Powder Auger Fillers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431483 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Powder Auger Fillers Market Size

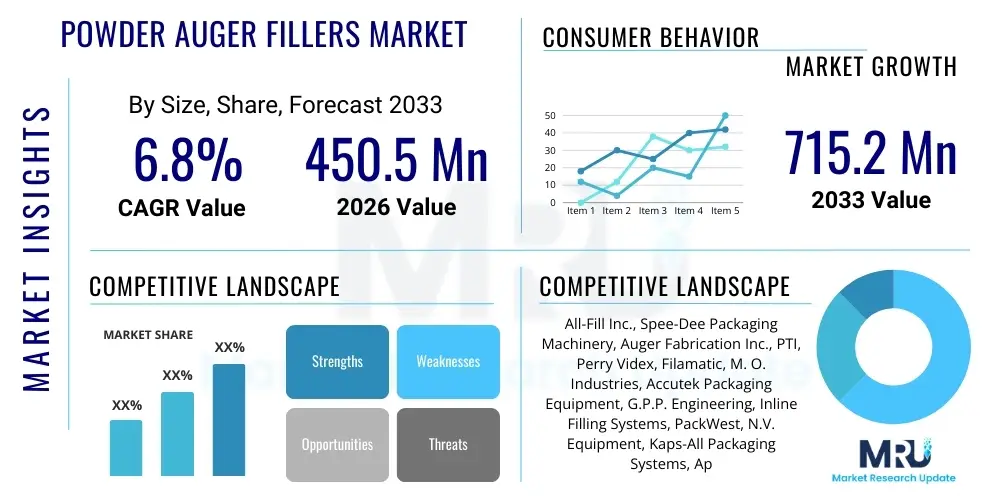

The Powder Auger Fillers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 715.2 Million by the end of the forecast period in 2033.

Powder Auger Fillers Market introduction

The Powder Auger Fillers Market encompasses the machinery and systems specifically designed for accurately measuring and dispensing powdered or granular products into various containers, such as bottles, pouches, jars, and cartons. Auger fillers utilize a precision-machined screw (the auger) rotating within a hopper to control the volume or weight of product released. These systems are critical for industries requiring high precision, especially when handling free-flowing or non-free-flowing powders, including flour, coffee, spices, chemical compounds, pharmaceuticals, and cosmetic powders. Market growth is fundamentally driven by the escalating demand for automated packaging solutions that can enhance throughput, minimize product giveaway, and maintain strict regulatory compliance across global manufacturing sectors.

Powder auger fillers are categorized primarily by their degree of automation (semi-automatic, automatic, and high-speed rotary systems) and the filling methodology employed (volumetric or gravimetric). Volumetric filling relies on consistent rotation of the auger to dispense a set volume, suitable for products with uniform density. Conversely, gravimetric filling incorporates checkweighing technology to ensure precise weight measurement, crucial for expensive or highly regulated materials like pharmaceuticals. Key applications span the Food and Beverage sector, where fast line speeds are required for bulk consumer goods, and the Pharmaceutical industry, demanding exceptional accuracy and sterility in dispensing Active Pharmaceutical Ingredients (APIs) or excipients.

The primary benefits of adopting modern auger filling technology include improved operational efficiency, reduced labor costs, and superior accuracy compared to manual or older mechanical filling methods. Driving factors for market expansion include the rapid globalization of supply chains necessitating standardized packaging, the stringent regulatory environment in healthcare and food safety mandating verifiable filling accuracy, and sustained investment in new production facilities, particularly in emerging economies across Asia Pacific and Latin America. Furthermore, advancements in servo motor technology and Human-Machine Interface (HMI) integration are making these machines more reliable, easier to calibrate, and quicker to change over between product runs, further boosting their attractiveness to manufacturers.

Powder Auger Fillers Market Executive Summary

The Powder Auger Fillers Market is poised for robust expansion, fundamentally propelled by strong global trends toward automation, enhanced packaging efficiency, and the necessity for highly accurate dosing in sensitive industries. Business trends indicate a significant shift towards fully integrated, high-speed automatic systems, leveraging servo-driven technology for superior control and minimized maintenance. Key market players are concentrating on developing modular designs, enabling easy integration with existing packaging lines and facilitating faster machine customization. Sustainability is emerging as a critical trend, pushing manufacturers to design equipment that minimizes product waste (product giveaway) and accommodates eco-friendly packaging materials, such as compostable pouches and recycled plastics, thereby aligning operational efficiency with corporate social responsibility goals.

Regionally, Asia Pacific is anticipated to be the fastest-growing market, driven by massive infrastructure investment in food processing, pharmaceutical manufacturing, and the rapidly expanding consumer goods sector, especially in populous nations like China and India. North America and Europe, while mature, maintain dominance due to high adoption rates of advanced gravimetric filling systems and strict regulatory frameworks demanding sophisticated validation capabilities. Regional trends also highlight a growing requirement for specialized machines capable of handling extremely fine, dusty powders or sticky, cohesive materials, leading to innovations in hopper agitation and product feed mechanisms to ensure consistent flow into the auger flighting.

Segment trends reveal that the Automatic Auger Fillers segment, particularly those utilizing multi-head rotary configurations, dominates in terms of revenue, catering to the large-scale production requirements of the Food and Beverage industry. However, the Gravimetric Filling Systems sub-segment is demonstrating the highest growth CAGR, fueled by stringent quality control needs in the Pharmaceutical and Specialty Chemical sectors, where filling accuracy is directly tied to product efficacy and regulatory compliance. Furthermore, the application segment of Pharmaceuticals is expected to experience accelerated growth due to continuous development and production of powdered dosage forms, including injectables, dry syrups, and powder inhalers, all requiring certified precision filling processes.

AI Impact Analysis on Powder Auger Fillers Market

User queries regarding the impact of Artificial Intelligence (AI) on the Powder Auger Fillers Market primarily revolve around predictive maintenance capabilities, optimization of filling accuracy through real-time feedback loops, and the integration of machine learning for minimizing product changeover times. Users frequently seek information on whether AI can dynamically adjust auger speed and density compensation based on subtle variations in powder characteristics (e.g., humidity absorption, bulk density changes during a production run). Furthermore, concerns center on the cost-effectiveness and complexity of integrating AI-driven diagnostic tools into existing legacy filling equipment, and the expected reduction in unplanned downtime achieved through pattern recognition and anomaly detection algorithms.

The convergence of AI and Industrial Internet of Things (IIoT) technologies is transforming the operation and maintenance protocols for powder auger fillers. AI-powered diagnostic systems collect vast streams of sensor data—covering motor temperatures, vibration levels, servo feedback, and fill weight deviations—to construct predictive models of machine failure. This shift from reactive or preventive maintenance to predictive maintenance significantly extends the mean time between failures (MTBF), reducing costly stoppages and maximizing asset utilization. Manufacturers are increasingly offering optional AI modules that provide prescriptive recommendations, such as suggesting the optimal cleaning schedule or anticipating component wear before a major breakdown occurs, thereby ensuring continuous, high-quality production output.

Beyond maintenance, AI is crucial in optimizing the filling process itself. Machine learning algorithms analyze historical batch data correlating material input properties (which often fluctuate slightly) with output accuracy, allowing the system to make micro-adjustments to the auger rotation parameters instantly. This real-time optimization minimizes the coefficient of variation (CV) in fill weights, leading to significant savings in product giveaway, especially for high-value powders. The ability of AI to rapidly analyze complex, multi-variable data sets makes advanced auger fillers fundamentally more adaptive and precise than traditional systems relying solely on predefined parameters or basic statistical process control (SPC) methods.

- AI-driven Predictive Maintenance: Reduces unplanned downtime by analyzing vibration and thermal sensor data to forecast component failure.

- Real-time Filling Optimization: Machine learning algorithms dynamically adjust auger speed and stroke to compensate for immediate changes in powder density and flowability, enhancing accuracy.

- Enhanced Quality Control: AI vision systems integrated with checkweighers detect and reject non-compliant packages with higher accuracy than traditional systems.

- Accelerated Changeover: AI analyzes previous changeover cycles and provides optimized setup parameters for new products, minimizing manual adjustments and time loss.

- Energy Efficiency Management: Machine learning optimizes motor usage based on production demand, leading to reduced operational energy consumption.

DRO & Impact Forces Of Powder Auger Fillers Market

The market dynamics of powder auger fillers are governed by a complex interplay of Drivers, Restraints, and Opportunities (DRO), collectively defining the market trajectory and potential for innovation. The core driver is the increasing global emphasis on automation and the need for precision dosing across high-value product streams. However, significant restraints include the high initial capital investment required for automated, high-end systems and the technical challenges associated with handling notoriously difficult powders (e.g., highly abrasive, sticky, or electrostatically charged materials) that can degrade accuracy or damage equipment. Opportunities lie prominently in integrating advanced robotics, developing specialized systems for sustainable packaging formats (like paper-based containers), and expanding into rapidly industrializing sectors, particularly in emerging economies where packaging standards are quickly maturing.

The primary impact forces propelling market growth are derived from regulatory pressure and consumer demand shifts. Strict regulations imposed by bodies like the FDA and EMA mandate verifiable precision in pharmaceutical and infant formula filling, directly driving demand for gravimetric auger fillers with advanced validation capabilities. Simultaneously, the global proliferation of convenience food products, instant beverages, and powdered nutritional supplements necessitates faster, more reliable packaging machinery. Conversely, restraining forces include supply chain volatility impacting component costs (especially for highly precise servo motors and stainless steel contact parts) and the persistent issue of finding skilled technicians capable of operating and maintaining complex, highly automated machinery. These forces collectively dictate the competitive landscape, favoring manufacturers who can provide integrated, reliable, and easily maintainable filling solutions.

Furthermore, technological disruption acts as a strong positive impact force. Innovations in modular machine design allow manufacturers to quickly reconfigure filling lines to handle diverse products and packaging formats without extensive downtime, catering to the growing trend of smaller batch sizes and greater product variety. The development of advanced materials, such as ceramic coatings and specialized polymers for auger components, enhances durability and reduces friction, making it easier to handle challenging powders and lowering the overall total cost of ownership (TCO). This focus on flexibility, precision, and material compatibility solidifies the growth potential for high-end, specialized auger filling equipment across all key end-user segments.

Segmentation Analysis

The Powder Auger Fillers Market is comprehensively segmented based on Type, Application, Filling Range, and Degree of Automation, providing granular insights into demand patterns across various industrial requirements. This segmentation highlights the functional differences in machinery, ranging from basic semi-automatic benchtop models used for small-scale operations to complex, multi-lane, fully automatic systems integrated into high-speed production lines. The Type segmentation (Volumetric vs. Gravimetric) is particularly critical as it differentiates machines based on the underlying technology used for measurement, directly influencing their suitability for high-accuracy applications like pharmaceuticals, versus high-throughput applications like bulk food packaging. Understanding these segments is vital for manufacturers to tailor their product offerings to meet specific end-user demands related to precision, speed, and cost efficiency.

- Type:

- Volumetric Auger Fillers

- Gravimetric Auger Fillers (Checkweigher Integrated)

- Application:

- Food and Beverage (Coffee, Milk Powder, Spices, Flour)

- Pharmaceutical (APIs, Powder Inhalers, Dry Syrups)

- Cosmetic and Personal Care (Talcum Powder, Make-up Powder)

- Chemical and Industrial (Detergents, Pigments, Specialty Chemicals)

- Nutraceuticals and Supplements

- Degree of Automation:

- Semi-Automatic Auger Fillers

- Automatic Single-Head Auger Fillers

- Automatic Multi-Head Rotary Systems

- Filling Range (Output Capacity):

- Low Speed (Under 50 CPM)

- Medium Speed (50 - 150 CPM)

- High Speed (Above 150 CPM)

Value Chain Analysis For Powder Auger Fillers Market

The value chain for the Powder Auger Fillers Market begins with upstream activities involving raw material procurement, primarily high-grade stainless steel (304 and 316L for contact parts), advanced servo motors, precision engineering components (gearing, bearings), and sophisticated electronic controls (PLCs, HMIs, sensors). Suppliers of these specialized components possess moderate bargaining power, particularly for proprietary servo drive systems essential for high-accuracy fillers. Research and Development activities are critical at this stage, focusing on material science (for handling abrasive powders) and software development for advanced control and IIoT connectivity. Efficiency in the upstream segment determines the final machinery quality, longevity, and overall precision capabilities.

The core value addition occurs during the manufacturing and assembly phase, where specialized OEMs design, fabricate, and integrate the filling systems. This stage includes custom engineering for specific powder characteristics and application environments (e.g., washdown capabilities for food, sterile design for pharmaceuticals). Post-manufacturing, the distribution channel plays a vital role. Direct distribution is often preferred for large, complex, and customized automatic systems, allowing OEMs to provide comprehensive installation, validation, and training services directly to the end-user. This direct model ensures that complex technical requirements and regulatory compliance needs are met precisely. Conversely, indirect channels, involving regional distributors or agents, are common for smaller, semi-automatic, or standard models, particularly in fragmented or geographically distant markets.

Downstream analysis focuses on installation, commissioning, after-sales service, and spare parts provision. Customer satisfaction heavily relies on the effectiveness of the aftermarket support, including rapid availability of wear parts (augurs, funnels, seals) and specialized maintenance services. The ultimate value delivery is realized when the auger filler is successfully integrated into the customer’s packaging line, maximizing throughput and maintaining fill accuracy over long periods. Potential customers (end-users) include large multinational corporations (MNCs) in the food and pharma sectors, medium-sized regional packaging houses, and contract manufacturers who seek flexible and reliable dosing solutions to meet diverse client specifications and high sanitary standards.

Powder Auger Fillers Market Potential Customers

The primary customers for powder auger fillers are organizations engaged in the large-scale production, processing, and packaging of dry particulate matter across various highly regulated or volume-intensive industries. These include major international food and beverage conglomerates requiring high-speed fillers for products like instant coffee, powdered milk, and protein supplements. Furthermore, global pharmaceutical manufacturers constitute a critical customer base, demanding fillers that meet stringent GMP (Good Manufacturing Practice) standards for sterile and precise dosing of active pharmaceutical ingredients (APIs), often utilizing gravimetric systems for mandatory compliance and batch traceability.

Beyond the core sectors of food and pharma, significant potential exists within the chemical and industrial sector, where manufacturers of specialty chemical powders, highly pigmented colorants, and agricultural chemicals utilize auger fillers for contained and dust-free packaging. The cosmetic and personal care industry represents a growing vertical, requiring precision filling for high-value products such as mineral makeup, talcum powders, and dry shampoos. These customers prioritize machine designs that offer quick cleanability and minimal cross-contamination risk when switching between different colored or scented powders, favoring modular and stainless steel construction with easy access for validation.

Moreover, contract packaging organizations (CPOs) and third-party manufacturers (3PMs) form a high-growth customer segment. These entities operate diversified production lines and require highly versatile auger fillers capable of handling a vast array of powder types and container formats with minimal changeover complexity. Their purchasing decisions are heavily influenced by machine flexibility, reliability, and the OEM's capacity to provide swift, localized technical support and calibration services, ensuring high operational uptime across multi-product environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 715.2 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | All-Fill Inc., Spee-Dee Packaging Machinery, Auger Fabrication Inc., PTI, Perry Videx, Filamatic, M. O. Industries, Accutek Packaging Equipment, G.P.P. Engineering, Inline Filling Systems, PackWest, N.V. Equipment, Kaps-All Packaging Systems, Apex Filling Systems, KBW Packaging, Weighpack Systems, Matrix Packaging Machinery, Adelphi Group, GEA Group, Syntegon Technology (Bosch Packaging Technology). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Powder Auger Fillers Market Key Technology Landscape

The technological landscape of the Powder Auger Fillers Market is defined by continuous evolution towards higher precision, enhanced automation, and superior connectivity. Modern auger fillers heavily utilize advanced servo motor technology, which has largely replaced older clutch-brake systems. Servo motors provide precise, repeatable control over auger revolutions, which is crucial for maximizing volumetric accuracy and minimizing overfill, particularly at high speeds. These systems are often paired with sophisticated Programmable Logic Controllers (PLCs) and user-friendly Human-Machine Interfaces (HMIs) that allow operators to store and recall hundreds of product recipes, significantly reducing the time and complexity required for product changeovers and calibration.

Another pivotal technological advancement involves the integration of high-speed, high-resolution load cell technology, forming the basis of gravimetric filling systems. These systems use integrated checkweighers to continuously monitor container weight and provide instantaneous feedback to the servo motor, adjusting the auger speed or duration mid-cycle to ensure the target weight is met within extremely tight tolerances. This technological convergence minimizes reliance on the consistency of the bulk powder density, making gravimetric fillers indispensable for handling expensive pharmaceuticals or products where regulatory mandate requires weight certification. Furthermore, dust mitigation technology, including specialized vacuum shrouds and closed-loop product feed systems, is now standard to maintain product integrity and ensure a clean, safe working environment compliant with occupational safety standards.

The burgeoning trend of Industry 4.0 has led to the widespread adoption of connectivity features, primarily through IIoT protocols. New generation auger fillers are equipped with sensors and communication modules that allow for remote monitoring, diagnostic capabilities, and integration with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems. This connectivity facilitates data-driven decision-making, enabling manufacturers to analyze Overall Equipment Effectiveness (OEE), optimize production schedules, and implement remote software updates or technical support. Future developments are focusing on incorporating Artificial Intelligence for advanced predictive maintenance and self-adjusting mechanisms to optimize machine performance autonomously across various environmental conditions.

Regional Highlights

- Asia Pacific (APAC) Dominance and Growth Momentum: APAC represents the fastest-growing market for powder auger fillers, driven by rapid industrialization, burgeoning pharmaceutical manufacturing capabilities, and massive population growth fueling the demand for packaged food and nutritional products. Countries like China and India are undergoing significant upgrades in their packaging infrastructure, transitioning from manual or semi-automatic filling methods to high-speed automatic lines to serve both domestic consumption and export markets. Local manufacturers are increasingly investing in modern, high-precision equipment to meet internationally recognized packaging standards and capitalize on growing middle-class spending power. The need for precise dosing in affordable generic pharmaceuticals and nutraceuticals is a powerful catalyst for market acceleration in this region.

- North America Market Maturity and Technology Adoption: North America holds a substantial share of the global market, characterized by high technological maturity and a dominant preference for advanced gravimetric and servo-driven auger fillers. The stringent regulatory environment in the US, particularly in the pharmaceutical and food safety sectors, drives demand for high-validation, high-accuracy systems capable of full audit trails and compliance with FDA regulations. Manufacturers in this region prioritize efficiency, reduced product giveaway, and integration capabilities with complex robotic handling systems. The market here is less about volume expansion and more about upgrading existing machinery with AI/IIoT features for optimized performance and lower operational costs.

- Europe's Focus on Precision and Sustainability: The European market is mature, stable, and highly focused on precision engineering, hygiene standards, and sustainability. European manufacturers exhibit a strong preference for custom-engineered solutions that integrate advanced powder handling technology to ensure maximum accuracy and minimal dust generation. Environmental regulations are also a significant driver, pushing demand for versatile fillers that can efficiently handle new, sustainable packaging formats (e.g., biodegradable plastics, fiber-based containers) without compromising line speed or fill accuracy. Germany, Italy, and the UK remain key technology hubs, often specializing in high-end pharmaceutical and specialty chemical filling equipment.

- Latin America's Infrastructure Investment: The Latin American market, particularly Brazil and Mexico, is undergoing significant infrastructure expansion in the food processing and domestic consumer packaged goods sectors. Demand is growing steadily, primarily for mid-range automatic auger fillers that offer a balance between speed, affordability, and reliability. Local companies are replacing aging equipment to improve competitiveness and meet escalating local quality standards. The beverage and snack industry, requiring filling solutions for flavored drink mixes and powdered food bases, is a primary revenue generator.

- Middle East and Africa (MEA) Emerging Opportunities: The MEA region is characterized by substantial government investment in diversification, including local pharmaceutical manufacturing and modernizing food processing capabilities, particularly in the Gulf Cooperation Council (GCC) states. The market here is growing from a smaller base but shows high potential, driven by the need for reliable, robust equipment capable of operating effectively in challenging climatic conditions (high heat and humidity) while adhering to high import quality standards. Initial demand often favors standardized, easy-to-maintain automatic filling solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Powder Auger Fillers Market.- All-Fill Inc.

- Spee-Dee Packaging Machinery

- Auger Fabrication Inc.

- PTI

- Perry Videx

- Filamatic

- M. O. Industries

- Accutek Packaging Equipment

- G.P.P. Engineering

- Inline Filling Systems

- PackWest

- N.V. Equipment

- Kaps-All Packaging Systems

- Apex Filling Systems

- KBW Packaging

- Weighpack Systems

- Matrix Packaging Machinery

- Adelphi Group

- GEA Group

- Syntegon Technology (Bosch Packaging Technology)

Frequently Asked Questions

Analyze common user questions about the Powder Auger Fillers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary distinction between volumetric and gravimetric auger fillers?

Volumetric auger fillers dispense product based on the consistent rotation of the auger screw, measuring volume, which is suitable for powders with uniform density. Gravimetric fillers, conversely, use load cells (checkweighers) to measure the exact weight dispensed in real time, offering superior accuracy and ensuring compliance for high-value or regulated products like pharmaceuticals.

Which factors are driving the adoption of automatic auger filling systems?

The key drivers include the necessity for increased production throughput, reduction of labor costs, the need to achieve superior filling accuracy to minimize product giveaway, and stringent regulatory requirements in food and pharmaceutical sectors demanding validated, high-speed dosing solutions.

How does the integration of IIoT and AI benefit the operation of modern auger fillers?

IIoT and AI integration enable predictive maintenance by analyzing sensor data to anticipate mechanical failures, optimize filling parameters in real time based on material fluctuations, and facilitate remote diagnostics, drastically improving machine uptime and overall operational efficiency (OEE).

What are the main challenges associated with operating powder auger fillers?

Major challenges include handling highly difficult powders that are extremely abrasive, sticky, or electrostatically charged, which can lead to inconsistency in fill weight, equipment wear, and dust control issues. High initial capital investment and the complexity of regulatory validation for pharmaceutical applications are also significant operational hurdles.

Which geographical region exhibits the highest growth potential for this market?

The Asia Pacific (APAC) region is projected to demonstrate the highest growth potential (CAGR) due to rapid industrial expansion, significant investment in food and pharmaceutical manufacturing infrastructure, and escalating consumer demand for packaged goods across countries like China, India, and Southeast Asian nations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager