Powder Molding Hydraulic Press Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433244 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Powder Molding Hydraulic Press Machine Market Size

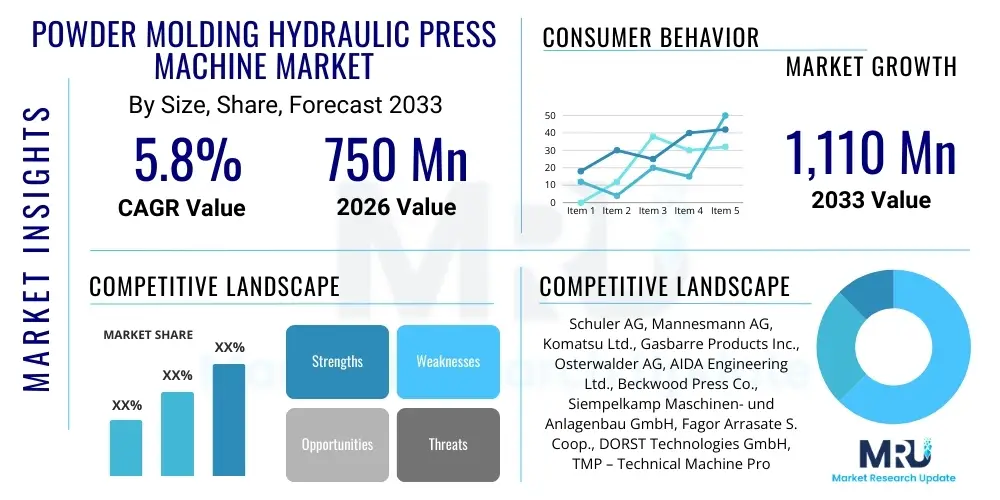

The Powder Molding Hydraulic Press Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 750 Million in 2026 and is projected to reach USD 1,110 Million by the end of the forecast period in 2033.

Powder Molding Hydraulic Press Machine Market introduction

The Powder Molding Hydraulic Press Machine Market encompasses specialized equipment utilized globally for compacting various powdered materials—including metals, ceramics, and composites—into precise, high-density components. These machines operate on the principle of hydrostatic pressure, delivering immense, accurately controlled force to shape parts, which is critical in processes such as Powder Metallurgy (PM) and technical ceramics manufacturing. The resultant green compacts possess dimensional stability and sufficient strength for subsequent sintering operations. The inherent reliability and capability for intricate shape production position hydraulic presses as foundational technology in advanced manufacturing sectors demanding consistency and high throughput.

Key applications of these hydraulic press machines are predominantly found in the automotive sector for producing complex engine components, gear parts, and braking systems, leveraging the efficiency of PM technology. Furthermore, the electronics and aerospace industries rely heavily on powder molding presses for manufacturing high-performance permanent magnets, structural ceramic insulators, and specialized composite components requiring high material utilization rates and tight tolerances. The precision achievable by modern servo-hydraulic systems allows manufacturers to produce near-net-shape parts, significantly reducing downstream machining costs and material waste, thereby enhancing overall production sustainability and cost-effectiveness across high-volume manufacturing lines.

Major driving factors fueling market expansion include the increasing global adoption of lightweight, high-strength materials in the electric vehicle (EV) sector, alongside robust demand for advanced ceramic components utilized in industrial machinery and medical devices. The shift towards higher automation and integration of closed-loop control systems in manufacturing processes necessitates the adoption of modern, high-precision hydraulic presses. Furthermore, stringent quality standards in industries like aerospace and defense compel manufacturers to utilize sophisticated powder molding equipment capable of providing exceptional repeatability and real-time process monitoring, thereby securing consistent component quality and driving market innovation.

Powder Molding Hydraulic Press Machine Market Executive Summary

The Powder Molding Hydraulic Press Machine Market exhibits robust growth driven primarily by structural advancements in material science and the global expansion of electric vehicle manufacturing, which demands precision-molded magnetic and structural components. Business trends indicate a decisive shift toward highly automated, energy-efficient servo-hydraulic presses, replacing traditional mechanical and conventional hydraulic systems. Manufacturers are increasingly prioritizing machines integrated with sophisticated process control software capable of predictive maintenance and remote diagnostics, focusing on enhancing throughput and reducing downtime across demanding production environments. Mergers, acquisitions, and strategic partnerships centered around technology transfer are becoming common strategies among key players to consolidate expertise in high-tonnage precision pressing and expand geographic footprints, particularly in rapidly industrializing regions.

Regionally, the Asia Pacific (APAC) continues to dominate the market, fueled by massive investments in automotive component manufacturing in countries like China, India, and Japan, alongside burgeoning electronics and technical ceramics production bases. North America and Europe demonstrate mature market characteristics, focusing on technological upgrades and the replacement of legacy machinery with advanced, high-tonnage presses tailored for complex metallurgy and specialized material applications in aerospace and medical device production. Latin America and the Middle East and Africa (MEA) are emerging as high-potential markets, spurred by localized infrastructure projects and initial phases of localized automotive manufacturing, increasing the need for entry-level and mid-range capacity hydraulic press solutions.

Segmentation trends highlight the increasing prominence of the high-tonnage segment (above 1,000 tons) due to growing requirements for large, dense structural components, particularly in industrial equipment and defense applications. By product type, the Servo-Hydraulic Press category is experiencing the fastest growth, offering superior control over pressing speed and pressure profiles, which is critical for molding complex powder geometries and minimizing material defects. The key application segments, particularly automotive and electronics, are expected to remain the highest contributors to revenue, underpinned by continuous product innovation in electric motor parts, battery components, and semiconductor packaging materials requiring extremely precise powder compaction.

AI Impact Analysis on Powder Molding Hydraulic Press Machine Market

User queries regarding AI's impact on the Powder Molding Hydraulic Press Machine Market frequently revolve around optimizing production yields, ensuring zero-defect manufacturing, and enhancing predictive maintenance capabilities. Common themes include how AI algorithms can interpret real-time sensor data from press operations to dynamically adjust pressing parameters (such as speed and decompression rates), thereby compensating for minor variations in powder feedstock density or composition. Users are keen to understand the shift from traditional statistical process control (SPC) to AI-driven quality assurance, which promises proactive defect mitigation rather than reactive identification. Expectations are high concerning the ability of AI to model complex powder behavior under pressure, which remains a significant challenge for conventional simulation software, thereby accelerating new product development and tool design cycles in highly competitive precision molding sectors.

The integration of Artificial Intelligence (AI) platforms into powder molding hydraulic presses fundamentally transforms operational efficiency and material utilization. AI algorithms leverage machine learning models to analyze vast datasets collected during pressing cycles—including pressure, temperature, strain, and acoustic emissions—to establish optimal operating parameters for specific material batches. This level of dynamic control minimizes component defects such as cracking, lamination, and density gradients, which are common challenges in powder compaction, leading to substantial reductions in scrap rates and material costs. Furthermore, AI facilitates automated quality inspection by processing images or sensor readings of the finished green compacts, ensuring 100% inspection reliability compared to human visual checks.

For press maintenance, AI dramatically enhances the accuracy and timeliness of predictive maintenance schedules. By continuously monitoring the health of critical machine components—such as hydraulic pumps, cylinders, and valve systems—AI models can predict component failure probabilities far in advance of detectable degradation. This transition to condition-based monitoring, enabled by deep learning, allows maintenance to be scheduled precisely when needed, rather than based on fixed time intervals, maximizing machine uptime and extending the lifespan of high-value capital equipment. This predictive capability is vital for high-volume manufacturers where unexpected downtime can lead to significant economic losses.

- AI enhances real-time process optimization by adjusting pressing profiles based on material characteristics.

- Predictive maintenance using AI minimizes unexpected machine downtime and extends equipment lifespan.

- Machine learning models improve yield rates by proactively mitigating compaction defects and anomalies.

- AI enables automated, high-speed, and non-destructive quality inspection of green compacts.

- Optimization of energy consumption by dynamically controlling servo-pump outputs based on cycle requirements.

- Accelerated tool design and simulation through AI modeling of complex powder flow and compaction dynamics.

DRO & Impact Forces Of Powder Molding Hydraulic Press Machine Market

The market is significantly propelled by robust Drivers, tempered by essential Restraints, and presents substantial Opportunities, all influenced by pervasive Impact Forces. The primary driver is the accelerating shift towards advanced manufacturing techniques requiring high-density, complex components, notably in the electric vehicle (EV) battery and motor segments, where powder metallurgy offers superior magnetic and thermal performance compared to traditional casting or machining. This demand is coupled with increasing government emphasis on energy efficiency, leading manufacturers to invest in newer, more precise hydraulic press technologies, particularly servo-hydraulic systems that reduce operating costs and improve repeatability, driving market momentum upward across industrialized and developing economies seeking competitive manufacturing advantages.

However, significant Restraints challenge market expansion. The high initial capital investment required for modern, high-tonnage hydraulic presses, coupled with the necessity for highly specialized operator training, acts as a barrier to entry for smaller manufacturers, particularly in emerging markets where capital availability is restricted. Furthermore, the volatility and fluctuating costs of raw materials, particularly metal powders (iron, copper, tungsten), introduce uncertainty in component production costs, which can temporarily dampen investment decisions in new pressing machinery. Technical restraints related to achieving uniform density and avoiding microstructure defects in extremely large or intricate powder compacts necessitate advanced tooling and complex control systems, which adds to the overall cost and complexity of the powder molding process, slowing the pace of adoption in less experienced fabrication facilities.

Opportunities for growth are abundant, primarily centered around technological innovation and market penetration in niche applications. The ongoing development of additive manufacturing (3D printing) technologies, while sometimes seen as a competitor, also creates opportunities for hybrid processes where powder compaction is followed by specialized sintering or post-processing techniques. Furthermore, the burgeoning demand for specialized medical components (implants, surgical tools) manufactured from biocompatible metal and ceramic powders, requiring ultra-high precision pressing, presents a lucrative high-margin market segment. Strategic geographic expansion into untapped markets in Southeast Asia and Africa, leveraging localized servicing and maintenance partnerships, represents a critical long-term growth avenue for established press manufacturers, focusing on mid-range machine capacities to serve emerging industrial clusters.

Segmentation Analysis

The Powder Molding Hydraulic Press Machine Market segmentation provides a granular view of market structure based on technical specifications, operational capacity, and end-use applications, offering crucial insights into current demand patterns and future growth trajectories. The market is primarily segmented by Type (Conventional Hydraulic Presses and Servo-Hydraulic Presses), by Tonnage Capacity (Low, Medium, and High), and by End-Use Application (Automotive, Electrical & Electronics, Aerospace & Defense, and Industrial Machinery). Understanding these segments is vital for stakeholders, as different pressing technologies cater to highly specialized material requirements and production volumes, directly influencing machine design and pricing strategies adopted by manufacturers globally.

The segmentation by Tonnage Capacity is particularly relevant, distinguishing machines designed for small, intricate parts (low tonnage, <100 tons) used often in electronics, from those required for large structural components (high tonnage, >1,000 tons) common in heavy machinery and defense applications. The shift toward higher tonnage machines reflects the industry's need for larger, net-shape structural components, reducing the reliance on secondary assembly and welding processes. Conversely, the segmentation by Type underscores the continuous technological evolution, with servo-hydraulic systems rapidly gaining market share due to their superior efficiency, precise control over the compaction curve, and significantly lower energy consumption compared to traditional hydraulic systems relying on constant-running pumps.

Application-wise, the automotive sector remains the largest segment, driven by the increasing integration of Powder Metallurgy (PM) components in internal combustion engine and, increasingly, electric vehicle platforms for highly efficient magnetic materials and structural parts. The electronics segment is experiencing rapid expansion, fueled by the demand for sophisticated ceramic packages, heatsinks, and specialized magnetic cores, all requiring exceptional dimensional accuracy achieved only through precise powder compaction methods. Analyzing these segments helps firms tailor their product offerings, focusing R&D efforts on areas like multi-platen pressing capabilities needed for complex PM gears or high-temperature pressing capabilities required for advanced ceramics in the aerospace industry, ensuring market relevance.

- By Type:

- Conventional Hydraulic Press

- Servo-Hydraulic Press

- Mechanical Press

- Isostatic Press (Cold/Hot)

- By Tonnage Capacity:

- Low Tonnage (Up to 100 Tons)

- Medium Tonnage (100 Tons to 500 Tons)

- High Tonnage (Above 500 Tons)

- By Application:

- Automotive Industry (Structural Components, Gears, Bearings)

- Electrical and Electronics (Magnets, Semiconductors, Heat Sinks)

- Aerospace and Defense (Turbine Components, Composite Materials)

- Industrial Machinery and Tools (Cutting Tools, Wear Parts)

- Medical Devices (Implants, Surgical Components)

- By End-Use Material:

- Metal Powders (Iron, Copper, Aluminum Alloys)

- Ceramic Powders (Alumina, Zirconia, Carbides)

- Composite Powders

Value Chain Analysis For Powder Molding Hydraulic Press Machine Market

The value chain for the Powder Molding Hydraulic Press Machine Market begins with the upstream suppliers responsible for high-grade components crucial for press operation and longevity. This upstream segment is dominated by specialized manufacturers of high-pressure hydraulic pumps, precision valves, control systems (PLCs, HMI interfaces), and high-strength steel used in the press frames and tooling components. The competitive advantage at this stage hinges on the quality, reliability, and precision of these components, particularly the servo-drive systems and closed-loop feedback sensors that dictate the press’s overall performance and energy efficiency. Strong relationships between press machine builders and Tier 1 component suppliers ensure technological consistency and optimized integration of cutting-edge hydraulic and electronic systems into the final press machine assembly.

The core segment of the value chain involves the press machine Original Equipment Manufacturers (OEMs), who undertake the design, fabrication, assembly, and rigorous testing of the hydraulic presses. OEMs are responsible for integrating components, developing proprietary pressing software, and ensuring compliance with international safety and performance standards. Distribution channels play a critical role, encompassing direct sales models for high-value, customized, and complex pressing solutions, typically involving long consultative sales cycles. Indirect channels, utilizing authorized distributors and specialized regional agents, are essential for penetrating geographically dispersed markets, particularly for standard-capacity machines, providing localized technical support and immediate spares availability.

Downstream analysis focuses on the end-users—the powder molding companies, component manufacturers, and research institutions—who utilize the presses to create finished compacts. The efficiency of the downstream operations is heavily reliant on effective post-sales support from the OEM, including maintenance contracts, software updates, specialized training for tooling changeovers, and troubleshooting complex molding defects. The feedback loop from downstream users back to the OEMs is critical for continuous product improvement, especially concerning achieving higher throughputs and managing increasingly complex material properties. Successful value chain management in this market requires minimizing lead times for customized press solutions and providing robust, long-term technical support to maximize end-user Return on Investment (ROI) in capital-intensive machinery.

Powder Molding Hydraulic Press Machine Market Potential Customers

The primary customers for Powder Molding Hydraulic Press Machines are sophisticated manufacturing entities requiring high precision and volume production of components from powdered raw materials. These include Tier 1 and Tier 2 suppliers in the automotive industry specializing in complex powder metallurgy parts such as synchronous hubs, planetary carriers, and soft magnetic composites (SMCs) for electric motors, driven by the necessity for lightweighting and enhanced performance in modern vehicles. Manufacturers of specialized cutting tools and wear-resistant parts, often utilizing cemented carbides and high-performance ceramic powders, represent a critical customer segment due to the requirement for extremely high compaction pressures to achieve material density and durability.

Another significant customer base comprises companies within the electrical and electronics sectors, particularly those focused on advanced packaging, passive components, and permanent magnet production for consumer electronics and industrial motors. These customers demand presses capable of micro-precision, high-speed operation, and exceptional repeatability to manage intricate ceramic insulators, multilayer electronic components, and neodymium-iron-boron (NdFeB) magnet compacts. The precise control offered by servo-hydraulic systems directly meets the stringent quality and dimensional tolerance requirements of this technology-driven industry, making them key investment decision makers in this domain.

Furthermore, aerospace and defense contractors constitute a high-value, albeit smaller volume, customer segment, requiring specialized hot isostatic pressing (HIP) and high-temperature hydraulic presses for manufacturing superalloys, thermal barrier coatings, and advanced composite components used in aircraft engines and structural airframe parts. Research institutions and specialized material laboratories also represent ongoing, albeit lower volume, customers, acquiring small-scale, highly versatile laboratory presses for material research, process development, and small batch production runs. These customers prioritize flexibility, advanced data logging capabilities, and the ability to handle exotic, non-standard material powders efficiently.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 750 Million |

| Market Forecast in 2033 | USD 1,110 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schuler AG, Mannesmann AG, Komatsu Ltd., Gasbarre Products Inc., Osterwalder AG, AIDA Engineering Ltd., Beckwood Press Co., Siempelkamp Maschinen- und Anlagenbau GmbH, Fagor Arrasate S. Coop., DORST Technologies GmbH, TMP – Technical Machine Products, Phoenix Press, Hydraulic Press Manufacturing (HPM), Greenerd Press & Machine Co., Sumitomo Heavy Industries, Kasto Machine Tool Solutions, Trens Unico, Macrodyne Technologies, PME Pressen- & Maschinenbau Eging GmbH, SEYI Presses |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Powder Molding Hydraulic Press Machine Market Key Technology Landscape

The technological landscape of the Powder Molding Hydraulic Press Machine Market is rapidly evolving, moving away from purely mechanical or conventional fixed-displacement hydraulic systems toward advanced servo-hydraulic and digitalized control architectures. Servo-hydraulic technology represents the most significant advancement, utilizing variable-speed electric motors to drive fixed-displacement pumps. This setup allows for precise, dynamic control over the pressing velocity, pressure, and decompression phases, enabling complex pressing profiles essential for multi-level powder compacts and materials prone to cracking during de-gassing or ejection. These systems offer superior energy efficiency, often reducing power consumption by up to 50% compared to traditional constant-running hydraulic power units, aligning with global sustainability mandates and reducing operational expenditure for high-volume manufacturers.

Another critical technological focus is the development of advanced multi-platen and multi-action pressing capabilities. Modern presses are designed to handle complex tooling that allows for simultaneous compaction from multiple axes (top, bottom, and side punches), which is necessary for creating intricate geometries like PM gears with varied density requirements. Integrated closed-loop force and displacement control systems, using highly sensitive linear variable displacement transducers (LVDTs) and precision load cells, ensure exceptional repeatability and micron-level accuracy. This precision is paramount for applications in specialized ceramics and soft magnetic materials, where dimensional tolerance directly impacts final product performance.

The adoption of Industry 4.0 principles is fundamentally reshaping the technology landscape. New presses feature integrated sensors and networking capabilities for real-time data acquisition and analysis, facilitating full connectivity with Manufacturing Execution Systems (MES) and enterprise resource planning (ERP) platforms. This digitalization supports remote diagnostics, enables AI-driven predictive maintenance, and allows for automatic logging and traceability of pressing parameters for every component produced. Furthermore, specialized technologies like Cold Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP) continue to evolve, offering improved capabilities for achieving near-100% theoretical density in critical, high-performance parts, especially in the aerospace and medical sectors demanding material perfection under extreme operating conditions.

Regional Highlights

The regional dynamics of the Powder Molding Hydraulic Press Machine Market show pronounced differences in maturity, growth rates, and technological adoption, reflecting local industrial capacities and investment trends. Asia Pacific (APAC) stands as the undisputed leader in terms of market size and growth potential. This dominance is attributed to the presence of high-volume manufacturing hubs in China, which leads in automotive component and consumer electronics production, and Japan, a center for advanced powder metallurgy innovation. Significant infrastructure investments and the accelerating shift to localized component manufacturing across Southeast Asia further cement APAC's status as the critical growth engine, driving massive demand for both standard and high-tonnage hydraulic presses to support rapid industrial expansion and supply chain diversification.

Europe and North America represent mature but highly technologically demanding markets. In these regions, the emphasis is less on volume expansion and more on technological advancement, particularly the rapid transition to servo-hydraulic presses to meet stringent energy efficiency regulations and achieve precision required for high-end applications like aerospace components and medical implants. European countries, notably Germany and Italy, are significant technology exporters and innovators in hydraulic press design, concentrating on customized, high-precision, and multi-functional machines that integrate advanced automation and safety standards. Replacement cycles for aging equipment in these regions contribute steadily to market demand, specifically targeting presses capable of integrating with sophisticated smart factory ecosystems.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging regions poised for rapid market uptake, albeit from a smaller base. Growth in LATAM is closely tied to the recovery and expansion of the localized automotive sector, particularly in Brazil and Mexico, creating initial demand for medium-tonnage hydraulic presses for structural and engine components. In MEA, demand is spurred by investments in localized defense manufacturing, energy infrastructure projects, and initial attempts at establishing regional component supply chains. While capital constraints are more pronounced, leading to slower adoption of the most advanced servo technology, the long-term outlook remains positive as industrialization initiatives gain momentum, requiring reliable and robust powder molding solutions to establish internal component manufacturing capabilities.

- Asia Pacific (APAC): Dominates the market due to robust automotive production (EV parts), large-scale electronics manufacturing in China and Korea, and significant investments in technical ceramics manufacturing infrastructure.

- North America: Focused on high-value, high-precision applications in aerospace, defense, and specialized medical component manufacturing, driving demand for technologically advanced servo-hydraulic and isostatic presses.

- Europe: Characterized by strong regulatory support for energy-efficient machinery; key innovator region specializing in customized, automated press solutions and high-tonnage presses for heavy industrial applications.

- Latin America (LATAM): Growth tied to local automotive and construction sectors; increasing imports of mid-range hydraulic presses to support localized component production in countries like Brazil and Mexico.

- Middle East and Africa (MEA): Emerging market driven by localized industrialization efforts, defense spending, and infrastructure development, leading to initial demand for reliable, versatile pressing equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Powder Molding Hydraulic Press Machine Market.- Schuler AG

- Mannesmann AG

- Komatsu Ltd.

- Gasbarre Products Inc.

- Osterwalder AG

- AIDA Engineering Ltd.

- Beckwood Press Co.

- Siempelkamp Maschinen- und Anlagenbau GmbH

- Fagor Arrasate S. Coop.

- DORST Technologies GmbH

- TMP – Technical Machine Products

- Phoenix Press

- Hydraulic Press Manufacturing (HPM)

- Greenerd Press & Machine Co.

- Sumitomo Heavy Industries

- Kasto Machine Tool Solutions

- Trens Unico

- Macrodyne Technologies

- PME Pressen- & Maschinenbau Eging GmbH

- SEYI Presses

Frequently Asked Questions

Analyze common user questions about the Powder Molding Hydraulic Press Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for high-tonnage powder molding presses?

The primary driver for high-tonnage powder molding presses is the increasing requirement across the automotive and industrial sectors for larger, near-net-shape structural components, such as transmission parts and heavy machine components. These large parts require compaction forces often exceeding 1,000 tons to achieve the necessary density and material integrity, minimizing subsequent machining and improving overall structural performance.

How do Servo-Hydraulic Presses differ from Conventional Hydraulic Presses in powder molding applications?

Servo-Hydraulic Presses offer superior precision and energy efficiency because they use a variable-speed electric motor to control the pump output, allowing dynamic adjustment of flow and pressure only when needed. Conventional presses run the pump constantly, consuming excess energy. The precise control in servo systems is crucial for molding complex, multi-level powder parts and delicate ceramic materials without inducing defects.

Which industry segment is the largest end-user of Powder Molding Hydraulic Press Machines globally?

The Automotive Industry is the largest end-user segment globally. This sector relies heavily on powder metallurgy for manufacturing high-volume, cost-effective, and high-performance components, including gears, bearings, connecting rods, and soft magnetic materials essential for the expanding electric vehicle (EV) market and high-efficiency internal combustion engines.

What impact does Industry 4.0 integration have on the market for these presses?

Industry 4.0 integration significantly enhances operational efficiency by enabling real-time data monitoring, remote diagnostics, and predictive maintenance through networked sensors and AI algorithms. This connectivity reduces downtime, optimizes pressing parameters for minimal waste, and ensures complete traceability of production parameters, meeting stringent quality requirements in aerospace and medical manufacturing.

What are the key technical challenges in powder molding related to press technology?

Key technical challenges include achieving uniform density distribution, particularly in large or complex geometries, and preventing defects such as cracking or lamination during compaction and ejection. Advanced multi-platen press designs and sophisticated, closed-loop pressure control systems are necessary to overcome these challenges, ensuring high component integrity and maximizing production yield rates.

This concludes the comprehensive market insights report on the Powder Molding Hydraulic Press Machine Market, adhering to all specified formatting and structural requirements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager