Precipitated Alumina Trihydrate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431754 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Precipitated Alumina Trihydrate Market Size

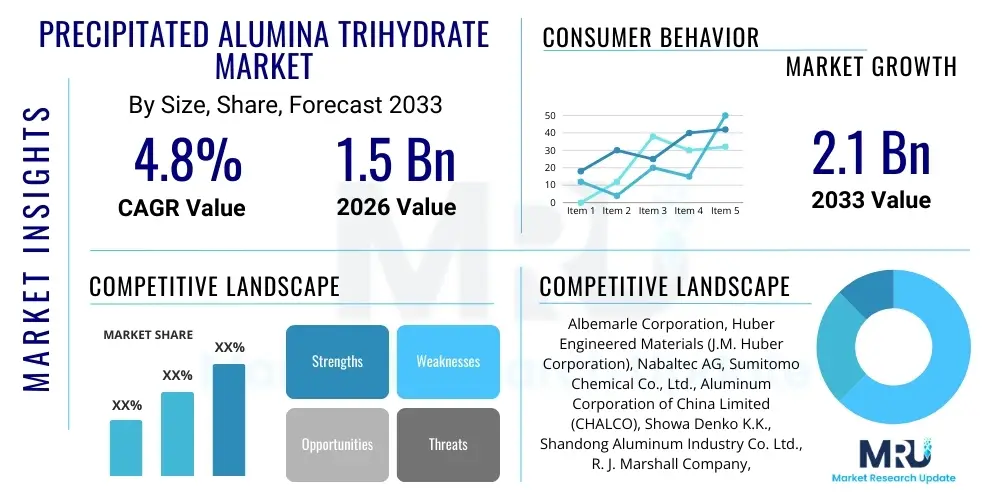

The Precipitated Alumina Trihydrate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.1 Billion by the end of the forecast period in 2033.

Precipitated Alumina Trihydrate Market introduction

Precipitated Alumina Trihydrate (ATH), chemically known as Al(OH)3, is a crucial functional filler derived from the Bayer process. It stands out in the specialty chemicals landscape due to its primary characteristic as a highly effective, non-toxic, and smoke-suppressing flame retardant. Unlike ground ATH, precipitated ATH features finer particles, a narrower particle size distribution, and higher purity, making it ideal for applications demanding superior finish, higher loading capacity, and consistent performance. This fine-grade material is essential in enhancing the physical and chemical properties of polymers, particularly in demanding sectors such as construction, electrical and electronics (E&E), and transportation, where fire safety standards are rigorously enforced. The growth of this market is intrinsically linked to global regulatory emphasis on fire safety and environmental concerns related to halogenated flame retardants.

The major applications of precipitated ATH span across numerous high-value industries. In the plastics and rubber sector, it is utilized extensively as a fire retardant additive in cables, wires, roofing materials, and composite panels. Its secondary function as a filler helps reduce the overall cost of end products while improving mechanical strength and stiffness. Furthermore, precipitated ATH is crucial in the production of specialized materials, including solid surface materials used for countertops and sinks, where its whiteness, transparency, and chemical inertness contribute significantly to the aesthetic and functional quality of the finished product. The increasing demand for sustainable and halogen-free fire protection solutions across Europe and North America is acting as a major catalyst for market expansion.

Key benefits of using precipitated ATH include its non-toxic nature, minimal smoke generation upon combustion, and cost-effectiveness compared to alternative halogen-free flame retardants. The primary driving factors for the market involve stringent fire safety regulations being implemented globally, especially within public infrastructure projects and transportation vehicles. Additionally, the rapid urbanization in Asia Pacific, particularly in China and India, is fueling unprecedented growth in the construction sector, requiring vast quantities of fire-safe building materials. The transition away from traditional, hazardous flame retardants toward environmentally benign alternatives further solidifies the market trajectory for precipitated ATH.

Precipitated Alumina Trihydrate Market Executive Summary

The Precipitated Alumina Trihydrate market is characterized by robust growth, driven primarily by evolving regulatory frameworks mandating fire safety across industrial and commercial applications. Business trends highlight a strong focus on capacity expansion, particularly in the Asia Pacific region, to meet the skyrocketing demand from the construction and E&E sectors. Key manufacturers are investing heavily in optimizing the precipitation process to produce ultra-fine and surface-treated ATH grades, enhancing compatibility with advanced polymer matrices and expanding the scope of application into high-performance engineering plastics. Furthermore, strategic partnerships and mergers aimed at vertical integration are becoming common, allowing companies to secure raw material supply chains and achieve cost efficiencies necessary to compete effectively in this increasingly competitive environment.

Regional trends indicate that Asia Pacific holds the dominant market share and is projected to exhibit the fastest growth over the forecast period, fueled by massive infrastructure development and rapid growth in the electronics manufacturing hubs of East Asia. North America and Europe, characterized by mature markets, demonstrate stable growth, largely driven by the adoption of high-purity and specialty grades of ATH, specifically in the aerospace, automotive interiors, and solid surface materials industries. These developed regions lead the innovation curve, prioritizing AEO-compliant and highly specialized products that offer superior processing characteristics and environmental profiles, often responding to sophisticated consumer and regulatory demands for sustainability.

Segment trends reveal that the fine precipitated grade segment, defined by particle sizes typically below 5 micrometers, commands a significant market share due to its superior dispersion and suitability for thin-walled applications, such as high-voltage cables and thin films. In terms of application, the flame retardant segment remains paramount, though the filler application in solid surface materials is demonstrating accelerated growth. Technological advancements are also segmenting the market based on surface treatment, where silane- or stearate-coated ATH products are gaining traction, offering improved hydrophobic properties and better mechanical performance when incorporated into thermoset and thermoplastic resins, thereby justifying premium pricing and specialized market niches.

AI Impact Analysis on Precipitated Alumina Trihydrate Market

User queries regarding AI's influence on the Precipitated Alumina Trihydrate market primarily revolve around operational efficiency, predictive maintenance, and R&D acceleration for new product formulations. Users frequently inquire about how AI-driven process optimization could reduce energy consumption in the highly energy-intensive Bayer process, leading to better cost structures and reduced environmental footprint. Additionally, there is significant interest in using machine learning algorithms to predict the performance characteristics (such as dispersibility, flame retardancy index, and thermal stability) of new ATH formulations based on input parameters like precipitation rate, temperature, and concentration. This capability would drastically shorten the time-to-market for specialized, high-performance ATH grades required by the automotive and aerospace industries. The overriding theme is the expectation that AI will transition the manufacturing of ATH from traditional batch processing toward continuous, highly optimized, and quality-controlled intelligent production systems.

- AI-driven optimization of the Bayer process parameters (temperature, pH, concentration) to maximize yield and minimize energy consumption.

- Predictive maintenance analytics deployed on large-scale calcination and precipitation reactors, reducing unexpected downtimes and maintenance costs.

- Machine learning algorithms used to simulate and predict the fire retardancy performance of ATH composites, accelerating new product development (NPD).

- Automation of quality control and particle size analysis using computer vision and deep learning models, ensuring consistent ultra-fine grading.

- Optimization of complex global supply chain logistics, routing, and inventory management for raw materials (bauxite) and finished ATH products.

- Enhanced market forecasting models leveraging external macroeconomic and regulatory data to predict demand fluctuations accurately across diverse end-user sectors.

DRO & Impact Forces Of Precipitated Alumina Trihydrate Market

The market is predominantly driven by the pervasive need for effective, non-toxic flame retardants, particularly as global fire safety regulations intensify across public spaces and residential construction. The unique combination of flame suppression, smoke reduction, and low toxicity inherent to ATH positions it favorably against halogenated alternatives, which are facing severe scrutiny and phase-out in many developed economies. Furthermore, the robust growth in end-use industries, including electric vehicle components, high-speed rail, and advanced wiring, necessitates materials that can withstand high temperatures while providing maximum fire safety, thereby accelerating the adoption of high-purity, precipitated ATH. These drivers are fundamentally structural, indicating sustained long-term market growth.

Restraints, however, pose challenges to the market expansion. The high loading requirement of ATH (often exceeding 50% by weight) to achieve optimal flame retardancy can compromise the mechanical properties and processability of the base polymer, limiting its use in specific high-performance applications. Additionally, the manufacturing process for ATH, which includes the Bayer process, is highly energy-intensive, leading to significant production costs that can fluctuate based on energy prices and bauxite availability. Competition from alternative halogen-free flame retardants, such as magnesium hydroxide and phosphorous-based compounds, also presents a restraint, especially where lower loading levels or superior processing characteristics are prioritized by manufacturers.

Opportunities for market players are substantial, centering on technological innovation and geographical expansion. The development of surface-modified or encapsulated precipitated ATH products that improve dispersion and reduce the negative impact on polymer mechanical properties represents a major opportunity for value addition and premiumization. Furthermore, emerging economies in Southeast Asia, Africa, and Latin America are beginning to implement stricter fire safety codes, opening new, untapped markets for ATH suppliers. The environmental impact forces are strongly positive, favoring ATH as it aligns perfectly with global sustainability initiatives seeking to minimize the use of hazardous chemicals in construction and electronics, driving substitution trends away from restricted substances toward safe, mineral-based fillers and flame retardants.

Segmentation Analysis

The Precipitated Alumina Trihydrate market is meticulously segmented based on grade, particle size, application, and end-use industry, reflecting the diverse requirements of the global specialty chemicals sector. Segmentation based on grade distinguishes between standard precipitated ATH and specialized surface-treated variants, which offer enhanced compatibility with hydrophobic polymers. Particle size is a crucial determinant of performance, separating fine and ultra-fine grades. Application segmentation clearly delineates between the dominant flame retardant use and its significant role as a functional filler, especially in solid surface and composite manufacturing, allowing suppliers to tailor their offerings precisely to industry needs.

- By Grade:

- Standard Precipitated Alumina Trihydrate

- Surface-Treated Precipitated Alumina Trihydrate (Silane-treated, Stearate-treated)

- By Particle Size:

- Fine Grade (typically 1 to 5 µm)

- Ultra-Fine Grade (typically < 1 µm)

- By Application:

- Flame Retardant

- Smoke Suppressant

- Filler (Composite, Solid Surface, Coating)

- By End-Use Industry:

- Plastics and Rubber (Wires, Cables, Films)

- Construction (Roofing, Wall Panels, Insulation)

- Electrical and Electronics (E&E)

- Transportation (Automotive, Aerospace interiors)

- Solid Surface Materials (Countertops, Baths)

- Paints and Coatings

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Precipitated Alumina Trihydrate Market

The value chain for the Precipitated Alumina Trihydrate market begins with the upstream processes focused on the mining and refinement of Bauxite ore, which is the primary raw material. Upstream analysis involves major players in the aluminum industry, as ATH is an intermediate product in the Bayer process used for alumina production. Secure and cost-effective access to high-quality bauxite deposits is a critical competitive advantage, leading many major ATH manufacturers to engage in vertical integration or long-term supply agreements. The complexity and high energy demands of the Bayer process significantly impact the final manufacturing cost of precipitated ATH, emphasizing the importance of operational efficiency at the upstream refinement stage.

Midstream activities involve the specialized precipitation and processing techniques that transform coarse ATH into the fine, high-purity precipitated grade required by specialty chemical consumers. This stage includes controlled crystallization, filtration, drying, and micronization, followed by optional surface treatments (e.g., silanization or stearate coating) to enhance compatibility with specific polymer systems. Direct and indirect distribution channels play a crucial role in delivering this product, given its bulk nature and specific handling requirements. Direct sales often cater to large volume consumers in the polymer compounding and solid surface manufacturing sectors, facilitating customized product specifications and technical support directly from the producer.

Downstream analysis focuses on the numerous processing industries that incorporate precipitated ATH into their final products. This includes plastic compounders, wire and cable manufacturers, and firms specializing in fire-resistant composites and coatings. The distribution channel is often indirect, relying on regional specialty chemical distributors and agents who manage inventory, warehousing, and just-in-time delivery to smaller end-users. Technical service and application expertise are essential at the downstream level, as the optimal loading and dispersion of ATH vary significantly across different polymer types (e.g., PVC, polyethylene, rubber), necessitating strong technical partnerships between manufacturers and end-users to maximize product performance and compliance with evolving fire safety standards.

Precipitated Alumina Trihydrate Market Potential Customers

The primary potential customers and end-users of precipitated Alumina Trihydrate are large-scale manufacturers operating within the construction, electrical, and transportation sectors, all of which prioritize fire safety and material longevity. In the construction industry, key buyers include manufacturers of cladding panels, insulation foam, roofing membranes, and interior finishing materials requiring compliance with high flame spread resistance codes. These customers demand ATH grades that offer consistent whiteness and low smoke density, ensuring minimal visual impact while meeting stringent building regulations, particularly in high-density urban developments and public transportation infrastructure projects globally.

Another major customer segment resides in the Electrical and Electronics (E&E) industry, encompassing cable and wire manufacturers, appliance producers, and makers of printed circuit boards (PCBs). For cable applications, particularly high-voltage and data cables, precipitated ATH is indispensable due to its ability to prevent dripping and suppress smoke in confined spaces. These buyers require ultra-fine ATH grades with specific surface treatments to maintain the integrity and flexibility of the polymer jackets while achieving maximal fire protection, often purchasing in large volumes under long-term supply contracts to ensure product quality consistency across manufacturing batches.

Furthermore, the producers of solid surface materials (used in kitchen countertops, bathroom fixtures, and commercial cladding) represent a high-growth customer base. These applications leverage ATH not just for its flame retardancy but also for its white pigmentation capability, low refractive index, and ability to impart hardness and chemical resistance to acrylic and polyester resins. The demand for aesthetically pleasing, seamless, and fire-safe solid surfaces in commercial and healthcare facilities drives this segment. Automotive and aerospace interior component manufacturers also constitute important customers, requiring specialized, lightweight ATH grades for applications such as seating foam, floor coverings, and trim parts where reducing mass while maximizing safety is critical.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.1 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Albemarle Corporation, Huber Engineered Materials (J.M. Huber Corporation), Nabaltec AG, Sumitomo Chemical Co., Ltd., Aluminum Corporation of China Limited (CHALCO), Showa Denko K.K., Shandong Aluminum Industry Co. Ltd., R. J. Marshall Company, Hindalco Industries Limited, LKAB Minerals AB, MAL Magyar Aluminium, Tor Minerals International Inc., Dadco, Specialty Chemical Resources Inc., Boke Technology Co., Ltd., Jiangsu Sanji, Zibo Aluminum Corporation, Minelco, Shandong Zhaofeng Group, and Sibelco. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Precipitated Alumina Trihydrate Market Key Technology Landscape

The technological landscape of the Precipitated Alumina Trihydrate market is characterized by continuous refinement of the precipitation process to achieve superior particle morphology and controlled particle size distribution (PSD). Historically, ATH production relied on basic crystallization from sodium aluminate solutions derived from the Bayer process. Modern technologies, however, focus on fine-tuning reaction kinetics—specifically temperature, residence time, and the use of seed crystals—to produce ultra-fine particles consistently below 1 micron. This ultra-fine grade is essential for applications requiring high transparency or use in thin polymer layers where larger particles would negatively impact mechanical strength or aesthetics. Achieving nano-scale precision in precipitation is a critical competitive edge.

A second major technological advancement involves surface modification and encapsulation techniques. Raw precipitated ATH is hydrophilic, which often leads to poor dispersion and weak bonding within hydrophobic polymer matrices like polyethylene or polypropylene, resulting in deteriorated mechanical properties. To counteract this, manufacturers employ advanced coating technologies, utilizing coupling agents such as silanes, titanates, or organic fatty acids like stearic acid. These treatments chemically modify the ATH surface, making it lipophilic and improving interfacial adhesion with the polymer. This allows for higher loading rates without compromising the physical properties of the composite, thereby meeting more stringent flame retardancy standards in automotive and E&E sectors.

Furthermore, process intensification technologies, including continuous crystallization reactors and specialized micronization equipment (such as fluid-bed jet mills), are increasingly adopted to enhance production efficiency and reduce energy consumption. These milling and classification technologies are crucial for creating highly uniform, specialized grades tailored for specific markets, such as solid surface applications that require high brightness and controlled oil absorption. The integration of advanced analytical tools, including laser diffraction particle size analyzers and sophisticated rheometers, ensures that the final product adheres to demanding performance specifications, upholding the stringent quality requirements mandated by high-end end-users.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant and fastest-growing region, driven primarily by exponential growth in the construction and infrastructure sectors, particularly in China, India, and Southeast Asia. The region’s massive electronics manufacturing base necessitates vast quantities of fire-retardant polymers for consumer devices, wiring, and housing components. Government investments in high-speed rail and public housing projects, coupled with gradual regulatory harmonization toward stricter fire codes, solidify APAC's position as the largest consumer of standard and fine precipitated ATH.

- North America: North America represents a mature, high-value market characterized by rigorous regulatory standards (e.g., UL, NFPA) and a strong demand for specialized, surface-treated ATH. Growth is driven by the steady adoption of halogen-free materials in the automotive industry (interior parts) and the consistent strength of the solid surface materials market, where high-purity ATH is a fundamental requirement for achieving premium aesthetic quality and fire rating in commercial buildings.

- Europe: Europe is a key market defined by stringent environmental and safety regulations (REACH, RoHS) that strongly favor non-halogenated flame retardants like ATH. The region is a hub for high-performance specialty chemicals, focusing on ultra-fine and customized ATH grades for use in advanced engineering plastics, aerospace components, and intricate E&E applications where low smoke toxicity and minimal particle size are paramount. Germany and the UK are primary consumers due to strong manufacturing bases.

- Latin America (LATAM): The LATAM market is emerging, demonstrating moderate growth fueled by urbanization and increasing foreign investment in infrastructure, especially in Brazil and Mexico. The demand for ATH is concentrated in the construction and basic electrical cable sectors, though price sensitivity often favors standard precipitated grades over highly specialized variants. Regulatory harmonization efforts are expected to accelerate ATH adoption in the medium term.

- Middle East and Africa (MEA): The MEA region shows promising potential, largely driven by large-scale commercial and residential construction projects in the GCC countries (Saudi Arabia, UAE). The focus here is on fire safety in large, modern buildings and industrial facilities, creating a solid demand base for ATH in composites and construction materials. However, political stability and fluctuating oil revenues can influence market trajectory, making demand slightly volatile compared to other regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Precipitated Alumina Trihydrate Market.- Albemarle Corporation

- Huber Engineered Materials (J.M. Huber Corporation)

- Nabaltec AG

- Sumitomo Chemical Co., Ltd.

- Aluminum Corporation of China Limited (CHALCO)

- Showa Denko K.K.

- Shandong Aluminum Industry Co. Ltd.

- R. J. Marshall Company

- Hindalco Industries Limited

- LKAB Minerals AB

- MAL Magyar Aluminium

- Tor Minerals International Inc.

- Dadco

- Specialty Chemical Resources Inc.

- Boke Technology Co., Ltd.

- Jiangsu Sanji

- Zibo Aluminum Corporation

- Minelco

- Shandong Zhaofeng Group

- Sibelco

Frequently Asked Questions

Analyze common user questions about the Precipitated Alumina Trihydrate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of Precipitated Alumina Trihydrate in industrial applications?

The primary function of Precipitated Alumina Trihydrate (ATH) is as a non-toxic, halogen-free flame retardant and smoke suppressant, particularly effective when incorporated into polymers, plastics, and rubber compounds. It releases water vapor when heated, cooling the material and diluting combustible gases, thereby stopping flame propagation effectively.

How do stringent fire safety regulations globally impact the demand for ATH?

Stringent fire safety regulations, especially those restricting the use of halogenated flame retardants due to toxicity concerns, directly accelerate the demand for ATH. Regulations in construction, transportation, and E&E sectors mandate the use of environmentally friendly, smoke-suppressing alternatives, positioning ATH as a preferred choice.

What is the key difference between precipitated ATH and ground ATH?

Precipitated ATH possesses a finer particle size (often less than 5 microns) and a highly controlled, narrow particle size distribution compared to ground ATH. This refinement allows precipitated grades to be used in high-quality, thin-walled applications, specialized coatings, and solid surface materials requiring superior finish and high transparency.

Which end-use industry is expected to drive the highest growth for Precipitated ATH?

The Construction industry, specifically in the Asia Pacific region, coupled with the global Electrical and Electronics (E&E) sector, is expected to drive the highest growth. This growth is linked to rapid urbanization, infrastructure development, and the continuous need for fire-safe wires, cables, and building panels.

What technological advancements are shaping the future of the ATH market?

Key technological advancements include the development of highly specialized surface-treated ATH grades (using silanes or stearates) to improve compatibility with hydrophobic polymers, and the utilization of continuous crystallization processes to consistently achieve ultra-fine particle sizes for high-performance applications like automotive composites.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager