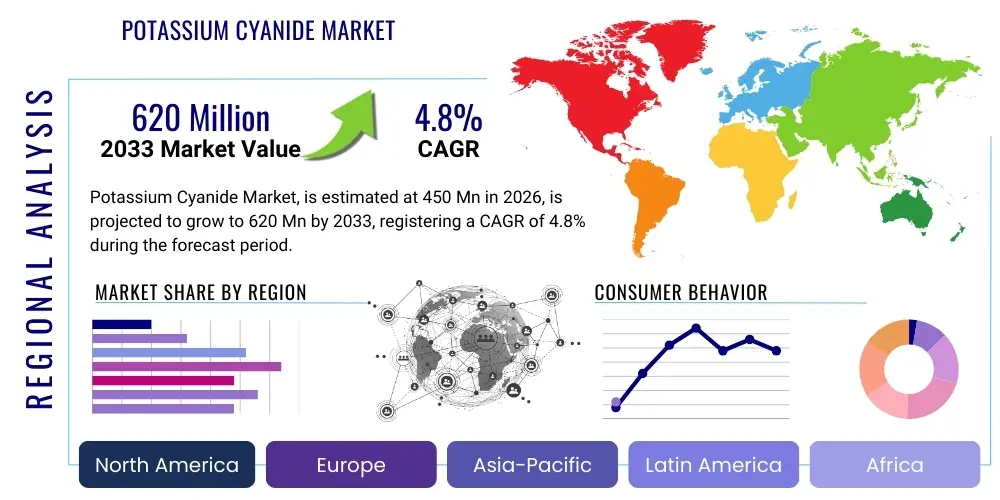

Potassium Cyanide Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439342 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Potassium Cyanide Market Size

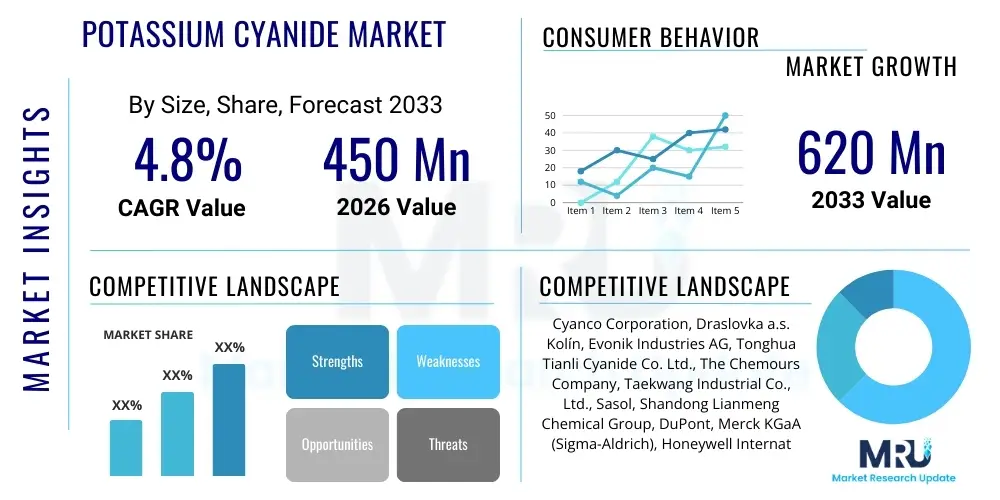

The Potassium Cyanide Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 620 Million by the end of the forecast period in 2033.

Potassium Cyanide Market introduction

Potassium cyanide (KCN) is a highly toxic inorganic compound, a salt with the formula KCN, widely recognized for its critical role in various industrial processes, despite its inherent dangers. It is typically a white crystalline solid, soluble in water, and smells faintly of bitter almonds, though not everyone can detect this odor. Its potent chemical properties, particularly its ability to form stable complexes with metals, make it indispensable in sectors such as mining and metallurgy, electroplating, and chemical synthesis. The market for potassium cyanide is characterized by stringent regulatory oversight, high safety standards, and continuous efforts to mitigate environmental and health risks associated with its production, handling, and disposal, making its demand a reflection of industrial necessity balanced against significant hazard management.

The primary application of potassium cyanide lies in the extraction of gold and silver from ores, a process known as cyanidation. This method leverages KCN's strong affinity for precious metals, forming soluble metal-cyanide complexes that can then be separated and reduced to pure metal. Beyond precious metal recovery, it is extensively used in the electroplating industry for depositing a smooth, bright, and durable finish of metals like gold, silver, copper, and brass onto various substrates. This application is crucial for manufacturing electronics, jewelry, and automotive components where surface properties are paramount. Furthermore, potassium cyanide serves as an essential reagent in organic synthesis, particularly in the production of nitriles, which are precursors to a wide array of pharmaceuticals, polymers, and other fine chemicals.

Despite its hazards, the continued demand for potassium cyanide is driven by its unparalleled efficiency and cost-effectiveness in certain industrial processes where alternatives either lack performance or are economically unviable. The benefits, from an industrial perspective, include high efficiency in gold leaching, precision in electroplating bath control, and its role as a versatile building block in complex chemical reactions. Global economic growth, particularly the increasing demand for gold as an investment and in jewelry, coupled with the expansion of the electronics and automotive industries that rely on electroplated components, continues to underpin the market’s stability and projected growth, albeit under tight regulatory scrutiny and continuous innovation for safer handling and application methods.

Potassium Cyanide Market Executive Summary

The global Potassium Cyanide market is experiencing a dynamic interplay of persistent industrial demand and evolving regulatory pressures. Business trends indicate a focus on optimizing supply chains for enhanced safety and security, driven by the hazardous nature of the product. Manufacturers are increasingly investing in advanced production technologies to improve purity and reduce environmental footprint, while also exploring vertical integration to gain better control over raw material sourcing and distribution. There is a discernible shift towards long-term contracts with established, compliant end-users to ensure market stability, rather than pursuing opportunistic sales. Furthermore, the market is witnessing a consolidation among smaller players or strategic alliances to leverage economies of scale and meet the rigorous compliance standards imposed by global regulatory bodies, emphasizing responsible stewardship throughout the product lifecycle.

Regional trends reveal a robust demand from the Asia Pacific region, primarily fueled by extensive gold mining operations in countries like China and Australia, along with a rapidly expanding electronics and manufacturing base that relies heavily on electroplating. North America and Europe, while having mature markets, are characterized by stringent environmental and safety regulations, necessitating continuous innovation in safer application techniques and waste management practices. Latin America, particularly countries with significant gold and silver reserves, also contributes substantially to the demand, often balancing economic development with increasing environmental consciousness. The Middle East and Africa regions present emerging opportunities, as new mining projects are initiated, although these areas typically face challenges related to infrastructure and adherence to international safety standards, making them areas of significant potential for growth tempered by operational complexities.

Segmentation analysis highlights that the gold extraction segment remains the largest consumer of potassium cyanide, directly linked to the fluctuating global prices of gold and silver and the profitability of mining operations. The electroplating segment, serving industries like automotive, aerospace, and consumer electronics, demonstrates steady growth, driven by the demand for high-performance and aesthetically pleasing metallic finishes. The chemical synthesis segment, though smaller in volume, is critical for the production of a diverse range of fine chemicals and pharmaceuticals, reflecting its indispensable role as a chemical intermediate. Purity grades and specific formulations are also becoming increasingly important, with high-purity grades fetching premium prices due to their requirement in sensitive applications. The market structure thus reflects a balance between high-volume, commodity-like applications and niche, high-value specialized uses, each with distinct demand drivers and regulatory challenges.

AI Impact Analysis on Potassium Cyanide Market

The integration of Artificial Intelligence (AI) in the Potassium Cyanide market, while not directly altering the chemical's intrinsic properties or primary applications, is poised to significantly enhance operational efficiency, safety protocols, and supply chain management. Users frequently question how AI can mitigate the inherent risks associated with such a hazardous substance, optimize its industrial use, and contribute to sustainability efforts. Key themes revolve around leveraging AI for predictive analytics in demand forecasting, real-time monitoring of manufacturing processes to ensure purity and reduce waste, and developing sophisticated risk assessment models for transportation and storage. There's an expectation that AI will lead to more robust regulatory compliance, improved environmental safeguards through smarter waste treatment, and potentially accelerate research into safer alternatives or more efficient detoxification methods, thereby transforming the landscape of this highly regulated chemical market by introducing layers of intelligence and automation previously unavailable.

- AI-driven predictive analytics optimize supply chain logistics, minimizing transportation risks and ensuring timely delivery for critical industrial operations.

- Real-time process monitoring using AI enhances safety and efficiency in KCN manufacturing, detecting anomalies and ensuring consistent product purity.

- AI algorithms improve environmental compliance by optimizing waste treatment processes and predicting potential emission points, reducing ecological impact.

- Advanced AI models can simulate and optimize gold extraction processes, leading to higher recovery rates and reduced KCN consumption, enhancing resource efficiency.

- Machine learning aids in the development of new, safer handling and storage protocols by analyzing vast datasets of incident reports and environmental conditions.

- AI can accelerate research and development for less hazardous alternatives or more effective detoxification agents by sifting through chemical libraries and predicting reaction outcomes.

- Automated monitoring systems powered by AI provide continuous surveillance of KCN facilities, alerting personnel to potential leaks or security breaches immediately.

DRO & Impact Forces Of Potassium Cyanide Market

The Potassium Cyanide market operates under a complex set of drivers, restraints, opportunities, and pervasive impact forces that collectively shape its trajectory. A primary driver is the persistent global demand for gold, which necessitates efficient extraction methods where cyanidation remains the most economically viable and widely adopted technology. Concurrently, the growth of the electronics, automotive, and jewelry industries fuels demand for high-quality electroplating processes, in which potassium cyanide plays a crucial, often irreplaceable, role for achieving specific finishes. Furthermore, its irreplaceable function as a key intermediate in the synthesis of various fine chemicals and pharmaceuticals ensures a steady, albeit niche, demand. These intrinsic industrial requirements are the fundamental propellers of the market, ensuring its resilience despite significant challenges, as industries seek efficient and cost-effective solutions for their core processes.

Conversely, the market is significantly restrained by the extreme toxicity of potassium cyanide, which necessitates stringent regulatory frameworks globally. These regulations impose substantial costs on production, transportation, storage, and disposal, limiting market access and increasing operational overheads for manufacturers and users alike. Public apprehension regarding its hazards, coupled with strong environmental activism, further restricts its application and drives the search for less hazardous alternatives, albeit often at a higher cost or with reduced efficacy. The high financial and reputational risks associated with accidents involving KCN also act as a powerful deterrent. Moreover, fluctuations in the price of gold can directly impact the profitability and activity levels of the mining sector, creating demand volatility for potassium cyanide in its largest application segment, thereby introducing an element of market instability.

Opportunities within the Potassium Cyanide market primarily stem from continuous innovation aimed at enhancing safety, efficiency, and sustainability. This includes the development of advanced technologies for safer handling, storage, and transportation, as well as improved detoxification methods that reduce environmental impact. Research into more environmentally friendly and equally effective gold extraction processes, even if not fully replacing KCN, can open new avenues for integrated solutions. Additionally, the growing demand for high-purity metals and specialized chemical compounds in emerging industries presents niche growth opportunities where KCN's precision capabilities are highly valued. Furthermore, expanding industrialization in developing economies, particularly those with significant natural resources, could drive new demand provided strict regulatory and safety standards are adhered to. The overarching impact forces include the volatile global gold market, increasingly stringent environmental and safety regulations, technological advancements in alternative processes, and the unwavering demand from critical industrial applications, all of which constantly influence market dynamics and strategic decisions.

Segmentation Analysis

The Potassium Cyanide market is comprehensively segmented to provide a granular view of its diverse applications and end-user industries. This segmentation is crucial for understanding the various demand drivers, regulatory influences, and competitive landscapes across different market verticals. Primarily, the market is segmented by application, purity grade, and end-use industry, each category revealing distinct consumption patterns and growth potentials. The dominance of certain segments underscores the compound's critical, albeit highly specialized, roles in global industry, necessitating tailored approaches for product development, distribution, and regulatory compliance. Analyzing these segments allows stakeholders to identify key growth areas, assess market saturation, and strategize for future expansion or risk mitigation within specific industrial contexts.

- By Application:

- Gold Extraction: The largest segment, driven by global gold prices and mining activity.

- Electroplating: Critical for various industries including electronics, automotive, and jewelry.

- Chemical Synthesis: Essential reagent in the production of nitriles and other organic compounds.

- Analytical Reagents: Used in laboratories for specific chemical tests and analyses.

- Other Applications: Includes niche uses in photography (historical), heat treatment, and specialized industrial processes.

- By Purity Grade:

- Industrial Grade: For large-scale industrial applications like mining and basic electroplating.

- Reagent Grade: Higher purity, used in laboratories and for specific chemical synthesis.

- High Purity Grade: For highly sensitive applications, often in electronics or specialized chemical manufacturing.

- By End-Use Industry:

- Mining & Metallurgy: The primary end-user, encompassing gold, silver, and other precious metal extraction.

- Electronics & Electrical: For electroplating components, connectors, and printed circuit boards.

- Chemicals & Pharmaceuticals: As a precursor for synthesizing various chemical intermediates and active pharmaceutical ingredients.

- Jewelry: For gold and silver plating to enhance aesthetics and durability.

Value Chain Analysis For Potassium Cyanide Market

The value chain for Potassium Cyanide is intricate and highly regulated, beginning with the upstream sourcing of raw materials. The primary raw materials typically include hydrogen cyanide (HCN) and potassium hydroxide (KOH), both of which require specialized manufacturing processes and handling due to their hazardous nature. Upstream analysis involves assessing the availability, cost stability, and regulatory compliance of these precursor chemicals. Key considerations at this stage include the energy-intensive nature of HCN production, which often relies on natural gas or ammonia, and the economic viability of KOH sourcing. Suppliers of these raw materials must adhere to strict safety standards and possess robust logistical capabilities to ensure a secure and uninterrupted supply to KCN manufacturers. The quality and purity of these initial inputs directly impact the quality and cost-effectiveness of the final potassium cyanide product, necessitating strong supplier relationships and rigorous quality control measures.

Midstream activities involve the synthesis and purification of potassium cyanide. This stage is dominated by specialized chemical manufacturers equipped with advanced production facilities designed to handle extremely toxic substances safely and efficiently. Processes like the Castner process (reacting hydrogen cyanide with potassium hydroxide) or other proprietary methods are employed. Manufacturers focus on achieving desired purity grades—industrial, reagent, or high purity—to meet diverse application requirements. Significant investment is made in closed-loop systems, advanced filtration, and waste treatment technologies to prevent environmental contamination and ensure worker safety. Regulatory compliance, including permitting, environmental impact assessments, and occupational health and safety standards, forms a critical part of the midstream value proposition, as non-compliance can lead to severe penalties, operational shutdowns, and reputational damage. Continuous process optimization to reduce costs and improve product consistency is a key strategic imperative at this stage.

Downstream activities involve the distribution, sales, and end-use of potassium cyanide, followed by its responsible disposal or detoxification. Distribution channels are highly specialized, relying on a limited number of certified logistics providers capable of transporting hazardous materials in compliance with international and local regulations. Direct sales often occur from manufacturers to large-scale industrial end-users like major mining companies or electroplating firms, allowing for closer technical support and bulk delivery. Indirect channels involve distributors or agents who manage smaller volumes and cater to diverse industrial users or research laboratories, often requiring specialized packaging and localized compliance knowledge. Post-use, the responsible management of cyanide waste, including detoxification processes and secure disposal, constitutes a critical and costly part of the value chain. This downstream responsibility extends to ensuring end-users are equipped with the knowledge and facilities to handle KCN safely and dispose of residues in an environmentally sound manner, thereby completing the cycle of stewardship for this hazardous but essential chemical.

Potassium Cyanide Market Potential Customers

The primary potential customers for potassium cyanide are concentrated within heavy industries and specialized manufacturing sectors where its unique chemical properties are indispensable. Heading this list are companies engaged in the mining and metallurgy sector, particularly those involved in the extraction of precious metals such as gold and silver. These mining corporations, ranging from multinational giants to smaller regional operators, rely on potassium cyanide for its unparalleled efficiency in the cyanidation process, which remains the most cost-effective and widespread method for recovering minute quantities of precious metals from ore. The scale of operation and the specific ore characteristics dictate the volume and purity of KCN required, making this segment a consistently significant consumer base, directly tied to global commodity prices and exploration activity, and demanding reliable supply chains capable of handling hazardous materials.

Another substantial segment of potential customers includes companies within the electroplating industry. This encompasses manufacturers in the electronics sector producing printed circuit boards, connectors, and other components requiring precise metallic coatings; automotive parts suppliers needing corrosion-resistant or decorative finishes; and jewelry manufacturers applying gold, silver, or rhodium plating. These businesses demand potassium cyanide for its ability to form stable complexes that enable uniform and high-quality deposition of various metals. The precise control offered by cyanide-based electroplating baths is often superior to alternatives for specific applications, making KCN an essential input. The growth in consumer electronics and electric vehicle manufacturing continues to drive demand from this segment, necessitating suppliers to offer consistent product quality and technical support for optimal bath management.

Beyond these two dominant sectors, potential customers also include a diverse array of chemical and pharmaceutical manufacturers, as well as research and development laboratories. In the chemical industry, potassium cyanide serves as a vital reagent for organic synthesis, especially in the production of nitriles which are key intermediates for polymers, agrochemicals, and various fine chemicals. Pharmaceutical companies use KCN as a precursor in synthesizing specific active pharmaceutical ingredients (APIs). Research laboratories across academia and industry utilize reagent-grade potassium cyanide for analytical testing, complex chemical reactions, and material science research. While these segments represent smaller volumetric demand compared to mining, they require extremely high purity grades and specialized packaging, often forming critical, high-value niches within the broader market that emphasize strict quality control and reliable, traceable sourcing from their suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 620 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Cyanco Corporation, Draslovka a.s. Kolín, Evonik Industries AG, Tonghua Tianli Cyanide Co. Ltd., The Chemours Company, Taekwang Industrial Co., Ltd., Sasol, Shandong Lianmeng Chemical Group, DuPont, Merck KGaA (Sigma-Aldrich), Honeywell International Inc., Avantor, Santa Cruz Biotechnology, Inc., Gelest Inc., Alfa Aesar (Thermo Fisher Scientific), Aldon Corporation, American Elements, Chem-Impex International Inc., Spectrum Chemical Mfg. Corp., Tokyo Chemical Industry Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Potassium Cyanide Market Key Technology Landscape

The technology landscape for the Potassium Cyanide market is primarily focused on optimizing its production, ensuring utmost safety in handling, and developing advanced methods for waste management, rather than revolutionary new applications of the chemical itself. Manufacturing processes, such as the Castner process (reacting hydrogen cyanide with potassium hydroxide) or other variants involving formamide, are well-established but continuously refined for improved efficiency, purity, and environmental control. This involves advancements in reactor design, material science for corrosion resistance, and energy optimization to reduce operational costs. The integration of process automation and real-time analytical techniques, such as spectroscopic methods and chromatographic analysis, ensures consistent product quality and immediate detection of impurities or deviations from standard operating parameters, thereby enhancing safety and product reliability for end-users requiring specific purity grades.

A significant area of technological innovation lies in the safe storage, transportation, and application of potassium cyanide. This includes the development of robust, leak-proof packaging and container systems engineered to withstand extreme conditions and prevent accidental exposure during transit. Advanced monitoring systems, incorporating sensors and IoT technologies, are deployed in storage facilities to detect airborne cyanide, manage ventilation, and provide immediate alerts in case of a breach or leak. In mining operations, technologies like carbon-in-pulp (CIP) and carbon-in-leach (CIL) methods, while not new, are continually optimized through better reagent control, aeration techniques, and tailored carbon adsorption processes to maximize gold recovery while minimizing KCN consumption and potential release into the environment. These application technologies are crucial for efficient resource utilization and mitigating the environmental footprint associated with large-scale industrial use.

Furthermore, the technological landscape extends to sophisticated detoxification and waste treatment solutions, which are paramount given potassium cyanide's toxicity. Technologies such as alkaline chlorination, hydrogen peroxide oxidation, and biological treatment methods are extensively researched and deployed to convert cyanide compounds into less toxic substances before discharge or disposal. Innovations in bioremediation, using specialized microorganisms to break down cyanide, offer more environmentally friendly alternatives for certain applications. Real-time online analyzers capable of monitoring cyanide levels in effluent streams ensure compliance with stringent discharge limits. Research also continues into developing "cyanide-free" or "low-cyanide" alternatives for gold extraction or electroplating, although these often present trade-offs in terms of cost, efficiency, or broader applicability. The overall technological drive in this market is toward achieving a balance between industrial effectiveness and enhanced environmental stewardship and safety management throughout the product lifecycle.

Regional Highlights

- Asia Pacific: Dominates the market due to extensive gold mining activities in countries like China, Australia, and Indonesia, coupled with a rapidly expanding electronics and automotive manufacturing base that drives demand for electroplating. Stringent environmental regulations are increasingly influencing operational practices, pushing for safer technologies.

- North America: A mature market characterized by advanced mining technologies in the US and Canada and significant demand from the electronics and chemical synthesis sectors. The region benefits from robust regulatory frameworks and a focus on high-purity chemical production.

- Europe: Features a specialized market driven by the chemical and pharmaceutical industries, as well as high-value electroplating applications. Strict environmental and occupational safety regulations mandate high standards for production and use, fostering innovation in safer handling and waste management.

- Latin America: A significant region for gold and silver mining, particularly in countries like Peru, Mexico, and Brazil, leading to substantial demand for potassium cyanide. The market here is sensitive to commodity price fluctuations and evolving local environmental policies.

- Middle East and Africa (MEA): Emerging market with increasing mining exploration and production, especially in South Africa and West African nations. Growth is anticipated with new investments in mining projects, though challenges related to infrastructure and regulatory enforcement remain.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Potassium Cyanide Market.- Cyanco Corporation

- Draslovka a.s. Kolín

- Evonik Industries AG

- Tonghua Tianli Cyanide Co. Ltd.

- The Chemours Company

- Taekwang Industrial Co., Ltd.

- Sasol

- Shandong Lianmeng Chemical Group

- DuPont

- Merck KGaA (Sigma-Aldrich)

- Honeywell International Inc.

- Avantor

- Santa Cruz Biotechnology, Inc.

- Gelest Inc.

- Alfa Aesar (Thermo Fisher Scientific)

- Aldon Corporation

- American Elements

- Chem-Impex International Inc.

- Spectrum Chemical Mfg. Corp.

- Tokyo Chemical Industry Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Potassium Cyanide market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary industrial uses of Potassium Cyanide?

Potassium cyanide is predominantly used in the extraction of gold and silver from ores (cyanidation) and in the electroplating industry for depositing a range of metals like gold, silver, and copper. It also serves as a crucial reagent in organic chemical synthesis for producing nitriles, which are precursors to pharmaceuticals and polymers.

How is the Potassium Cyanide market affected by environmental regulations?

Environmental regulations significantly impact the Potassium Cyanide market by mandating stringent safety protocols for production, storage, transportation, and disposal. These regulations drive up operational costs, encourage investment in safer technologies, and push for the development of effective waste treatment and detoxification methods to minimize environmental contamination.

Are there safer alternatives to Potassium Cyanide for gold extraction?

While research into less hazardous alternatives for gold extraction is ongoing (e.g., thiourea, thiosulfate, halide-based methods), potassium cyanide remains the most economically viable and efficient option for many large-scale operations. Alternatives often present trade-offs in cost, efficiency, or specific application suitability, leading to limited widespread adoption currently.

What are the key drivers for the growth of the Potassium Cyanide market?

The key drivers include the sustained global demand for gold, the expansion of the electronics and automotive industries which rely on electroplating for various components, and its irreplaceable role as a reagent in specific chemical synthesis processes. Industrialization in emerging economies further contributes to market growth.

How is AI impacting the safety and efficiency of Potassium Cyanide use?

AI is impacting the market by enhancing safety through predictive analytics for risk assessment and real-time monitoring of facilities. It improves efficiency in manufacturing processes, optimizes supply chain logistics, and aids in developing advanced waste treatment methods, leading to more responsible and controlled use of the chemical.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager