Portable Cutting Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437376 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Portable Cutting Machines Market Size

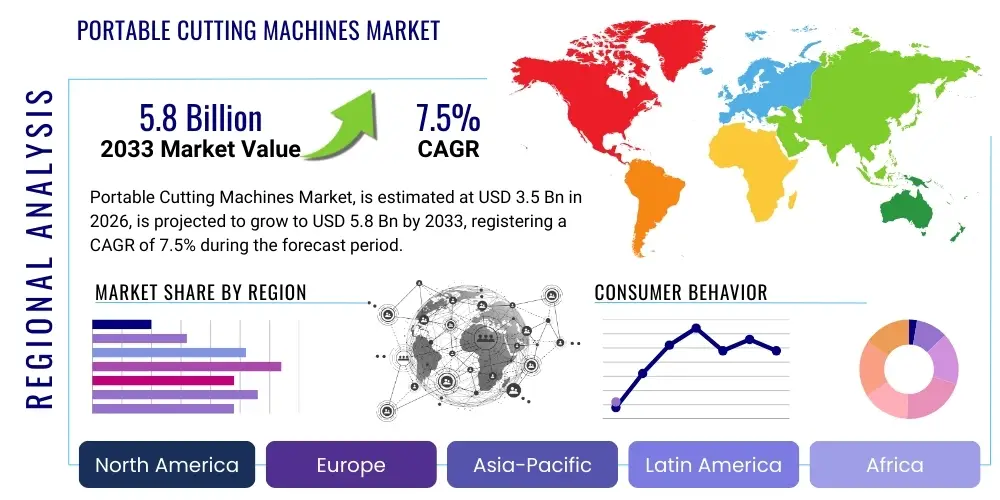

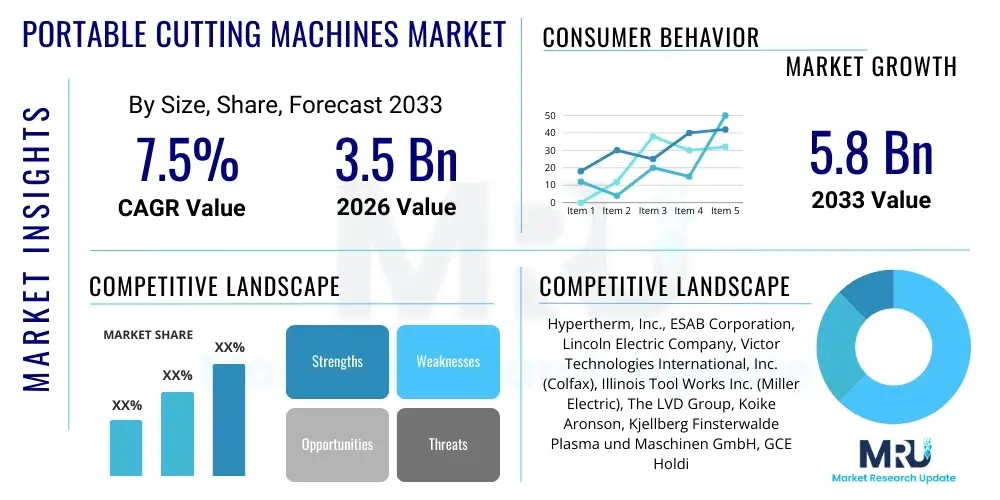

The Portable Cutting Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.8 Billion by the end of the forecast period in 2033.

Portable Cutting Machines Market introduction

Portable cutting machines are specialized, lightweight equipment designed for precision cutting of various materials, including metal, plastics, composites, and stone, utilized across diverse industrial and construction settings. These machines offer mobility, allowing operators to perform cutting tasks directly at the point of operation, significantly enhancing efficiency in field environments compared to traditional stationary cutting systems. Key product offerings within this market segment include portable plasma cutters, oxy-fuel cutters, abrasive saws, laser cutters, and specialized pipe cutting machines, catering to different material thicknesses and accuracy requirements.

The primary applications of portable cutting machines span infrastructure development, shipbuilding, automotive repair, HVAC installation, and general fabrication workshops. Their inherent flexibility makes them indispensable for maintenance, repair, and overhaul (MRO) activities, particularly in demanding environments like oil and gas pipelines or remote construction sites where access to centralized power and heavy equipment is restricted. The shift towards modular construction and just-in-time fabrication practices further amplifies the demand for reliable, high-performance portable solutions.

Major driving factors influencing market expansion include the global increase in construction and infrastructure spending, the rising adoption of automation and semi-automated cutting technologies in fabrication, and the growing emphasis on worker safety and ergonomic design. The continuous innovation in power source technology, such as inverter-based plasma systems, results in lighter, more energy-efficient, and powerful portable units. Furthermore, the necessity for quick, accurate repairs in sectors requiring rapid deployment, such as disaster recovery and military operations, consistently fuels product demand across all geographic regions.

Portable Cutting Machines Market Executive Summary

The Portable Cutting Machines Market is experiencing robust growth, driven primarily by strong business trends focusing on operational efficiency, remote fabrication capabilities, and technological integration. The construction and shipbuilding sectors remain pivotal end-users, adopting compact, high-precision cutting tools to reduce downtime and material waste. Key business trends include the consolidation of manufacturing capabilities toward producing multi-process systems and the strategic emphasis on digital connectivity for enhanced machine diagnostics and predictive maintenance services. Furthermore, market players are prioritizing lightweight composite materials in machine construction to optimize portability without compromising durability or cutting performance.

Regionally, the Asia Pacific (APAC) stands out as the fastest-growing market, propelled by massive government investment in infrastructure projects, rapid urbanization, and the flourishing manufacturing base in countries like China, India, and Southeast Asia. North America and Europe, while mature, continue to hold significant market share, characterized by high adoption rates of advanced technologies such as laser and high-definition plasma cutting systems, driven by stringent quality standards and high labor costs necessitating automated solutions. Emerging economies in Latin America and MEA are increasingly investing in portable solutions to modernize their fabrication and oil & gas pipeline maintenance infrastructure.

Segment-wise, the plasma cutting segment dominates due to its versatility, speed, and ability to cut various conductive metals efficiently. However, the laser cutting segment is projected to exhibit the highest CAGR, benefiting from its unparalleled precision and minimal heat-affected zone (HAZ), making it ideal for high-tolerance applications. End-user trends show a strong shift toward professional/industrial-grade machines over DIY models, indicating a market preference for reliability, duty cycle, and advanced features like CNC integration and torch height control (THC) systems, further defining the landscape for specialized, high-value portable equipment.

AI Impact Analysis on Portable Cutting Machines Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Portable Cutting Machines Market typically center on how AI can enhance cutting precision, optimize material utilization, and simplify complex operational procedures for field technicians. Users are primarily concerned with whether AI integration will make equipment easier to use for less skilled labor, the cost implications of smart portable machines, and the ability of AI algorithms to perform real-time diagnostics and predictive failure analysis in remote locations. The prevailing theme is the expectation that AI will transition portable cutting from a manual skill-based operation to an algorithm-guided process, significantly minimizing human error and maximizing material yields.

The integration of AI and machine learning (ML) is fundamentally changing the functional dynamics of portable cutting systems. AI algorithms are increasingly utilized for optimizing cutting paths (nesting), dynamically adjusting parameters (speed, power, gas pressure) based on material thickness, type, and temperature, ensuring superior cut quality and extending consumable life. This smart optimization reduces reliance on manual parameter settings and minimizes the need for costly rework, a critical factor for field operations where consistency is often challenging to maintain.

Furthermore, AI-driven diagnostics enable portable machines to monitor their own performance metrics in real-time, predicting component failures, scheduling proactive maintenance, and identifying anomalies that could degrade performance. This predictive capability translates directly into higher uptime, which is crucial for maximizing productivity on project timelines. As 5G connectivity expands, the data collected by these smart portable cutters can be analyzed remotely, allowing manufacturers to offer advanced maintenance contracts and continuous software improvements, effectively embedding AI as a critical value differentiator in high-end portable cutting solutions.

- AI optimizes nesting patterns to minimize scrap material wastage.

- Machine learning algorithms enable real-time parameter adjustment for consistent cut quality.

- Predictive maintenance schedules are generated based on operational data analysis.

- Computer vision systems, guided by AI, enhance precision in complex contour cutting.

- AI simplifies user interfaces, allowing semi-skilled operators to achieve professional results.

- Automated torch height control (THC) systems utilize ML for superior arc stabilization.

- Data analytics gathered from multiple portable units inform future product design and durability improvements.

DRO & Impact Forces Of Portable Cutting Machines Market

The market dynamics are shaped by powerful Drivers, structural Restraints, and significant Opportunities (DRO), all acting under the influence of various Impact Forces. Key drivers include accelerated infrastructure investments globally, particularly in developing nations, coupled with the rising demand for lightweight and ergonomic tools that comply with strict occupational health and safety regulations. The imperative across various industries, such as oil and gas and construction, to minimize operational downtime and improve field fabrication capabilities significantly boosts the adoption of highly portable, durable cutting solutions. These drivers collectively establish a strong foundational demand base.

Conversely, the market faces notable restraints, primarily the high initial investment cost associated with advanced portable cutting technologies, especially high-definition plasma and portable fiber laser systems, which limits adoption in small and medium-sized enterprises (SMEs). Furthermore, the operational challenge lies in the necessity for skilled operators capable of maintaining the precision and calibration of these sophisticated machines in rugged field conditions. Volatility in raw material prices, particularly for crucial components like copper and specialized alloys used in torch and nozzle manufacturing, also poses a structural constraint on pricing and profit margins.

Opportunities for market expansion are abundant, centered around the integration of Internet of Things (IoT) capabilities for remote monitoring and diagnostics, allowing manufacturers to offer value-added services and recurring revenue streams. The growing trend toward battery-powered portable cutting solutions addresses constraints related to power accessibility in remote locations, opening new application areas. Moreover, developing nations provide significant potential for market penetration as they modernize their industrial fabrication processes, favoring robust, energy-efficient portable equipment over older, stationary alternatives. These opportunities are driving innovation and competitive strategies among major market players.

Segmentation Analysis

The Portable Cutting Machines Market is meticulously segmented based on the technology utilized, the type of end-product, and the primary application sector, allowing for a detailed examination of market penetration and growth trajectories across various niches. Technology segmentation primarily includes plasma cutting, oxy-fuel cutting, and specialized saw-based cutting, with plasma systems dominating due to their versatility across conductive metals. End-product differentiation focuses on machine capabilities, ranging from high-precision, CNC-integrated portable cutters used in shipbuilding to simpler, manually operated systems prevalent in maintenance and repair operations.

Further analysis of the segmentation highlights the importance of the power source (electric/battery-operated vs. fuel-based) and the level of automation (manual, semi-automatic, or fully automated via portable CNC systems). The rapid development of high-capacity lithium-ion batteries is driving the growth in battery-operated portable tools, enhancing freedom of movement and eliminating reliance on external power grids in construction environments. Application segmentation confirms that heavy fabrication and infrastructure remain the largest consumers, demanding rugged, high-duty cycle machines, while the rise of specialized industries like aerospace and medical device fabrication drives demand for extremely high-precision portable laser systems.

- By Technology:

- Plasma Cutting

- Oxy-Fuel Cutting

- Abrasive Cutting (Saws and Wheels)

- Laser Cutting (Fiber and CO2)

- Waterjet Cutting (Portable Units)

- By Operation:

- Manual

- Semi-Automatic

- CNC Portable

- By Power Source:

- Electric (Corded/Inverter)

- Battery-Powered

- Gas/Fuel Powered

- By End-Use Industry:

- Construction and Infrastructure

- Oil & Gas and Pipeline Installation

- Automotive and Transportation

- Shipbuilding and Marine

- Aerospace and Defense

- Metal Fabrication Workshops

Value Chain Analysis For Portable Cutting Machines Market

The value chain for the Portable Cutting Machines Market begins with the upstream procurement of specialized raw materials, primarily focusing on high-grade components crucial for precision, durability, and thermal resilience. This includes copper for torches, specialized steel alloys for machine frames, advanced ceramics for nozzles and electrodes, and complex electronic components for inverter power supplies and control boards. Upstream activities are critical for quality control, as the performance and lifespan of portable cutters are highly dependent on the integrity of consumables and power source components. Strategic partnerships with reliable material suppliers are essential for managing cost volatility and ensuring a consistent supply chain for high-demand parts.

The midstream stage involves the design, manufacturing, and assembly of the portable cutting units. This stage includes significant investment in R&D to enhance portability, improve energy efficiency (through inverter technology), and integrate smart features (IoT/AI). Manufacturing processes are characterized by high precision engineering, focusing on reducing the weight of the machine while maintaining a high duty cycle and robustness required for industrial environments. Effective quality assurance protocols during assembly are paramount to ensure the machine meets regulatory safety standards and delivers advertised performance specifications, particularly arc stability and cutting speed.

Downstream distribution channels play a pivotal role in market reach, leveraging a mix of direct sales and an extensive network of indirect distributors and authorized dealers. Direct sales are often utilized for large industrial clients, providing specialized support and custom integration, while indirect channels serve a broader market, including SMEs and repair shops, offering inventory availability and local technical support. Aftermarket services, including the supply of high-wear consumables (nozzles, tips, electrodes) and repair services, form a crucial component of the downstream value chain, providing continuous revenue streams and ensuring customer loyalty, particularly for high-end industrial equipment.

Portable Cutting Machines Market Potential Customers

The primary end-users and potential buyers of portable cutting machines represent a wide spectrum of industrial entities, fundamentally driven by the need for on-site material processing, repair, and modification capabilities. The largest customer segments include large-scale construction contractors involved in infrastructure projects (bridges, high-rises, tunnels) who require efficient and mobile tools for structural steel cutting and site modifications. Additionally, companies specializing in oil and gas pipeline maintenance and installation are critical customers, requiring durable, reliable oxy-fuel and specialized pipe cutting systems capable of operating in harsh, remote environments with limited power access.

Another significant customer base lies within the metal fabrication industry, particularly small to medium-sized workshops and mobile welding operations that require versatile equipment for job site tasks and flexible workshop use. The shipbuilding and marine repair sectors are consistently high-volume purchasers, demanding portable plasma and specialized magnetic track cutting machines for hull repair and modification where precision and minimum distortion are critical. Furthermore, the automotive aftermarket and repair shops represent a growing customer segment, utilizing portable plasma and abrasive cutters for body work and component replacement due to their speed and efficiency over traditional methods.

Government agencies, including military and disaster relief organizations, also constitute an important segment, requiring rugged, rapidly deployable portable cutting equipment for field repairs and emergency response operations. The demand from these sectors is typically focused on reliability, robust design, and multi-process capabilities to handle various materials encountered during mission deployment. Overall, any industrial entity performing material cutting operations outside of a fixed manufacturing facility is considered a prime potential customer for specialized portable cutting machine solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.8 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hypertherm, Inc., ESAB Corporation, Lincoln Electric Company, Victor Technologies International, Inc. (Colfax), Illinois Tool Works Inc. (Miller Electric), The LVD Group, Koike Aronson, Kjellberg Finsterwalde Plasma und Maschinen GmbH, GCE Holding AB, Swifty Cut, Piranha Machinery, CEBORA S.p.A., Thermal Dynamics, Riland Industry, Messer Cutting Systems, AJAN CNC, Hornet Cutting Systems, Harris Products Group, WELDONE, SAF-FRO. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Portable Cutting Machines Market Key Technology Landscape

The technology landscape of the Portable Cutting Machines Market is rapidly evolving, moving towards greater efficiency, portability, and digital integration. A dominant technology remains inverter-based plasma cutting, which allows for significantly lighter and more energy-efficient power supplies compared to older transformer-based systems. Inverter technology facilitates high-frequency, stable arc initiation and enables features like automated voltage control and precise amperage settings, translating directly into superior cut quality and reduced operator fatigue. Furthermore, the development of high-definition (HD) plasma technology in portable formats is providing near-laser quality cuts on thicker metals, expanding the utility of portable systems into high-tolerance fabrication environments.

The increasing prominence of battery technology is another transformative area. Advances in lithium-ion and other high-density battery chemistries are enabling the creation of powerful, cordless portable cutting tools, primarily targeting thin-gauge metal applications and construction site work where electrical accessibility is variable. This shift enhances user mobility and safety by eliminating cord hazards, particularly critical for abrasive saws and smaller plasma units. Manufacturers are focusing on maximizing the duty cycle and optimizing battery recharge times to make these cordless units viable for sustained industrial use, thereby addressing a crucial operational bottleneck.

Beyond power sources, the integration of automation through portable CNC systems represents a key technological frontier. These smaller, rugged CNC tables and magnetic track systems utilize sophisticated controllers and user-friendly software to allow complex, repeatable cuts in the field. This integration includes features like automatic torch height control (THC), collision detection, and remote diagnostic capabilities enabled by IoT sensors. The convergence of precise mechanical movement, advanced power electronics, and embedded software is ensuring that portable cutting machines can deliver workshop-level accuracy in any outdoor or remote operational setting.

Regional Highlights

- Asia Pacific (APAC): The APAC region is projected to register the highest growth rate, driven by monumental investments in infrastructure development, including railways, smart cities, and power grids, particularly in India, China, and Southeast Asian nations. The region’s burgeoning automotive and shipbuilding industries, coupled with lower manufacturing costs attracting global fabrication outsourcing, make it the largest consumer and producer of portable cutting equipment.

- North America: North America holds a substantial market share, characterized by a strong demand for advanced, high-technology portable solutions, specifically high-definition plasma and portable laser systems. The market is mature but highly focused on efficiency and labor-saving devices due to high labor costs. Stringent safety regulations and high construction standards favor reliable, premium-priced equipment from established global players.

- Europe: Europe represents a significant market, with demand concentrated in sophisticated fabrication and precision engineering sectors, notably in Germany, the UK, and Italy. The market growth is underpinned by robust shipbuilding maintenance (MRO) and the automotive sector's continuous need for quick, accurate repair solutions. Environmental regulations strongly influence technology adoption, favoring energy-efficient inverter and laser systems.

- Latin America (LATAM): LATAM is an emerging market showing steady growth, driven primarily by investments in oil and gas infrastructure expansion and mining operations, which require robust, field-ready portable cutting machines for remote pipe cutting and structural modifications. Economic stability and industrial modernization efforts are key factors promoting market penetration in countries like Brazil and Mexico.

- Middle East and Africa (MEA): The MEA region is expanding, dominated by large-scale oil and gas pipeline projects and urban development initiatives, particularly in the GCC countries. The demand is skewed towards heavy-duty, durable portable oxy-fuel and plasma systems capable of handling extreme environmental conditions (high heat, sand). Infrastructure expansion remains the central driver for equipment acquisition.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Portable Cutting Machines Market.- Hypertherm, Inc.

- ESAB Corporation

- Lincoln Electric Company

- Victor Technologies International, Inc. (Colfax)

- Illinois Tool Works Inc. (Miller Electric)

- The LVD Group

- Koike Aronson

- Kjellberg Finsterwalde Plasma und Maschinen GmbH

- GCE Holding AB

- Swifty Cut

- Piranha Machinery

- CEBORA S.p.A.

- Thermal Dynamics

- Riland Industry

- Messer Cutting Systems

- AJAN CNC

- Hornet Cutting Systems

- Harris Products Group

- WELDONE

- SAF-FRO

Frequently Asked Questions

Analyze common user questions about the Portable Cutting Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected Compound Annual Growth Rate (CAGR) for the Portable Cutting Machines Market?

The Portable Cutting Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% over the forecast period from 2026 to 2033. This growth is primarily fueled by global infrastructure spending and technological advancements in portable plasma and battery systems.

Which technology segment dominates the Portable Cutting Machines Market?

The Plasma Cutting technology segment currently dominates the market due to its high speed, versatility in cutting various conductive metals, and continuous improvements in inverter technology leading to enhanced portability and efficiency, making it suitable for both field and workshop applications.

How is AI impacting the performance and operations of portable cutting machines?

AI integration is significantly enhancing portable cutting performance by optimizing cutting parameters in real-time, improving material utilization through sophisticated nesting algorithms, and enabling predictive maintenance capabilities. This reduces human error and maximizes machine uptime in remote locations.

Which region shows the highest growth potential for portable cutting machine adoption?

The Asia Pacific (APAC) region is anticipated to exhibit the highest growth potential. This is driven by rapid industrialization, massive government investments in infrastructure and urbanization projects, and the expansion of the regional manufacturing and shipbuilding sectors.

What are the primary restraints affecting the market growth?

Primary restraints include the relatively high initial capital expenditure required for sophisticated, high-precision portable cutting systems (like portable CNC plasma or fiber laser), challenges related to training a sufficiently skilled operator base for field deployment, and potential fluctuations in raw material costs for consumables.

What are the key benefits of battery-powered portable cutting tools?

Battery-powered portable cutting tools offer superior mobility, eliminate the safety hazards associated with power cords in construction environments, and allow operations in remote areas lacking reliable grid power. Advances in battery chemistry are ensuring longer duty cycles suitable for professional use.

In which end-use industry is the demand for heavy-duty portable cutting equipment strongest?

The demand is strongest in the Construction and Infrastructure sector and the Oil & Gas/Pipeline installation industry. These segments require robust, high-duty cycle machines, such as specialized pipe cutters and high-capacity plasma systems, for essential on-site structural modifications and maintenance activities.

How do portable CNC cutting systems differ from standard manual portable cutters?

Portable CNC (Computer Numerical Control) cutting systems incorporate automated track systems and specialized software, allowing them to execute complex, repeatable, and high-precision cuts with minimal operator input. This contrasts with manual systems, which rely entirely on operator skill and template guides for trajectory and speed control.

What is the role of inverter technology in modern portable cutting machines?

Inverter technology is crucial as it allows manufacturers to produce significantly smaller, lighter, and more energy-efficient power supplies compared to older transformer models. This results in enhanced portability, greater power control, and improved arc stability, which is essential for maintaining cut quality in field environments.

Which company is considered a leading innovator in portable plasma cutting technology?

Hypertherm, Inc., is consistently recognized as a leading innovator, particularly known for its advancements in high-definition plasma technology and the development of power sources that maximize consumable life and optimize cut performance across various material thicknesses.

How does the value chain manage the distribution of portable cutting machine consumables?

The downstream segment of the value chain is vital for consumables management. Distribution is handled through extensive indirect dealer networks and specialized industrial suppliers who ensure regional inventory of high-wear items like nozzles, electrodes, and tips, providing critical aftermarket support and reliable continuous operation for end-users.

What impact do strict occupational safety standards have on product development?

Strict occupational safety standards significantly drive product development toward lighter, more ergonomic designs and features that minimize operator exposure to heat, noise, and fumes. This includes the implementation of safer torch designs and greater adoption of automation to reduce manual handling risks.

Are portable waterjet cutting machines gaining market traction?

While still a niche segment due to complexity, portable waterjet cutting machines are gaining traction in specialized applications where heat-affected zones (HAZ) must be minimized, such as in aerospace composite cutting and sensitive material decommissioning. Advancements focus on making the intensifier pump units smaller and more mobile.

What is the major differentiation point between professional and DIY portable cutters?

The major differentiation lies in the duty cycle, durability, and features. Professional/industrial-grade cutters offer extended duty cycles (ability to cut for longer periods continuously), rugged construction, higher amperage output for thicker materials, and advanced features like gas control and CNC compatibility, unlike less durable DIY models.

How does the market address the issue of power scarcity in remote field applications?

The market addresses power scarcity primarily through two means: rapid adoption of high-capacity battery-powered systems for light to medium cutting tasks, and the reliance on highly fuel-efficient oxy-fuel cutting systems or high-efficiency inverter plasma cutters that minimize power draw from available portable generators.

What role does the shipbuilding sector play in driving demand for portable cutting machines?

The shipbuilding sector drives significant demand, especially for repair and maintenance operations (MRO). Portable cutting machines, particularly magnetic track plasma cutters, are essential for on-site hull modifications, section replacement, and decommissioning, requiring high precision and minimal setup time.

Which cutting mechanism offers the highest precision in the portable market?

Portable fiber laser cutting systems generally offer the highest precision, providing narrow kerf widths and minimal heat distortion. Although less common in the general portable segment due to size and cost, portable laser solutions are increasingly used in high-tolerance applications like aerospace and thin sheet metal fabrication.

What are the strategic implications of IoT integration for manufacturers?

For manufacturers, IoT integration allows for remote monitoring of machine performance, enabling predictive maintenance services, gathering valuable usage data for product improvement, and facilitating continuous software updates. This shifts the business model towards offering value-added services and maximizing customer equipment uptime.

How do portable cutting machines contribute to sustainability in construction?

Portable cutting machines contribute to sustainability by enabling precise, optimized cutting operations in the field, which minimizes material scrap and waste. Newer inverter-based technologies also improve energy efficiency, reducing the overall carbon footprint compared to older, high-consumption equipment.

What is the significance of the shift toward lightweight composite materials in machine construction?

The use of lightweight composite materials in portable cutting machine construction is critical for improving portability and ergonomics. Reducing the overall weight makes the equipment easier to transport, set up, and handle on site, directly addressing the core requirement of mobility for field operators without sacrificing structural integrity or performance.

What factors influence the choice between plasma and oxy-fuel portable cutting for industrial use?

The choice is governed by material type and thickness. Oxy-fuel is preferred for very thick carbon steel and applications where portability outweighs speed, as it requires no electricity. Plasma cutting is faster, handles a wider range of conductive metals (including stainless steel and aluminum), and is preferred when electricity is available and higher cutting speed is necessary.

How are emerging markets accelerating the adoption of portable cutting solutions?

Emerging markets in APAC and LATAM are accelerating adoption by bypassing older stationary equipment installations and moving directly to advanced portable solutions to modernize their burgeoning construction and fabrication industries. The low initial infrastructure requirement of portable tools is a significant benefit.

What role do distribution channels play in the overall market growth?

Robust and specialized distribution channels are essential for market growth, ensuring product availability, providing localized technical support, and offering essential aftermarket services like consumables sales and repair. Strong dealer networks are vital for reaching dispersed construction and fabrication customers globally.

What are the main considerations for portable pipe cutting machine buyers?

Buyers prioritize ease of setup, accuracy of the cut (especially crucial for welding preparation), durability in pipeline environments, and the machine's ability to handle various pipe diameters and wall thicknesses. Safety features and compatibility with automated beveling operations are also key considerations.

How is the aerospace sector utilizing portable cutting technologies?

The aerospace sector uses highly precise portable cutting machines, often specialized laser or small waterjet units, for cutting advanced composite materials and high-strength alloys during maintenance, modification, and repair activities, where absolute precision and minimal thermal distortion are mandatory.

What market trend indicates a move towards multi-process portable equipment?

The increasing consolidation of cutting, welding, and gouging functionalities into single, portable power sources (multi-process machines) indicates a strong market trend. This offers enhanced versatility, reduces the need for multiple pieces of equipment, and maximizes efficiency for mobile fabrication and repair crews.

What is the typical lifespan for consumables in industrial portable plasma cutters?

The lifespan of consumables (electrodes and nozzles) in industrial portable plasma cutters varies widely but is heavily influenced by operational parameters, including amperage, piercing height, and cut speed. Optimized usage, often guided by manufacturer recommendations and smart machine software, can significantly extend consumable life, which is a major operating cost factor.

How does the volatile pricing of copper affect the market for portable cutting machines?

Copper is a critical component in the manufacturing of power cables, torches, and internal components of the power supply. Volatile copper pricing directly impacts the upstream supply chain, potentially increasing the manufacturing costs for portable cutting machines and subsequently affecting the final product pricing for consumers.

What measures are manufacturers taking to make portable cutters easier for less-skilled operators?

Manufacturers are implementing simplified, graphical user interfaces, automatic parameter setting features (where the machine suggests optimal settings based on material input), and integrating AI-guided operational feedback to minimize the required skill level, ensuring consistent, professional-quality results from semi-skilled labor.

What is the expected market performance of manual vs. CNC portable cutting solutions?

While manual portable solutions will continue to dominate volume sales due to their lower cost and basic utility, CNC portable solutions are expected to demonstrate a higher CAGR. This growth is driven by increasing demand for high accuracy, repeatability, and efficient material nesting in complex industrial field projects.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager