Portable UV Curing Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433594 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Portable UV Curing Machine Market Size

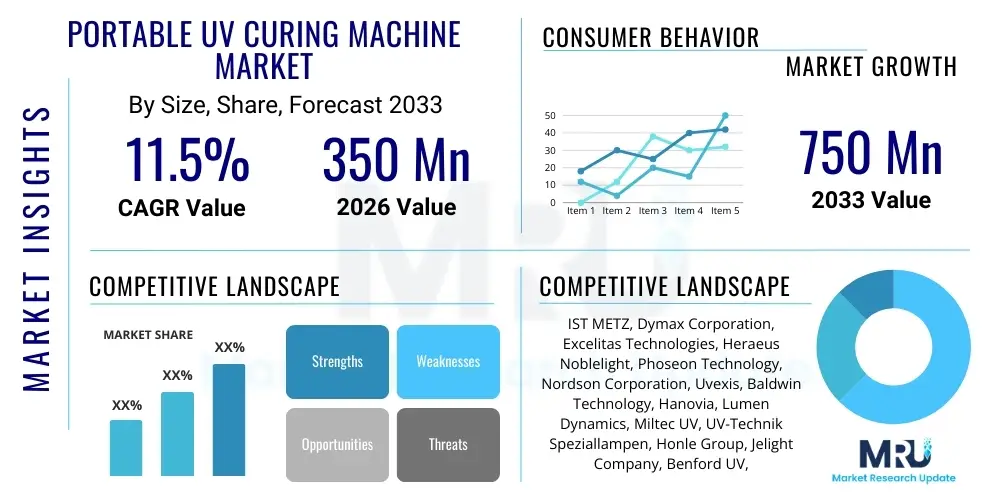

The Portable UV Curing Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.5% between 2026 and 2033. The market is estimated at USD 350 Million in 2026 and is projected to reach USD 750 Million by the end of the forecast period in 2033.

Portable UV Curing Machine Market introduction

The Portable UV Curing Machine Market encompasses devices designed for rapidly curing UV-sensitive coatings, inks, and adhesives using ultraviolet light sources, primarily for localized or repair applications where traditional fixed curing systems are impractical. These machines offer critical advantages such as reduced curing time, lower energy consumption, and increased operational flexibility, making them essential tools across diverse industrial sectors. The core technology involves highly specialized UV lamps, increasingly dominated by UV-LED technology, which provides precise wavelength control and extended operational lifespan compared to traditional mercury arc lamps.

Major applications of portable UV curing technology span the electronics sector, particularly in smartphone and PCB manufacturing for adhesive bonding and conformal coating repairs, and the automotive industry for interior trim sealing and headlamp lens restoration. Additionally, the technology is crucial in graphics arts for spot curing specialized prints, and in construction and infrastructure maintenance for localized concrete repair and protective coating application. The primary product description highlights their compact, ergonomic design, often battery-powered capabilities, and high radiant power output necessary for instantaneous curing reactions.

Driving factors propelling market expansion include the global shift towards faster, more efficient manufacturing processes, stringent environmental regulations necessitating the use of solvent-free, UV-curable materials, and the accelerating demand for high-quality surface finishes and durable bonding solutions in high-tech manufacturing. Furthermore, the increasing adoption of UV-LED technology is significantly lowering the total cost of ownership (TCO) for end-users, while enhancing operational safety due to the elimination of ozone generation associated with mercury lamps, thus cementing the market’s positive trajectory.

Portable UV Curing Machine Market Executive Summary

The Portable UV Curing Machine Market is characterized by robust technological innovation, driven predominantly by the shift from traditional mercury arc lamps to highly efficient UV-LED systems, enhancing portability, energy efficiency, and operational lifespan. Current business trends indicate a strong focus on developing integrated solutions that incorporate advanced optics and thermal management systems to deliver higher irradiance levels for demanding industrial applications, such as thick-film curing in aerospace components and demanding automotive repair scenarios. Strategic partnerships between UV equipment manufacturers and material suppliers (inks, coatings, adhesives) are becoming crucial to ensure system compatibility and optimize curing profiles, thereby streamlining the overall customer value proposition and accelerating market penetration in specialized niches.

Regionally, the Asia Pacific (APAC) stands out as the primary engine of growth, fueled by massive investments in electronics manufacturing, particularly in China, South Korea, and Taiwan, where portable curing solutions are integral to high-volume assembly and repair operations. North America and Europe maintain significant market shares, characterized by early adoption of UV-LED technology, driven by strict regulatory mandates pertaining to Volatile Organic Compounds (VOCs) reduction and a high concentration of high-precision industries like medical device manufacturing and advanced automotive repair workshops. These developed regions demand sophisticated, high-power density portable units optimized for complex substrates and specialized protective coatings.

Segment trends highlight the dominance of the UV-LED segment due to its superior performance characteristics, pushing mercury arc-based systems towards obsolescence in new equipment sales. Application-wise, the electronics and automotive repair segments lead the market, although the medical sector is rapidly emerging as a high-value segment, requiring portable systems for sterilizing and bonding catheters and other disposable medical instruments under controlled environments. Future growth will be significantly shaped by the adoption of smart, connected UV curing tools capable of logging curing parameters and integrating with IoT systems for quality assurance and predictive maintenance.

AI Impact Analysis on Portable UV Curing Machine Market

User queries regarding AI's impact on portable UV curing typically revolve around optimizing curing processes, enhancing quality control, and integrating these tools into automated, smart factory environments. Users seek to understand how AI algorithms can analyze real-time variables—such as substrate temperature, ambient humidity, material viscosity, and lamp intensity—to dynamically adjust curing parameters (e.g., exposure time, power output) to ensure consistent, defect-free results, especially in complex or sensitive applications like precision electronics repair or medical bonding. Key concerns center on the practicality of embedding sophisticated AI processing capabilities into compact, portable devices, and the need for standardized data protocols to allow seamless communication between the curing machine, robotics, and centralized Quality Management Systems (QMS).

The integration of Artificial Intelligence and Machine Learning (ML) is fundamentally transforming the operational paradigm of portable UV curing equipment, moving them beyond simple mechanical tools into intelligent, adaptive systems. AI models can be trained on vast datasets of successful and failed curing cycles to identify optimal operating windows and predict potential curing defects before they occur. This predictive capability significantly reduces material waste and minimizes rework, offering quantifiable improvements in operational efficiency and cost savings. For example, in automated repair stations utilizing portable UV units, AI manages the complex interplay of movement speed and light intensity to achieve perfect adhesion regardless of minor variations in component placement or environmental conditions, something human operators struggle to achieve consistently.

Furthermore, AI facilitates predictive maintenance for the portable units themselves. By monitoring the performance characteristics of the UV-LED array or the power supply components, ML algorithms can forecast the end-of-life or efficiency degradation of critical parts, prompting maintenance alerts before failure impacts production quality or uptime. This shift toward self-diagnosing, autonomous curing tools represents the next generation of portable UV technology, ensuring higher reliability and enabling integration into Industry 4.0 infrastructures. The successful implementation of AI hinges on developing user-friendly interfaces that translate complex optimization algorithms into simple, actionable insights for technicians and maintenance staff operating in field or workshop settings.

- AI-Driven Parameter Optimization: Machine learning algorithms automatically adjust light intensity and exposure time based on real-time material feedback and environmental factors.

- Predictive Quality Assurance (PQA): AI models predict curing defects by analyzing spectral data and irradiance variance, ensuring process stability.

- Autonomous Calibration and Diagnostics: Integration of self-calibration routines and failure prediction based on historical performance data.

- Robotics Integration: Facilitating seamless use of portable UV heads by collaborative robots (cobots) in high-precision, repetitive tasks.

- Data Logging and Traceability: Automated, AI-validated logging of curing profiles for regulatory compliance and enhanced traceability across supply chains.

DRO & Impact Forces Of Portable UV Curing Machine Market

The Portable UV Curing Machine Market dynamics are shaped by a powerful confluence of driving forces, regulatory constraints, and emergent technological opportunities. Key drivers include the overwhelming industry demand for rapid production cycles, where the instantaneous curing capability of UV technology bypasses lengthy thermal drying processes, and the increasing global emphasis on sustainability, which favors solvent-free, low-VOC UV curable formulations. However, restraints such as the relatively high initial investment costs associated with advanced UV-LED systems and the specific material compatibility requirements (only certain materials are UV-curable) pose significant barriers to mass adoption in highly cost-sensitive sectors. The fundamental impact force propelling the market forward remains the continuous evolution of UV-LED technology, offering higher power output and broader wavelength availability, thereby addressing previous application limitations and opening new market avenues in demanding industrial repair and composite manufacturing.

A primary opportunity lies in the burgeoning medical device manufacturing sector, where stringent quality requirements and the need for sterile, precise bonding of sensitive materials create a high-value niche for portable, verifiable UV curing systems. Furthermore, market penetration can be significantly deepened in emerging economies through the introduction of modular, scalable, and affordable portable units tailored for small and medium-sized enterprises (SMEs) engaged in local repair and refinishing services. The impact of competitive forces is moderate, characterized by intense technological rivalry among leading manufacturers striving for irradiance leadership and system compactness, while the threat of substitutes remains relatively low due to the unique speed and performance advantages of UV technology over traditional heat or solvent-based curing methods.

The market is constantly reacting to external environmental pressures, most notably the impact force related to regulatory shifts, particularly in Europe and North America, favoring non-mercury, energy-efficient technologies. This regulatory push accelerates the transition to UV-LED based portable systems, creating a structured obsolescence for older arc lamp models and stimulating research into novel UV material chemistries. Ultimately, the market trajectory is defined by the critical need for versatility; users increasingly require portable units that can reliably cure a wide array of materials in unpredictable field conditions, pushing manufacturers toward developing robust, multi-wavelength, and smart-enabled portable curing solutions that minimize operator error and maximize curing uniformity.

Segmentation Analysis

The Portable UV Curing Machine Market is rigorously segmented based on key differentiators including the underlying lamp technology, the power range of the equipment, and the diverse industrial applications where these machines are deployed. This structured segmentation provides manufacturers and stakeholders with granular insights into market trends and growth pockets. The technological segmentation, differentiating between LED-based and traditional Arc Lamp systems, is currently the most dynamic area, reflecting the aggressive market shift towards energy efficiency and environmental compliance. Application segmentation is crucial as performance requirements vary drastically; for instance, curing requirements in high-speed electronics assembly differ significantly from those in rugged automotive repair or expansive composite manufacturing processes, necessitating tailored portable solutions.

Segmentation by power output dictates the suitability for specific tasks, ranging from low-power handheld devices used for cosmetic repairs or spot curing in laboratories, to medium and high-power systems designed for industrial-scale adhesive bonding and wide-area coating applications. This granularity assists purchasers in selecting equipment that provides the optimal balance between portability, curing speed, and depth of penetration. The overall market analysis confirms that while the application diversity continues to broaden, the performance demanded of portable systems consistently moves towards higher irradiance levels within smaller, lighter form factors, challenging engineering limits in thermal management and power delivery.

- By Lamp Type

- UV-LED (Light Emitting Diode)

- Mercury Arc Lamp (Traditional Systems)

- By Application

- Automotive (Repair and Refinishing)

- Electronics (PCB, Display Bonding, Conformal Coating Repair)

- Medical Devices (Bonding, Sterilization, Coating)

- Printing and Graphics Arts (Spot Curing, Specialty Inks)

- Adhesive and Sealant Curing (Industrial Assembly)

- Aerospace and Composites

- By Power Range

- Low Power (< 100 W/cm²)

- Medium Power (100 W/cm² to 500 W/cm²)

- High Power (> 500 W/cm²)

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Portable UV Curing Machine Market

The value chain for the Portable UV Curing Machine Market is characterized by a high degree of specialization and technical input, commencing with upstream suppliers who provide critical components. Upstream analysis focuses intensely on the procurement of high-performance UV-LED chips, often sourced from specialized semiconductor manufacturers, and advanced optical components (reflectors, lenses, filters) essential for precise light focusing and thermal dissipation. The complexity and proprietary nature of these components mean that suppliers often have significant bargaining power. Successful curing equipment manufacturers rely on robust relationships with these suppliers to ensure consistency in wavelength (typically 365 nm, 385 nm, or 405 nm) and guaranteed irradiance output, which are the fundamental determinants of the machine's efficacy and market value.

Midstream activities involve the design, assembly, and testing of the final portable units. This stage includes sophisticated thermal management engineering—critical for maintaining LED lifespan and output stability—and the integration of power electronics and control software. Manufacturers often differentiate themselves here through ergonomic design, battery life optimization, and incorporation of smart features like data logging and connectivity, which add considerable value. Quality control and certification (e.g., CE, UL) are paramount, especially for devices destined for regulated industries like medical or aerospace, adding complexity and cost to the manufacturing process.

Downstream distribution channels are segmented into direct sales, utilized for large industrial clients requiring custom solutions and direct technical support, and indirect sales, leveraging specialized industrial distributors, equipment resellers, and e-commerce platforms particularly for standard, off-the-shelf portable models. The crucial last step involves extensive customer training and after-sales service, as the proper use of these high-intensity light sources, coupled with specific material chemistry knowledge, is necessary to achieve optimal results. Indirect channels often rely on specialized third-party technical support networks to maintain customer satisfaction and market reach across disparate geographical locations and end-user segments.

Portable UV Curing Machine Market Potential Customers

Potential customers for portable UV curing machines represent a diverse cross-section of manufacturing, maintenance, and repair industries that demand rapid, localized, and reliable adhesive bonding or coating solidification. The primary buyers include Original Equipment Manufacturers (OEMs) in the electronics sector—specifically those involved in the assembly and repair of printed circuit boards (PCBs), consumer displays, and complex sensor units—where portable units are used for high-precision conformal coating spot repairs and secure component bonding. Another significant segment is the automotive repair and refinishing market, encompassing body shops and dedicated service centers that utilize these systems for accelerated paint repair, clear coat curing, and structural adhesive setting, significantly reducing vehicle turnaround time.

The medical device industry constitutes a rapidly growing, high-value customer base. Manufacturers require portable UV curing for assembling sensitive components like catheters, endoscopes, and various disposable diagnostic tools, where UV adhesives offer excellent strength and biocompatibility, and the portable nature allows for precise curing in cleanroom environments. Furthermore, industrial maintenance and field service technicians represent a recurring customer segment, using portable UV units for infrastructure repair, pipeline coating applications, and localized composite material repair in challenging or remote environments where large fixed equipment is infeasible.

Secondary buyers include specialty printers and graphic arts professionals needing localized curing for screen printing inks, digital inks, and specialty varnishes in small-batch or artistic production. Research and development laboratories, particularly those focused on material science and photochemistry, also represent key purchasers, relying on the flexibility and precise control offered by portable systems for material testing and process development. The core characteristic linking these diverse potential customers is the need for a non-thermal, fast, and highly reliable curing method that can be deployed flexibly outside of dedicated production lines, prioritizing efficiency and operational mobility.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 750 Million |

| Growth Rate | CAGR 11.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | IST METZ, Dymax Corporation, Excelitas Technologies, Heraeus Noblelight, Phoseon Technology, Nordson Corporation, Uvexis, Baldwin Technology, Hanovia, Lumen Dynamics, Miltec UV, UV-Technik Speziallampen, Honle Group, Jelight Company, Benford UV, Primarc, Clearstone Technologies, GEW (EC) Limited, CureUV, UViterno |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Portable UV Curing Machine Market Key Technology Landscape

The technological landscape of the Portable UV Curing Machine Market is overwhelmingly defined by the accelerating dominance of UV-LED (Ultraviolet Light Emitting Diode) technology. This shift represents a generational leap from traditional mercury vapor and arc lamps, driven primarily by the superior operational characteristics of LEDs: instantaneous on/off capability, significantly longer operational lifespan (often exceeding 20,000 hours compared to 1,000–2,000 hours for arc lamps), zero ozone generation, and focused, narrow-band wavelength emission. Manufacturers are heavily investing in enhancing the power density of these portable LED arrays, achieving irradiance levels previously only possible with large, fixed systems, thereby making them viable for curing thick-film coatings and deep-cure adhesives that require high energy doses.

A critical technical advancement involves thermal management systems. Since LED performance and lifespan are highly sensitive to heat, portable units now integrate sophisticated cooling mechanisms—often relying on advanced heat sinks, optimized airflow, or even liquid cooling in high-power models—to ensure consistent performance and prevent wavelength drift during prolonged operation in challenging environments. Furthermore, multi-wavelength technology is gaining traction, allowing a single portable unit to emit multiple, switchable wavelengths (e.g., 365 nm and 395 nm) to accommodate the diverse photoinitiator systems used in modern UV curable materials, greatly enhancing the equipment's versatility and addressing compatibility restraints that historically limited single-wavelength LED adoption.

The integration of smart electronics is another defining feature, incorporating microprocessors and sensors to monitor and control key curing parameters. These devices often include integrated radiometers for real-time irradiance measurement and data logging capabilities to ensure verifiable quality control (QC). This capability is paramount for regulatory compliance in industries such as medical devices and aerospace. Future technological focus is expected to concentrate on miniaturization, battery technology improvement for truly cordless high-power operation, and the incorporation of communication protocols (Bluetooth, Wi-Fi) for remote diagnostics and integration into centralized factory management systems (MES/SCADA), pushing the boundaries of true portability and connectivity.

Regional Highlights

- Asia Pacific (APAC) Market Dominance: APAC commands the largest market share and is projected to exhibit the highest growth rate, primarily driven by China, Japan, South Korea, and India. This region is the global hub for electronics manufacturing (including semiconductors and displays) and automotive production, demanding high volumes of portable UV curing equipment for precision assembly, bonding, and repair operations. The high concentration of contract manufacturers and the rapid adoption of automation technologies further fuel demand for efficient, portable curing solutions.

- North America's Regulatory Drive: North America holds a mature market characterized by early and widespread adoption of UV-LED technology, driven largely by stringent environmental regulations aimed at minimizing VOC emissions. The high-value medical device manufacturing sector in the US and Canada heavily utilizes portable UV curing for bonding specialized components in cleanroom environments, demanding systems with rigorous validation and traceability features. Technological innovation, particularly in high-power UV-LED systems and integration with robotics, defines this region.

- Europe's Emphasis on Industrial Maintenance: The European market, encompassing Germany, France, and the UK, shows significant uptake in the automotive repair, industrial coatings, and specialty printing sectors. Europe prioritizes energy efficiency and long-term sustainability, rapidly transitioning away from mercury-based systems in compliance with directives like RoHS. Demand is strong for portable units capable of large-area coverage for industrial maintenance and infrastructure repair applications.

- Latin America and MEA Emerging Opportunities: Latin America (LATAM) and the Middle East & Africa (MEA) are emerging markets, primarily driven by growth in localized infrastructure projects and the expansion of the regional automotive aftermarket. While adoption lags behind developed regions, the need for cost-effective, localized repair solutions is increasing, creating fertile ground for entry-level and medium-power portable UV curing solutions, particularly in countries like Brazil, Mexico, and the UAE.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Portable UV Curing Machine Market.- IST METZ

- Dymax Corporation

- Excelitas Technologies

- Heraeus Noblelight

- Phoseon Technology

- Nordson Corporation

- Uvexis

- Baldwin Technology

- Hanovia

- Lumen Dynamics

- Miltec UV

- UV-Technik Speziallampen

- Honle Group

- Jelight Company

- Benford UV

- Primarc

- Clearstone Technologies

- GEW (EC) Limited

- CureUV

- UViterno

Frequently Asked Questions

Analyze common user questions about the Portable UV Curing Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Portable UV Curing Machine Market?

The primary factor driving market growth is the widespread industry shift from traditional thermal or solvent-based curing methods to rapid, environmentally friendly UV-LED curing technology. This transition is motivated by the need for faster production throughput, enhanced energy efficiency, and compliance with strict environmental regulations mandating the reduction of Volatile Organic Compounds (VOCs).

How does UV-LED technology compare to traditional mercury arc lamps in portable devices?

UV-LED technology significantly outperforms mercury arc lamps in portable applications due to its longer lifespan (up to 10-20 times longer), instant on/off capability, superior energy efficiency, and the complete elimination of ozone generation. Furthermore, LEDs offer narrow-band, consistent wavelength output, which is crucial for high-precision, repeatable curing processes.

Which industry segment is the largest user of portable UV curing machines?

The Electronics sector, encompassing PCB assembly, display manufacturing, and consumer electronics repair, currently represents the largest application segment. Portable UV units are indispensable here for high-precision adhesive bonding, localized conformal coating repair, and ensuring the structural integrity of compact components without inducing thermal damage.

What are the main technical challenges for manufacturers of high-power portable UV systems?

The main technical challenge involves effective thermal management. Generating high irradiance levels in a compact, portable form factor produces significant heat, which must be efficiently dissipated to prevent LED degradation, maintain consistent wavelength output, and ensure the operational lifespan and reliability required by industrial standards.

How is Artificial Intelligence (AI) expected to influence the functionality of portable UV curing equipment?

AI is expected to transform functionality by enabling intelligent process control, using machine learning algorithms to dynamically adjust curing parameters (irradiance, exposure time) in real-time based on material feedback and environmental factors. This results in optimized curing profiles, minimized defects, and enhanced integration with Industry 4.0 automation systems for improved quality assurance and traceability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager