Polysulfone Resin Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439968 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Polysulfone Resin Market Size

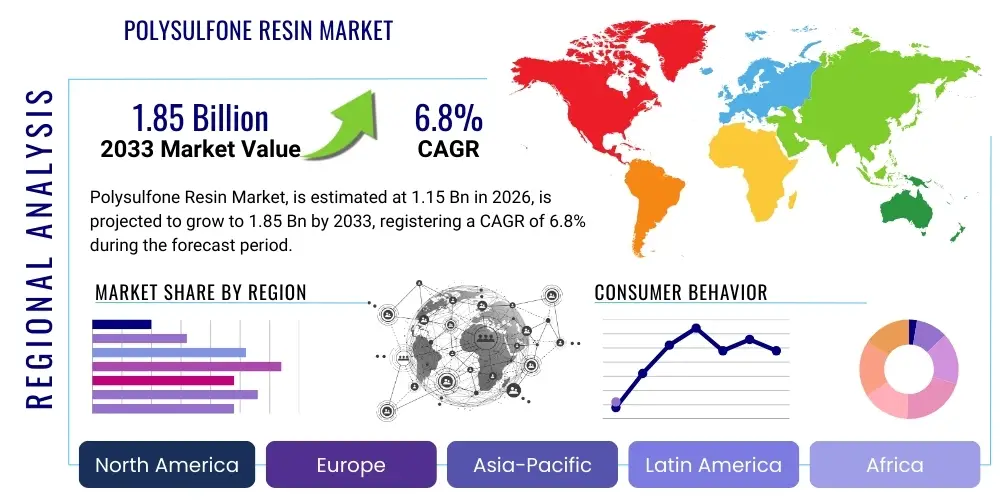

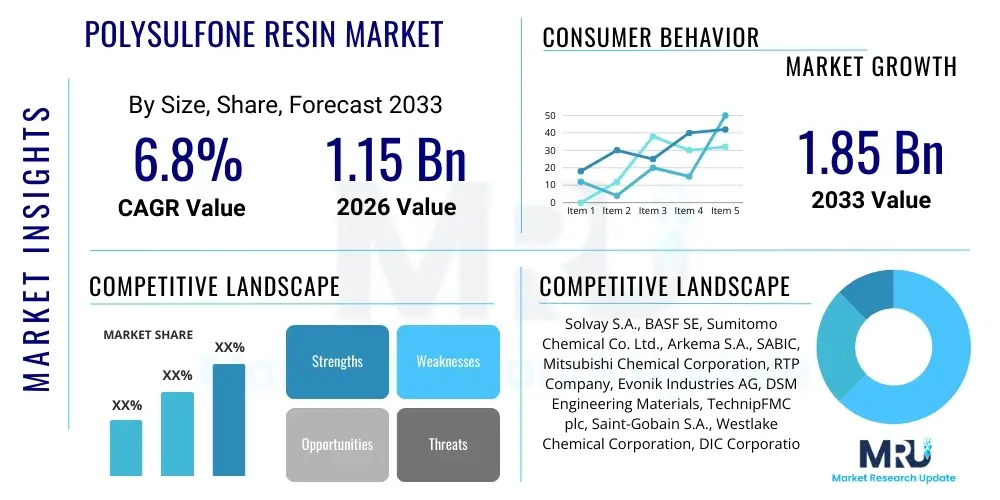

The Polysulfone Resin Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.15 billion in 2026 and is projected to reach USD 1.85 billion by the end of the forecast period in 2033.

Polysulfone Resin Market introduction

The Polysulfone Resin Market encompasses the production, distribution, and application of high-performance thermoplastic polymers known for their exceptional thermal stability, mechanical strength, and chemical resistance. These amorphous thermoplastics, including Polysulfone (PSU), Polyethersulfone (PES), and Polyphenylsulfone (PPSU), offer superior properties such as high heat deflection temperature, hydrolytic stability, and inherent flame retardancy, making them indispensable in demanding environments. Their unique combination of attributes allows them to outperform conventional plastics in critical applications, often serving as a lightweight alternative to metals.

Major applications for polysulfone resins span diverse industries including medical devices, automotive components, electrical and electronics, water filtration membranes, and aerospace parts. In the medical sector, their biocompatibility and sterilizability make them ideal for surgical instruments and dialysis equipment. For automotive applications, polysulfone resins contribute to lightweighting initiatives and enhanced performance under high temperatures. The market benefits from increasing demand for durable and high-performance materials across these end-use sectors, driven by technological advancements and stringent regulatory standards. The inherent advantages of polysulfone resins, such as excellent dimensional stability, good electrical insulation properties, and transparency, further solidify their market position.

Key driving factors for market growth include the escalating demand for advanced filtration solutions, particularly in industrial and domestic water purification, and the expanding use of high-performance plastics in healthcare due to an aging global population and rising healthcare expenditures. Furthermore, the push for energy efficiency and lightweight materials in the automotive and aerospace industries continues to fuel innovation and adoption. Continuous research and development efforts aimed at enhancing processing techniques and exploring new applications are also critical in sustaining the market's upward trajectory, alongside a growing emphasis on sustainable and recyclable material solutions.

Polysulfone Resin Market Executive Summary

The Polysulfone Resin Market is experiencing robust growth, primarily driven by the increasing adoption of high-performance polymers across several key industries. Business trends indicate a focus on strategic collaborations, mergers, and acquisitions among leading manufacturers to expand product portfolios and geographical reach, aiming to capture a larger share of niche and high-value applications. Innovations in compounding and processing technologies are also central to market development, enabling the creation of customized polysulfone grades with enhanced properties tailored for specific end-user requirements, including improved chemical resistance and mechanical strength. Furthermore, sustainability initiatives are influencing market dynamics, with a growing emphasis on developing more eco-friendly production methods and exploring recycling opportunities for polysulfone resins to address environmental concerns and align with global green manufacturing trends.

Regionally, the Asia Pacific market stands out as a significant growth engine, fueled by rapid industrialization, burgeoning manufacturing sectors, and increasing investments in healthcare and water infrastructure, particularly in countries like China and India. North America and Europe also maintain substantial market shares, driven by well-established automotive, aerospace, and medical device industries, coupled with stringent regulatory standards that favor the use of high-performance materials. These regions are characterized by a strong emphasis on research and development, fostering innovation in polysulfone resin applications and processing techniques. Latin America, the Middle East, and Africa are showing promising potential, with increasing industrial development and infrastructure projects gradually boosting the demand for polysulfone resins in various applications, particularly in water treatment and general industrial sectors.

Segment-wise, the medical and healthcare sector continues to be a dominant application area for polysulfone resins, driven by the demand for sterilizable and biocompatible materials in surgical instruments, dialysis membranes, and drug delivery systems. The water purification segment is another major contributor, with polysulfone membranes being crucial for ultrafiltration and microfiltration processes due to their excellent hydrolytic stability and fouling resistance. In the automotive industry, the lightweighting trend and demand for materials that can withstand high temperatures and harsh operating conditions are propelling the use of polysulfone resins in engine components, electrical connectors, and structural parts. The electrical and electronics sector also presents significant opportunities, leveraging the resins' superior electrical insulation and heat resistance properties for connectors, circuit boards, and other electronic components, reflecting a broad and diversified application landscape that underscores the market's resilience and growth potential.

AI Impact Analysis on Polysulfone Resin Market

The integration of Artificial Intelligence (AI) is poised to revolutionize various facets of the Polysulfone Resin market, addressing common user questions related to efficiency, quality, and innovation. Users frequently inquire about how AI can optimize manufacturing processes, predict material performance, and accelerate the discovery of new formulations. There is significant interest in AI's potential to enhance supply chain resilience by forecasting demand and managing inventory more effectively, mitigating the impact of disruptions. Furthermore, stakeholders are keen to understand AI's role in improving product quality through real-time monitoring and anomaly detection, as well as its capacity to support the development of sustainable polysulfone solutions by simulating material properties and optimizing recycling processes. The overarching expectation is that AI will drive operational excellence, foster material innovation, and provide a competitive edge in a highly specialized market.

- AI-driven predictive maintenance for manufacturing equipment, reducing downtime and operational costs.

- Optimization of polymer synthesis and processing parameters through machine learning algorithms, enhancing yield and quality.

- Accelerated material discovery and formulation development by simulating molecular structures and predicting performance characteristics.

- Enhanced supply chain management and logistics through AI-powered demand forecasting and inventory optimization.

- Improved quality control and defect detection in polysulfone components using computer vision and AI analytics.

- Development of smart polysulfone-based sensors and devices with integrated AI for real-time monitoring and data analysis.

- Personalization of polysulfone resin properties for specific applications through AI-guided material design.

- Analysis of complex market data to identify emerging trends, customer needs, and competitive strategies.

- Robotics and automation, often integrated with AI, improving precision and consistency in manufacturing processes.

- Facilitation of sustainable practices through AI-driven optimization of energy consumption and waste reduction in production.

DRO & Impact Forces Of Polysulfone Resin Market

The Polysulfone Resin market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, collectively forming the impact forces shaping its trajectory. Key drivers include the exceptional properties of polysulfone resins, such as their high thermal stability, inherent flame retardancy, superior mechanical strength, and excellent chemical resistance, which make them preferred materials in demanding applications. The burgeoning demand from the medical and healthcare sector for biocompatible and sterilizable materials, coupled with the rapid expansion of water treatment and filtration technologies globally, further propels market growth. Additionally, the increasing focus on lightweighting and enhanced performance in the automotive and aerospace industries is fueling the adoption of polysulfone resins as alternatives to traditional materials, contributing substantially to their market penetration and overall demand.

However, the market faces several restraints that could impede its growth. The high cost associated with the production of polysulfone resins, driven by complex synthesis processes and specialized raw materials, represents a significant barrier to entry for new players and can limit widespread adoption in price-sensitive applications. Furthermore, the intricate processing requirements of these high-performance polymers, which demand specialized equipment and expertise, can pose challenges for manufacturers. Intense competition from other high-performance thermoplastics and engineering plastics that offer similar properties at potentially lower costs also acts as a restraint, forcing polysulfone resin manufacturers to continually innovate and differentiate their products to maintain market share. Regulatory hurdles in certain highly regulated applications, especially in the medical and food contact sectors, also require extensive testing and approvals, adding to product development time and cost.

Despite these restraints, numerous opportunities exist for market expansion and innovation. The emergence of new applications in electric vehicles, advanced filtration systems, and additive manufacturing (3D printing) presents significant avenues for growth, allowing polysulfone resins to demonstrate their unique advantages in novel contexts. Furthermore, the growing emphasis on sustainable material solutions and the development of recyclable or bio-based polysulfone resins offer manufacturers a chance to align with global environmental trends and cater to eco-conscious consumers and industries. Continued research and development into novel polysulfone derivatives with enhanced properties, improved processability, and reduced costs could unlock new market segments and applications. Strategic collaborations and partnerships across the value chain, from raw material suppliers to end-use manufacturers, are also crucial opportunities to accelerate market penetration and foster technological advancements, ensuring the long-term vitality and expansion of the polysulfone resin market.

Segmentation Analysis

The Polysulfone Resin market is extensively segmented to provide a detailed understanding of its varied applications, product types, and end-use industries, enabling targeted market strategies and insights. This segmentation helps in analyzing market dynamics by breaking down the broad market into more manageable and specific categories. The primary segmentation typically includes classifications by type, application, and end-use industry, each revealing distinct growth patterns and competitive landscapes. Understanding these segments is crucial for stakeholders to identify promising areas for investment, product development, and geographic expansion, tailoring their offerings to meet specific market demands and exploit niche opportunities effectively.

- By Type:

- Polysulfone (PSU)

- Polyethersulfone (PES)

- Polyphenylsulfone (PPSU)

- By Application:

- Membranes (Ultrafiltration, Microfiltration, Gas Separation)

- Medical Devices (Surgical Instruments, Dialysis Equipment, Sterilization Trays)

- Automotive & Electrical Components (Connectors, Housings, Light Bezels, Battery Components)

- Filtration (Industrial, Food & Beverage, Pharmaceutical)

- Cookware & Food Service (Microwave Components, Food Trays, Coffee Makers)

- Others (Aerospace Components, Industrial Parts, Consumer Goods)

- By End-Use Industry:

- Healthcare & Medical

- Automotive

- Electrical & Electronics

- Water Purification & Treatment

- Aerospace & Defense

- Consumer Goods

- Industrial

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For Polysulfone Resin Market

The value chain for the Polysulfone Resin market is a complex network involving multiple stages, from the sourcing of raw materials to the final consumption of polysulfone-based products. It begins with the upstream analysis, focusing on the procurement of essential monomers and precursors such as bisphenol A, dichlorodiphenyl sulfone, and hydroquinone, which are critical chemical building blocks for synthesizing polysulfone resins. These raw materials are typically sourced from the petrochemical industry and undergo rigorous quality checks before being supplied to resin manufacturers. The efficiency and cost-effectiveness of this initial stage significantly impact the overall profitability and competitiveness of polysulfone resin production, making strong supplier relationships and strategic raw material procurement vital for market players.

Further along the chain, resin manufacturers convert these monomers into various grades of polysulfone resins through specialized polymerization processes. This stage often involves significant R&D investment to develop proprietary manufacturing techniques that enhance product properties, reduce production costs, and meet specific application requirements. Post-production, these resins may be supplied directly to large-scale end-users or proceed to compounders and fabricators. Compounders often blend polysulfone resins with additives, fillers, and reinforcing agents to create customized compounds with enhanced characteristics like improved impact strength, color, or electrical conductivity. Fabricators then process these resins and compounds using techniques like injection molding, extrusion, and blow molding to produce semi-finished goods or finished components, such as membranes, medical device parts, or automotive components, which are then integrated into final products.

The downstream analysis primarily concerns the distribution and sales channels, which can be direct or indirect. Direct channels involve resin manufacturers selling directly to large industrial end-users or major original equipment manufacturers (OEMs) in sectors like healthcare, automotive, or aerospace, often involving long-term contracts and technical support. Indirect channels involve a network of distributors, agents, and specialty chemical suppliers who provide polysulfone resins and compounds to smaller manufacturers or across diverse geographical regions, offering logistical support and regional market expertise. Effective distribution channels are crucial for market penetration and ensuring timely delivery of products to a wide range of customers. The efficiency and robustness of this entire value chain, from raw material sourcing to end-user delivery, are paramount for the sustained growth and competitive success of the polysulfone resin market, heavily relying on collaboration and technological integration across all stages.

Polysulfone Resin Market Potential Customers

The Polysulfone Resin market caters to a diverse range of end-users and buyers who require high-performance materials for critical applications across various industries. Primary potential customers include manufacturers of medical devices and equipment, who utilize polysulfone resins for sterilizable surgical instruments, dialysis filters, intravenous connectors, and laboratory ware due to their excellent biocompatibility, chemical resistance, and ability to withstand repeated sterilization cycles. Another significant customer base comprises companies in the water purification and treatment sector, including membrane manufacturers and system integrators, who rely on polysulfone membranes for ultrafiltration, microfiltration, and gas separation applications due to their hydrolytic stability, chemical resistance to disinfectants, and good mechanical strength, ensuring efficient and reliable water purification processes for municipal, industrial, and domestic uses.

In the automotive industry, potential customers are component manufacturers and OEMs seeking lightweight, high-temperature resistant materials for under-the-hood applications such as electrical connectors, pump impellers, and sensor housings, contributing to improved fuel efficiency and enhanced vehicle performance. The electrical and electronics sector also represents a key customer segment, with manufacturers of connectors, circuit boards, coil bobbins, and protective casings leveraging polysulfone resins for their excellent electrical insulation properties, dimensional stability, and high heat resistance, crucial for the reliability and longevity of electronic devices. Furthermore, the aerospace and defense industries are increasingly adopting polysulfone resins for lightweight structural components, interior parts, and specialized housings where high strength-to-weight ratio and resistance to harsh environments are paramount, making these sectors vital for high-value applications of polysulfone resins and driving ongoing innovation in material science.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.15 Billion |

| Market Forecast in 2033 | USD 1.85 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Solvay S.A., BASF SE, Sumitomo Chemical Co. Ltd., Arkema S.A., SABIC, Mitsubishi Chemical Corporation, RTP Company, Evonik Industries AG, DSM Engineering Materials, TechnipFMC plc, Saint-Gobain S.A., Westlake Chemical Corporation, DIC Corporation, Avient Corporation (formerly PolyOne), Lotte Chemical Corporation, Shandong Dawn Polymer Co. Ltd., Zhejiang Sanhe Plastic Co. Ltd., Jiangsu Jincheng Group, Guangzhou Lushan New Materials Co. Ltd., Victrex plc |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polysulfone Resin Market Key Technology Landscape

The Polysulfone Resin market is characterized by a sophisticated technological landscape focused on optimizing material properties, enhancing processing efficiency, and broadening application scope. Key technologies primarily revolve around the advanced polymerization methods used for synthesizing Polysulfone (PSU), Polyethersulfone (PES), and Polyphenylsulfone (PPSU) from their respective monomers. These processes often involve nucleophilic aromatic substitution reactions under controlled conditions to achieve high molecular weights and desired performance characteristics. Continuous advancements in reaction engineering, catalyst development, and purification techniques are crucial for improving the yield, purity, and consistency of the resins, directly impacting their end-use performance and economic viability, ensuring the production of high-quality materials for demanding applications.

Beyond synthesis, significant technological efforts are directed towards processing and fabrication techniques. Precision injection molding and extrusion technologies are essential for transforming polysulfone resins into complex shapes and intricate components with tight tolerances, especially in medical and automotive applications. The development of specialized compounding technologies allows for the incorporation of various additives, fillers, and reinforcing agents, such as glass fibers or carbon nanofibers, to tailor the mechanical, thermal, or electrical properties of the resins for specific performance requirements. This includes flame retardants, UV stabilizers, and colorants, which expand the functional capabilities of polysulfone compounds and open up new design possibilities for engineers and product developers across diverse industrial sectors.

Emerging technologies like additive manufacturing, particularly 3D printing techniques such as Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS), are also gaining traction for polysulfone resins. These technologies enable the production of highly complex geometries, prototypes, and low-volume custom parts with reduced tooling costs and accelerated design iterations, offering unparalleled flexibility in product development. Furthermore, advancements in membrane fabrication technologies, including phase inversion and electrospinning, are critical for producing high-performance polysulfone membranes used in water purification and gas separation, enhancing their flux, selectivity, and fouling resistance. The continuous evolution and integration of these manufacturing and processing technologies are vital for driving innovation, expanding market applications, and maintaining the competitive edge of polysulfone resins in the high-performance plastics market.

Regional Highlights

- North America: This region represents a mature yet robust market for polysulfone resins, driven by significant demand from its well-established medical and healthcare industries, including stringent regulatory frameworks that favor high-performance, biocompatible materials. The aerospace and defense sectors also contribute substantially, requiring lightweight and high-temperature resistant polymers. Strong R&D capabilities and a focus on advanced manufacturing further bolster market growth.

- Europe: Europe is a key market, propelled by its strong automotive sector's continuous demand for lightweighting solutions and high-temperature resistant components, alongside a sophisticated medical device industry. Environmental regulations and a push towards sustainable materials also drive innovation and the adoption of advanced polymers. Germany, France, and the UK are major contributors.

- Asia Pacific (APAC): The APAC region is the fastest-growing market for polysulfone resins, primarily due to rapid industrialization, expanding manufacturing bases, and increasing investments in water treatment infrastructure and healthcare facilities in countries like China, India, and Japan. The burgeoning electrical and electronics industry, coupled with economic growth, fuels significant demand.

- Latin America: This region shows promising growth potential, with increasing industrial development and investments in infrastructure and manufacturing, particularly in Brazil and Mexico. The expanding automotive and general industrial sectors are driving the demand for polysulfone resins, albeit from a smaller base compared to other regions.

- Middle East & Africa (MEA): The MEA market is gradually emerging, driven by investments in water desalination and purification projects, as well as developing healthcare infrastructure and industrialization initiatives. The demand for advanced materials in the oil and gas sector also contributes to the market's gradual expansion in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polysulfone Resin Market.- Solvay S.A.

- BASF SE

- Sumitomo Chemical Co. Ltd.

- Arkema S.A.

- SABIC

- Mitsubishi Chemical Corporation

- RTP Company

- Evonik Industries AG

- DSM Engineering Materials

- TechnipFMC plc

- Saint-Gobain S.A.

- Westlake Chemical Corporation

- DIC Corporation

- Avient Corporation (formerly PolyOne)

- Lotte Chemical Corporation

- Shandong Dawn Polymer Co. Ltd.

- Zhejiang Sanhe Plastic Co. Ltd.

- Jiangsu Jincheng Group

- Guangzhou Lushan New Materials Co. Ltd.

- Victrex plc

Frequently Asked Questions

What are Polysulfone Resins and their primary characteristics?

Polysulfone resins are a family of high-performance thermoplastic polymers known for their exceptional thermal stability, mechanical strength, and chemical resistance. Key characteristics include high heat deflection temperatures, excellent hydrolytic stability, inherent flame retardancy, and good electrical insulation properties, making them ideal for demanding applications where high temperature and corrosive environments are prevalent.

In which industries are Polysulfone Resins most commonly used?

Polysulfone resins are widely utilized across various industries. Their most common applications are found in healthcare and medical devices (e.g., surgical instruments, dialysis membranes), water purification (e.g., ultrafiltration membranes), automotive (e.g., under-the-hood components, electrical connectors), and electrical and electronics (e.g., circuit board components, insulation). They are also used in aerospace, food service, and industrial applications.

What are the key advantages of using Polysulfone Resins over other engineering plastics?

The primary advantages of polysulfone resins include their superior high-temperature performance, exceptional hydrolytic stability which allows for repeated sterilization, and excellent resistance to a broad range of chemicals. They also offer good mechanical properties, dimensional stability, and are often inherently flame retardant, providing a unique combination of attributes that many other engineering plastics cannot match in critical applications.

What are the main factors driving the growth of the Polysulfone Resin market?

The market growth is primarily driven by increasing demand from the medical and healthcare sector for biocompatible and sterilizable materials, the expanding need for advanced water filtration and purification technologies, and the growing adoption of lightweight, high-performance materials in the automotive and aerospace industries to improve fuel efficiency and performance. Technological advancements and innovation in new applications also play a significant role.

What are the future trends and opportunities in the Polysulfone Resin market?

Future trends include the increasing integration of polysulfone resins in emerging applications such as electric vehicle components, advanced additive manufacturing (3D printing), and specialized filtration systems for industrial processes. Opportunities also lie in the development of sustainable polysulfone solutions, including recyclable and bio-based variants, and the exploration of novel composite materials to meet evolving industry demands and environmental regulations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager