically cobalt or nickel). Recent technological breakthroughs focus on optimizing this synthesis process, including advancements in binder leach technology (creating "leached" or "veinless" PCD) to prevent chemical wear when machining ferrous materials accidentally, and the development of thermally stable PCD (TSPCD) grades capable of withstanding higher cutting temperatures without degradation, expanding the tool's usable range.

Fabrication technology is another critical area of innovation. Traditional methods like Electrical Discharge Machining (EDM) and conventional grinding are increasingly being replaced or augmented by advanced laser processing and precision electro-erosion techniques. Laser cutting and ablation are highly effective for cutting complex PCD geometries and creating extremely sharp, precise micro-cutting edges with minimal risk of chipping or thermal damage to the diamond layer, which is crucial for achieving high surface finish requirements. Furthermore, manufacturers are focusing on integrating advanced tool coatings, such as Chemical Vapor Deposition (CVD) diamond coatings on tungsten carbide substrates, to offer intermediate solutions that bridge the performance gap between traditional carbides and full PCD tools, catering to a wider range of machining tasks.

The integration of Industry 4.0 technologies, including advanced Computer-Aided Design (CAD) for tool geometry optimization, Finite Element Analysis (FEA) for stress testing, and real-time process monitoring via embedded sensors, defines the cutting-edge of the PCD tool market. Smart PCD holders and tools are now equipped with miniature accelerometers and temperature sensors that transmit data wirelessly, allowing operators and manufacturing execution systems (MES) to monitor tool health and predict failure with high fidelity. This digital integration maximizes the return on investment for high-cost PCD tools by ensuring optimal usage, feed rate compensation based on wear, and seamless integration into automated production lines, solidifying the market's shift toward intelligent manufacturing solutions.

Regional Highlights

Asia Pacific (APAC) stands as the fastest-growing and largest regional market for Polycrystalline Diamond Tools, driven by massive industrialization, high-volume production in the automotive sector (including substantial EV manufacturing capabilities in China and South Korea), and a rapidly expanding consumer electronics base. China remains the epicenter of demand, fueled by governmental investments in high-end manufacturing (Made in China 2025 initiative) and the proliferation of mega-factories requiring constant supplies of high-performance tooling for aluminum processing. The region benefits from a robust supply chain, competitive domestic manufacturing capabilities, and a constant drive to upgrade tooling quality to meet stringent export standards. Countries like India and Vietnam are also contributing significantly to market expansion as manufacturing shifts accelerate, increasing the localized need for precision machining solutions across diverse industries.

North America holds a mature and technologically sophisticated market share, characterized by high demand for specialized and custom PCD tooling, primarily from the aerospace and defense industries. The stringent quality and material requirements of aerospace machining—involving complex composites, titanium alloys, and high-strength aluminum—drive premium pricing and continuous innovation in tool geometry and material grades. The region also maintains significant consumption in the high-precision medical device sector. While volume growth may be slower compared to APAC, the high value of custom engineering services, coupled with strong adoption of advanced manufacturing technologies like automation and AI-driven monitoring systems, ensures North America remains a crucial revenue generator in the global PCD landscape. Investment in tool refurbishment and recycling services is also notably high here, reflecting the market's emphasis on total cost of ownership.

Europe represents another critical mature market, dominated by the German automotive sector and the advanced machinery and equipment manufacturing base throughout Central and Western Europe. European manufacturers are pioneering the shift towards sustainable machining practices, which naturally favors the long lifespan and high efficiency of PCD tools. Stringent environmental and operational standards necessitate tools that reduce energy consumption and minimize waste. The region is a key hub for research and development in cutting tool materials, actively collaborating between academic institutions and major tooling corporations to introduce new PCD grades optimized for future materials, such as lightweight structural foams and next-generation composite alloys. The market in Europe is also characterized by a strong presence of specialized small-to-midsize enterprises (SMEs) that offer highly specialized tool refurbishment and customized precision tooling solutions.

- Asia Pacific (APAC): Dominates market size and growth, driven by China's automotive and electronics production; massive investment in EV manufacturing infrastructure; increasing regional adoption of complex machining processes.

- North America: High revenue generation from the aerospace and defense sectors; focus on specialized, custom-engineered PCD tools for composites and high-strength alloys; early adopter of smart tooling and Industry 4.0 integration.

- Europe: Strong presence in high-precision automotive (especially Germany) and machinery manufacturing; emphasis on sustainable production and high efficiency; significant R&D activities leading to advanced PCD material grades.

- Latin America (LATAM): Emerging market driven by regional automotive assembly and expansion of mining equipment manufacturing; localized demand for standard PCD inserts and basic tooling applications.

- Middle East and Africa (MEA): Growth tied to oil and gas exploration (PDC drill bits, a related technology), infrastructure projects, and developing localized automotive assembly plants; high potential but currently low market penetration for precision machining PCD tools.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polycrystalline Diamond Tool Market.- Sandvik AB (Seco Tools)

- Kennametal Inc.

- Mitsubishi Materials Corporation

- Sumitomo Electric Industries, Ltd.

- Element Six (E6)

- Hyperion Materials & Technologies

- DIACUT GmbH

- Lach Diamant GmbH

- Ceratizit Group

- Tungaloy Corporation (IMC Group)

- Mapal Präzisionswerkzeuge Dr. Kress KG

- Kyocera Corporation

- Asahi Diamond Industrial Co., Ltd.

- De Beers Industrial Diamonds

- US Synthetic (A Dover Company)

- Worldia

- Nanjing Wanan Industrial Co., Ltd.

- Iscar Ltd. (IMC Group)

- PCD Tools Inc.

- Zhuzhou Cemented Carbide Cutting Tools Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Polycrystalline Diamond Tool market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Polycrystalline Diamond (PCD) tools and natural diamond tools?

PCD tools are synthetic composite materials made by sintering industrial diamond particles onto a carbide substrate under extreme pressure, offering enhanced toughness and wear resistance for industrial machining. Natural diamond tools are single crystals, primarily used for ultra-precision finishing (mirror finishes) but are more brittle and expensive, limiting their use in high-impact, interrupted cutting applications typical in general manufacturing.

Which industrial application drives the highest demand volume for PCD tools globally?

The Automotive Industry is the largest consumer by volume, primarily due to the mass production requirements for machining lightweight, high-silicon aluminum alloys used in engine blocks, transmission components, and, increasingly, battery casings for electric vehicles. PCD tools are essential here for maintaining high throughput and minimizing abrasive wear when machining these demanding materials.

How does the adoption of Electric Vehicles (EVs) impact the PCD Tool Market?

EV adoption significantly boosts the demand for PCD tools because EVs require extensive precision machining of aluminum and composite battery enclosures, motor housings, and heat sinks. These materials are highly abrasive and demand the superior hardness and longevity of PCD tooling to ensure efficient, high-quality production compared to traditional Internal Combustion Engine (ICE) components.

What are the key technological restraints limiting the use of PCD tools?

The main restraints are the high initial purchase cost relative to standard carbide tools and the inability of PCD tools to efficiently machine ferrous materials (steel, iron) due to chemical reactivity between the diamond carbon and iron at high cutting temperatures, leading to rapid tool wear. Highly specialized processes like EDM are also required for machining the PCD tips themselves.

What role does tool refurbishment play in the overall PCD tool lifecycle?

Refurbishment, which includes high-precision regrinding and re-polishing of worn PCD tips, is critical for maximizing the economic lifespan of these high-value assets. It significantly lowers the total cost of ownership (TCO) by allowing the tool to be restored to near-original performance specifications multiple times, making PCD technology financially viable for high-volume operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager