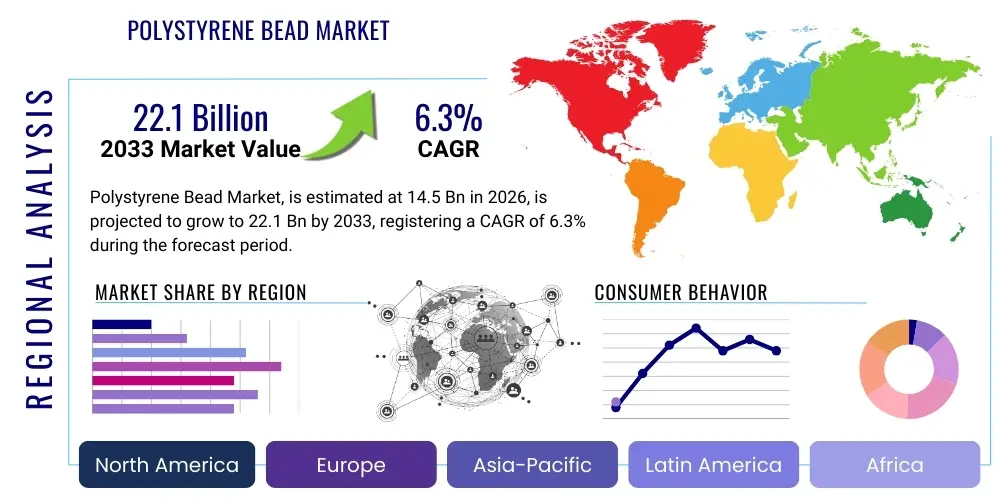

Polystyrene Bead Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440668 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Polystyrene Bead Market Size

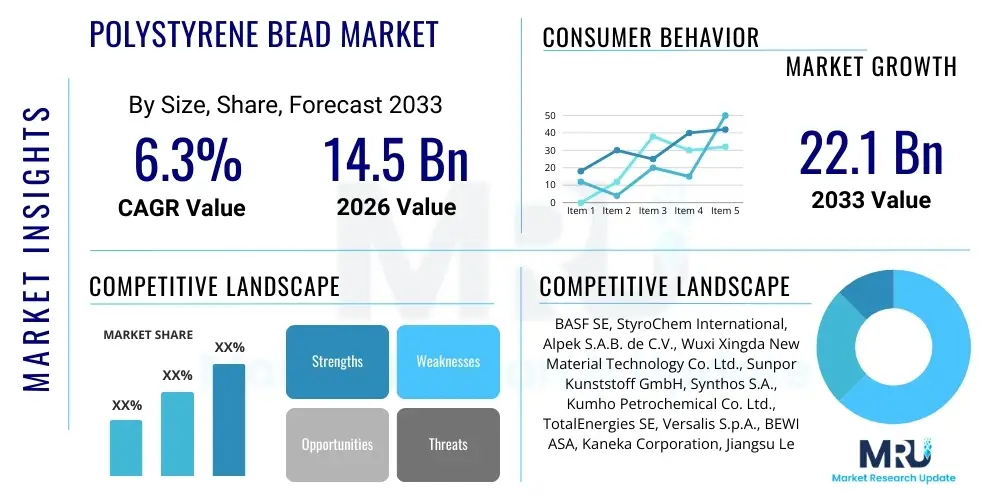

The Polystyrene Bead Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.3% between 2026 and 2033. The market is estimated at USD 14.5 Billion in 2026 and is projected to reach USD 22.1 Billion by the end of the forecast period in 2033.

Polystyrene Bead Market introduction

Polystyrene beads are versatile thermoplastic polymers, renowned for their lightweight, excellent insulation properties, and ease of processing. Primarily derived from styrene monomer, these beads undergo a polymerization process, often incorporating a blowing agent, to produce various forms such as Expandable Polystyrene (EPS) and Extrudable Polystyrene (XPS). EPS beads, in particular, are small, spherical granules that expand significantly when exposed to steam, forming lightweight foam products widely used across numerous industries.

Major applications of polystyrene beads span diverse sectors including construction, packaging, automotive, and consumer goods. In construction, they are critical for thermal insulation in walls, roofs, and floors, contributing significantly to energy efficiency in buildings. For packaging, their superior shock absorption capabilities make them ideal for protecting delicate items during transit, ranging from electronics to fresh produce. Furthermore, they are used in craft supplies, geotechnical fill, and even in some water treatment applications.

The primary benefits of polystyrene beads include their excellent thermal and acoustic insulation, high strength-to-weight ratio, moisture resistance, and cost-effectiveness. These attributes make them a preferred material over alternatives in many applications where lightweighting and insulation are paramount. The market is currently driven by increasing demand from the construction sector, particularly for energy-efficient building materials, coupled with the rising need for protective packaging solutions due to the growth of e-commerce and global supply chains. Innovations in sustainable production and recycling also present new growth avenues.

Polystyrene Bead Market Executive Summary

The global polystyrene bead market is poised for significant expansion, driven by robust demand across key end-use industries and a growing focus on energy efficiency and lightweight materials. Business trends indicate a strong emphasis on product innovation, particularly in developing flame-retardant and high-performance EPS and XPS beads that meet stringent building codes and automotive standards. Furthermore, manufacturers are increasingly investing in circular economy initiatives, focusing on advanced recycling technologies and the development of bio-based or recycled content polystyrene beads to address environmental concerns and regulatory pressures. Strategic partnerships and mergers are also prevalent as companies seek to consolidate market share and enhance their technological capabilities.

Regionally, the Asia Pacific (APAC) continues to dominate the market, largely owing to rapid urbanization, extensive infrastructure development projects, and a booming manufacturing sector, especially in countries like China and India. North America and Europe also present significant opportunities, driven by strict energy efficiency mandates, increasing renovation activities, and a growing adoption of sustainable building practices. Emerging economies in Latin America and the Middle East & Africa are demonstrating nascent but promising growth, fueled by rising disposable incomes and expanding industrial bases. Localized supply chains and regional regulatory frameworks play a crucial role in shaping market dynamics across these geographies, necessitating tailored market entry and growth strategies.

Segment-wise, the Expanded Polystyrene (EPS) segment is expected to retain its leading position, attributed to its widespread use in thermal insulation, protective packaging, and geofoam applications. Innovations in manufacturing processes are enhancing the performance and versatility of EPS beads, expanding their utility into new areas. The Extruded Polystyrene (XPS) segment is also showing steady growth, particularly in demanding insulation applications where higher compressive strength and superior moisture resistance are required. End-use industries such as construction and packaging will remain the largest consumers, but the automotive sector is emerging as a critical growth area, with polystyrene beads contributing to lightweight components and enhanced fuel efficiency. The market's overall trajectory is positive, underpinned by continuous product development and evolving application requirements.

AI Impact Analysis on Polystyrene Bead Market

The impact of Artificial Intelligence (AI) on the Polystyrene Bead Market is multifaceted, promising significant advancements in efficiency, sustainability, and competitive differentiation. Common user questions revolve around how AI can optimize production processes, improve supply chain management, enhance product development, and facilitate sustainable practices within the industry. Stakeholders are particularly interested in AI's potential to reduce operational costs, minimize waste, and meet evolving market demands with greater agility. There is also a keen interest in how AI can support predictive analytics for raw material procurement and demand forecasting, navigating the volatile nature of petrochemical markets.

AI's influence is expected to streamline manufacturing operations through predictive maintenance of machinery, optimizing energy consumption in expansion and molding processes, and ensuring consistent product quality. By analyzing vast datasets from sensors and production lines, AI algorithms can identify anomalies, predict equipment failures before they occur, and suggest optimal operating parameters, thereby reducing downtime and increasing output. This level of operational precision can lead to substantial cost savings and a more efficient utilization of resources, directly impacting the profitability of polystyrene bead manufacturers.

Furthermore, AI is set to revolutionize supply chain logistics, from raw material sourcing to final product distribution. AI-powered platforms can analyze global market trends, geopolitical factors, and logistics data to forecast styrene monomer prices and availability, enabling more strategic purchasing decisions. Demand forecasting models, leveraging machine learning, can predict customer needs with higher accuracy, reducing inventory holding costs and minimizing the risk of overproduction or stockouts. In research and development, AI can accelerate the discovery of new formulations, especially for bio-based or recycled polystyrene, by simulating material properties and predicting performance characteristics, thus fostering innovation and sustainability in the market.

- AI-driven process optimization for enhanced manufacturing efficiency and reduced energy consumption.

- Predictive maintenance systems to minimize downtime and extend equipment lifespan in production facilities.

- Advanced supply chain analytics for optimal raw material procurement and logistics management.

- Improved demand forecasting through machine learning models, leading to optimized inventory levels.

- Accelerated R&D for new product formulations, including bio-based and recycled polystyrene beads.

- Enhanced quality control and defect detection using AI-powered vision systems during production.

- Smart factory integration for real-time monitoring and autonomous adjustments in bead production.

- Data-driven sustainability initiatives, such as waste reduction and recycling process optimization.

- Personalized customer insights and market trend analysis for strategic business development.

- Automated compliance monitoring with environmental and safety regulations.

DRO & Impact Forces Of Polystyrene Bead Market

The polystyrene bead market is influenced by a complex interplay of Drivers, Restraints, Opportunities, and a range of Impact Forces that shape its growth trajectory and competitive landscape. Key drivers propelling the market forward include the burgeoning global construction industry, particularly the demand for thermal insulation in residential and commercial buildings to meet increasingly stringent energy efficiency standards. The rapid expansion of the e-commerce sector is simultaneously boosting the demand for protective packaging solutions, where lightweight and shock-absorbing polystyrene beads are indispensable. Furthermore, their versatility and cost-effectiveness across diverse applications continue to support their widespread adoption.

However, the market faces significant restraints, primarily stemming from environmental concerns surrounding plastic waste and the non-biodegradable nature of conventional polystyrene. This has led to mounting regulatory pressures and public scrutiny, prompting a push towards sustainable alternatives and enhanced recycling efforts. Volatility in raw material prices, particularly styrene monomer which is derived from crude oil, poses another substantial challenge, impacting production costs and profit margins for manufacturers. The competitive landscape is also intensified by the availability of alternative insulation and packaging materials, requiring continuous innovation from polystyrene bead producers to maintain market share.

Despite these restraints, the market presents compelling opportunities. The development of advanced recycling technologies, such as chemical recycling which can revert polystyrene back to its monomer, holds immense potential to address waste concerns and create a circular economy for the material. Innovations in bio-based and biodegradable polystyrene alternatives are also emerging, offering pathways for sustainable growth. Furthermore, expansion into untapped applications, such as lightweighting in automotive components and specialized geotechnical fills, can open new revenue streams. The increasing focus on smart cities and green building initiatives globally provides a fertile ground for high-performance and sustainable polystyrene bead solutions, driving future market evolution and fostering a more environmentally conscious industry.

Segmentation Analysis

The polystyrene bead market is extensively segmented based on various critical parameters, providing a detailed understanding of its dynamics and potential growth areas. These segmentations allow for a granular analysis of market demand across different product types, applications, and end-use industries, enabling stakeholders to identify specific opportunities and tailor their strategies effectively. The primary segmentations include product type, which differentiates between various forms of polystyrene beads based on their properties and manufacturing processes, and application, which categorizes their usage across a multitude of industries. Understanding these segments is crucial for mapping the market landscape and predicting future trends.

- By Product Type:

- Expanded Polystyrene (EPS) Beads

- Standard EPS

- Flame Retardant EPS

- High-Density EPS

- Graphite-Enhanced EPS

- Extruded Polystyrene (XPS) Beads

- Standard XPS

- High-Compressive Strength XPS

- Moisture-Resistant XPS

- General Purpose Polystyrene (GPPS) Beads

- High Impact Polystyrene (HIPS) Beads

- Specialty Polystyrene Beads

- Biopolymer-Blended Beads

- Recycled Content Polystyrene Beads

- Conductive Polystyrene Beads

- Expanded Polystyrene (EPS) Beads

- By Application:

- Construction & Insulation

- Wall Insulation (Cavity, External, Internal)

- Roof Insulation (Flat, Pitched)

- Floor Insulation (Underfloor Heating, Slab)

- Geofoam (Road Construction, Embankment Stabilization)

- Decorative Elements (Cornices, Moldings)

- Packaging

- Protective Packaging (Electronics, Appliances, Automotive Parts)

- Food Packaging (Trays, Containers, Meat & Produce)

- Insulated Packaging (Cold Chain Logistics)

- Loose Fill Packaging (Packing Peanuts)

- Custom-Molded Packaging

- Automotive

- Lightweight Interior Components

- Energy Absorption Systems (Bumpers, Impact Dampeners)

- Insulation for EVs (Battery Packs)

- Consumer Goods

- Crafts and Decorative Items

- Furniture Components

- Buoyancy Aids (Life Vests, Floats)

- Sports Equipment (Helmets, Surfboards)

- Other Industrial Applications

- Water Treatment Filtration Media

- Horticulture (Soil Amendments)

- Flotation Devices

- Construction & Insulation

- By End-Use Industry:

- Building & Construction

- Packaging Industry

- Automotive & Transportation

- Electronics & Electrical

- Consumer Appliances

- Sports & Leisure

- Food & Beverage

- Marine

- Healthcare & Pharmaceutical

Value Chain Analysis For Polystyrene Bead Market

The value chain for the polystyrene bead market is a complex network involving several stages, beginning from raw material extraction and extending to the final end-user consumption. Understanding this chain is crucial for identifying areas of cost optimization, supply chain resilience, and strategic positioning. The upstream segment of the value chain is dominated by the petrochemical industry, where crude oil and natural gas are processed to produce benzene and ethylene. These precursors are then chemically reacted to synthesize styrene monomer, the fundamental building block for polystyrene. A few major chemical companies often control the production of styrene monomer, giving them significant leverage in pricing and supply dynamics within the entire value chain. Strategic sourcing and long-term contracts with these upstream suppliers are critical for polystyrene bead manufacturers to ensure a stable supply of raw materials and manage price volatility effectively.

Moving downstream, the styrene monomer is polymerized through various processes, primarily suspension or emulsion polymerization, to produce polystyrene resin or directly into expandable polystyrene beads. This midstream segment involves specialized chemical manufacturers who transform raw monomers into the desired bead form, incorporating additives like flame retardants, colorants, and blowing agents to impart specific properties. These manufacturers then supply the beads to converters or molders, who use processes like steam chest molding (for EPS) or extrusion (for XPS) to create finished foam products. These converters play a vital role in shaping the beads into insulation boards, packaging inserts, or other customized products according to specific application requirements. Efficiency in these conversion processes, including optimized cycle times and minimal waste, is essential for profitability.

The distribution channel for polystyrene beads and their derived products involves a mix of direct and indirect sales. Direct sales are common for large-volume industrial customers, such as major construction firms or large-scale packaging companies, where manufacturers can negotiate directly and offer tailored solutions. Indirect channels involve a network of distributors, wholesalers, and retailers who facilitate market access to smaller businesses, regional contractors, and specialized niche markets. These intermediaries provide crucial logistical support, inventory management, and local market expertise. Both direct and indirect channels are essential for comprehensive market penetration, with the choice often depending on the scale of the customer, geographical reach, and the nature of the product. The increasing reliance on e-commerce platforms also represents a growing distribution avenue, particularly for standardized products and craft supplies, expanding market reach and operational efficiency.

Polystyrene Bead Market Potential Customers

The potential customer base for the polystyrene bead market is diverse and spans a wide array of industries, reflecting the material's broad applicability and versatility. End-users and buyers are primarily driven by the need for lightweight materials with excellent insulation, protective, and structural properties, making polystyrene beads an indispensable component in their manufacturing and operational processes. These customers range from large multinational corporations to small and medium-sized enterprises (SMEs), each utilizing polystyrene beads for specific applications that cater to their unique market demands and product requirements. Identifying and understanding the needs of these varied customer segments is paramount for market players to develop targeted sales and marketing strategies.

In the construction sector, potential customers include residential and commercial building developers, general contractors, insulation manufacturers, and specialized contractors for roofing, flooring, and exterior finishing systems. These buyers prioritize polystyrene beads for their superior thermal performance, moisture resistance, and ease of installation, which contribute to energy-efficient buildings and reduced operational costs. The demand from this segment is also influenced by green building certifications and evolving architectural designs that increasingly incorporate advanced insulation materials. Geotechnical engineers and civil construction companies also represent a significant customer group, utilizing geofoam blocks made from EPS beads for lightweight fill in road construction, bridge abutments, and slope stabilization projects, offering an advantageous alternative to traditional earth fill materials.

Another major segment of potential customers resides within the packaging industry, encompassing manufacturers of protective packaging, food packaging, and cold chain logistics providers. E-commerce companies and their fulfillment centers are also rapidly growing buyers, requiring custom-molded polystyrene packaging to safely transport fragile electronics, consumer goods, and perishable items. Beyond industrial applications, the consumer goods sector attracts customers such as furniture manufacturers, toy makers, craft suppliers, and producers of sports and leisure equipment (e.g., surfboards, life vests) who value the material's lightweight nature, buoyancy, and moldability. The automotive industry is also an emerging customer, with manufacturers exploring polystyrene beads for lightweight components, acoustic insulation, and energy-absorbing elements to enhance vehicle performance and fuel efficiency.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 14.5 Billion |

| Market Forecast in 2033 | USD 22.1 Billion |

| Growth Rate | 6.3% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, StyroChem International, Alpek S.A.B. de C.V., Wuxi Xingda New Material Technology Co. Ltd., Sunpor Kunststoff GmbH, Synthos S.A., Kumho Petrochemical Co. Ltd., TotalEnergies SE, Versalis S.p.A., BEWI ASA, Kaneka Corporation, Jiangsu Leasty Chemicals Co. Ltd., Trinseo PLC, Ineos Styrolution, Ravago S.A., Vidya Polymers Private Limited, Sinopec Group, Lotte Chemical Corporation, SABIC, Atlas Roofing Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polystyrene Bead Market Key Technology Landscape

The technology landscape for the polystyrene bead market is continuously evolving, driven by the need for enhanced performance, cost efficiency, and improved environmental sustainability. Production technologies primarily revolve around the polymerization of styrene monomer and the subsequent expansion or extrusion processes that create the beads. Suspension polymerization remains a dominant method for producing expandable polystyrene (EPS) beads, where styrene monomer droplets are suspended in water and polymerized in the presence of an initiator and a blowing agent. Innovations in this area focus on optimizing reaction kinetics, controlling bead size distribution, and incorporating additives to enhance properties such as flame retardancy or thermal conductivity, for instance, through the inclusion of graphite particles to create grey EPS.

Beyond the core production of raw beads, significant technological advancements are occurring in the post-processing and application stages. For Expanded Polystyrene (EPS), technologies like pre-expansion, molding, and cutting are critical. Modern pre-expanders are designed for greater energy efficiency and precise density control, while molding machines incorporate advanced automation and rapid cycle times to meet high production demands for insulation panels and packaging forms. For Extruded Polystyrene (XPS), the extrusion process involves melting polystyrene resin and a blowing agent under high pressure, then extruding the mixture through a die to form a continuous foam board. Technological improvements in XPS production focus on developing advanced blowing agents with lower global warming potential (GWP) and optimizing die designs to achieve superior cell structure and surface finish, enhancing insulation performance and moisture resistance.

The push for sustainability is also driving a major technological shift, with increasing investment in recycling and bio-based polystyrene production. Mechanical recycling technologies for post-consumer and post-industrial polystyrene waste are being refined to improve efficiency and yield higher-quality recycled material. More significantly, chemical recycling, such as depolymerization (pyrolysis or catalytic processes) that converts polystyrene back into styrene monomer, represents a groundbreaking technology. This enables a truly circular economy, as the recovered monomer can be used to produce virgin-grade polystyrene beads, addressing waste concerns and reducing reliance on virgin fossil resources. Furthermore, research into bio-based styrene derived from renewable biomass and the development of biodegradable alternatives are emerging technologies poised to reshape the future of the polystyrene bead market, offering long-term sustainable solutions.

Regional Highlights

- Asia Pacific (APAC): The APAC region stands as the undisputed leader in the polystyrene bead market, primarily fueled by robust economic growth, rapid urbanization, and extensive infrastructure development, particularly in China and India. The burgeoning construction sector, coupled with a massive manufacturing base and a booming e-commerce market, drives high demand for both insulation and protective packaging applications. Government initiatives promoting energy-efficient buildings also contribute significantly to market expansion, making it a critical region for investment and production.

- Europe: Europe represents a mature but steadily growing market, characterized by stringent energy efficiency regulations and a strong emphasis on sustainable building practices. Countries like Germany, France, and the UK are key consumers, driven by renovation activities, green building codes, and a rising awareness of environmental impact. The region is also at the forefront of adopting advanced recycling technologies and exploring bio-based alternatives, positioning itself as a hub for innovation in sustainable polystyrene solutions.

- North America: The North American market is experiencing consistent growth, supported by steady expansion in the construction industry, particularly in residential and commercial sectors, and increasing demand for high-performance insulation materials. The growing e-commerce penetration and the need for durable, lightweight packaging solutions further bolster market demand. Innovation in specialized applications, such as high-performance insulation for extreme climates and advanced packaging for sensitive goods, is a key regional trend.

- Latin America: Latin America presents an emerging market with significant growth potential. Countries such as Brazil, Mexico, and Argentina are witnessing increasing construction activities and industrialization, leading to a rising demand for polystyrene beads in both building and packaging applications. Economic development and improving living standards are driving consumption, though the market is still in its developing phase compared to more established regions, offering substantial opportunities for new market entrants.

- Middle East & Africa (MEA): The MEA region is characterized by ongoing large-scale infrastructure projects, especially in the Gulf Cooperation Council (GCC) countries, which are driving the demand for insulation materials to combat extreme temperatures. Investments in new residential and commercial developments, coupled with growing industrialization, contribute to market expansion. The region also benefits from its strategic location for petrochemical production, influencing raw material availability and pricing.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polystyrene Bead Market.- BASF SE

- StyroChem International

- Alpek S.A.B. de C.V.

- Wuxi Xingda New Material Technology Co. Ltd.

- Sunpor Kunststoff GmbH

- Synthos S.A.

- Kumho Petrochemical Co. Ltd.

- TotalEnergies SE

- Versalis S.p.A.

- BEWI ASA

- Kaneka Corporation

- Jiangsu Leasty Chemicals Co. Ltd.

- Trinseo PLC

- Ineos Styrolution

- Ravago S.A.

- Vidya Polymers Private Limited

- Sinopec Group

- Lotte Chemical Corporation

- SABIC

- Atlas Roofing Corporation

Frequently Asked Questions

What are polystyrene beads primarily used for?

Polystyrene beads are primarily used for thermal insulation in construction (walls, roofs, floors), protective packaging for electronics and perishable goods, and lightweight components in automotive and consumer products. Their excellent insulation, shock absorption, and lightweight properties make them ideal for these diverse applications, contributing significantly to energy efficiency and product protection across various industries.

What is the projected growth rate for the Polystyrene Bead Market?

The Polystyrene Bead Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.3% between 2026 and 2033. This growth is driven by increasing demand from the construction sector, expanding e-commerce activities requiring protective packaging, and continuous innovation in product applications and sustainability efforts across global markets.

What are the main environmental concerns associated with polystyrene beads?

The main environmental concerns associated with polystyrene beads relate to their non-biodegradable nature, contributing to plastic waste accumulation in landfills and oceans. However, the industry is actively addressing these concerns through advanced recycling technologies, including chemical recycling, and the development of bio-based and recycled content polystyrene alternatives to promote a more circular economy and mitigate environmental impact.

How does AI impact the Polystyrene Bead Market?

AI impacts the Polystyrene Bead Market by optimizing production processes through predictive maintenance and energy management, enhancing supply chain efficiency with advanced demand forecasting and raw material procurement, and accelerating R&D for sustainable formulations. AI-driven solutions aim to reduce operational costs, minimize waste, and improve overall product quality and market responsiveness, driving innovation across the value chain.

Which region dominates the Polystyrene Bead Market?

The Asia Pacific (APAC) region currently dominates the Polystyrene Bead Market. This leadership is attributed to rapid urbanization, extensive infrastructure development, and a booming manufacturing sector in countries like China and India. Strong demand from the construction industry for insulation and the growing e-commerce sector for packaging solutions are key factors propelling the market in APAC.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager