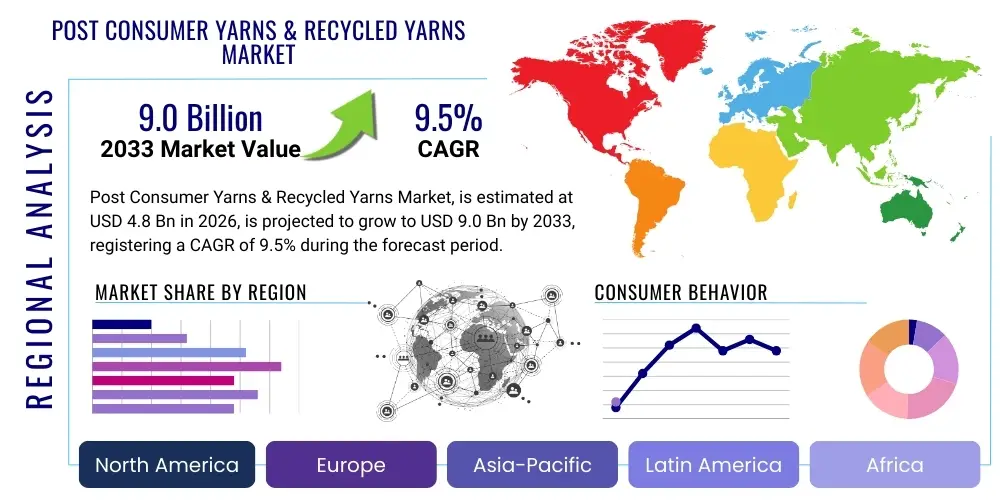

Post Consumer Yarns & Recycled Yarns Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434978 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Post Consumer Yarns & Recycled Yarns Market Size

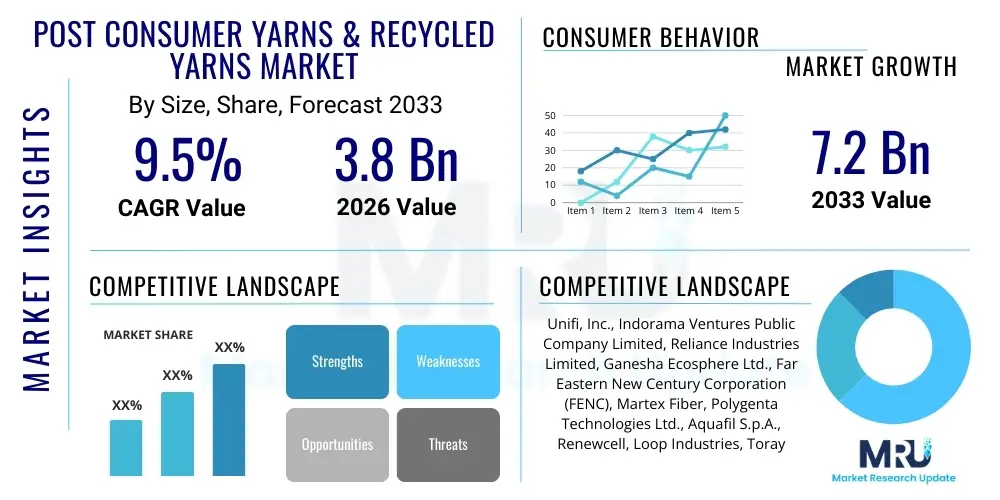

The Post Consumer Yarns & Recycled Yarns Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at USD 3.8 Billion in 2026 and is projected to reach USD 7.2 Billion by the end of the forecast period in 2033.

Post Consumer Yarns & Recycled Yarns Market introduction

The Post Consumer Yarns & Recycled Yarns Market encompasses the production and trade of fibers derived from waste materials, predominantly textile discards, used plastic bottles (PET), and other post-consumer waste streams. This segment is a critical component of the broader circular economy within the textile industry, aiming to minimize reliance on virgin resources and reduce landfill waste associated with fast fashion and single-use plastics. The core product involves spinning these recovered materials into usable yarns through processes such as mechanical recycling, which involves shredding and re-polymerization, or chemical recycling, which breaks down polymers to their original monomers for synthesis. These yarns offer a sustainable alternative to conventional fibers, maintaining comparable quality and performance characteristics necessary for high-end applications.

Major applications of recycled yarns span a wide array of consumer and industrial products, including apparel, footwear, home textiles (carpets, bedding), and the automotive sector (upholstery, interior components). The market is heavily driven by increasing consumer awareness regarding environmental responsibility, stringent governmental regulations mandating sustainable sourcing, and corporate commitments towards achieving net-zero emissions and promoting material circularity. These factors collectively establish a robust foundation for market expansion, pushing manufacturers across the supply chain to prioritize sustainable sourcing and integrate recycled content into their product offerings. The adoption is particularly accelerated in developed economies where consumers are willing to pay a premium for ethically and sustainably produced goods.

The principal benefits associated with the adoption of post-consumer and recycled yarns include significant reductions in water and energy consumption compared to virgin material production, lowered greenhouse gas emissions, and a tangible decrease in reliance on non-renewable fossil fuel resources, especially for synthetic fibers like polyester and nylon. Furthermore, recycling initiatives help mitigate the global plastic waste crisis, particularly in maritime environments, by transforming polyethylene terephthalate (PET) bottles and discarded fishing nets into valuable textile feedstock. These inherent environmental and economic benefits serve as powerful driving factors, supported by continuous technological advancements in sorting and de-polymerization processes, which enhance the quality, consistency, and scalability of recycled yarn production.

Post Consumer Yarns & Recycled Yarns Market Executive Summary

The global Post Consumer Yarns & Recycled Yarns Market is currently experiencing robust momentum, underpinned by transformative shifts in business ethics and regulatory landscapes emphasizing sustainability. Key business trends include the vertical integration of recycling technologies by major textile manufacturers and the proliferation of certification standards, such as the Global Recycled Standard (GRS) and Recycled Claim Standard (RCS), which provide necessary supply chain transparency and consumer trust. Furthermore, strategic collaborations between waste management entities and textile producers are streamlining the collection and segregation processes, crucial bottlenecks that previously hindered large-scale adoption. Corporate social responsibility mandates and stakeholder pressure are forcing brands to set ambitious targets for recycled content integration, driving sustained high demand across various end-use segments.

Regionally, the market exhibits differential growth rates influenced by local regulatory maturity and consumer purchasing power. Asia Pacific (APAC) stands out as a leading manufacturing hub and a rapidly growing consumption market, benefiting from large-scale textile production capacity, particularly in China and India. Europe, driven by the EU’s Green Deal and proactive legislation banning textile waste disposal, showcases the highest rate of innovation in chemical recycling technologies and premium sustainable product development. North America is characterized by significant investment in domestic recycling infrastructure and strong brand commitments from major sportswear and lifestyle companies, accelerating the transition away from conventional fibers. These regional variations create diverse opportunities for technological transfer and localized supply chain optimization.

Segmentation trends highlight the dominance of recycled polyester (rPET) derived from plastic bottles due to its cost-effectiveness, established infrastructure, and versatility, especially within the fast-fashion and sportswear sectors. However, the fastest-growing segment is expected to be recycled cotton, propelled by innovations in mechanical recycling that minimize fiber damage and enhance output quality, addressing concerns related to textile waste in mature markets. In terms of process, chemical recycling, while currently more capital intensive, is projected to gain substantial traction as it offers superior quality outputs capable of meeting the rigorous standards required for automotive and high-performance apparel applications, effectively closing the material loop for complex polymer mixes.

AI Impact Analysis on Post Consumer Yarns & Recycled Yarns Market

Users frequently inquire about how Artificial Intelligence (AI) can enhance the efficiency and scalability of textile recycling, particularly focusing on complex challenges like automated sorting, contamination detection, and optimizing chemical recycling processes. Key themes revolve around leveraging AI-driven computer vision systems to accurately identify and separate mixed textile waste streams, which is currently a major technical barrier. Concerns often address the required initial investment for sophisticated AI sorting infrastructure and the need for standardized material tagging (digital passports) to feed reliable data into AI models. Expectations are high regarding AI's potential to dramatically lower operational costs, improve the purity of recycled feedstock, and accelerate the development of novel recycling chemistries through data modeling and predictive analytics, ultimately making recycled yarns more cost-competitive with virgin alternatives.

- AI-enhanced sorting systems utilize hyperspectral imaging and machine learning algorithms to achieve high-purity separation of mixed fiber types, critical for high-quality recycling.

- Predictive maintenance analytics, powered by AI, optimize the operational uptime and energy efficiency of complex mechanical and chemical recycling plants.

- Supply chain transparency and traceability are significantly improved using AI to process data from RFID tags and blockchain records, verifying the origin and recycled content percentage of yarns.

- AI modeling accelerates R&D for chemical recycling by simulating reactions and optimizing de-polymerization conditions, enhancing yield and reducing processing time for challenging synthetic blends.

- Demand forecasting and inventory management benefit from AI, synchronizing the unstable supply of post-consumer waste feedstock with the variable production demands of yarn manufacturers.

DRO & Impact Forces Of Post Consumer Yarns & Recycled Yarns Market

The market growth is overwhelmingly driven by stringent environmental regulations, particularly in Europe and North America, alongside escalating consumer preference for sustainable products, creating immense pressure on brands to incorporate recycled content. However, the market faces significant restraints, primarily stemming from the variable quality and inconsistent supply of post-consumer textile waste (feedstock volatility), coupled with high initial capital expenditure required for advanced chemical recycling facilities. Opportunities lie prominently in the development of scalable chemical recycling technologies capable of processing blended fabrics, which currently represent the largest segment of landfill waste. Additionally, the expansion into high-value applications, such as medical textiles and technical performance wear, offers superior margin potential.

The key drivers include the global push toward a circular economy model, facilitated by corporate sustainability goals (e.g., targets set by major apparel brands to use 100% sustainable materials by 2030) and favorable tax incentives for green manufacturing. The primary restraint remains the logistical complexity and cost associated with collecting, sorting, and cleaning contaminated textile waste globally, which often requires manual labor or expensive, early-stage automated solutions. Technological limitations in efficiently separating dyes and complex polymer blends also inhibit the production of 'virgin-like' quality yarns from mixed textile input, limiting market penetration in quality-sensitive segments.

Impact forces acting upon the market involve both PESTEL factors and competitive dynamics. Regulatory forces, such as extended producer responsibility (EPR) schemes forcing accountability onto brands for end-of-life products, are the strongest external drivers. Economic forces, including the fluctuating prices of virgin polymers and fossil fuels, influence the cost competitiveness of recycled yarns. The competitive landscape is shaped by innovation in both mechanical (improving fiber length preservation) and chemical recycling (low-temperature de-polymerization), seeking to reduce processing costs and environmental footprint while achieving premium product specifications. These interacting forces collectively dictate the adoption rate and market valuation of recycled textile products globally.

Segmentation Analysis

The Post Consumer Yarns & Recycled Yarns Market is segmented based on the type of source material, the nature of the recycled material, the recycling process utilized, and the final application of the yarn. Analyzing these segments provides crucial insights into growth pockets and technological investment priorities. The Source Material segmentation reveals the market's dependence on readily available waste streams, with PET bottles currently dominating volumes. Conversely, the Process segmentation indicates a strategic shift towards chemical recycling as companies seek better quality and infinite recyclability, especially for synthetic fibers. These segmentations are vital for brands aiming to optimize their sustainable sourcing strategies.

The application segmentation is critical for understanding demand drivers, showing strong growth in the Apparel sector, particularly in the activewear and casual segments, where consumers readily accept recycled content. Home furnishing and automotive segments are also increasing their uptake, driven by durability and corporate procurement policies emphasizing sustainable materials. The continuous refinement of mechanical recycling processes has made recycled cotton suitable for blending with rPET, allowing for higher recycled content in diverse fabric structures, thus expanding the serviceable market significantly beyond initial expectations focused purely on polyester materials.

- Source Material:

- Post-Consumer PET Bottles (rPET)

- Post-Consumer Textile Waste (Pre- and Post-Consumer Garments/Scraps)

- Discarded Fishing Nets and Ocean Waste (Recycled Nylon)

- Other Plastic Waste Streams (HDPE, PP)

- Recycled Material Type:

- Recycled Polyester (rPET)

- Recycled Cotton

- Recycled Nylon/Polyamide

- Recycled Acrylic and Wool Blends

- Recycling Process:

- Mechanical Recycling (Physical reprocessing)

- Chemical Recycling (Depolymerization and Purification)

- Thermal Recycling

- Application:

- Apparel (Activewear, Casual Wear, Outerwear)

- Home Furnishings (Carpets, Upholstery, Bedding)

- Automotive (Interior Trim, Upholstery)

- Industrial and Technical Textiles (Geotextiles, Filtration)

Value Chain Analysis For Post Consumer Yarns & Recycled Yarns Market

The value chain for post-consumer yarns begins with complex upstream analysis focusing on waste collection, sorting, and preparation, which involves municipal waste handlers and specialized textile waste aggregators. The efficiency of this initial stage directly dictates the quality and cost of the feedstock. Midstream activities involve the actual recycling processes, whether mechanical (shredding, melting, spinning) or chemical (depolymerization, purification, repolymerization). Technological innovation at this stage determines the final yarn performance characteristics and certification compliance, establishing a crucial link between waste quality and market price.

Downstream analysis focuses on yarn processing, textile manufacturing, and final product fabrication. Recycled yarn producers sell directly to spinning mills or integrated fabric manufacturers who then supply textiles to major brand houses in the apparel, home goods, and automotive sectors. The shift towards transparency and traceability is integrated throughout the downstream chain, often relying on blockchain technology to authenticate the journey of the recycled material from waste bin to retail shelf. Direct distribution primarily occurs for high-volume, standardized products like rPET yarns sold to large-scale textile processors.

Indirect distribution involves intermediaries such as specialized fiber distributors and agents, particularly in fragmented markets or for niche recycled materials like unique fiber blends or chemically recycled output sold at a premium. The increasing prevalence of certification bodies like GRS and RCS ensures that both direct and indirect channels adhere to verifiable environmental claims. The efficacy of the entire value chain is dependent on robust reverse logistics capabilities and effective cross-industry collaboration between waste management, chemical companies, and textile manufacturers to ensure a continuous, high-quality material loop.

Post Consumer Yarns & Recycled Yarns Market Potential Customers

The primary end-users and buyers of post-consumer and recycled yarns are large, multinational apparel and footwear corporations that have committed publicly to substantial reductions in virgin material usage, driven by Environmental, Social, and Governance (ESG) mandates and strong brand positioning goals. This includes major sportswear brands and fast-fashion retailers seeking scalable, cost-effective recycled polyester, as well as luxury brands exploring high-quality recycled nylon and specialty fibers for premium collections. These customers demand stringent quality control, consistent supply, and verified certification standards to back their marketing claims of sustainability.

Another significant customer segment is the home furnishing industry, including manufacturers of carpets, upholstery, and bedding, who utilize these yarns for durable and aesthetically pleasing applications. This sector is motivated by longevity and the desire to meet green building standards or consumer preference for eco-friendly home products. Furthermore, automotive manufacturers represent a growing customer base, integrating recycled fibers into interior components to meet tightening regulatory requirements for material sustainability and reduce vehicle weight, often prioritizing recycled polyester and polypropylene for their resilience and performance properties.

In addition to these major industries, potential customers include technical textile producers specializing in geotextiles, medical textiles, and protective wear, where the performance characteristics of certain chemically recycled polymers can be advantageous. Government and institutional procurement agencies, often operating under mandates to choose sustainable options, also constitute a stable customer base, particularly for items such as uniforms and office textiles. These diversified end-users create a resilient demand structure across multiple economic sectors, reducing market dependency on any single industry.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.8 Billion |

| Market Forecast in 2033 | USD 7.2 Billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Unifi, Inc., Indorama Ventures Public Company Limited, Reliance Industries Limited, Ganesha Ecosphere Ltd., Far Eastern New Century Corporation (FENC), Martex Fiber, Polygenta Technologies Ltd., Aquafil S.p.A., Renewcell, Loop Industries, Toray Industries, Inc., Teijin Limited, Bemberg, Wellman International, Leigh Fibers, Haggar Group, Patagonia (Supply Chain), Lenzing AG, Birla Cellulose, Huvis Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Post Consumer Yarns & Recycled Yarns Market Key Technology Landscape

The technology landscape in the Post Consumer Yarns & Recycled Yarns Market is defined by a dichotomy between highly scalable, established mechanical recycling methods and nascent, high-potential chemical recycling processes. Mechanical recycling, primarily used for rPET and cotton, relies on physical processing like washing, shredding, melting, and re-extrusion. Advancements here focus on optimizing fiber integrity during shredding to minimize length degradation, improving the output quality of recycled cotton suitable for open-end spinning, and enhancing automated sorting using spectroscopic analysis to ensure cleaner input streams.

Chemical recycling represents the technological frontier, particularly for synthetic fibers like polyester and nylon, offering the capability to return polymers to their monomer form, thus producing materials chemically identical to virgin fibers. Key technologies include glycolysis, methanolysis, and hydrolysis for PET, and depolymerization for nylon (e.g., Aquafil's ECONYL system for fishing nets). Investment is heavily channeled into developing economically viable and environmentally benign solvents and catalysts, capable of separating complex blended fabrics into constituent raw materials without significant loss of quality, thereby overcoming the blending barrier inherent in textile waste.

Further technological innovations include advanced decontamination processes, necessary to remove dyes, finishes, and persistent organic pollutants from waste textiles, ensuring the final yarn meets stringent safety and regulatory standards for sensitive applications, such as baby clothing and medical uses. Furthermore, integration with digital technologies like Internet of Things (IoT) sensors and Artificial Intelligence (AI) for real-time monitoring of feedstock quality and process parameters is crucial for improving efficiency, reducing waste within the recycling plants, and achieving the consistent quality required for widespread market adoption across diverse end-use sectors.

Regional Highlights

The geographic analysis reveals that market growth and technological adoption are unevenly distributed, primarily influenced by regional environmental policies, manufacturing capacities, and consumer demands. Asia Pacific (APAC) currently holds the dominant market share in terms of volume, largely driven by its established role as the world's largest textile manufacturing hub, especially for recycled polyester derived from PET bottles. Countries like China, India, and Vietnam are increasingly investing in sophisticated recycling infrastructure to meet global demand for sustainably sourced materials, benefiting from readily available waste streams, though regulatory enforcement on textile waste remains variable compared to Western counterparts.

Europe represents the fastest-growing region in terms of innovation and regulatory push, spearheaded by the European Union’s Circular Economy Action Plan and upcoming mandates on textile collection and recycling. This region is a leader in developing cutting-edge chemical recycling technologies and implementing Extended Producer Responsibility (EPR) schemes that place financial responsibility for end-of-life management onto textile companies. Germany, France, and the Nordic countries are pioneering advanced automated sorting and fiber-to-fiber recycling plants, focusing on high-value applications and minimizing environmental impact through cleaner processes.

North America, particularly the United States, is characterized by strong commitments from major consumer brands (Apparel and Automotive) and significant private sector investment in domestic recycling infrastructure, aiming to reduce reliance on Asian suppliers. While the adoption rate of mechanical recycling is high, the market is actively exploring chemical recycling solutions to tackle complex municipal solid waste streams. Consumer awareness and willingness to pay for certified sustainable products are exceptionally high here, creating a premium market for traceable, high-quality recycled fibers.

- Asia Pacific (APAC): Dominates manufacturing volume, led by China and India; focuses primarily on rPET production and rapid adoption of large-scale mechanical recycling due to robust supply chains.

- Europe: Exhibits the highest innovation rate, driven by strict regulatory frameworks (EU Green Deal) and heavy investment in chemical recycling facilities to achieve true material circularity.

- North America: Strong brand commitment and high consumer willingness to pay for sustainability; significant investment in localized, technologically advanced sorting and recycling facilities to meet domestic demand.

- Latin America (LATAM): Emerging market showing increasing focus on waste collection infrastructure development, primarily focusing on rPET for domestic consumption and export markets, driven by regional environmental pressures.

- Middle East and Africa (MEA): Limited current market penetration but high potential for future growth, particularly in regions addressing plastic waste management through textile upcycling initiatives and investments in local manufacturing capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Post Consumer Yarns & Recycled Yarns Market.- Unifi, Inc.

- Indorama Ventures Public Company Limited

- Reliance Industries Limited

- Ganesha Ecosphere Ltd.

- Far Eastern New Century Corporation (FENC)

- Martex Fiber

- Polygenta Technologies Ltd.

- Aquafil S.p.A.

- Renewcell

- Loop Industries

- Toray Industries, Inc.

- Teijin Limited

- Bemberg

- Wellman International

- Leigh Fibers

- Haggar Group

- Patagonia (Supply Chain Influence)

- Lenzing AG

- Birla Cellulose

- Huvis Corporation

Frequently Asked Questions

Analyze common user questions about the Post Consumer Yarns & Recycled Yarns market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between mechanical and chemical recycling for yarns?

Mechanical recycling physically processes waste (shredding, melting) to create new yarn, which can degrade fiber quality over cycles. Chemical recycling breaks down polymers into their basic monomers, allowing the synthesis of 'virgin-like' quality yarn, enabling infinite recycling loops.

Which material segment currently drives the largest volume in the recycled yarns market?

Recycled Polyester (rPET), derived predominantly from post-consumer PET bottles, currently drives the largest market volume due to established collection infrastructure, cost-effectiveness, and versatility in apparel and home furnishings applications.

What are the main regulatory factors accelerating market growth for recycled yarns?

Key accelerators include the implementation of Extended Producer Responsibility (EPR) schemes, mandatory sustainable sourcing targets set by governments, and the EU’s forthcoming legislation banning or restricting textile waste from landfills by 2025.

What is the biggest challenge in scaling up high-quality post-consumer textile recycling?

The primary challenge is feedstock volatility and inconsistency, specifically the difficulty and high cost associated with accurately sorting mixed, complex textile waste streams, especially colored and blended fabrics, which compromises the purity required for advanced recycling processes.

How does the Post Consumer Yarns market contribute to the circular economy?

It closes the material loop by diverting waste from landfills and oceans, reducing the need for virgin resources (like petroleum or water-intensive cotton farming), and regenerating materials into high-value products, thereby minimizing environmental footprint and promoting resource efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager