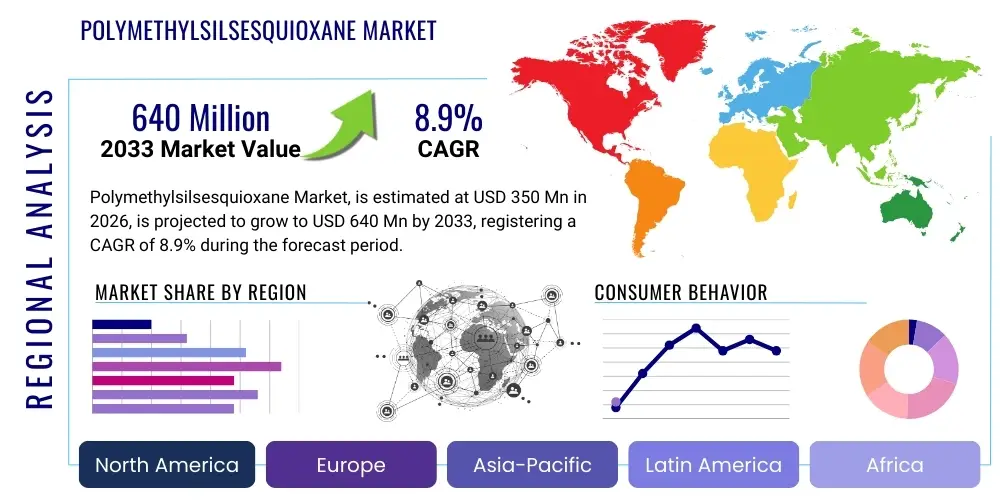

Polymethylsilsesquioxane Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438922 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Polymethylsilsesquioxane Market Size

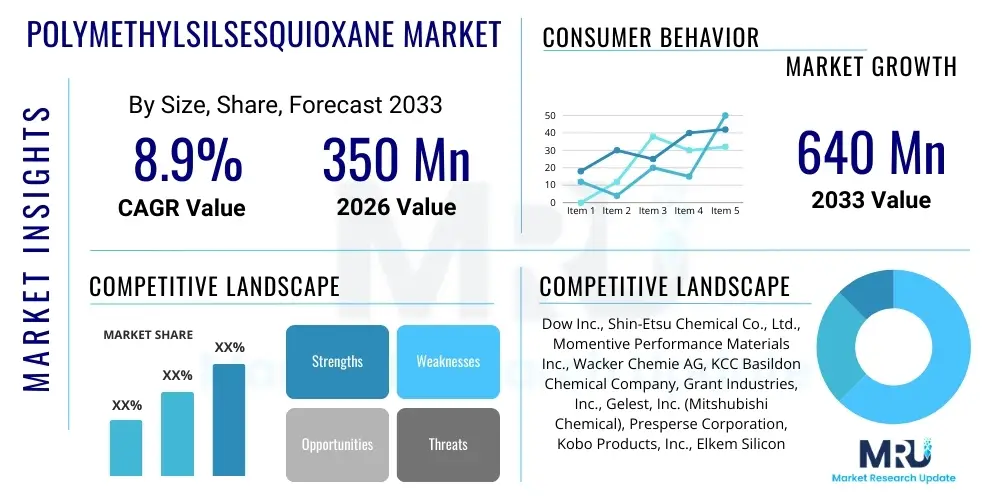

The Polymethylsilsesquioxane Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.9% between 2026 and 2033. The market is estimated at USD 350 Million in 2026 and is projected to reach USD 640 Million by the end of the forecast period in 2033.

Polymethylsilsesquioxane Market introduction

Polymethylsilsesquioxane (PMSQ) is a high-performance silicone resin characterized by its unique spherical particulate structure and exceptional physical properties. Chemically defined by the general formula (CH3SiO1.5)n, PMSQ is predominantly utilized as a multifunctional ingredient across various industrial and consumer sectors, primarily driven by the cosmetics and personal care industry. Its key functionality includes providing superior tactile sensory attributes, achieving a desirable soft-focus effect in cosmetic formulations, and serving as an effective oil and sebum absorbent. This versatility positions PMSQ as a critical additive in achieving sophisticated product performance characteristics, such as enhanced wear time, matte finish, and smooth spreadability.

The primary applications of PMSQ span color cosmetics (foundations, pressed powders), skincare products (moisturizers, sunscreens), and specialized industrial uses like optical coatings and thermal insulators. In cosmetics, PMSQ excels due to its low refractive index and light-scattering capabilities, which visibly minimize the appearance of fine lines and pores. This aesthetic benefit, coupled with its excellent heat stability and chemical inertness, makes it highly valued in premium and performance-driven formulations. The shift in consumer preference towards products offering both sensory elegance and practical performance significantly drives the demand for high-purity PMSQ materials globally, necessitating continuous innovation in particle size and surface treatment technologies by manufacturers.

Market expansion is fundamentally driven by the sustained growth of the global personal care industry, particularly in emerging economies where disposable incomes are rising, leading to increased adoption of premium cosmetic products. Furthermore, the inherent benefits of PMSQ, such as improved durability, reduced tackiness, and superior compatibility with various organic and inorganic raw materials, ensure its sustained replacement of traditional filler materials. Regulatory stability concerning silicone-based materials in major markets also provides a favorable environment for manufacturers. These combined factors—consumer demand for sophisticated sensory profiles, technological adoption in advanced materials, and favorable regulatory landscapes—cement PMSQ's position as a high-growth segment within the specialty chemical market.

Polymethylsilsesquioxane Market Executive Summary

The Polymethylsilsesquioxane (PMSQ) market is experiencing robust expansion, primarily fueled by strong business trends focusing on high-end cosmetic and dermatological applications. Companies are strategically investing in R&D to develop ultra-fine particle sizes and innovative surface modifications of PMSQ to meet niche demands for enhanced feel and stability in challenging formulations, such as water-in-oil emulsions and anhydrous systems. A key business trend involves vertically integrated suppliers optimizing synthesis pathways to improve product purity and consistency, crucial for ensuring compliance with stringent quality standards in the beauty sector. Furthermore, the increasing prominence of clean beauty and sustainable sourcing is influencing production, prompting players to evaluate bio-based alternatives or environmentally friendlier manufacturing processes for silicone-based materials, though PMSQ remains a highly effective synthetic polymer.

Regional trends indicate that the Asia Pacific (APAC) region is the fastest-growing market, driven by massive consumption growth in China, Japan, and South Korea, which are global trendsetters in both cosmetics and advanced materials manufacturing. These nations exhibit a high adoption rate of sophisticated personal care routines requiring ingredients with superior sensory profiles, directly benefiting PMSQ demand. Conversely, North America and Europe remain mature markets characterized by strict regulatory oversight regarding material safety and transparency, leading to sustained demand for high-quality, established PMSQ grades. Investment is often concentrated in developing novel, application-specific grades in these regions, particularly for use in specialized medical aesthetics and high-durability automotive coatings, showcasing diversification away from purely consumer applications.

Segmentation trends highlight that the cosmetic grade segment holds the largest market share due to the widespread use of PMSQ as a primary texturizer and soft-focus agent. Within this, the color cosmetics subsegment, particularly foundation and powder formulations, generates the highest revenue. However, the industrial grade segment, focused on applications like semiconductor encapsulation, protective coatings, and thermal insulation, is projected to register the fastest growth rate. This accelerated growth is attributed to the inherent thermal stability and dielectric properties of PMSQ, making it indispensable in high-performance electronics and aerospace materials. Market profitability is increasingly shifting towards specialty grades that offer enhanced functionality, such as higher oil absorption capacity or superior dispersibility, demanding complex manufacturing capabilities and offering higher margins.

AI Impact Analysis on Polymethylsilsesquioxane Market

Common user questions regarding AI's impact on the PMSQ market revolve around four main themes: how AI can accelerate material discovery for novel silicone derivatives, the optimization of complex chemical synthesis processes, predictive quality control during manufacturing, and AI-driven personalized formulation development in cosmetics. Users are primarily concerned with whether AI can identify suitable, cost-effective, and sustainable substitutes for conventional PMSQ structures, or if AI can drastically reduce the time-to-market for new PMSQ variants tailored for specific sensory attributes. Expectations are high regarding AI's capability to manage the vast complexity of chemical interactions, allowing formulators to predict the precise feel and performance characteristics of PMSQ in different matrices without extensive physical testing, thereby revolutionizing R&D efficiency and production accuracy within the specialty chemical domain.

The implementation of Artificial Intelligence and Machine Learning (ML) models is expected to profoundly optimize various stages of the PMSQ value chain, particularly in research and manufacturing. In R&D, AI algorithms can rapidly analyze thousands of precursor chemical combinations and reaction conditions to identify optimal synthesis routes for desired PMSQ particle sizes (e.g., controlling diameters between 1 to 10 micrometers) and morphology. This capability significantly shortens the experimentation cycle, leading to quicker development of tailored products for demanding sectors like specialized medical device coatings or high-clarity optical films. For instance, ML can predict how modifications in the hydrolysis and condensation steps during the sol-gel process affect the final material characteristics, dramatically improving process control and reducing waste generation, which is a major concern in high-purity chemical manufacturing.

Furthermore, in the realm of end-user application, particularly cosmetics, AI plays a crucial role in enhancing product personalization and consumer engagement. AI-powered formulation platforms analyze consumer preferences, skin types, regional climate data, and desired aesthetic outcomes (e.g., level of matte finish or oil control) to recommend the optimal inclusion level and specific grade of PMSQ. This data-driven approach ensures highly effective product development and minimizes formulation failures. Manufacturers are also deploying AI in their production facilities for real-time quality control. Computer vision and sensor data are analyzed by ML models to detect anomalies in particle size distribution or surface defects during continuous manufacturing, ensuring the high uniformity required for premium cosmetic ingredients, thereby minimizing batch variability and enhancing overall operational excellence.

- AI-Driven Formulation Optimization: Accelerating the discovery of new PMSQ-based cosmetic and coating formulas by predicting stability and sensory performance.

- Synthetic Pathway Acceleration: Utilizing machine learning to optimize reaction parameters (temperature, pressure, catalyst) for PMSQ synthesis, enhancing yield and purity.

- Predictive Quality Control: Implementing AI and sensor fusion in manufacturing to monitor particle morphology and size distribution in real-time, reducing batch inconsistency.

- Supply Chain Forecasting: AI algorithms improving demand forecasting for specific PMSQ grades based on fluctuating cosmetic market trends and seasonal consumer preferences.

- Sustainable Material Screening: Using computational chemistry powered by AI to screen for and develop environmentally less impactful precursors for silsesquioxane synthesis.

- Personalized Cosmetic Recommendations: AI engines recommending precise PMSQ concentrations to consumers or brands based on desired skin finish and specific application needs.

DRO & Impact Forces Of Polymethylsilsesquioxane Market

The Polymethylsilsesquioxane market is shaped by a complex interplay of Drivers, Restraints, and Opportunities, collectively representing the key Impact Forces influencing its trajectory. The primary driver is the relentless consumer demand for superior sensorial experiences and matte finishes in personal care and cosmetic products, where PMSQ's unique spherical structure delivers unparalleled soft focus and sebum control. Conversely, the high production cost associated with achieving the required particle uniformity and purity in PMSQ resins acts as a significant restraint, limiting its adoption in mass-market, budget-sensitive formulations. The opportunity lies in expanding high-end industrial applications, leveraging PMSQ's thermal and mechanical stability in demanding environments like aerospace composites and advanced electronic packaging. These opposing and propelling forces create a dynamic market environment where technological differentiation and cost management are paramount to sustained competitive success.

Key drivers include technological advancements in microsphere manufacturing, allowing for greater control over particle size, which expands the functional versatility of PMSQ across various applications, from high-definition makeup to anti-glare coatings. Furthermore, the increasing trend of incorporating functional fillers in plastic and polymer matrices to enhance mechanical properties or thermal stability, particularly in automotive and electronics industries, significantly boosts industrial demand. The rising disposable income across APAC and Latin American regions allows consumers to trade up to premium cosmetic brands that heavily rely on PMSQ for high-quality product aesthetics and longevity. These macro-economic and technological advancements create a sustained positive pressure on market growth, justifying continuous investment in capacity expansion and product portfolio diversification by leading chemical manufacturers.

However, the market faces notable restraints, including the complex regulatory landscape surrounding silicone-based ingredients, particularly in Europe, where ongoing scrutiny regarding environmental persistence and safety necessitates careful compliance and robust toxicology data from manufacturers. Another substantial restraint is the availability of cost-effective substitute materials, such as synthetic polymers (e.g., polyethylene waxes) and various forms of silica or calcium carbonate, which, while offering inferior performance in terms of feel and soft-focus effect, provide a cheaper alternative for price-sensitive segments. Addressing these restraints requires manufacturers to focus on demonstrating the superior cost-in-use benefits and high performance of PMSQ grades, justifying their premium pricing structure. The major opportunity remains the exploration of novel applications in drug delivery systems and biomedical fields, leveraging the biocompatibility and controlled porosity of silsesquioxane cages, potentially opening entirely new, high-value market segments.

Segmentation Analysis

The Polymethylsilsesquioxane (PMSQ) market is systematically segmented based on Grade Type, Application, and End-Use Industry, providing a clear framework for analyzing market dynamics and competitive positioning. Segmentation by Grade Type primarily differentiates between Cosmetic Grade and Industrial Grade, reflecting distinct purity, particle size, and surface treatment requirements necessary for diverse end-use performance. The Application segmentation focuses on the functional role PMSQ plays, such as opacifying agents, texturizers, binding agents, or thermal insulators. This granular breakdown helps identify specific high-growth areas, with the Texturizer application dominating the market due to its widespread adoption in foundations and skin primers designed for sensory excellence.

The End-Use Industry segmentation is critical, highlighting the market reliance on two major pillars: Personal Care and Cosmetics, and Specialty Chemicals/Industrial. While cosmetics drive the majority of volume and revenue, the industrial segment, which includes electronics, construction, and specialized coatings, provides higher revenue per unit volume due to the stringent specifications and lower elasticity of demand. This diversification across industries acts as a market stabilizer, ensuring sustained growth even if one sector experiences cyclical downturns. Understanding these segments is vital for suppliers to tailor product specifications—from highly spherical, uniformly sized cosmetic powders to irregularly shaped, high-surface-area industrial fillers—and optimize distribution strategies accordingly.

- Grade Type:

- Cosmetic Grade

- Industrial Grade (Technical Grade)

- Application:

- Texturizers and Sensory Enhancers

- Soft-Focus and Opacifying Agents

- Sebum and Oil Absorbing Agents

- Binding and Thickening Agents

- Thermal and Electrical Insulation

- End-Use Industry:

- Personal Care and Cosmetics

- Color Cosmetics (Foundation, Powders)

- Skincare (Sunscreens, Moisturizers)

- Hair Care

- Electronics and Electrical

- Coatings and Paints

- Automotive and Aerospace

- Medical and Pharmaceutical

- Personal Care and Cosmetics

Value Chain Analysis For Polymethylsilsesquioxane Market

The value chain for Polymethylsilsesquioxane begins with upstream activities focused on securing and processing essential raw materials, primarily organosilicon monomers such as methyltrimethoxysilane (MTMS) or methyltrichlorosilane. These foundational materials are derivatives of basic silicon chemistry, requiring specialized chemical synthesis and purification processes. Efficiency at this initial stage is critical as the cost and purity of these precursors heavily influence the final product quality and manufacturing feasibility. Key upstream players include major chemical giants and silicone manufacturers who often produce these monomers internally or source them under long-term contracts. Ensuring a stable and high-purity supply of these raw materials is a crucial competitive advantage, particularly given the rigorous quality demands of the cosmetic and electronics industries, which require extremely low impurity levels in the final PMSQ powder.

The central manufacturing stage involves the polymerization and processing of these precursors, typically through controlled hydrolysis and condensation reactions (the sol-gel process) to form the silsesquioxane structure, followed by critical steps such as particle size control (to achieve the desired spherical shape and uniform diameter), filtration, drying, and potentially surface treatment. Specialized processing technologies, including spray drying or controlled precipitation, are essential for creating the unique, non-aggregating spherical particles that define high-quality PMSQ. Quality control at this stage focuses intently on morphology, surface area, and oil absorption characteristics. Downstream activities involve the distribution channel, which is often segmented into direct sales to large, multinational cosmetic and specialty chemical companies and indirect sales via highly specialized chemical distributors catering to smaller regional formulators and niche industrial clients.

The distribution channel utilizes both direct and indirect routes. Direct sales are preferred for high-volume, established relationships with major multinational cosmetic manufacturers, allowing for customized logistical solutions and specialized technical support regarding formulation integration. Indirect distribution, leveraging local chemical distributors, is essential for penetrating fragmented regional markets and reaching smaller producers in the coatings, plastics, and local beauty sectors. These distributors provide essential services, including local inventory management, technical assistance, and compliance with regional chemical regulations. Ultimately, the end-users integrate the PMSQ into their final products (e.g., foundations, high-temperature composites). The successful operation of the value chain relies heavily on strong collaborations between manufacturers and specialized distributors to ensure efficient product delivery and application-specific technical guidance, crucial for maximizing the functional performance of this sophisticated ingredient.

Polymethylsilsesquioxane Market Potential Customers

The potential customer base for the Polymethylsilsesquioxane market is diverse, spanning multiple high-value industries but heavily concentrated within the personal care and high-tech manufacturing sectors. The most significant buyers are large, multinational cosmetic and dermatological product manufacturers who utilize PMSQ as a core functional ingredient for aesthetic enhancement and sensory modification. These customers prioritize suppliers capable of guaranteeing consistent particle size, high purity, and regulatory compliance across global markets, demanding specific grades optimized for foundation, powder, primer, and sunscreen formulations. Their purchasing decisions are driven by formulation stability, the sensory perception provided to the end-consumer (smoothness, matte finish), and the efficacy of oil control, making them premium segment buyers.

A secondary, yet rapidly expanding, segment of potential customers includes specialty chemicals and advanced material producers, particularly those focused on electronics, coatings, and aerospace components. In the electronics sector, PMSQ is valued for its superior dielectric properties, thermal stability, and low coefficient of thermal expansion, making it ideal for encapsulation materials, printed circuit board substrates, and semiconductor processing aids. Customers in the coatings industry seek PMSQ to enhance scratch resistance, provide matting effects in industrial finishes, and improve the weatherability of protective paints. These industrial buyers are highly technical, requiring detailed specification sheets, performance data under extreme conditions, and strict adherence to industrial quality certifications, often purchasing in bulk quantities for continuous production processes.

Furthermore, niche potential customers are emerging in the medical device and pharmaceutical fields. Researchers and product developers in these areas are exploring the unique cage structure of silsesquioxanes for applications such as controlled drug delivery systems, bone cements, and biocompatible coatings for implants. While currently smaller in volume, these customers represent a high-growth, high-margin opportunity due to the specialized nature of the material requirements and the stringent regulatory hurdles that, once cleared, lock in long-term supply relationships. The diverse range of buyers—from aesthetic-focused formulators to performance-driven material scientists—necessitates a flexible sales and technical support strategy from PMSQ manufacturers to effectively serve this multifaceted market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 640 Million |

| Growth Rate | 8.9% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dow Inc., Shin-Etsu Chemical Co., Ltd., Momentive Performance Materials Inc., Wacker Chemie AG, KCC Basildon Chemical Company, Grant Industries, Inc., Gelest, Inc. (Mitshubishi Chemical), Presperse Corporation, Kobo Products, Inc., Elkem Silicones (Bluestar), Merck KGaA, Crodarom, Sunjin Beauty Science, Giga Chemical, Guangzhou Tinci Materials Technology Co., Ltd., Hangzhou Dayang Chemical Co., Ltd., Sichuan Xinhua Basic Chemical Co., Ltd., Jiangsu Liyang Silicone Materials Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polymethylsilsesquioxane Market Key Technology Landscape

The technology landscape for the Polymethylsilsesquioxane market is primarily centered on enhancing particle uniformity, surface functionalization, and developing more sustainable synthesis methods. The core technology remains the highly controlled sol-gel process, but innovation is focused on refining the hydrolysis and condensation reaction kinetics to achieve tighter control over the spherical morphology and particle size distribution (PSD). Achieving monodisperse particles—where all particles are nearly the same size—is crucial for premium cosmetic grades, as uniformity directly correlates with superior sensory feel and consistent soft-focus performance. Advanced manufacturing techniques, such as microfluidics and spray-drying optimization, are being employed to scale up production of these highly uniform microspheres while minimizing aggregation and maintaining structural integrity, which presents significant technical challenges due to the fragility of the resulting polymer structures.

A second critical area of technological focus is surface modification, which enhances the compatibility of the inherently hydrophobic PMSQ powder with diverse formulation matrices (both oil- and water-based systems). Techniques involve grafting specialized chemical groups onto the silsesquioxane surface using silane coupling agents or other polymer treatments. Common modifications include coating with fatty acids, silicone elastomers, or pigments to improve dispersibility in specific solvents, increase adherence to the skin, or enhance resistance to humidity. These specialized surface treatments transform generic PMSQ into high-value functional ingredients, commanding premium prices and opening doors to complex formulations, such as long-wearing, water-resistant foundations or high-performance, weather-resistant industrial coatings. The ability to precisely tailor the surface energy is a key technological differentiator among leading market players.

Furthermore, technology is being deployed to improve the sustainability and efficiency of PMSQ production. Research into greener chemistry approaches, such as using supercritical carbon dioxide as a reaction medium or exploring solvent-free synthesis routes, aims to reduce the environmental footprint associated with traditional sol-gel processing which often involves significant solvent use. Additionally, manufacturers are investing in advanced characterization technologies, including sophisticated electron microscopy and dynamic light scattering, to accurately monitor the physical characteristics of the particles throughout the manufacturing process. This commitment to continuous improvement in synthesis control, functional modification, and stringent quality assurance defines the competitive technological edge in the contemporary Polymethylsilsesquioxane market, ensuring the materials meet the increasingly demanding performance specifications of end-user industries.

Regional Highlights

- Asia Pacific (APAC): APAC is anticipated to be the fastest-growing market, primarily due to the significant expansion of the cosmetics and personal care industry in countries like China, India, and South Korea. South Korea and Japan are centers of excellence for high-end skincare and makeup, demanding premium PMSQ grades for innovative formulations. Additionally, the region’s strong electronics manufacturing base utilizes industrial-grade PMSQ for encapsulation and thermal management materials, driving dual-sector growth.

- North America: North America represents a mature, high-value market characterized by robust regulatory frameworks and a strong focus on advanced material science R&D. Demand is driven by established cosmetic brands and a dynamic specialty chemicals sector serving the aerospace, automotive, and high-performance coating industries. Manufacturers in this region emphasize product safety, consistent quality, and localized supply chains.

- Europe: Europe is a key market, heavily influenced by strict chemical regulations such as REACH, which mandates stringent testing and compliance for silicone-based materials. The demand profile is high-quality, with significant uptake in premium and 'clean beauty' cosmetic segments. Germany, France, and the UK are central hubs for both cosmetic formulation expertise and industrial coating technology, demanding specialized, high-specification PMSQ products.

- Latin America: This region shows promising growth potential, driven by expanding middle-class populations and increasing urbanization, leading to higher consumption of branded personal care products, particularly in Brazil and Mexico. The market is often price-sensitive but shows growing adoption of internationally formulated cosmetics, creating opportunities for mid-to-high-grade PMSQ suppliers focused on cost-efficiency.

- Middle East and Africa (MEA): Growth in MEA is moderate but steady, largely concentrated in the GCC nations where high disposable incomes support the luxury cosmetic sector. PMSQ demand is also linked to infrastructure development and industrial projects (coatings, construction materials), especially in Saudi Arabia and the UAE, where materials requiring high-temperature and harsh-environment resistance are essential.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polymethylsilsesquioxane Market.- Dow Inc.

- Shin-Etsu Chemical Co., Ltd.

- Wacker Chemie AG

- Momentive Performance Materials Inc.

- KCC Basildon Chemical Company

- Grant Industries, Inc.

- Gelest, Inc. (Mitshubishi Chemical)

- Presperse Corporation

- Kobo Products, Inc.

- Elkem Silicones (Bluestar)

- Merck KGaA

- Crodarom

- Sunjin Beauty Science

- Giga Chemical

- Guangzhou Tinci Materials Technology Co., Ltd.

- Hangzhou Dayang Chemical Co., Ltd.

- Sichuan Xinhua Basic Chemical Co., Ltd.

- Jiangsu Liyang Silicone Materials Co., Ltd.

- BRB International BV

- Evonik Industries AG

Frequently Asked Questions

Analyze common user questions about the Polymethylsilsesquioxane market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Polymethylsilsesquioxane (PMSQ) and what is its primary function?

Polymethylsilsesquioxane is a spherical silicone resin powder used extensively in cosmetics and industrial applications. Its primary function is to serve as a soft-focus agent, diffusing light to minimize the appearance of pores and fine lines, and as a powerful texturizer and sebum control agent in personal care formulations.

Which industry holds the largest market share for Polymethylsilsesquioxane?

The Personal Care and Cosmetics industry currently holds the largest market share due to the widespread use of PMSQ as a premium sensory modifier and filler in high-end foundations, pressed powders, primers, and advanced skincare products globally.

How do manufacturers control the particle size of PMSQ, and why is this critical?

Manufacturers control particle size primarily through the controlled sol-gel polymerization process, optimizing reaction kinetics (hydrolysis and condensation). Precise control over particle size (typically 1-10 microns) is critical because it directly determines the product's functional properties, such as oil absorption capacity and the effectiveness of the soft-focus light diffusion effect.

What major restraints challenge the growth of the PMSQ market?

Major restraints include the relatively high production cost associated with achieving high purity and uniform particle size, which limits adoption in mass-market products, and the continuous regulatory scrutiny faced by silicone-based ingredients in mature markets like Europe.

Which geographical region is expected to show the fastest growth rate for PMSQ?

The Asia Pacific (APAC) region is expected to exhibit the fastest growth, driven by burgeoning consumption in the cosmetics sector of economies like China and South Korea, coupled with significant industrial demand from the region’s dominant electronics and specialty materials manufacturing base.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager