Polyvinyl Formal Resins Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439690 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Polyvinyl Formal Resins Market Size

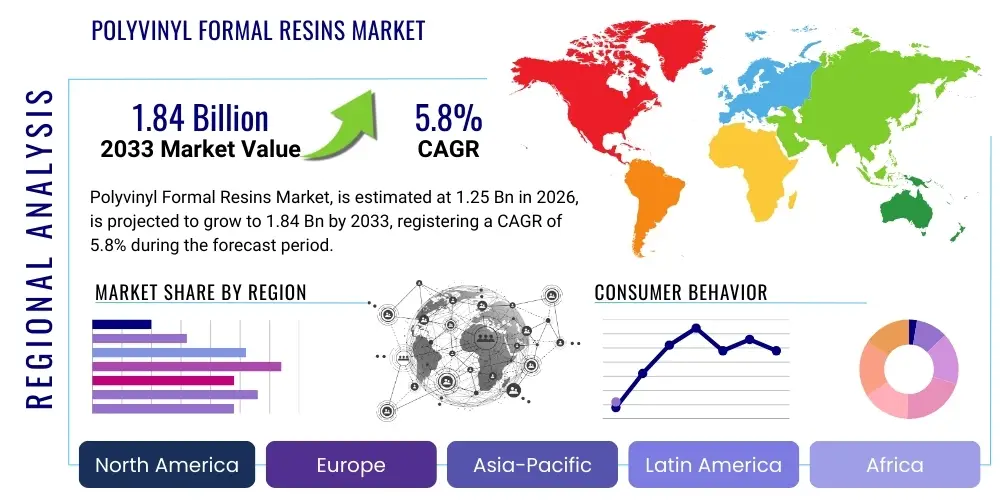

The Polyvinyl Formal Resins Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.84 Billion by the end of the forecast period in 2033.

Polyvinyl Formal Resins Market introduction

Polyvinyl Formal (PVF) resins are synthetic thermoplastic polymers derived from polyvinyl alcohol through a formalization reaction with formaldehyde. These versatile resins are known for their exceptional properties, including excellent adhesion to various substrates, high mechanical strength, superior electrical insulation capabilities, and resistance to chemicals and solvents. Primarily utilized in demanding applications, PVF resins serve as critical components in electrical insulation enamels, magnet wire coatings, automotive primers, specialty adhesives, and protective coatings for diverse industrial uses. Their unique combination of flexibility, hardness, and thermal stability makes them indispensable in environments requiring robust performance and durability. The market’s expansion is largely driven by the increasing demand from the electronics, automotive, and construction sectors, alongside continuous advancements in material science seeking enhanced performance characteristics.

Polyvinyl Formal Resins Market Executive Summary

The Polyvinyl Formal Resins Market is experiencing steady growth, propelled by robust industrial expansion and technological advancements across key end-use sectors. Business trends indicate a rising demand for high-performance materials in electronics, automotive, and construction, where PVF resins provide critical functional benefits like insulation, adhesion, and protective barriers. Regional analysis reveals that Asia Pacific continues to dominate the market due to rapid industrialization, burgeoning manufacturing hubs, and increasing investments in infrastructure and electronics production, particularly in China and India. Europe and North America also contribute significantly, driven by stringent regulatory standards for material quality and a focus on advanced manufacturing. Segmentation trends highlight the prominence of electrical insulation applications, especially for magnet wires, alongside strong growth in specialty coatings and adhesives, underscoring the resin's versatility and unique property profile in specialized industrial contexts. Innovation in sustainable PVF production and advanced formulations for enhanced performance are also key drivers influencing market dynamics.

AI Impact Analysis on Polyvinyl Formal Resins Market

User inquiries about the impact of Artificial Intelligence (AI) on the Polyvinyl Formal Resins Market predominantly revolve around its potential to optimize manufacturing processes, enhance material discovery, and improve supply chain efficiencies. Key themes include how AI can facilitate predictive maintenance for production equipment, leading to reduced downtime and operational costs, and its role in accelerating the R&D cycle for novel PVF formulations with superior properties. There is also significant interest in AI's capacity to streamline logistics, inventory management, and demand forecasting, ultimately contributing to a more resilient and responsive market. Concerns often surface regarding the initial investment required for AI integration, the need for specialized data scientists, and the potential impact on workforce dynamics. However, the overarching expectation is that AI will introduce unprecedented levels of precision, efficiency, and innovation, fundamentally transforming how PVF resins are produced, customized, and utilized across industries, making manufacturing smarter and more adaptive.

- AI can optimize manufacturing parameters, leading to higher yield and reduced energy consumption in PVF resin production.

- Predictive analytics powered by AI can forecast equipment failures, enabling proactive maintenance and minimizing production disruptions.

- AI-driven material informatics accelerates the discovery and development of new PVF formulations with enhanced properties like thermal stability or adhesion.

- Supply chain management benefits from AI through optimized logistics, real-time inventory tracking, and improved demand forecasting, reducing waste and lead times.

- Quality control can be automated and enhanced using AI for defect detection, ensuring consistent product quality and reducing manual inspection efforts.

- AI facilitates personalized product development by analyzing market needs and customer data to tailor PVF resin properties for specific applications.

- Process automation and robotics, often integrated with AI, can improve safety and efficiency in hazardous manufacturing environments.

- AI-powered simulations can model the performance of PVF resins in various end-use applications, reducing the need for extensive physical testing.

- Data analysis of production processes by AI can identify bottlenecks and inefficiencies, driving continuous improvement initiatives.

- Market intelligence gathered and analyzed by AI can provide deeper insights into competitive landscapes and emerging application areas for PVF resins.

DRO & Impact Forces Of Polyvinyl Formal Resins Market

The Polyvinyl Formal Resins Market is significantly shaped by a complex interplay of drivers, restraints, and opportunities, alongside various impact forces that influence its growth trajectory. Key drivers include the escalating demand from the electrical and electronics industry, particularly for high-performance magnet wire insulation due to global expansion in electronics manufacturing and electric vehicle production. The automotive sector's increasing reliance on advanced coatings and adhesives for enhanced durability and performance also fuels market growth. Furthermore, ongoing industrialization in emerging economies, coupled with significant investments in infrastructure development, propels the demand for PVF resins in construction materials and protective coatings. These factors collectively underscore the resin's critical role in modern industrial applications, pushing innovation and expanding its market footprint.

However, the market faces notable restraints that could impede its progress. The volatility of raw material prices, primarily polyvinyl alcohol and formaldehyde, poses a significant challenge, leading to fluctuating production costs and potential pressures on profit margins for manufacturers. Stricter environmental regulations concerning chemical emissions and waste disposal during the manufacturing process necessitate substantial investments in compliance and sustainable production technologies. Additionally, the availability of alternative high-performance polymers and resins, while not always directly comparable, presents competitive pressure, requiring continuous innovation from PVF resin manufacturers to maintain market share. These challenges demand strategic responses, including diversification of raw material sourcing and investment in greener technologies.

Despite these restraints, the Polyvinyl Formal Resins Market is ripe with opportunities that promise substantial growth. Emerging economies, particularly in Asia Pacific and Latin America, offer untapped potential due to their rapid industrialization and growing consumer bases, which translate into increased demand for electronics, automotive components, and construction materials. Research and development efforts focused on creating novel PVF formulations with enhanced properties, such as improved thermal resistance, flexibility, or biodegradability, open new application avenues and expand market reach. Moreover, the increasing global emphasis on sustainable manufacturing practices and the development of bio-based or recycled PVF resins could unlock new market segments and appeal to environmentally conscious consumers and industries. Strategic collaborations and investments in these areas are crucial for capitalizing on future growth prospects.

The impact forces influencing the market are multifaceted, ranging from technological advancements that enable more efficient production methods and superior product performance, to economic factors such as global GDP growth and industrial output that directly correlate with demand. Regulatory changes, particularly those pertaining to environmental protection and product safety, compel manufacturers to innovate and adapt, potentially leading to the development of more sustainable and compliant products. Geopolitical stability and trade policies can also significantly affect raw material supply chains and market access. Social trends, such as increasing urbanization and consumer demand for durable and efficient products, indirectly drive the need for high-quality materials like PVF resins. These forces require continuous monitoring and strategic adaptation from market participants to navigate the evolving landscape effectively.

Segmentation Analysis

The Polyvinyl Formal Resins market is broadly segmented based on various factors, including type, application, and end-use industry, each reflecting distinct product characteristics and market demand dynamics. Understanding these segmentations is crucial for a comprehensive market analysis, allowing stakeholders to identify niche opportunities and tailor strategies effectively. The intrinsic properties of PVF resins, such as their viscosity and molecular weight, often dictate their suitability for specific applications, thus forming the basis for type-based segmentation. Meanwhile, the diverse industrial requirements drive application and end-use industry segmentations, highlighting the resin's versatility across critical sectors. This multi-dimensional segmentation provides a granular view of the market structure and competitive landscape.

- By Type

- High Viscosity Polyvinyl Formal Resins

- Medium Viscosity Polyvinyl Formal Resins

- Low Viscosity Polyvinyl Formal Resins

- By Application

- Electrical Insulation (e.g., Magnet Wire Enamels)

- Adhesives (e.g., Structural Adhesives, Wood Adhesives)

- Coatings (e.g., Protective Coatings, Automotive Primers)

- Printing Inks

- Films and Sheets

- Abrasives

- Others (e.g., binders for non-wovens, textile finishing)

- By End-Use Industry

- Electronics and Electrical Industry

- Automotive Industry

- Construction Industry

- Packaging Industry

- Textile Industry

- Aerospace Industry

- General Industrial

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Polyvinyl Formal Resins Market

The value chain for the Polyvinyl Formal Resins market encompasses a series of interconnected stages, beginning with the sourcing of raw materials and culminating in the delivery of finished products to end-use industries. At the upstream end, key raw materials such as polyvinyl alcohol (PVA) and formaldehyde are critical. PVA is primarily derived from petrochemical sources (ethylene), while formaldehyde can be produced from methanol. The quality and cost of these precursors significantly influence the overall production cost and performance characteristics of the final PVF resin. Suppliers of these base chemicals form the initial crucial link in the chain, requiring robust procurement strategies and strong supplier relationships to ensure consistent quality and availability. This foundational stage determines much of the subsequent process efficiency and product quality.

Moving downstream, the manufacturing process involves the formalization of PVA with formaldehyde under specific conditions, followed by purification, drying, and grinding to produce the desired PVF resin powder or granules. This stage requires specialized chemical expertise, advanced manufacturing facilities, and stringent quality control measures to ensure that the resins meet the diverse specifications required by various applications. Manufacturers may integrate some raw material production or engage in strategic partnerships to optimize costs and ensure supply security. Post-production, the distribution channels play a pivotal role. These channels can be direct, where manufacturers supply directly to large industrial end-users, or indirect, involving a network of distributors, wholesalers, and specialized chemical traders who cater to smaller businesses or specific regional markets. The choice of distribution channel often depends on the scale of operation, geographic reach, and the nature of customer relationships.

Direct distribution offers manufacturers greater control over pricing, customer relationships, and direct feedback, which is invaluable for product development and market adaptation. It is often preferred for high-volume sales to major industrial clients in the electrical, automotive, and construction sectors. Indirect channels, conversely, allow manufacturers to leverage the extensive networks and local market knowledge of distributors, thereby expanding market penetration, especially into fragmented or geographically dispersed markets. These intermediaries often provide value-added services such as technical support, localized inventory, and just-in-time delivery, which are essential for many end-users. The efficiency and effectiveness of these distribution networks are critical for ensuring that PVF resins reach their diverse applications across industries like electronics, automotive, packaging, and general industrial sectors, ultimately impacting market accessibility and competitive positioning. Understanding and optimizing each link in this value chain is paramount for sustained growth and profitability in the Polyvinyl Formal Resins market.

Polyvinyl Formal Resins Market Potential Customers

The Polyvinyl Formal Resins market serves a diverse array of end-user industries, each utilizing the unique properties of PVF resins for specific applications where high performance, durability, and reliability are paramount. These potential customers range from large multinational corporations in electronics and automotive manufacturing to specialized companies in the construction, packaging, and textile sectors. The broad applicability stems from PVF resins' excellent adhesion, superior electrical insulation, mechanical strength, and resistance to chemicals and solvents, making them indispensable components in demanding environments. Identifying and understanding the specific needs and challenges of these varied customer segments is crucial for manufacturers to tailor their product offerings and marketing strategies effectively. The versatility of PVF resins ensures a wide and robust customer base across the industrial landscape.

In the electronics and electrical industry, potential customers primarily include manufacturers of magnet wires, electric motors, transformers, and various electronic components. These companies rely heavily on PVF resins for their dielectric strength and thermal stability, which are critical for insulating copper wires used in windings. The automotive industry represents another significant customer segment, where PVF resins are utilized in primers, topcoats, and specialty adhesives for enhanced corrosion resistance, chip protection, and structural bonding. Manufacturers of vehicles, automotive components, and aftermarket repair solutions are key buyers. The construction sector also presents opportunities, with customers seeking PVF resin-based coatings and adhesives for flooring, architectural coatings, and protective layers due to their durability and excellent bonding capabilities to various building materials.

Beyond these major industries, other potential customers include manufacturers in the packaging industry requiring strong laminating adhesives, and the textile industry utilizing PVF resins as binders or finishing agents to impart stiffness, water resistance, or improved handfeel to fabrics. The aerospace sector values PVF resins for their high-performance characteristics in demanding environments. General industrial applications encompass a wide range, including abrasives, specialty inks, and various protective coatings for machinery and equipment. The fragmented nature of some of these customer bases necessitates a strategic approach to sales and distribution, often involving specialized distributors who can cater to unique requirements. Continuous innovation to meet evolving industry standards and performance demands remains a key factor in attracting and retaining these diverse potential customers for Polyvinyl Formal Resins.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.84 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mitsubishi Chemical Corporation, Sekisui Chemical Co. Ltd., Kuraray Co. Ltd., Wuxi Baichuan Chemical Industrial Co. Ltd., Changshu Yongrui Chemical Co. Ltd., Guangzhou Keli Chemical Co. Ltd., Shanghai Huayi Group, Sinopec Corp., Arkema S.A., Eastman Chemical Company, BASF SE, The Dow Chemical Company, Showa Denko K.K., Denka Company Limited, Toyobo Co. Ltd., DIC Corporation, Zhejiang Longsheng Group Co. Ltd., Shandong Xinchen Chemical Co. Ltd., Anhui Wanwei Group Co. Ltd., Nippon Gohsei (Japan VAM & POVAL Co. Ltd.) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polyvinyl Formal Resins Market Key Technology Landscape

The Polyvinyl Formal Resins market is characterized by a dynamic technology landscape focused on enhancing product performance, optimizing manufacturing processes, and addressing sustainability concerns. The core technology revolves around the controlled formalization of polyvinyl alcohol (PVA) with formaldehyde, a process that requires precise control over reaction conditions, catalyst selection, and subsequent purification steps to achieve specific molecular weights and degrees of formalization. Advancements in polymerization techniques, such as continuous reactors versus batch processes, are constantly being explored to improve yield, reduce energy consumption, and ensure batch-to-batch consistency. Furthermore, novel approaches in modifying the PVA backbone or employing alternative aldehyde sources are critical areas of research aimed at developing PVF resins with tailored properties for emerging applications, offering improved thermal stability, flexibility, or biodegradability, which are increasingly demanded by specialized end-use sectors.

Beyond the fundamental synthesis, significant technological efforts are directed towards the formulation of PVF resin-based products, particularly in solvent systems, dispersion technologies, and additive packages. For electrical insulation applications, the development of eco-friendly, low-VOC (Volatile Organic Compound) solvent systems or water-borne dispersions is a key technological trend, driven by stringent environmental regulations and a preference for safer working environments. Innovations in additive chemistry, including the incorporation of plasticizers, cross-linking agents, and flame retardants, are crucial for enhancing the performance characteristics of PVF resins in end-use applications like automotive coatings or structural adhesives. These additives can significantly improve properties such as adhesion strength, impact resistance, and weatherability without compromising the inherent benefits of the PVF matrix. The integration of nanotechnology is also being explored to introduce functionalities such as improved barrier properties or enhanced thermal conductivity, pushing the boundaries of traditional PVF applications.

Furthermore, digital technologies are playing an increasingly important role in the PVF resin technology landscape. Advanced process control systems, leveraging sensors and real-time data analytics, are being implemented to monitor and adjust reaction parameters, leading to more consistent product quality and reduced operational costs. Computational chemistry and materials informatics, often supported by artificial intelligence and machine learning, are accelerating the discovery and optimization of new PVF formulations by predicting material properties based on molecular structure, thereby significantly shortening the R&D cycle. These computational tools also aid in understanding complex polymer interactions and designing sustainable manufacturing processes. The adoption of green chemistry principles, including the development of bio-based formaldehyde precursors or processes that minimize waste generation, represents a forward-looking technological imperative. Overall, the technology landscape is driven by a continuous pursuit of higher performance, greater sustainability, and more efficient production methods, ensuring the long-term relevance and competitiveness of Polyvinyl Formal Resins in high-demand industrial applications.

Regional Highlights

- Asia Pacific: This region is anticipated to remain the dominant market for Polyvinyl Formal Resins, driven by rapid industrialization, particularly in China, India, and Southeast Asian countries. The burgeoning electronics manufacturing sector, coupled with massive investments in automotive production and infrastructure development, creates a high demand for PVF resins in electrical insulation, coatings, and adhesives. The presence of numerous manufacturing facilities and a growing middle class further propels consumption, making it a key strategic region for market players.

- North America: The North American market is characterized by a mature industrial base and stringent quality standards. Demand for PVF resins is robust in the automotive sector for high-performance coatings and in the aerospace industry for specialized applications. The region also sees significant R&D activities focused on developing advanced PVF formulations with enhanced properties, driven by a strong emphasis on innovation and regulatory compliance in high-tech manufacturing.

- Europe: Europe represents a significant market, particularly due to its strong automotive, electronics, and construction industries. Strict environmental regulations are driving innovation towards more sustainable and low-VOC PVF resin formulations and application methods. Countries like Germany, France, and the UK are key consumers, with a focus on high-quality, long-lasting industrial applications, and a growing emphasis on circular economy principles in material usage.

- Latin America: The market in Latin America is projected to witness steady growth, fueled by improving economic conditions, urbanization, and increasing foreign investments in manufacturing and infrastructure. Brazil and Mexico are key contributors, with rising demand from the automotive, construction, and general industrial sectors. The region offers considerable growth opportunities as industrial capacities expand and technology adoption increases.

- Middle East and Africa (MEA): The MEA region is expected to show moderate growth, primarily driven by ongoing infrastructure development projects, diversification of economies away from oil dependence, and rising investments in industrial sectors like construction and manufacturing. Countries in the GCC region, along with South Africa, are leading the demand, particularly for protective coatings and industrial adhesives required in harsh environmental conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polyvinyl Formal Resins Market.- Mitsubishi Chemical Corporation

- Sekisui Chemical Co. Ltd.

- Kuraray Co. Ltd.

- Wuxi Baichuan Chemical Industrial Co. Ltd.

- Changshu Yongrui Chemical Co. Ltd.

- Guangzhou Keli Chemical Co. Ltd.

- Shanghai Huayi Group

- Sinopec Corp.

- Arkema S.A.

- Eastman Chemical Company

- BASF SE

- The Dow Chemical Company

- Showa Denko K.K.

- Denka Company Limited

- Toyobo Co. Ltd.

- DIC Corporation

- Zhejiang Longsheng Group Co. Ltd.

- Shandong Xinchen Chemical Co. Ltd.

- Anhui Wanwei Group Co. Ltd.

- Nippon Gohsei (Japan VAM & POVAL Co. Ltd.)

Frequently Asked Questions

What is Polyvinyl Formal Resin and its primary uses?

Polyvinyl Formal Resin is a synthetic thermoplastic polymer known for excellent adhesion, electrical insulation, and chemical resistance. Its primary uses include magnet wire enamels for electrical insulation, automotive primers, specialty adhesives, and protective coatings across various industries.

What are the main drivers of growth in the Polyvinyl Formal Resins Market?

The key growth drivers are increasing demand from the electronics and electrical industry, expanding automotive sector for high-performance coatings, and rapid industrialization in emerging economies, alongside continuous advancements in material science.

Which region dominates the Polyvinyl Formal Resins Market?

Asia Pacific dominates the Polyvinyl Formal Resins Market due to robust industrial growth, extensive manufacturing activities, and significant investments in infrastructure and electronics production in countries like China and India.

What challenges does the Polyvinyl Formal Resins Market face?

The market faces challenges such as volatility in raw material prices (polyvinyl alcohol and formaldehyde), stringent environmental regulations impacting production, and competition from alternative high-performance polymers.

How is AI expected to influence the Polyvinyl Formal Resins Market?

AI is anticipated to optimize manufacturing processes, enhance material discovery and R&D, improve supply chain efficiencies through predictive analytics and demand forecasting, and facilitate automated quality control, leading to smarter and more adaptive production.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager