Portable Anti Static Mat Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431351 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Portable Anti Static Mat Market Size

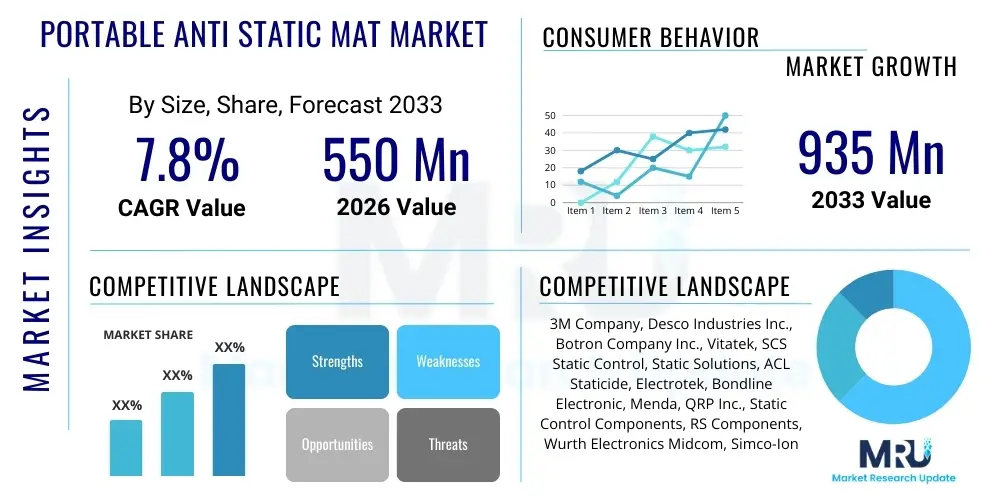

The Portable Anti Static Mat Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at $550 Million in 2026 and is projected to reach $935 Million by the end of the forecast period in 2033.

Portable Anti Static Mat Market introduction

The Portable Anti Static Mat Market encompasses specialized solutions designed to mitigate the risks associated with Electrostatic Discharge (ESD) in environments where mobility and temporary setups are critical. These mats are engineered using conductive or dissipative materials, such as synthetic rubber, vinyl, or specialized polymers, formulated to safely shunt static electricity away from sensitive components. The fundamental purpose of these portable solutions is to create an Electrostatic Protected Area (EPA) instantly, safeguarding microelectronics, assemblies, and personnel during maintenance, repair, and field service operations outside of traditional fixed ESD workstations. The market growth is inherently tied to the increasing miniaturization and complexity of electronic devices, making them highly susceptible to static damage even from low-voltage discharges.

Product descriptions typically highlight features like flexibility, durability, ease of rolling up, and resistance to chemicals, ensuring they maintain their ESD performance across various challenging field conditions. Major applications span across telecommunications, IT infrastructure management, aerospace maintenance, consumer electronics repair, and military applications where quick deployment of ESD protection is non-negotiable. These mats often come equipped with grounding cords, wrist strap attachments, and snap connections, facilitating immediate setup and connection to earth ground, thus providing a complete ESD control solution that complies with industry standards such as ANSI/ESD S20.20.

The primary benefits driving market demand include enhanced component reliability, prevention of catastrophic hardware failures, reduction in warranty claims, and compliance with stringent quality control mandates in electronics manufacturing and servicing sectors. Key driving factors include the rapid expansion of the global IT service sector, the proliferation of complex integrated circuits requiring superior ESD protection, and growing regulatory pressure worldwide to implement effective static control measures. Furthermore, the rising adoption of field programmable gate arrays (FPGAs) and other advanced semiconductors in industrial and automotive electronics significantly increases the need for high-quality, reliable portable ESD protection solutions.

Portable Anti Static Mat Market Executive Summary

The Portable Anti Static Mat Market is experiencing robust growth fueled by intensifying reliance on sensitive electronic components across critical industries and the concurrent expansion of field service operations globally. Business trends indicate a shift towards advanced, multi-layer materials offering superior chemical resistance and extended lifespan, catering to high-reliability applications like defense and medical device repair. Manufacturers are increasingly focusing on incorporating antimicrobial properties and utilizing sustainable materials to appeal to cleanroom and environmentally conscious segments, driving product innovation and differentiation. Strategic mergers and acquisitions among material suppliers and ESD control solution providers are aimed at consolidating market share and achieving vertical integration, optimizing supply chain efficiency and product customization capabilities.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market, largely due to its dominance in electronics manufacturing, coupled with the rapid development of its telecommunications and IT infrastructure sectors which demand frequent maintenance and repair services. North America and Europe remain mature markets, driven by strict adherence to ESD standards (e.g., ANSI/ESD S20.20, IEC 61340) and high adoption rates in aerospace and specialized industrial maintenance, where protection of high-value assets is paramount. Latin America and the Middle East & Africa (MEA) are emerging regions showing promising growth as industrialization accelerates, necessitating professional field service capabilities for complex machinery and electronic systems.

Segment trends reveal that the use of synthetic rubber mats holds a dominant share due to their exceptional durability and electrical properties, although vinyl mats are preferred for cost-effectiveness and general field repair tasks. The demand for customizable sizes and colors is increasing, particularly among large corporate field service teams requiring branding and specific workplace safety adherence. Furthermore, the E-commerce and direct distribution channels are gaining traction, allowing specialized ESD providers to reach a wider base of small to medium-sized repair businesses directly, accelerating market penetration for standardized portable kits.

AI Impact Analysis on Portable Anti Static Mat Market

Common user questions regarding AI's impact on the Portable Anti Static Mat Market often center on how automation and smart diagnostics might reduce human interaction with components, potentially lessening the frequency of static issues, or conversely, how AI-driven robots and automated field systems themselves might require new forms of portable ESD grounding. Users are concerned about the integration of sensors and data analytics into traditional ESD monitoring systems and whether AI can predict and proactively prevent static buildup in variable field environments. Key themes revolve around optimizing the placement and utilization of portable mats based on real-time risk assessment, enhancing training protocols through AI-powered simulations, and ultimately, whether AI will drive the development of "smart" mats capable of self-diagnosing damage or improper grounding, thus ensuring continuous EPA integrity during crucial operations.

- AI integration enhances predictive maintenance algorithms, reducing the duration components are exposed in non-EPA environments.

- AI-driven automated guided vehicles (AGVs) used in smart warehouses and repair facilities necessitate customized portable ESD flooring and mats for robot servicing bays.

- Advanced image recognition powered by AI assists in verifying correct portable mat setup and grounding compliance during remote field audits.

- Machine learning models analyze environmental data (humidity, temperature) to recommend optimal portable mat material types and grounding intervals for specific tasks.

- AI optimizes supply chain logistics for portable mats, ensuring just-in-time delivery to remote service locations based on projected project requirements.

DRO & Impact Forces Of Portable Anti Static Mat Market

The Portable Anti Static Mat Market dynamics are shaped by a complex interplay of Drivers (D), Restraints (R), Opportunities (O), and the resulting Impact Forces. The primary drivers are the exponential growth of electronics manufacturing and servicing across diverse industries, particularly automotive, IoT, and IT repair, where the protection of high-cost, static-sensitive components is paramount. This demand is further amplified by stringent global regulatory standards like ANSI/ESD S20.20 and IEC 61340, compelling organizations to adopt professional ESD control solutions even in temporary workspaces. Additionally, the increasing complexity and vulnerability of next-generation semiconductors significantly elevate the risk of static damage, thus mandating the use of reliable, high-performance portable mats to maintain product integrity and reduce significant financial losses related to component failure.

However, market growth faces significant restraints. A major challenge is the lack of standardized enforcement and low awareness regarding proper ESD practices, particularly in developing economies or among smaller field service organizations which may opt for cheaper, non-compliant alternatives. Furthermore, the inherent durability and chemical resistance of some portable mat materials can degrade over time and exposure to harsh field conditions, requiring frequent replacement, which represents a recurring cost and potential point of failure. The logistical difficulty of ensuring continuous grounding in highly mobile or outdoor environments also restricts the absolute effectiveness of these portable solutions, creating a perceptual barrier to adoption in some ultra-rugged applications.

Significant opportunities exist in the development of "smart" portable mats embedded with RFID tags or IoT sensors for real-time monitoring of resistance and grounding status, offering integrated diagnostic capabilities crucial for high-stakes environments like defense maintenance. Expansion into niche markets, such as mobile cleanrooms for medical devices or temporary research laboratories, presents new avenues for growth. The increasing focus on sustainability also provides an opportunity for manufacturers to innovate with recyclable and bio-based conductive polymers, appealing to corporate social responsibility mandates. These forces collectively shape the competitive landscape, emphasizing the need for continuous material innovation and education regarding ESD best practices to capture maximum market potential and overcome inherent operational challenges.

Segmentation Analysis

The Portable Anti Static Mat Market is segmented based on the type of material used, the physical format, the primary application, and the end-use industry. This segmentation provides a granular view of market dynamics, revealing varying demand patterns based on required electrical properties, durability, and cost sensitivity across different user groups. Material segmentation is crucial as it determines the mat's static dissipation rate and resistance to wear and tear. Furthermore, understanding the end-use applications—ranging from highly specialized military electronics repair to common consumer device servicing—allows manufacturers to tailor product specifications, focusing either on high-performance features (for aerospace) or cost-effectiveness and ease of use (for IT field service).

The market analysis distinguishes between materials like synthetic rubber, which offers superior heat and chemical resistance, and vinyl, which provides a more economical option suitable for light to medium duty use. Format segmentation includes both roll-up mats and fold-up mats, catering to different space constraints and transportation needs. The convergence of these segmentations highlights the increasing consumer demand for integrated ESD kits that bundle portable mats with wrist straps, coil cords, and grounding hardware, facilitating immediate compliance and operational readiness for technicians in the field.

- By Material Type:

- Synthetic Rubber (Nitrile Butadiene Rubber - NBR, others)

- Vinyl (PVC)

- Polyethylene (PE)

- Other Specialty Polymers

- By Format:

- Roll-Up Mats (Standard and Custom Lengths)

- Fold-Up Mats (Modular Sections)

- Portable Workbench Kits (Integrated Grounding)

- By Application:

- Field Service Repair

- Temporary Assembly & Manufacturing

- Testing & Calibration

- Data Recovery

- By End-Use Industry:

- Electronics and Telecommunications

- Aerospace and Defense

- Automotive Electronics

- Healthcare and Medical Devices

- Industrial Automation

- IT and Data Centers

Value Chain Analysis For Portable Anti Static Mat Market

The value chain for the Portable Anti Static Mat Market begins with upstream activities, focusing on the sourcing and processing of raw materials. This stage involves the procurement of highly specialized conductive and dissipative components, including synthetic rubbers, vinyl resins, carbon black or carbon fibers, and antistatic agents. Material suppliers specializing in polymer compounding and chemical formulation play a critical role, as the quality and consistency of these inputs directly determine the final product's electrical performance and durability. Upstream efficiency, driven by long-term supplier contracts and optimization of polymerization processes, is essential for maintaining competitive pricing and ensuring compliance with strict material toxicity and environmental standards required by international certifications.

The subsequent midstream activities involve the manufacturing and fabrication process. This includes mixing, molding, calendaring, and cutting the mats, followed by the integration of conductive layers and grounding hardware (snaps, cords). Manufacturers invest heavily in precision machinery to ensure uniform surface resistance across the entire mat surface, which is vital for effective ESD protection. Quality control and testing—including surface resistance testing and decay rate measurements—are stringent requirements at this stage. Customization and product differentiation, such as adding specific branding or modular interconnectivity features, are often implemented here to meet specific large-scale client requirements, particularly those in the defense or IT enterprise sectors.

Downstream activities center on distribution and end-user engagement. Distribution channels are varied, encompassing direct sales to large corporations and government agencies (often preferred for large volume orders and bespoke requirements), indirect sales through specialized industrial safety distributors and electronics component wholesalers, and a growing reliance on e-commerce platforms and technical catalogs for reaching small to medium-sized repair shops. Effective marketing emphasizes the educational aspect of ESD control and the return on investment derived from preventing component damage. Customer service, post-sale technical support, and warranty provisions form the final, crucial step in the value chain, ensuring proper setup and compliance consultation for highly technical end-users.

Portable Anti Static Mat Market Potential Customers

Potential customers for Portable Anti Static Mats primarily comprise organizations and individual technicians involved in the installation, maintenance, repair, and testing of static-sensitive electronic equipment outside of fixed manufacturing facilities. This includes a broad spectrum of professionals ranging from IT field service engineers who service servers and networking gear on site, to military maintenance personnel repairing avionics in forward operating bases, and specialized technicians working on sensitive medical imaging equipment in hospitals. The common thread among these buyers is the absolute necessity of maintaining an electrostatic protected environment (EPA) under dynamic, non-permanent conditions, thus making portability and immediate grounding capability key purchasing criteria.

Major end-user segments include large-scale Original Equipment Manufacturers (OEMs) that operate extensive global service networks, requiring thousands of standardized, high-quality portable ESD kits for their authorized repair centers and mobile teams. Independent computer repair shops and data recovery specialists also represent a crucial customer base, seeking reliable, cost-effective solutions to protect client hardware. Furthermore, educational institutions and corporate R&D departments utilize portable mats for temporary lab setups and student projects where electronics experimentation is conducted in flexible environments, minimizing the risk of accidental static damage.

Procurement departments within these organizations typically prioritize mats that offer high durability, certified compliance with international ESD standards (like IEC 61340-5-1), and mats that are resistant to common solvents used in cleaning and maintenance. The buying decision is heavily influenced not only by unit price but also by the long-term reliability and the reputation of the supplier in the specialized ESD control industry. The demand is often cyclical, aligning with major hardware deployment cycles and increasing technician headcount in field service divisions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550 Million |

| Market Forecast in 2033 | $935 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Desco Industries Inc., Botron Company Inc., Vitatek, SCS Static Control, Static Solutions, ACL Staticide, Electrotek, Bondline Electronic, Menda, QRP Inc., Static Control Components, RS Components, Wurth Electronics Midcom, Simco-Ion, Static Eliminator, Conductive Containers Inc., Transforming Technologies LLC, Microstat, Elcom |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Portable Anti Static Mat Market Key Technology Landscape

The technology landscape for the Portable Anti Static Mat Market centers fundamentally on materials science and surface engineering to achieve consistent and reliable static dissipation. The dominant technology involves utilizing multi-layer materials, typically comprising a conductive bottom layer to ensure immediate grounding, and a static dissipative top layer that controls the speed at which the charge is safely transferred. Innovations are focused on enhancing the elasticity, tear resistance, and chemical compatibility of these layers, often through the use of advanced polymer blending techniques involving specialized conductive fillers such as carbon nanotubes (CNTs) or intrinsically conductive polymers (ICPs) to replace traditional carbon black, aiming for lighter weight and superior electrical uniformity.

A key technological advancement driving market value is the implementation of smart integration within the portable mat system. This includes the development of embedded monitoring technologies, such as micro-sensors or printed electronics integrated directly into the mat material. These systems are designed to continuously measure key parameters like surface resistivity, grounding connection integrity, and ambient humidity. When connected to a technician's mobile device or a central monitoring system, these smart mats can provide real-time alerts if the EPA integrity is compromised, significantly improving operational compliance and accountability in high-risk field environments. This IoT integration transforms the mat from a passive protective layer into an active diagnostic tool.

Furthermore, rapid prototyping and advanced manufacturing techniques, such as laser cutting and thermal welding, are enabling manufacturers to produce complex, customized portable kits quickly. The focus is also shifting towards highly effective, non-shedding, and cleanroom-compatible portable mats that meet the stringent requirements of pharmaceutical and advanced semiconductor maintenance. Technology is continually evolving to strike a balance between high static-dissipative performance, portability (weight and foldability), and long-term mechanical durability, which is essential for products subjected to frequent rolling, unrolling, and transport in harsh conditions.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing region, primarily driven by its overwhelming concentration of electronics manufacturing hubs (China, South Korea, Taiwan, India) and massive investment in 5G infrastructure and data centers. The high volume of PCB assembly, device servicing, and the subsequent need for reliable field repair services fuels the demand for portable ESD solutions. Competitive pricing and the availability of raw material suppliers also contribute to its dominance.

- North America: North America is characterized by high compliance standards, particularly within the aerospace, defense, and high-tech IT sectors. Market growth is robust, driven by the replacement and maintenance cycles of sophisticated, expensive equipment where the cost of component failure is exceptionally high. Demand here is focused on premium, certified products, often requiring specialized features like high-temperature resistance and chemical inertness.

- Europe: The European market demonstrates steady growth, motivated by strict adherence to the IEC 61340 series of standards and significant activities in the automotive electronics and industrial automation repair segments. Germany, France, and the UK are key contributors, emphasizing regulatory compliance and the adoption of portable solutions for mobile workshops and specialized industrial maintenance teams.

- Latin America (LATAM): LATAM represents an emerging market with increasing industrialization and foreign investment in manufacturing facilities (especially Mexico and Brazil). While adoption is currently moderate, awareness of professional ESD control is rapidly improving, leading to increased procurement of basic and mid-range portable mat kits for newly established field service operations.

- Middle East and Africa (MEA): Growth in MEA is largely concentrated in the Gulf Cooperation Council (GCC) countries, driven by significant government spending on IT infrastructure, telecommunications, and military technology. The climate challenges (low humidity often exacerbating static buildup) make reliable, durable portable anti static solutions critically important for maintaining sensitive data center components and critical infrastructure systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Portable Anti Static Mat Market.- 3M Company

- Desco Industries Inc.

- Botron Company Inc.

- Vitatek

- SCS Static Control

- Static Solutions

- ACL Staticide

- Electrotek

- Bondline Electronic

- Menda

- QRP Inc.

- Static Control Components

- RS Components

- Wurth Electronics Midcom

- Simco-Ion

- Static Eliminator

- Conductive Containers Inc.

- Transforming Technologies LLC

- Microstat

- Elcom

Frequently Asked Questions

Analyze common user questions about the Portable Anti Static Mat market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between anti static mats and standard mats?

The primary difference is their electrical function. Standard mats provide physical protection but do not manage electrical charges. Portable anti static mats, conversely, are engineered using conductive or dissipative materials specifically designed to control the generation, accumulation, and discharge of static electricity, safely shunting it to a designated ground point to protect sensitive electronic components from electrostatic damage.

Which material is most recommended for portable anti static mats used in harsh field service environments?

Synthetic rubber, particularly Nitrile Butadiene Rubber (NBR), is generally recommended for harsh field service environments. This material offers superior resilience, heat resistance, and chemical resistance compared to vinyl, ensuring the mat maintains consistent surface resistivity and physical integrity despite repeated rolling, temperature fluctuations, and exposure to oils or solvents common in industrial settings.

How often should portable anti static mats be tested for compliance?

Portable anti static mats used in critical field service or temporary EPA settings should be tested regularly, ideally before each high-stakes operation or at least quarterly, depending on the organizational compliance policy (such as ANSI/ESD S20.20 requirements). Testing ensures that the surface resistance and grounding path integrity have not been compromised by damage, dirt, or degradation during transportation and use.

What are the key compliance standards governing the portable anti static mat market?

The primary global compliance standards are ANSI/ESD S20.20 (the U.S. standard for developing ESD control programs) and the international standard IEC 61340-5-1. These standards dictate the required surface resistance range (typically 106 to 109 ohms for dissipative materials) and define the procedures for verifying the effectiveness and installation of the portable mats within an electrostatic protected area.

Are smart portable anti static mats worth the investment for small businesses?

For small businesses handling high-value components or engaging in frequent critical field repairs, smart mats, which incorporate IoT monitoring for real-time compliance verification, are increasingly justifiable. While the initial investment is higher, the enhanced data logging, proactive fault detection (improper grounding), and reduced risk of costly component failures often lead to a significant long-term return on investment by ensuring immediate, verified ESD protection during every service call.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager