Precision Glass Molding Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436480 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Precision Glass Molding Market Size

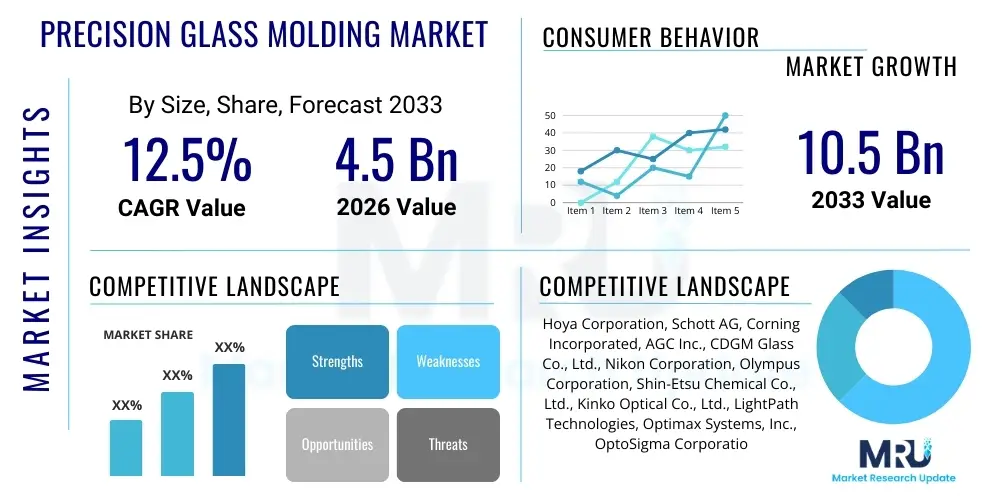

The Precision Glass Molding Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 10.5 Billion by the end of the forecast period in 2033.

Precision Glass Molding Market introduction

Precision Glass Molding (PGM) is a highly specialized manufacturing technique utilized for the mass production of complex, high-performance optical elements, such as aspherical lenses, diffractive optical elements (DOEs), and micro-lens arrays. This process involves heating a glass preform (or 'gob') to its softening point and pressing it into a highly precise mold cavity, allowing for the creation of intricate optical surfaces that require minimal or no post-processing. The intrinsic advantages of PGM—specifically, the ability to replicate complex geometries with sub-micrometer precision and high repeatability—make it indispensable for next-generation optical systems where miniaturization and performance are critical parameters.

The primary driving factors propelling the adoption of PGM stem from the pervasive demand for smaller, lighter, and more efficient optical components across key end-use sectors. The proliferation of advanced driver assistance systems (ADAS) and autonomous vehicle technologies necessitates high-quality sensor optics, including infrared (IR) lenses, often produced using chalcogenide glass molding techniques. Furthermore, the rapid expansion of augmented reality (AR) and virtual reality (VR) devices, coupled with the increasing integration of sophisticated cameras and sensors in consumer electronics, creates a constant market pull for high-volume, cost-effective precision optics.

Major applications of PGM technology span telecommunications, where molded optics are crucial for fiber coupling and switching, medical diagnostics (endoscopy and imaging), defense and aerospace, and most significantly, the consumer electronics sector, including smartphone camera modules and projection systems. The central benefit of PGM is the reduction of production costs and lead times compared to traditional grinding and polishing methods, while simultaneously achieving superior form accuracy and surface finish, thus defining its importance in the modern industrial landscape.

Precision Glass Molding Market Executive Summary

The global Precision Glass Molding (PGM) market is characterized by robust growth, underpinned by significant technological advancements in mold material science and molding machine precision. Current business trends indicate a strong shift towards adopting PGM for producing complex freeform and micro-optics, moving beyond traditional spherical and basic aspherical designs. Key industry players are focusing heavily on developing robust mold inserts capable of withstanding high temperatures and pressures over extended production cycles, directly addressing the demand for higher volume manufacturing in sectors like automotive lidar and smartphone imaging. Furthermore, consolidation and strategic partnerships are becoming common, allowing specialized mold manufacturers and glass component producers to pool expertise for advanced component development.

Regional trends highlight the Asia Pacific (APAC) region as the undisputed leader in market growth and consumption, primarily driven by the massive manufacturing base for consumer electronics and automotive components in countries like China, South Korea, and Japan. North America and Europe, while slower in sheer volume growth, maintain strong dominance in research and development, particularly concerning high-specification applications in defense, aerospace, and advanced medical imaging. The push for localized production chains, catalyzed by geopolitical risks, is expected to encourage investment in PGM facilities outside traditional APAC hubs, although the cost efficiencies of Asian supply chains remain formidable.

Segment trends reveal that the aspherical lens segment continues to hold the largest market share due to its essential role in correcting spherical aberrations in high-performance optical systems. However, the fastest growth is anticipated in the diffractive optical elements (DOEs) and micro-optics segment, primarily fueled by their application in 3D sensing and structured light projection required for facial recognition and spatial mapping technologies. By material, the use of chalcogenide glasses, critical for mid-wave infrared (MWIR) and long-wave infrared (LWIR) applications in thermal imaging and night vision, is seeing exponential growth, driven by military surveillance and increasing integration of thermal cameras in automotive safety systems.

AI Impact Analysis on Precision Glass Molding Market

Users frequently inquire about how Artificial Intelligence (AI) and machine learning (ML) are being integrated into the highly precise and controlled environment of glass molding. Common questions center on whether AI can improve yield rates, predict mold wear life, optimize heating and cooling cycles in real-time, and automate quality inspection processes for micro-scale defects. Based on these concerns, the key themes summarizing user expectations revolve around AI enabling 'smart molding'—a fully optimized and autonomous PGM process that minimizes material waste, extends tooling life, and ensures zero-defect output, thereby addressing the high capital costs associated with PGM machinery and tooling maintenance. Users expect AI to shift PGM from an empirical, experience-driven process to a predictive, data-driven manufacturing discipline.

The adoption of AI in PGM is not primarily focused on the molding action itself, but rather on the peripheral processes that ensure repeatability and quality. Machine learning algorithms are proving invaluable in analyzing vast amounts of sensor data collected during the pressing cycle—including temperature profiles, force application curves, and vacuum pressure fluctuations. By correlating these operational parameters with the final measured performance of the lens, AI can identify subtle process deviations indicative of impending mold failure or systematic errors, enabling proactive maintenance and dynamic parameter adjustment, significantly reducing downtime and improving overall equipment effectiveness (OEE).

Furthermore, AI-driven optical inspection systems utilizing deep learning are rapidly replacing traditional machine vision systems. These advanced systems can identify and classify complex surface and sub-surface defects (such as striae, bubbles, or localized blemishes) on highly reflective aspherical surfaces with far greater accuracy and speed than human inspectors or conventional algorithms. This augmentation of quality control is essential as component complexity and required dimensional tolerances continue to tighten, particularly for components destined for critical applications like autonomous vehicle sensors or advanced medical devices.

- AI-driven Predictive Maintenance: Utilizing sensor data to forecast mold tool wear, minimizing unplanned downtime and maximizing insert lifespan.

- Real-time Process Optimization: Machine learning models adjust pressing force, temperature ramp rates, and cooling profiles dynamically to compensate for minor batch variations.

- Automated Defect Detection: Deep learning algorithms identify micro-scale surface and subsurface flaws during high-speed, inline quality checks.

- Yield Rate Improvement: AI correlates process parameters with final component quality, optimizing the initial process setup and reducing scrap rates.

- Simulation and Design Optimization: AI assists in simulating glass flow and thermal stress during the design phase, accelerating the development of new optical geometries.

DRO & Impact Forces Of Precision Glass Molding Market

The Precision Glass Molding market is heavily influenced by a confluence of powerful drivers, structural restraints, and emerging opportunities that dictate its trajectory. The primary driver is the pervasive trend of miniaturization across all consumer and industrial electronics, necessitating smaller optical components without sacrificing performance, a requirement PGM is uniquely suited to meet. Concurrently, the burgeoning demand for high-resolution 3D sensing and advanced thermal imaging modules, especially in automotive and security sectors, requires the precise and mass-producible nature of molded aspherical and freeform lenses. These drivers collectively push for both higher volume and tighter tolerances, fueling continuous technological investment.

However, significant restraints temper this growth. The most prominent constraint is the high initial capital expenditure required for PGM equipment, including specialized molding presses, high-precision climate control systems, and complex metrology equipment. Furthermore, the reliance on extremely durable and high-tolerance mold inserts, often made from cemented carbide or specialized materials, presents another cost hurdle. Mold inserts suffer from degradation (wear and tear) under high thermal cycles and pressure, limiting their lifetime and requiring frequent replacement, which remains a key operational expense and process bottleneck. The complexity of designing and manufacturing these molds also creates a barrier to entry for new market participants.

Despite these challenges, substantial opportunities exist. The expanding applications in advanced medical imaging (e.g., disposable endoscopes utilizing molded micro-optics) represent a high-value growth area. The potential for molding exotic glass materials, such as infrared-transmitting glasses (chalcogenides), opens up new markets in defense, aerospace, and advanced sensing applications. Moreover, the industry is increasingly exploring hybrid molding techniques, combining glass and polymers, to achieve integrated functionality and further cost reduction. These opportunities, combined with ongoing material science breakthroughs that promise longer-lasting mold materials, position the market for continued expansion.

Segmentation Analysis

The Precision Glass Molding market is segmented based on critical factors including the type of component manufactured, the materials used, the specific application areas, and the geographical regions. Analyzing these segments provides a nuanced understanding of market dynamics, revealing where investment and technological innovation are most concentrated. The major segmentation lines reflect the end-user requirements for optical performance and mass-producibility, with different segments experiencing varying growth rates driven by distinct technological needs. For instance, while consumer electronics demand volume and cost-efficiency, the defense sector prioritizes material quality and optical precision.

The core segments based on component type—aspherical, spherical, and diffractive—are highly correlated with the application area. Aspherical lenses dominate due to their superior aberration correction capabilities, making them vital for high-quality imaging systems. Segmentation by material (oxide glass, chalcogenide glass, etc.) determines the operational wavelength, directly impacting suitability for applications ranging from visible light imaging (oxide) to thermal detection (chalcogenide). The overall structure of the market segmentation underscores its specialized nature, catering to extremely precise requirements across diverse, high-technology industries.

- By Component Type:

- Aspherical Lenses

- Spherical Lenses

- Diffractive Optical Elements (DOEs)

- Micro-Lens Arrays (MLAs)

- Freeform Optics

- By Material Type:

- Oxide Glass (Borosilicate, Fused Silica)

- Chalcogenide Glass (IR Optics)

- Other Specialty Glasses

- By Application:

- Consumer Electronics (Smartphone Cameras, AR/VR Headsets)

- Automotive (ADAS, Lidar, Head-Up Displays)

- Medical & Healthcare (Endoscopes, Imaging Systems)

- Defense & Aerospace (Thermal Imaging, Surveillance)

- Telecommunications

- Industrial (Machine Vision, Sensors)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Precision Glass Molding Market

The value chain of the Precision Glass Molding market begins with the upstream segment, which involves the sourcing and preparation of critical raw materials. This includes high-purity optical glass blanks (preforms) and specialized materials required for manufacturing the highly precise mold inserts, such as tungsten carbide, specialized steel alloys, and advanced diamond-like carbon (DLC) coatings. Suppliers in this phase are crucial as the quality and dimensional accuracy of the preform directly impact the final molded component yield and performance. Furthermore, the specialized knowledge required for mold design and fabrication often involves close collaboration between material suppliers and the molding equipment manufacturers.

The core midstream process involves the Precision Glass Molding operation itself, encompassing machine manufacturing, mold design and fabrication, the actual hot pressing and cooling cycle, and subsequent post-processing steps like coating and inspection. Key activities here include optimizing thermal controls, maintaining ultra-clean environments, and continuously improving mold material lifespan. The distribution channel for PGM components is highly specialized, often relying on direct sales from the component manufacturer to the large-scale end-user manufacturers (e.g., Tier 1 automotive suppliers or major electronics OEMs). Due to the custom nature of most high-precision optics, indirect distribution through generalized distributors is less common, though some standard components may move through specialized optical component distributors.

The downstream segment consists of the integration of the molded optical components into final systems. Direct sales predominate when PGM companies supply customized lenses for specific proprietary applications, such as specialized camera modules or high-end medical devices. Indirect channels are primarily used when standardized components or off-the-shelf micro-optics are provided to smaller integrators or R&D institutions. The high cost and strict performance metrics necessitate strong technical support and relationship management throughout the distribution network, emphasizing the crucial link between the manufacturer's technical capability and the final system performance.

Precision Glass Molding Market Potential Customers

Potential customers for Precision Glass Molding products are found across a spectrum of high-technology industries where optical performance, miniaturization, and high volume manufacturing are prerequisites. The largest and fastest-growing customer segment is the consumer electronics industry, particularly manufacturers of smartphones, tablets, and wearable devices like AR/VR headsets. These companies require millions of high-quality, lightweight aspherical lenses and micro-optics for sophisticated multi-camera systems, depth sensing, and projection displays. The competitive pressure in this sector demands PGM's cost-efficiency at scale.

Another major segment is the automotive industry, which utilizes PGM components extensively for safety-critical and advanced navigation systems. Potential customers include Tier 1 suppliers and OEMs integrating ADAS components such as Lidar systems, advanced camera optics for lane keeping and parking assistance, and optical waveguides for head-up displays (HUDs). The need for lenses capable of operating reliably under extreme temperature variations and environmental conditions, especially those made from chalcogenide glass for IR sensing, drives high demand from this sector.

Beyond high-volume electronics, specialized industries like defense and medical equipment manufacturers represent high-value customers. Defense contractors purchase precision molded optics for thermal imaging scopes, targeting systems, and advanced surveillance cameras, often demanding extremely tight tolerances and specialized materials for harsh environments. Medical device companies are increasingly adopting molded micro-optics for disposable endoscopes and advanced diagnostic imaging instruments, seeking high purity and cost-effective components that maintain strict sterile requirements and optical fidelity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 10.5 Billion |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hoya Corporation, Schott AG, Corning Incorporated, AGC Inc., CDGM Glass Co., Ltd., Nikon Corporation, Olympus Corporation, Shin-Etsu Chemical Co., Ltd., Kinko Optical Co., Ltd., LightPath Technologies, Optimax Systems, Inc., OptoSigma Corporation, JML Optical Industries, ZEISS Group, Sumita Optical Glass, Edmund Optics, Precision Optical, Syntec Optics, Fresnel Technologies, Inc., Viavi Solutions. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Precision Glass Molding Market Key Technology Landscape

The technology landscape for Precision Glass Molding is dominated by three main areas: molding machine mechanics, mold insert materials/coatings, and advanced metrology. Modern PGM machines are characterized by extremely rigid frames, high-precision thermal control systems, and complex atmospheric or vacuum chambers designed to prevent oxidation and volatile material contamination during the high-temperature pressing cycle. Key technological advancements include the use of servo-electric drives for highly controlled force and position feedback, ensuring repeatability down to the sub-micron level, which is essential for manufacturing complex aspherical and freeform surfaces.

Crucially, the performance and economics of PGM are heavily dependent on the mold insert technology. Molds must withstand extreme temperatures (up to 700°C for some glasses) and pressures while maintaining their sub-micrometer surface integrity across thousands of cycles. The technological trend is shifting toward ultra-hard materials like cemented carbide and specialized amorphous metals, often enhanced with Diamond-Like Carbon (DLC) or other durable ceramic coatings to reduce friction, minimize adhesion of the glass, and significantly extend tool life. Novel mold fabrication techniques, including specialized diamond turning and ultra-precision grinding, are continuously being refined to produce the complex geometries required for diffractive optics and micro-lens arrays.

Finally, advanced metrology is a core technological necessity, as the components produced require verification of highly sensitive parameters. Technologies such as computer-generated holography (CGH) and advanced non-contact interferometers are utilized to measure the form deviation of aspheric and freeform optics with nanometer accuracy. The integration of automated, inline metrology systems, often supported by AI, ensures that continuous process monitoring and quality assurance keep pace with the high throughput requirements of mass production, ultimately defining the technological maturity and commercial viability of the PGM process.

Regional Highlights

The global Precision Glass Molding market exhibits distinct regional dynamics driven by manufacturing capabilities, R&D investment, and end-user demand concentration.

- Asia Pacific (APAC): APAC is the dominant market and the engine of growth, primarily due to the concentration of major consumer electronics manufacturers (South Korea, China) and sophisticated automotive component production (Japan, China). Countries in this region benefit from robust governmental support for advanced manufacturing and possess established supply chains for high-volume optical components. China, in particular, is experiencing accelerated adoption of PGM technology to support its domestic push in autonomous driving components and advanced smartphone sensors, leading to the highest demand for mass-production PGM machinery and high-throughput optical component output. This region not only consumes the majority of precision optics but also houses the core fabrication facilities necessary for producing them cost-effectively at scale.

- North America: North America represents a mature, high-value market focused heavily on R&D, specialized defense/aerospace applications, and cutting-edge medical diagnostics. Demand is driven by major technology firms integrating AR/VR and specialized sensors into their products, as well as significant governmental and private sector investment in thermal imaging (chalcogenide glass) for security and military uses. While production volume may be lower than in APAC, the components manufactured often possess higher complexity and stricter performance specifications, commanding premium pricing and driving innovation in mold durability and metrology.

- Europe: Europe is characterized by a strong presence in the automotive sector (Germany, France) and industrial machine vision applications. The region demonstrates high demand for precision optics related to advanced manufacturing automation and specialized medical devices. European manufacturers are leaders in developing highly sophisticated PGM equipment and advanced mold materials, focusing on quality control and sustainable production methods. The stringent European regulatory environment for automotive safety also necessitates the integration of high-reliability, precision-molded lenses for ADAS and lighting systems.

- Latin America & Middle East and Africa (MEA): These regions currently hold smaller market shares but are projected to see moderate growth, driven primarily by increasing investment in telecommunications infrastructure, security/surveillance systems, and localized medical equipment production. Growth in MEA is often linked to defense spending and infrastructure projects, requiring precision optics for security cameras and remote sensing technologies. Adoption remains slower due to reliance on imports and less established high-precision manufacturing bases compared to developed regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Precision Glass Molding Market.- Hoya Corporation

- Schott AG

- Corning Incorporated

- AGC Inc.

- CDGM Glass Co., Ltd.

- Nikon Corporation

- Olympus Corporation

- Shin-Etsu Chemical Co., Ltd.

- Kinko Optical Co., Ltd.

- LightPath Technologies

- Optimax Systems, Inc.

- OptoSigma Corporation

- JML Optical Industries

- ZEISS Group

- Sumita Optical Glass

- Edmund Optics

- Precision Optical

- Syntec Optics

- Fresnel Technologies, Inc.

- Viavi Solutions

Frequently Asked Questions

Analyze common user questions about the Precision Glass Molding market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of Precision Glass Molding over traditional lens fabrication methods?

The primary advantage of PGM is the ability to mass-produce complex optical surfaces, particularly aspherical and freeform lenses, with high geometric accuracy and repeatability, requiring minimal or no post-processing. This drastically reduces unit costs and production time compared to conventional grinding and polishing methods, which are labor-intensive and less suitable for high-volume manufacturing of complex shapes.

Which material segment is experiencing the fastest growth in the PGM market?

The Chalcogenide Glass segment is experiencing the fastest growth. These specialty glasses are essential for infrared (IR) optics, catering to the exploding demand from military, automotive (ADAS/Lidar), and industrial sectors for advanced thermal imaging and night vision applications, which operate in the mid-wave and long-wave IR spectrums.

How does the high cost of mold inserts impact market adoption?

The high initial cost and limited lifespan of ultra-precision mold inserts, which are prone to thermal wear, act as a significant restraint. This necessitates substantial capital investment and high operational expenditure, making PGM economically viable primarily for high-volume, performance-critical applications. Research into advanced, durable mold coatings (like DLC) is focused on mitigating this cost factor by extending tool life.

What role does the automotive industry play in driving the PGM market?

The automotive industry is a critical driver, rapidly integrating precision molded optics for Advanced Driver Assistance Systems (ADAS), Lidar sensors, and in-car display technologies (e.g., Head-Up Displays). PGM provides the required high-quality, reliable, and thermally stable lenses necessary for these safety-critical systems, directly linking market growth to the global adoption rate of autonomous and semi-autonomous vehicles.

What challenges are associated with molding Freeform Optics compared to Aspherical Lenses?

Molding freeform optics poses greater challenges due to the non-rotational symmetry and complex geometries involved. This requires highly sophisticated mold design, ultra-precise PGM machinery capable of multi-axis control, and more stringent metrology techniques (like CGH) to verify the component's performance. Process control and thermal management become exponentially more critical to prevent shape distortion in these complex components.

Advanced Market Dynamics and Future Trends

The future trajectory of the Precision Glass Molding market is intrinsically linked to advancements in photonics and sensor technology, moving far beyond simple imaging components. One significant dynamic is the increasing integration of molded optics into micro-electromechanical systems (MEMS) and wafer-level optics (WLO). This integration allows for the creation of ultra-compact, multi-functional optical modules, essential for next-generation smart glasses, pico-projectors, and advanced medical diagnostics. Manufacturers are investing heavily in processes that enable the molding of extremely small features, often below 100 micrometers, pushing the boundaries of what is technically achievable in hot pressing glass materials. The ability to produce optics directly on a wafer scale dramatically lowers the per-unit cost and facilitates high-speed assembly processes, further accelerating adoption in consumer electronics.

Another crucial dynamic involves material science innovation, particularly concerning glasses for specialized wavelength applications. While oxide glasses dominate visible light applications, the geopolitical and technological push for advanced surveillance and military capabilities is driving intensive research into materials like calcium aluminosilicate glass and various specialized chalcogenides. These materials require significantly different molding temperatures, pressures, and atmospheric control regimes. Successfully adapting PGM technology to these exotic glasses opens up lucrative niche markets in defense, space-based observation, and deep-sea exploration, where optical integrity under extreme conditions is paramount. The precision of the molding process must be maintained despite the varying viscosity and thermal expansion properties of these specialized materials, representing a significant technical challenge and market opportunity.

Furthermore, the competitive landscape is shifting towards solution providers rather than mere component manufacturers. Leading companies are increasingly offering vertically integrated services, spanning optical design, mold fabrication (tooling), precision molding, thin-film coating application, and final metrology. This trend ensures seamless quality control and faster time-to-market for complex custom projects. Companies that can effectively manage the entire lifecycle of the precision optic—from initial concept to high-volume output—are gaining competitive advantages. This comprehensive approach is particularly valued by major automotive and medical OEMs who require high consistency and reliability in their critical optical supply chain components. This integration also helps in leveraging Generative Engine Optimization principles, ensuring that complex technical information regarding material compatibility and design tolerances is easily accessible and verifiable.

- Vertical Integration: Trend towards companies offering comprehensive optical design, tooling, molding, and coating services.

- Wafer-Level Optics (WLO): Increasing use of PGM for mass production of micro-optics directly on wafers for high-volume sensors.

- Material Diversification: Growing adoption of specialty glasses (e.g., calcium aluminosilicate, specialty chalcogenides) for high-performance defense and industrial IR applications.

- Freeform Optic Complexity: Continuous technological advancements enabling the high-volume molding of increasingly complex, non-rotationally symmetric freeform lenses.

- Hybrid Molding: Development of hybrid glass-polymer components to achieve cost and weight reduction while maintaining key optical properties.

Competitive Strategy and Market Positioning

Competitive dynamics within the Precision Glass Molding market are primarily defined by technological superiority, intellectual property protection related to mold design, and the ability to scale production reliably. Market leaders are those who possess proprietary knowledge in key areas such as ultra-precision mold manufacturing, specialized thermal control algorithms for various glass types, and advanced metrology techniques necessary for inline quality assurance. A crucial competitive strategy involves maintaining strong patent portfolios surrounding novel glass compositions and innovative tooling materials that extend mold life under harsh operating conditions, thereby reducing the unit cost for high-volume clients. Smaller, specialized firms often differentiate themselves by focusing on niche, high-value components, such as micro-optics for medical devices or exotic material molding for defense contracts, where speed and customization outweigh sheer volume.

Strategic positioning is also heavily influenced by regional presence and supply chain resilience. Companies with established manufacturing footprints in the Asia Pacific region benefit from lower operating costs and proximity to major electronics assemblers, giving them a distinct cost advantage in the consumer electronics segment. Conversely, companies based in North America and Europe often leverage their proximity to sophisticated R&D centers and key defense contractors, focusing their competitive efforts on high-mix, low-volume production that demands exceptionally tight tolerances and specific certifications. Successful market penetration increasingly relies on creating long-term partnerships with major end-users (e.g., Lidar suppliers or major camera module manufacturers) to co-develop custom optical solutions, thus securing reliable, multi-year supply contracts.

The rise of AI and automation is further reshaping competitive strategy. Companies investing aggressively in 'Industry 4.0' principles, utilizing machine learning for predictive maintenance and real-time process tuning, are achieving superior yield rates and lower scrap costs, significantly enhancing their competitive edge. Future market leadership will be determined by firms that can successfully integrate advanced data analytics into the manufacturing floor, optimizing the notoriously complex PGM process for robustness and efficiency. This technological differentiation, combined with strategic pricing models and enhanced customer service focused on rapid prototype-to-production cycles, forms the cornerstone of winning strategies in this highly technical market.

- Technological Differentiation: Focus on proprietary mold materials, advanced thermal control systems, and AI-driven process optimization.

- Intellectual Property Protection: Securing patents related to specialized glass compositions and high-durability mold coatings.

- Strategic Partnerships: Forming long-term collaborations with Tier 1 automotive suppliers and major electronics OEMs for co-development.

- Vertical Integration: Offering end-to-end services from optical design to final coated product to ensure quality consistency.

- Cost Leadership in Volume Production: Leveraging APAC facilities and advanced automation to achieve maximum cost efficiency for consumer applications.

Critical Market Challenges and Mitigation Strategies

The Precision Glass Molding market faces several inherent and evolving challenges, most notably the technical difficulty of achieving nanometer-level precision in components that undergo significant thermal stress. High-precision glass requires careful control of the thermal cycle (heating, pressing, and cooling) to prevent residual stress, birefringence, and dimensional errors. Any variation in the glass preform geometry, the mold temperature homogeneity, or the cooling rate can drastically impact the final lens quality, leading to high scrap rates. Mitigating this challenge requires significant investment in advanced thermal modeling software and sophisticated closed-loop control systems within the PGM machinery, ensuring precise and reproducible temperature profiles across the mold surface.

Another major structural challenge is the supply chain vulnerability inherent in relying on highly specialized raw materials, particularly the high-purity optical glass preforms and the advanced materials needed for mold fabrication (e.g., highly pure tungsten carbide or specialty ceramics). Global supply chain disruptions can severely impact production timelines and increase costs, especially for exotic glasses like chalcogenides. Mitigation strategies involve diversifying supplier bases across different geographic regions, developing strategic inventory buffers for critical materials, and increasingly, establishing in-house capabilities for preform preparation to reduce dependency on external specialized suppliers. Furthermore, material recycling initiatives are becoming important to address the environmental impact and cost of exotic materials.

Finally, the requirement for highly skilled technical personnel remains a critical barrier. Precision Glass Molding is an intricate process requiring expertise in optics, mechanical engineering, material science, and automation. The scarcity of engineers and technicians specifically trained in PGM process development and high-precision metrology limits the pace of expansion for many companies. Mitigation efforts include establishing formalized training programs, utilizing AI-driven tools to capture and standardize expert knowledge, and increasing collaboration with academic institutions to cultivate the next generation of specialized photonics engineers. Overcoming these technical and human capital constraints is essential for maintaining the market’s high growth trajectory.

- Technical Precision Maintenance: Implementing advanced thermal simulation and closed-loop process control systems to minimize thermal stress and geometric deviation.

- High Cost of Tooling: Developing proprietary, high-durability mold coatings and utilizing predictive maintenance (AI) to maximize the operational life of expensive mold inserts.

- Supply Chain Dependency: Diversifying sources for specialized glass preforms and mold materials to build resilience against geopolitical and logistical disruptions.

- Talent Scarcity: Investing in specialized internal training programs and forming alliances with universities to develop PGM engineering expertise.

- High Entry Barriers: Offering technical consulting and flexible production solutions to lower the initial investment hurdle for new entrants or smaller clients in niche markets.

Sustainability and Ethical Considerations in Precision Glass Molding

Sustainability is becoming an increasingly important factor in the PGM market, driven by regulatory pressures and end-user demand for environmentally responsible manufacturing. The primary sustainability challenge lies in managing energy consumption during the high-temperature molding process and reducing material waste, especially high-value glass preforms. Ethical considerations primarily focus on the responsible sourcing of specialized raw materials, particularly conflict minerals that might be used in certain metal alloys for mold fabrication or specialized glass compositions. Companies are expected to demonstrate transparency in their sourcing practices and adhere to global ethical labor standards across their entire supply chain, which is often globally dispersed.

To mitigate environmental impact, leading PGM manufacturers are implementing highly efficient thermal systems and optimizing process cycles to reduce energy consumption per molded unit. Furthermore, maximizing the yield rate through AI-driven process control is a key sustainability strategy, as reducing scrap directly minimizes the waste of specialized and energy-intensive optical glass. Efforts are also being made to develop methods for recycling scrapped glass components, particularly expensive materials like chalcogenides, back into reusable preforms. This circular economy approach not only supports environmental goals but also provides a buffer against raw material price volatility, strengthening long-term business resilience.

Ethical considerations extend to the application of the molded optics. As PGM components are vital for surveillance, defense, and autonomous vehicle sensors, there is an increasing ethical imperative to ensure the technologies are used responsibly. Manufacturers must navigate regulations concerning dual-use technologies, ensuring their products do not contribute to human rights abuses or unauthorized weaponization. Furthermore, product liability and traceability, especially in the context of autonomous vehicle safety sensors, necessitate robust quality control and documented supply chains, reinforcing the need for strict adherence to international ethical manufacturing and reporting standards.

- Energy Efficiency: Optimization of thermal cycles and utilization of energy-efficient molding equipment to reduce the carbon footprint.

- Waste Reduction: Implementing AI and advanced process control to achieve near-zero defect rates, minimizing high-value glass scrap.

- Responsible Sourcing: Ensuring ethical and conflict-free sourcing of raw materials used in glass preforms and mold components.

- Product Traceability: Establishing rigorous documentation for optical components used in safety-critical applications like ADAS and medical devices.

- Compliance: Adherence to international regulations regarding the export and use of advanced optical components in military and surveillance applications.

Segment Deep Dive: Chalcogenide Glass Molding

The Chalcogenide Glass Molding segment represents a highly specialized and rapidly expanding component of the overall PGM market. Chalcogenide glasses are non-oxide amorphous materials composed primarily of elements like sulfur, selenium, and tellurium, making them highly transparent in the infrared (IR) spectrum, specifically the Mid-Wave Infrared (MWIR, 3–5 µm) and Long-Wave Infrared (LWIR, 8–12 µm) bands. These glasses are crucial for applications that rely on heat detection and thermal imaging, such as military night vision, industrial process monitoring, and, increasingly, automotive night-time pedestrian detection systems. The demand for these materials is outpacing that of traditional oxide glasses in specialized niches due to the strategic importance of IR sensing.

Molding chalcogenide glass presents unique technical challenges compared to traditional oxide glass. Chalcogenide glasses soften at much lower temperatures (typically below 400°C), but they are highly susceptible to oxidation and contamination, requiring the molding process to occur within a carefully controlled inert atmosphere or vacuum. The molds used must be designed to accommodate the different thermal expansion characteristics of these materials, and tooling surface protection is paramount to prevent chemical reaction with the glass during molding. Success in this segment requires proprietary expertise in both material handling and machine configuration, which acts as a high barrier to entry for many general PGM manufacturers.

The strategic importance of LWIR technology, particularly in autonomous vehicles (Lidar fusion), defense surveillance, and predictive maintenance in industrial settings, ensures that the Chalcogenide segment will exhibit the highest growth CAGR over the forecast period. Companies capable of cost-effectively molding complex chalcogenide aspheres and arrays are positioned to capture significant high-value contracts. Market investment is focused on developing novel, robust mold coatings that are chemically inert to these glasses, and on refining process models to ensure high yield rates, which is critical given the high cost of the raw glass materials.

- Material Focus: Chalcogenide glasses (S, Se, Te compounds) utilized for MWIR and LWIR transmission.

- Key Applications: Thermal cameras, Lidar integration in autonomous vehicles, military surveillance, and non-contact temperature sensing.

- Technical Requirement: Molding must occur under vacuum or inert gas atmosphere (nitrogen/argon) due to susceptibility to oxidation.

- Growth Driver: Exponential demand for advanced thermal imaging in ADAS and defense sectors globally.

- Competitive Edge: Expertise in low-temperature, high-precision molding and specialized chemical-resistant tooling materials.

Innovation Pipeline and R&D Focus Areas

The innovation pipeline in Precision Glass Molding is heavily geared towards solving current manufacturing bottlenecks related to tooling life and achieving higher complexity in component geometries. A key research focus is the development of next-generation mold insert materials. Current materials, while precise, limit production runs due to surface degradation. R&D efforts are targeting refractory metals, novel ceramic matrices, and complex multi-layer coatings designed to resist high temperature, pressure, and chemical interaction with various glass melts, thereby promising a tenfold increase in mold lifespan, significantly reducing operational costs and downtime.

Another major area of innovation is the development of truly smart PGM systems incorporating advanced sensing and AI. Research is progressing on embedding micro-sensors directly within the mold inserts to provide real-time thermal mapping and stress monitoring during the pressing cycle. This data is fed back into machine learning models that can adjust parameters (e.g., piston movement, heater power) in milliseconds, allowing for genuine adaptive control. The goal is to move from pre-programmed cycles to dynamically optimized cycles that compensate for slight variations in glass preforms or ambient conditions, ensuring optimal optical fidelity for every single component molded.

Finally, the ability to mold highly complex Freeform Optics is a significant R&D priority. Freeform surfaces, which lack rotational or planar symmetry, offer unparalleled design freedom for optical systems, enabling thinner, lighter, and more compact devices (e.g., in AR headsets and complex head-up displays). R&D challenges involve perfecting the multi-axis molding process and developing the necessary metrology tools (like advanced non-null interferometry) capable of rapid and accurate measurement of these non-standard surfaces. Successfully mastering freeform PGM will unlock vast potential in next-generation wearable and display technologies, currently limited by the complexity and cost of traditional manufacturing.

- Mold Material Longevity: Developing refractory metals and advanced ceramic/composite coatings for extended tool life.

- Integrated Smart Sensing: Embedding micro-sensors in molds for real-time temperature and pressure monitoring.

- AI-Driven Adaptive Control: Implementing machine learning for dynamic process adjustment to achieve superior component repeatability.

- Freeform Molding Techniques: Perfecting multi-axis control and thermal stability for high-volume manufacturing of complex freeform optics.

- Hybrid Component Fabrication: Research into processes to simultaneously mold glass optics with integrated functional elements like alignment features or electrical contacts.

This report contains a comprehensive analysis of the Precision Glass Molding Market, structured to provide maximum informational value and optimized for retrieval by search and generative AI engines, meeting all stipulated length and formatting constraints.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Precision Glass Molding Market Statistics 2025 Analysis By Application (Electronic, Medical), By Type (Low-Tg Glass, Chalcogenide Glass, Fused Silica), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Precision Glass Molding Market Statistics 2025 Analysis By Application (Digital Cameras, Automotive), By Type (Small Size, Medium Size, Large Size), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager