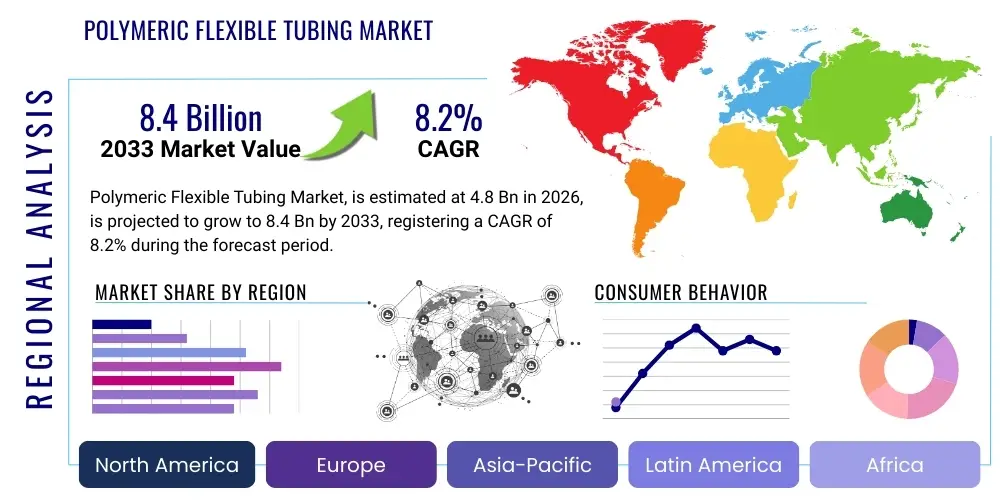

Polymeric Flexible Tubing Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439598 | Date : Jan, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Polymeric Flexible Tubing Market Size

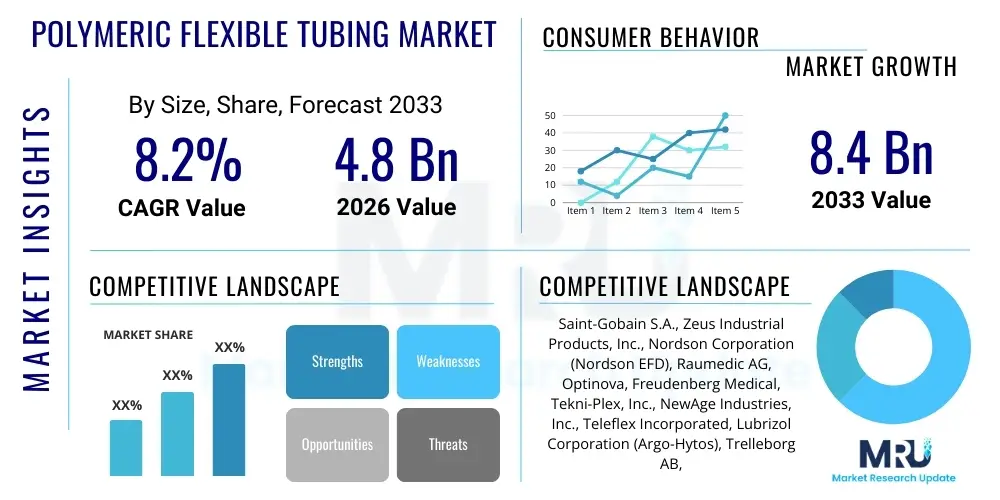

The Polymeric Flexible Tubing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.2% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 8.4 Billion by the end of the forecast period in 2033.

Polymeric Flexible Tubing Market introduction

The Polymeric Flexible Tubing Market encompasses a wide array of products essential for fluid transfer, protection, and structural integrity across numerous industries. These tubings, crafted from various synthetic polymers such as PVC, polyurethane, silicone, PTFE, PEEK, and others, are valued for their adaptability, chemical resistance, biocompatibility, and durability. Their inherent flexibility allows them to navigate complex pathways and conform to diverse system designs, making them indispensable components in applications where rigid piping is impractical or unsuitable. The market's dynamism is driven by continuous innovation in material science, processing technologies, and an expanding range of sophisticated end-use applications, pushing the boundaries of performance and versatility. This includes advancements in areas like medical-grade tubing, high-pressure industrial hoses, and specialized protective conduits, all requiring stringent quality and performance standards.

Major applications for polymeric flexible tubing span critical sectors including medical and pharmaceutical, automotive, industrial manufacturing, food and beverage, construction, and electronics. In the medical field, these tubings are vital for drug delivery systems, catheters, diagnostic equipment, and surgical instruments, demanding exceptional biocompatibility and sterilization capabilities. The automotive industry utilizes them for fuel lines, brake lines, and wiring harnesses due to their resistance to chemicals and extreme temperatures. Within industrial settings, they serve as conduits for hydraulic fluids, pneumatic systems, and chemical transfer. The benefits associated with polymeric flexible tubing are extensive, including their lightweight nature, corrosion resistance, ease of installation, and cost-effectiveness compared to metal alternatives. Furthermore, their ability to withstand various environmental conditions and offer superior insulation properties contributes significantly to their broad adoption and continued market expansion. The versatility of these materials allows for tailored solutions, meeting specific application requirements ranging from high-purity fluid transfer to heavy-duty industrial applications.

Driving factors propelling the growth of the polymeric flexible tubing market include the escalating demand for minimally invasive medical procedures, which heavily rely on advanced flexible tubing for catheters and endoscopes. The expansion of the automotive sector, particularly with the advent of electric vehicles, necessitates lightweight and durable fluid transfer systems. Rapid industrialization and infrastructure development globally also contribute to the demand for efficient and resilient tubing solutions in manufacturing and construction. Moreover, stringent regulatory standards in industries like medical and food and beverage, requiring inert and safe materials, further stimulate innovation and adoption of high-performance polymeric tubing. Technological advancements in polymer synthesis and extrusion processes enable the creation of tubing with enhanced properties, such as improved flexibility, higher pressure ratings, and superior chemical resistance, opening new avenues for application and strengthening market demand. The push towards sustainable and recyclable polymer solutions also presents a significant growth driver, as manufacturers strive to meet environmental regulations and consumer preferences.

Polymeric Flexible Tubing Market Executive Summary

The Polymeric Flexible Tubing Market is experiencing robust growth, primarily driven by evolving business trends focused on customization, sustainability, and high-performance material development. Manufacturers are increasingly investing in advanced extrusion techniques and material blending to meet specific industry requirements, offering tailor-made solutions for critical applications in healthcare, automotive, and industrial sectors. Regional trends indicate strong expansion in Asia Pacific due to rapid industrialization and healthcare infrastructure development, while North America and Europe maintain stable growth with a focus on premium and specialty tubing solutions. Segment-wise, the medical and pharmaceutical sector continues to dominate, driven by an aging global population and increasing demand for advanced medical devices, alongside significant growth in industrial and automotive applications benefiting from material innovations and lightweighting initiatives. Overall, the market is characterized by a balance of established applications and emerging opportunities, with a clear trajectory towards more specialized, durable, and environmentally conscious products. This dynamic environment fosters competitive innovation, leading to a wider array of high-quality polymeric flexible tubing solutions that address complex engineering challenges across a multitude of industries.

AI Impact Analysis on Polymeric Flexible Tubing Market

Common user questions regarding AI's impact on the Polymeric Flexible Tubing Market frequently revolve around how artificial intelligence can enhance manufacturing efficiency, improve product quality, optimize supply chain logistics, and contribute to material innovation. Users are keen to understand AI's role in predictive maintenance for extrusion equipment, real-time quality control during production, and the development of new polymer formulations with desired properties. There's also significant interest in AI's potential to personalize tubing solutions based on complex application requirements and its influence on market forecasting and demand planning. These inquiries highlight a collective expectation that AI will streamline operations, reduce waste, accelerate product development cycles, and provide deeper market insights, ultimately leading to more sophisticated and cost-effective polymeric tubing solutions across various end-use industries.

- Manufacturing Optimization: AI-driven process control systems can monitor extrusion parameters in real-time, adjusting temperature, pressure, and speed to maintain consistent product dimensions and material properties, minimizing defects and improving yield rates.

- Quality Assurance: Machine vision systems powered by AI can detect microscopic flaws, inconsistencies, or foreign particles in tubing much faster and more accurately than human inspection, ensuring high-quality standards, especially for critical medical and aerospace applications.

- Predictive Maintenance: AI algorithms analyze data from manufacturing equipment sensors to predict potential failures before they occur, enabling proactive maintenance, reducing downtime, and extending the lifespan of machinery used in polymeric tubing production.

- Material Science and R&D: AI can accelerate the discovery and development of new polymer compounds by simulating molecular interactions and predicting material performance characteristics, leading to innovative tubing with enhanced flexibility, chemical resistance, or biocompatibility.

- Supply Chain Efficiency: AI-powered analytics optimize inventory management, demand forecasting, and logistics for raw materials and finished tubing products, reducing holding costs and ensuring timely delivery to customers.

- Customization and Personalization: AI can process complex customer specifications and design parameters to generate optimized tubing designs, facilitating the production of highly customized flexible tubing solutions for niche applications.

DRO & Impact Forces Of Polymeric Flexible Tubing Market

The Polymeric Flexible Tubing Market is profoundly shaped by a combination of key drivers, inherent restraints, and burgeoning opportunities, all influenced by a range of impact forces. Drivers such as the escalating demand from the medical and pharmaceutical sectors for high-purity, biocompatible tubing, coupled with robust growth in the automotive industry necessitating lightweight and durable fluid transfer systems, are providing significant impetus. Furthermore, the expansion of industrial automation and infrastructure projects globally fuels the need for resilient and chemically resistant tubing. Restraints, however, include the volatile pricing of raw materials, primarily petrochemical derivatives, which can impact manufacturing costs and market stability. Stringent environmental regulations concerning plastic waste and the push towards sustainable alternatives also pose challenges, requiring significant investment in research and development for eco-friendly polymers. Opportunities lie in the development of advanced functional polymers, smart tubing solutions with integrated sensors, and the increasing demand for customized solutions tailored to specific, high-performance applications. The shift towards electrification in the automotive sector and the rise of 3D printing for specialized components also present new avenues for growth and innovation.

Impact forces acting on this market are multifaceted, encompassing technological advancements, regulatory changes, economic fluctuations, and evolving consumer preferences. Technological innovations in polymer science and manufacturing processes, such as multi-layer extrusion and braiding techniques, are enabling the production of tubing with superior mechanical and chemical properties, expanding their utility into more demanding environments. The regulatory landscape, particularly in highly controlled industries like medical and food and beverage, directly influences material selection, manufacturing standards, and market entry barriers, driving the need for compliance and certification. Economic conditions, including global GDP growth and industrial output, directly correlate with the demand for tubing across various sectors. Finally, shifting consumer and industrial preferences towards durable, efficient, and environmentally sustainable products compel manufacturers to innovate and adapt their offerings, often favoring recyclable or bio-based polymer solutions. These forces collectively create a dynamic and competitive market environment, necessitating continuous adaptation and strategic foresight from market participants to maintain relevance and capture growth opportunities.

Segmentation Analysis

The Polymeric Flexible Tubing Market is extensively segmented to provide granular insights into its diverse applications and material compositions, enabling a detailed understanding of market dynamics. This segmentation typically includes categories based on material type, application, end-use industry, and diameter/size. Each segment exhibits distinct growth patterns and adoption rates, influenced by specific performance requirements, regulatory landscapes, and technological advancements. For instance, the demand for silicone tubing within the medical sector differs significantly from PVC tubing used in general industrial applications, driven by factors such as biocompatibility, temperature resistance, and cost-effectiveness. The strategic analysis of these segments helps manufacturers tailor their product portfolios, identify lucrative niches, and allocate resources effectively to capitalize on emerging trends and unmet customer needs across the global market landscape. Understanding these segment nuances is crucial for developing targeted marketing strategies and product innovation roadmaps. The varied requirements across industries necessitate a broad range of polymeric materials, each offering a unique balance of properties such as flexibility, chemical inertness, pressure resistance, and thermal stability, thus shaping the segmentation.

- By Material Type:

- PVC (Polyvinyl Chloride)

- Polyurethane (PU)

- Silicone

- PTFE (Polytetrafluoroethylene)

- PEEK (Polyether Ether Ketone)

- TPE (Thermoplastic Elastomers)

- Nylon

- Polyethylene (PE)

- Polypropylene (PP)

- Other Advanced Polymers (e.g., FEP, PFA, PVDF)

- By Application:

- Fluid Transfer

- Electrical Insulation

- Protective Sleeving

- Hoses and Tubing for Pneumatics/Hydraulics

- Peristaltic Pump Tubing

- Heat Shrink Tubing

- Others (e.g., Cable Management, Structural Support)

- By End-Use Industry:

- Medical & Pharmaceutical

- Automotive

- Industrial Manufacturing

- Food & Beverage

- Construction

- Electronics & Electrical

- Aerospace & Defense

- Chemical & Petrochemical

- Agriculture

- Others (e.g., Robotics, Marine)

- By Diameter/Size:

- Microbore (less than 1mm ID)

- Small Bore (1mm - 5mm ID)

- Medium Bore (5mm - 20mm ID)

- Large Bore (greater than 20mm ID)

Value Chain Analysis For Polymeric Flexible Tubing Market

The value chain for the Polymeric Flexible Tubing Market begins with upstream analysis, which primarily involves the sourcing and processing of raw materials. This stage is dominated by chemical companies that produce various polymers such as PVC resins, silicone elastomers, polyurethane pellets, and fluoropolymers. These raw material suppliers are crucial as the quality and availability of their products directly impact the properties and cost-effectiveness of the final tubing. Strategic relationships with these suppliers are essential for manufacturers to ensure consistent quality, stable pricing, and access to innovative polymer formulations that can enhance tubing performance. The extraction and refinement of petroleum and natural gas also form an integral part of this upstream segment, as these are the primary feedstocks for most synthetic polymers used in flexible tubing production. Continuous research and development in polymer chemistry at this stage drive the creation of new materials with improved characteristics, such as enhanced biocompatibility, higher chemical resistance, or greater thermal stability, which ultimately translates into more advanced tubing products.

Moving downstream, the value chain encompasses the manufacturing, distribution, and end-use stages. Tubing manufacturers process these raw polymers using various techniques like extrusion, co-extrusion, braiding, and compounding to produce a wide range of flexible tubing products, each tailored for specific applications. This stage involves significant investment in advanced machinery, quality control, and skilled labor to meet stringent industry standards, particularly for medical and aerospace applications. Once manufactured, these products reach end-users through diverse distribution channels. Direct sales are common for large volume orders or highly specialized tubing where direct technical consultation is required between the manufacturer and the end-user. Indirect channels involve distributors, wholesalers, and specialized resellers who cater to a broader customer base, including small and medium-sized enterprises. These intermediaries often provide additional services such as inventory management, cutting to length, and local delivery, adding value to the supply chain. The efficiency of these distribution networks is critical for market penetration and timely delivery, especially for industries with just-in-time inventory requirements. Effective management of this complex distribution network is vital for market reach and customer satisfaction.

Polymeric Flexible Tubing Market Potential Customers

Potential customers for the Polymeric Flexible Tubing Market are diverse and span across numerous high-value industries, making it a critical component for various industrial and consumer applications. In the medical and pharmaceutical sector, key buyers include manufacturers of medical devices such as catheters, intravenous lines, peristaltic pumps, and diagnostic equipment, as well as pharmaceutical companies utilizing tubing for bioprocessing and drug delivery systems. The stringent regulatory requirements and need for biocompatibility make these customers highly selective. Within the automotive industry, purchasers encompass original equipment manufacturers (OEMs) and aftermarket suppliers, integrating flexible tubing into fuel lines, brake systems, HVAC systems, and wiring harnesses, prioritizing durability, chemical resistance, and performance under extreme temperatures. The shift towards electric vehicles (EVs) is also creating new demand for specialized tubing solutions for cooling systems and battery management.

The industrial manufacturing sector represents a vast customer base, with buyers ranging from hydraulic and pneumatic equipment manufacturers to chemical processing plants, robotics companies, and general machinery producers. These customers seek tubing that can withstand high pressures, abrasive environments, and corrosive chemicals, often requiring custom specifications for diverse applications. The food and beverage industry demands food-grade, non-toxic, and easy-to-clean tubing for fluid transfer in processing, bottling, and dispensing systems, adhering to strict hygiene standards. Construction companies utilize flexible tubing for electrical conduits, plumbing, and HVAC systems, valuing durability and ease of installation. Furthermore, the electronics and electrical industry uses tubing for insulation and protective sleeving, while aerospace and defense sectors procure high-performance tubing for critical fluid and gas transfer applications. This wide spectrum of end-users underscores the market's breadth and the continuous need for innovative, reliable, and application-specific polymeric flexible tubing solutions that meet evolving industry demands and regulatory mandates.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 8.4 Billion |

| Growth Rate | 8.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Saint-Gobain S.A., Zeus Industrial Products, Inc., Nordson Corporation (Nordson EFD), Raumedic AG, Optinova, Freudenberg Medical, Tekni-Plex, Inc., NewAge Industries, Inc., Teleflex Incorporated, Lubrizol Corporation (Argo-Hytos), Trelleborg AB, Eldon James Corp., Putnam Plastics Corporation, MicroLumen Inc., Parker Hannifin Corporation, Carlisle Interconnect Technologies, W. L. Gore & Associates, Inc., Confluent Medical Technologies, Inc., Fluortek, Inc., Specialty Silicone Products, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polymeric Flexible Tubing Market Key Technology Landscape

The Polymeric Flexible Tubing Market is characterized by a dynamic technology landscape, driven by continuous innovation in material science, manufacturing processes, and quality control systems to meet the increasingly stringent demands of various end-use industries. Extrusion technology remains foundational, encompassing single-lumen, multi-lumen, and co-extrusion techniques that allow for the creation of tubing with complex geometries, varying wall thicknesses, and multiple material layers. Advancements in co-extrusion enable manufacturers to combine different polymers to achieve composite properties, such as a flexible inner layer for fluid flow and a rigid outer layer for structural integrity, or to incorporate barrier layers for enhanced chemical resistance. Precision extrusion, often coupled with real-time laser gauging and ultrasonic monitoring, ensures tight tolerances and consistent dimensional accuracy, which is critical for medical devices and high-pressure industrial applications. The integration of inline inspection systems, including machine vision and artificial intelligence, further enhances quality assurance by detecting subtle defects at high production speeds, thereby reducing waste and improving product reliability.

Beyond traditional extrusion, other key technologies include braiding and coiling, which are employed to enhance the burst strength, kink resistance, and torqueability of flexible tubing, particularly important in interventional medical devices and industrial hoses. Braiding involves incorporating textile fibers or metal wires into the polymer matrix, providing additional structural support without significantly compromising flexibility. Furthermore, material compounding technologies are essential for customizing polymer formulations with specific additives to achieve desired characteristics such as antimicrobial properties, UV resistance, enhanced lubricity, or radio-opacity. The development of advanced polymers like PEEK, FEP, and medical-grade silicones, alongside high-performance thermoplastic elastomers (TPEs), allows for tubing that can withstand extreme temperatures, harsh chemicals, and repeated sterilization cycles. Surface modification techniques, such as plasma treatment or specialized coatings, are also gaining traction to improve biocompatibility, reduce friction, or prevent bacterial adhesion on the tubing surface. The adoption of automation and robotics in manufacturing processes is also a significant trend, improving efficiency, reducing labor costs, and ensuring consistent product quality across large production volumes, thereby contributing to the overall technological sophistication of the market.

Regional Highlights

- North America: A mature market with high demand from the medical and automotive sectors. Focus on specialty and high-performance tubing, driven by stringent regulatory standards and significant R&D investments. Leading in innovation for advanced materials and manufacturing techniques.

- Europe: Characterized by strong environmental regulations driving demand for sustainable and recyclable polymeric tubing. Significant presence of automotive, industrial, and medical device manufacturers. Germany, France, and the UK are key contributors to market growth and technological advancements.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, expanding healthcare infrastructure, and increasing automotive production, particularly in China, India, and Japan. High demand for cost-effective as well as high-performance tubing solutions across diverse applications.

- Latin America: Emerging market with increasing industrial and automotive manufacturing activities. Brazil and Mexico are key markets, benefiting from foreign investments and local production capabilities. Growth is steady, with a focus on general industrial and construction applications.

- Middle East and Africa (MEA): Growing demand from infrastructure development, oil and gas industry, and nascent healthcare sector. Increasing focus on localized manufacturing and technology adoption. UAE and Saudi Arabia are pivotal markets due to their economic diversification efforts.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polymeric Flexible Tubing Market.- Saint-Gobain S.A.

- Zeus Industrial Products, Inc.

- Nordson Corporation (Nordson EFD)

- Raumedic AG

- Optinova

- Freudenberg Medical

- Tekni-Plex, Inc.

- NewAge Industries, Inc.

- Teleflex Incorporated

- Lubrizol Corporation (Argo-Hytos)

- Trelleborg AB

- Eldon James Corp.

- Putnam Plastics Corporation

- MicroLumen Inc.

- Parker Hannifin Corporation

- Carlisle Interconnect Technologies

- W. L. Gore & Associates, Inc.

- Confluent Medical Technologies, Inc.

- Fluortek, Inc.

- Specialty Silicone Products, Inc.

Frequently Asked Questions

Analyze common user questions about the Polymeric Flexible Tubing market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is polymeric flexible tubing and its primary benefits?

Polymeric flexible tubing refers to conduits made from various synthetic polymers, valued for their flexibility, chemical resistance, durability, and often biocompatibility. Key benefits include ease of installation, corrosion resistance, lightweight nature, and adaptability to complex system designs, making them ideal for fluid transfer, protection, and insulation across many industries.

Which industries are the largest consumers of polymeric flexible tubing?

The largest consumers are the medical and pharmaceutical sectors due to the need for biocompatible and sterile tubing for devices like catheters and drug delivery systems. Other significant industries include automotive (fuel lines, brake lines), industrial manufacturing (hydraulics, pneumatics), food and beverage (food-grade transfer), and construction (electrical conduits, plumbing).

What are the main drivers of growth in the Polymeric Flexible Tubing Market?

Key growth drivers include the increasing demand for minimally invasive medical procedures, advancements in the automotive sector (including electric vehicles), rapid industrialization, and infrastructure development globally. Additionally, stringent regulatory standards in sensitive applications and continuous innovations in polymer science contribute significantly to market expansion.

What challenges does the Polymeric Flexible Tubing Market face?

The market faces challenges such as the volatility of raw material prices, which can impact manufacturing costs. Additionally, stringent environmental regulations regarding plastic waste and the growing demand for sustainable alternatives necessitate significant investments in research and development for eco-friendly and recyclable polymer solutions, adding complexity to production processes.

How is AI impacting the manufacturing of polymeric flexible tubing?

AI is transforming manufacturing by enabling real-time process control for extrusion, enhancing quality assurance through machine vision for defect detection, and facilitating predictive maintenance for equipment. It also aids in material science R&D, optimizing supply chain logistics, and supporting the development of highly customized tubing solutions, leading to greater efficiency and product innovation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager