Porous Titanium Plate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439992 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Porous Titanium Plate Market Size

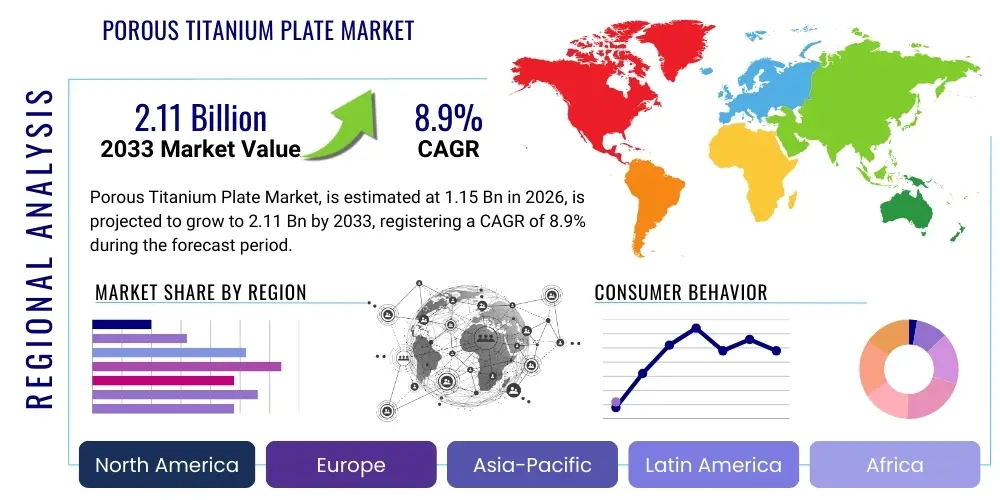

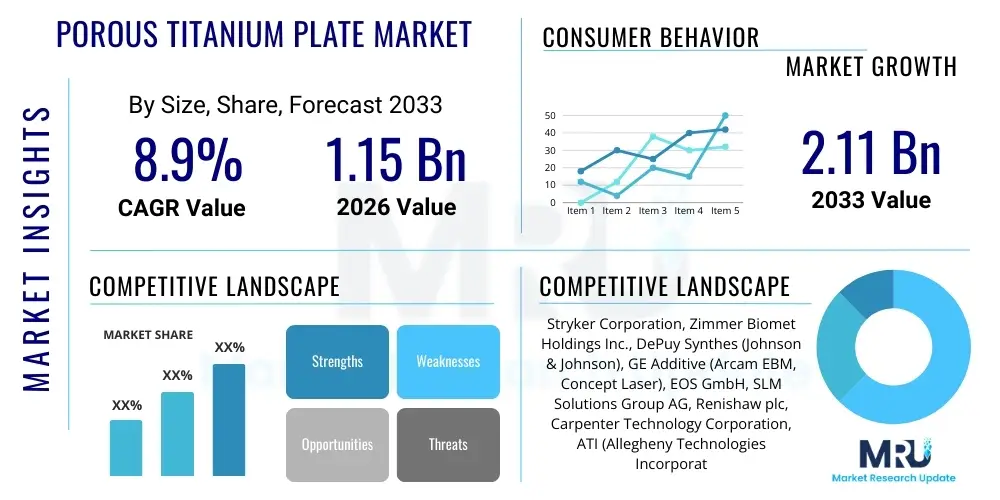

The Porous Titanium Plate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.9% between 2026 and 2033. The market is estimated at USD 1.15 Billion in 2026 and is projected to reach USD 2.11 Billion by the end of the forecast period in 2033.

Porous Titanium Plate Market introduction

The Porous Titanium Plate Market encompasses the production, distribution, and application of titanium materials engineered with controlled porosity. These advanced materials are characterized by interconnected pore networks that enhance properties such as biocompatibility, bone ingrowth potential, and lightweight structural integrity. Porous titanium plates find extensive utility across various high-tech sectors, primarily due to titanium's inherent corrosion resistance, high strength-to-weight ratio, and excellent biological inertness, which are further augmented by the engineered porosity. This unique combination of attributes makes them indispensable in critical applications where performance and reliability are paramount.

Major applications of porous titanium plates include biomedical implants, particularly in orthopedics for joint replacements, spinal fusion devices, and dental implants, where the porous structure facilitates osseointegration and reduces stress shielding effects. Beyond healthcare, these plates are increasingly utilized in aerospace for lightweight structural components, in chemical processing for advanced filtration and catalytic supports, and in various industrial applications requiring corrosion-resistant, high-strength, and often biocompatible materials. The benefits of porous titanium plates stem from their ability to mimic natural bone structure, improve implant fixation, and offer enhanced surface area for catalytic reactions or filtration processes, alongside their superior mechanical properties compared to many other materials.

The primary driving factors propelling the growth of this market include the escalating demand for advanced medical implants due to an aging global population and rising incidence of orthopedic conditions, coupled with significant technological advancements in additive manufacturing techniques like Selective Laser Melting (SLM) and Electron Beam Melting (EBM). These manufacturing innovations enable precise control over pore size, distribution, and overall geometric complexity, thus expanding the scope and efficacy of porous titanium products. Additionally, increasing investments in aerospace research and development for lighter and more robust materials further contribute to market expansion, as does the demand for high-performance materials in challenging industrial environments.

Porous Titanium Plate Market Executive Summary

The Porous Titanium Plate Market is experiencing robust growth, driven by sustained innovation in material science and manufacturing technologies, particularly additive manufacturing. Key business trends indicate a strong focus on research and development to optimize pore structures for specific applications, enhancing biocompatibility for medical devices and improving strength-to-weight ratios for aerospace components. There is a growing trend towards customization and patient-specific implants, leveraging digital design and 3D printing capabilities. Strategic collaborations between material suppliers, medical device manufacturers, and aerospace companies are also shaping the competitive landscape, fostering joint ventures and licensing agreements to accelerate product development and market penetration. Furthermore, investments in advanced quality control and regulatory compliance are critical, ensuring the safety and efficacy of these high-performance materials.

Regional trends highlight North America and Europe as dominant markets, primarily due to well-established healthcare infrastructure, high healthcare expenditure, and significant R&D activities in aerospace and biomedical fields. The Asia Pacific region is emerging as a rapidly growing market, propelled by increasing healthcare access, a large patient pool, expanding manufacturing capabilities, and rising government investments in medical and defense sectors, particularly in countries like China, Japan, and India. Latin America and the Middle East & Africa are also witnessing gradual market penetration, driven by improving healthcare facilities and a growing awareness of advanced material benefits, though market expansion in these regions is still in nascent stages compared to developed economies.

Segmentation trends reveal that the biomedical application segment, particularly orthopedic and dental implants, holds the largest market share and is expected to maintain its dominance throughout the forecast period due to the critical need for osseointegration and long-term implant stability. The additive manufacturing segment, encompassing techniques like SLM and EBM, is poised for the highest growth, driven by its unparalleled ability to create complex, customized porous structures with high precision and repeatability, overcoming limitations of traditional manufacturing methods. Furthermore, the macro-porous segment, favored for its bone ingrowth characteristics, is expected to see significant demand, while research into meso- and micro-porous structures for drug delivery and advanced filtration is also gaining traction, indicating diversification in product development and application areas.

AI Impact Analysis on Porous Titanium Plate Market

User inquiries about AI's impact on the Porous Titanium Plate Market frequently revolve around optimizing design, enhancing manufacturing processes, improving material characterization, and enabling personalized medical solutions. Users are keen to understand how AI can reduce costs, accelerate R&D cycles, predict material performance, and contribute to the development of "smart" implants. Concerns often include data privacy for patient-specific designs, the complexity of integrating AI into existing manufacturing workflows, and the need for robust validation frameworks for AI-driven material and product innovations. Expectations are high for AI to revolutionize the precision, efficiency, and intelligence embedded within porous titanium products, ultimately leading to superior functional outcomes and expanded market opportunities.

- AI-driven generative design for optimized porous structures, leading to enhanced mechanical properties and improved biological response.

- Predictive analytics for material properties and manufacturing defects, reducing waste and improving product consistency.

- Machine learning algorithms for real-time monitoring and control of additive manufacturing processes, ensuring precise pore size and distribution.

- AI-powered image analysis for rapid and accurate quality inspection of porous titanium plates, identifying micro-defects invisible to the human eye.

- Personalized implant design through AI, utilizing patient-specific anatomical data for custom-fitted and highly effective medical devices.

- Optimization of supply chain and inventory management for raw titanium powder and finished products, leveraging AI for demand forecasting.

- Accelerated research and development by simulating material performance under various physiological or operational conditions, reducing experimental costs.

- Integration of AI in "smart" porous implants for sensing physiological parameters or enabling controlled drug release, enhancing therapeutic efficacy.

DRO & Impact Forces Of Porous Titanium Plate Market

The Porous Titanium Plate Market is significantly influenced by a confluence of drivers, restraints, and opportunities, alongside various impact forces that shape its trajectory. Key drivers include the ever-increasing demand for highly biocompatible and osseointegrative medical implants, particularly in orthopedics and dentistry, driven by an aging global population and a rising incidence of musculoskeletal disorders. Furthermore, rapid advancements in additive manufacturing technologies, such as Selective Laser Melting (SLM) and Electron Beam Melting (EBM), have made the precise and cost-effective production of complex porous structures feasible, fueling innovation and expanding application possibilities. The growing emphasis on lightweight and high-strength materials in the aerospace and defense sectors also acts as a substantial market driver, pushing demand for advanced titanium alloys with enhanced structural integrity and reduced weight for critical components.

Conversely, several restraints impede the market's growth. The high initial investment costs associated with advanced additive manufacturing equipment and the specialized raw materials (titanium powder) remain a significant barrier for smaller manufacturers and new entrants. Moreover, the stringent regulatory approval processes, especially for medical devices, involve extensive testing, clinical trials, and documentation, leading to lengthy time-to-market cycles and substantial compliance costs. Technical complexities in achieving precise control over pore size, interconnectivity, and mechanical properties across different manufacturing batches also pose challenges, requiring sophisticated process control and quality assurance measures. These factors collectively contribute to the high barrier of entry and operational overheads within the industry.

However, substantial opportunities exist for market expansion and innovation. The development of customized, patient-specific implants tailored to individual anatomical requirements represents a major growth avenue, leveraging the flexibility of additive manufacturing. Furthermore, exploring new applications beyond traditional biomedical and aerospace sectors, such as advanced industrial filtration, catalytic converters, and energy storage systems, could unlock significant untapped market potential. The integration of advanced surface modification techniques and coatings to further enhance biological response or functional performance of porous titanium plates also presents a promising area for research and commercialization. The overarching impact forces include ongoing technological advancements that continually refine manufacturing processes and material properties, evolving regulatory landscapes that necessitate adaptive strategies, economic fluctuations impacting healthcare spending and industrial investments, and the global availability and pricing of raw titanium, all of which dynamically influence market dynamics.

Segmentation Analysis

The Porous Titanium Plate Market is segmented comprehensively across various parameters to provide a detailed understanding of its dynamics, key growth areas, and competitive landscape. These segments offer insights into how different applications, manufacturing methods, and material characteristics influence market demand and product development strategies. The primary segmentation categories include analysis by application, which delineates the end-use industries leveraging porous titanium plates; by manufacturing method, highlighting the technological processes employed for their creation; and by pore size, categorizing products based on their structural characteristics. This multi-faceted segmentation allows for a granular assessment of market opportunities and challenges within specific niches.

- By Application

- Biomedical

- Orthopedic Implants (Joint Replacements, Spinal Fusion Devices, Trauma Fixation)

- Dental Implants (Root Form, Plate Form, Subperiosteal)

- Cranio-Maxillofacial Implants

- Surgical Tools

- Aerospace & Defense (Structural Components, Heat Exchangers, Lightweight Brackets)

- Chemical & Petrochemical (Catalytic Supports, Filtration Systems, Heat Exchangers)

- Other Industrial (Automotive, Filtration, Energy Storage)

- Biomedical

- By Manufacturing Method

- Additive Manufacturing

- Selective Laser Melting (SLM)

- Electron Beam Melting (EBM)

- Direct Metal Laser Sintering (DMLS)

- Powder Metallurgy

- Sintering

- Hot Isostatic Pressing (HIP)

- Metal Injection Molding (MIM)

- Fiber Sintering

- Foam Replication

- Additive Manufacturing

- By Pore Size

- Macro-Porous (Pore size > 200 µm)

- Meso-Porous (Pore size 50-200 µm)

- Micro-Porous (Pore size < 50 µm)

Value Chain Analysis For Porous Titanium Plate Market

The value chain for the Porous Titanium Plate Market is intricate, beginning with the meticulous extraction and processing of raw titanium and extending through highly specialized manufacturing, distribution, and final end-user applications. Upstream activities primarily involve the mining of titanium ore (ilmenite and rutile), followed by its purification to produce titanium sponge, which is then further processed into titanium ingots. This stage is capital-intensive and requires specialized metallurgical expertise. Key suppliers at this stage include large-scale titanium producers who provide high-purity titanium powder or billets to manufacturers, often adhering to strict quality standards demanded by critical applications like medical implants and aerospace components. The quality of raw material directly impacts the mechanical and biological properties of the final porous titanium plate, making supplier selection a crucial strategic decision.

Midstream activities encompass the manufacturing of porous titanium plates, which is largely dominated by advanced techniques such as additive manufacturing (e.g., SLM, EBM) and sophisticated powder metallurgy processes (e.g., sintering, hot isostatic pressing). These manufacturers invest heavily in R&D to optimize pore structure, interconnectivity, and mechanical strength, often employing advanced simulation and testing methodologies. They transform raw titanium into specific porous forms, tailored for various applications, by controlling parameters like powder characteristics, energy input, and post-processing treatments. This stage adds significant value through technological expertise, precision engineering, and adherence to stringent quality and regulatory standards, particularly for biomedical products.

Downstream activities involve the distribution, sales, and final application of porous titanium plates. Distribution channels are typically specialized, often utilizing direct sales teams for major industrial clients in aerospace or through a network of medical device distributors and wholesalers for the healthcare sector. Direct distribution allows for closer relationships with end-users and facilitates customization requests. Indirect distribution, though less common for highly specialized products, may involve partnerships with larger medical supply companies. The end-users, such as orthopedic surgeons, dental professionals, aerospace engineers, and chemical plant operators, integrate these plates into their final products or systems. This phase also includes post-sales support, technical assistance, and potential long-term follow-up for performance monitoring, especially crucial for implantable devices. The efficiency and reliability of these distribution channels are vital for ensuring timely delivery and widespread adoption of porous titanium solutions in their respective markets.

Porous Titanium Plate Market Potential Customers

Potential customers for porous titanium plates span a diverse range of high-technology industries, primarily driven by the material's unique combination of biocompatibility, high strength-to-weight ratio, and corrosion resistance. In the healthcare sector, the primary end-users are medical device manufacturers, orthopedic surgeons, dental implantologists, and cranio-maxillofacial specialists who require advanced biomaterials for implantable devices. These customers seek materials that promote osseointegration, reduce stress shielding, and offer long-term stability within the human body, directly benefiting patients requiring joint replacements, spinal fusion, dental restoration, or facial reconstruction. Hospitals and surgical centers also act as indirect customers through their procurement of medical implants from device manufacturers, prioritizing materials that lead to improved patient outcomes and reduced revision surgeries.

Beyond healthcare, the aerospace and defense industries represent a significant customer base. Manufacturers of aircraft, spacecraft, and defense systems are constantly seeking lightweight, high-strength materials capable of withstanding extreme operational conditions while reducing overall vehicle weight to enhance fuel efficiency and performance. Porous titanium plates are utilized in structural components, heat exchangers, and specialized brackets, where their unique properties contribute to robust and durable designs. Engineers and procurement specialists within these sectors are keen on materials that offer superior fatigue resistance, high-temperature stability, and corrosion protection, making porous titanium an attractive solution for critical applications requiring material reliability under stringent performance specifications.

Furthermore, the chemical and petrochemical industries constitute another emerging segment of potential customers, particularly for applications requiring advanced filtration systems, catalytic supports, and components resistant to aggressive corrosive environments. Companies involved in chemical processing, water treatment, and specialized industrial manufacturing seek porous titanium for its inertness, high surface area, and mechanical integrity in harsh operating conditions. Researchers and development teams in these fields are continually exploring the use of porous titanium for novel catalytic applications or efficient separation technologies. The automotive sector, though currently a smaller segment, is also showing nascent interest in porous titanium for lightweighting and performance enhancement in specialized vehicle components, further expanding the potential customer landscape for this versatile material.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.15 Billion |

| Market Forecast in 2033 | USD 2.11 Billion |

| Growth Rate | 8.9% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Stryker Corporation, Zimmer Biomet Holdings Inc., DePuy Synthes (Johnson & Johnson), GE Additive (Arcam EBM, Concept Laser), EOS GmbH, SLM Solutions Group AG, Renishaw plc, Carpenter Technology Corporation, ATI (Allegheny Technologies Incorporated), VSMPO-AVISMA Corporation, Sandvik AB (Additive Manufacturing), H.C. Starck Solutions, Advanced Metallurgical Group N.V. (AMG), Xtant Medical Holdings Inc., Osaka Titanium Technologies Co., Ltd., Global Titanium Inc., Ametek Inc., Alfa Aesar (Thermo Fisher Scientific), Puris LLC, Uniformity Labs. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Porous Titanium Plate Market Key Technology Landscape

The Porous Titanium Plate Market is profoundly shaped by a dynamic and evolving technological landscape, primarily centered around advanced manufacturing processes that enable precise control over material porosity and mechanical properties. The most impactful technologies include additive manufacturing techniques, notably Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Direct Metal Laser Sintering (DMLS). These methods allow for the layer-by-layer fabrication of complex three-dimensional structures directly from titanium powder, offering unparalleled design freedom to create intricate, interconnected pore networks with controlled pore size, morphology, and distribution. This precision is critical for optimizing properties like osseointegration in biomedical implants or enhancing surface area for catalytic reactions. The continuous refinement of these additive manufacturing processes, including advancements in laser/electron beam power, scanning strategies, and powder feedstock quality, is a key driver for market innovation, leading to faster production cycles, improved material integrity, and reduced waste. Furthermore, in-situ monitoring systems and post-processing treatments, such as hot isostatic pressing (HIP) and surface modification techniques, are essential for achieving desired mechanical properties, fatigue resistance, and biocompatibility in the final porous titanium components.

Beyond additive manufacturing, traditional powder metallurgy techniques continue to play a significant role, particularly for applications where very high production volumes or specific pore characteristics are required. Methods such as conventional sintering, often combined with space-holder techniques, and hot isostatic pressing (HIP) are utilized to produce porous titanium structures. Sintering involves compacting titanium powder and heating it below its melting point to bond the particles, while space-holder methods incorporate removable particles (e.g., salts, polymers) within the powder bed to create porosity upon their removal. HIP is crucial for densifying porous structures, reducing internal defects, and improving mechanical properties. Recent innovations in powder metallurgy focus on developing novel titanium alloys and optimizing powder characteristics (e.g., particle size distribution, morphology) to achieve superior porous structures with enhanced performance. Additionally, techniques like fiber sintering, which involve weaving or pressing titanium fibers and then sintering them, offer unique fibrous porous structures, particularly beneficial for certain filtration or biomedical scaffolding applications. Each of these technologies brings distinct advantages in terms of cost-effectiveness, scalability, and achievable pore characteristics, contributing to a diverse technological portfolio within the market.

The technological landscape also extends to sophisticated material characterization and simulation tools that are indispensable for the research, development, and quality assurance of porous titanium plates. Advanced imaging techniques such as micro-computed tomography (µCT) and scanning electron microscopy (SEM) are employed to meticulously analyze pore architecture, interconnectivity, and surface topography, providing crucial feedback for process optimization. Mechanical testing (e.g., compression, tensile, fatigue) specific to porous materials is performed to ensure structural integrity and functional performance under expected load conditions. Furthermore, computational modeling and simulation techniques, including Finite Element Analysis (FEA) and computational fluid dynamics (CFD), are increasingly utilized to predict the mechanical behavior, fluid flow, and biological responses within porous structures, accelerating design cycles and reducing the need for extensive physical prototyping. The integration of artificial intelligence (AI) and machine learning (ML) is also emerging as a transformative trend, enabling AI-driven generative design of optimized porous geometries, predictive maintenance for manufacturing equipment, and real-time process control, thereby pushing the boundaries of what is possible in porous titanium plate manufacturing and application.

Regional Highlights

- North America: This region stands as a dominant force in the Porous Titanium Plate Market, primarily driven by a robust healthcare sector, significant investments in orthopedic and dental research, and a strong presence of key medical device manufacturers. The United States, in particular, leads in adopting advanced surgical techniques and biomaterials, fueled by high healthcare expenditure and an aging population. Additionally, substantial contributions from the aerospace and defense industries, which demand high-performance lightweight materials for critical applications, further solidify the region's market position. Strict regulatory frameworks also drive innovation towards high-quality, reliable products.

- Europe: Europe represents another major market for porous titanium plates, characterized by advanced medical technology, well-established research institutions, and a strong automotive industry. Countries like Germany, France, and the UK are at the forefront of additive manufacturing adoption and material science innovation, contributing significantly to both biomedical and industrial applications. European regulatory bodies, such as the European Medicines Agency (EMA), ensure stringent quality standards for medical implants, fostering a competitive environment focused on product excellence.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market, experiencing rapid expansion due to improving healthcare infrastructure, increasing disposable incomes, and a large patient pool across countries like China, India, and Japan. Government initiatives to promote domestic manufacturing and reduce reliance on imports, coupled with rising investments in R&D for medical devices and aerospace components, are propelling market growth. The region's expanding industrial base also contributes to the demand for porous titanium in chemical processing and other industrial applications.

- Latin America: This region shows steady, albeit slower, growth in the Porous Titanium Plate Market. Increasing healthcare accessibility and awareness, coupled with rising foreign investments in medical device manufacturing, are contributing factors. Countries such as Brazil and Mexico are leading the adoption of advanced medical implants and gradually expanding their industrial applications, though the market is still in its nascent stages compared to more developed regions.

- Middle East and Africa (MEA): The MEA region is characterized by emerging market potential, driven by improving healthcare facilities, increasing government spending on healthcare, and diversification efforts away from oil-dependent economies. Significant investments in infrastructure development and medical tourism, particularly in the UAE and Saudi Arabia, are creating new opportunities. However, the market faces challenges related to economic disparities and nascent industrialization in several countries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Porous Titanium Plate Market.- Stryker Corporation

- Zimmer Biomet Holdings Inc.

- DePuy Synthes (Johnson & Johnson)

- GE Additive (Arcam EBM, Concept Laser)

- EOS GmbH

- SLM Solutions Group AG

- Renishaw plc

- Carpenter Technology Corporation

- ATI (Allegheny Technologies Incorporated)

- VSMPO-AVISMA Corporation

- Sandvik AB (Additive Manufacturing)

- H.C. Starck Solutions

- Advanced Metallurgical Group N.V. (AMG)

- Xtant Medical Holdings Inc.

- Osaka Titanium Technologies Co., Ltd.

- Global Titanium Inc.

- Ametek Inc.

- Alfa Aesar (Thermo Fisher Scientific)

- Puris LLC

- Uniformity Labs

Frequently Asked Questions

What are porous titanium plates primarily used for?

Porous titanium plates are primarily used in biomedical applications for orthopedic and dental implants, due to their excellent biocompatibility and ability to promote bone ingrowth (osseointegration). They are also increasingly utilized in aerospace for lightweight structural components and in chemical processing for advanced filtration and catalytic supports.

How do porous titanium plates benefit medical implants?

For medical implants, porous titanium plates significantly enhance biological fixation by allowing bone cells to grow into the pores, creating a strong biological bond with the implant. This reduces the risk of implant loosening, minimizes stress shielding, and improves long-term implant stability and patient outcomes.

What manufacturing technologies are commonly used for porous titanium plates?

Common manufacturing technologies include additive manufacturing techniques like Selective Laser Melting (SLM) and Electron Beam Melting (EBM), which allow for precise control over pore size and interconnectedness. Powder metallurgy methods, such as sintering and hot isostatic pressing (HIP), are also employed.

What are the key drivers of the Porous Titanium Plate Market growth?

Key drivers include the rising global demand for biocompatible medical implants, rapid advancements in additive manufacturing technologies, an aging population, increasing prevalence of orthopedic and dental disorders, and growing applications in the aerospace and defense sectors for lightweight, high-performance materials.

What challenges does the Porous Titanium Plate Market face?

The market faces challenges such as high manufacturing costs associated with specialized equipment and raw materials, stringent regulatory approval processes for medical devices leading to extended time-to-market, and technical complexities in consistently achieving precise pore structures and mechanical properties across production batches.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager