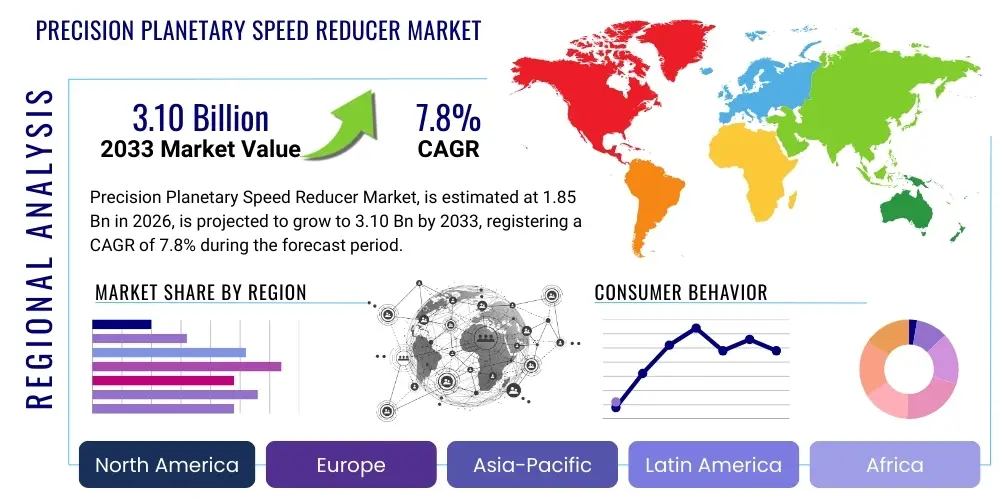

Precision Planetary Speed Reducer Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440061 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Precision Planetary Speed Reducer Market Size

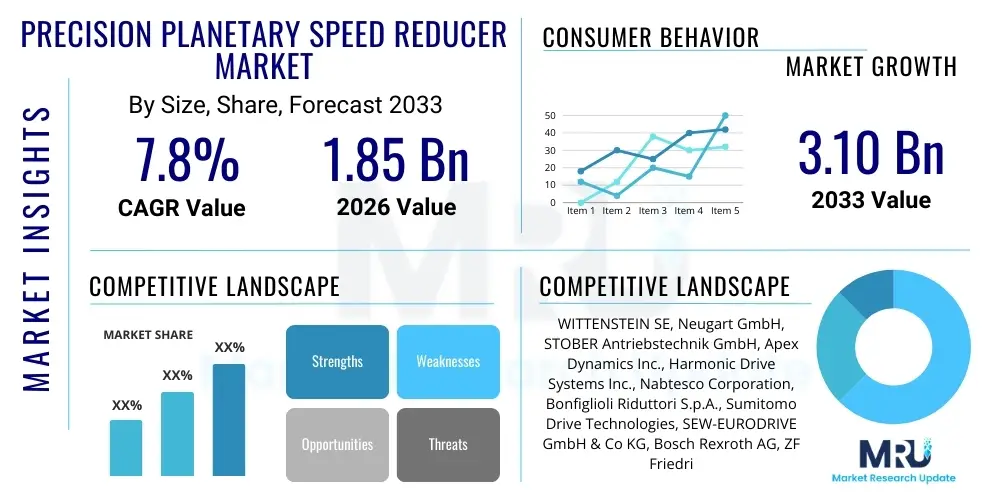

The Precision Planetary Speed Reducer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 3.10 Billion by the end of the forecast period in 2033.

Precision Planetary Speed Reducer Market introduction

The precision planetary speed reducer market encompasses advanced mechanical components designed to provide high torque transmission, exceptional accuracy, and minimal backlash in motion control systems. These reducers employ a planetary gear arrangement where multiple planet gears revolve around a central sun gear, all encased within an internally toothed ring gear. This configuration allows for compact designs, high power density, and efficient power transfer, making them indispensable in applications demanding precise positioning and smooth operation. The product range includes various types such as inline, right-angle, and flange-mounted configurations, each tailored to specific space constraints and operational requirements, ensuring versatility across diverse industrial sectors. Their robust construction and ability to withstand significant loads while maintaining precise motion control make them a preferred choice for critical applications.

Major applications for precision planetary speed reducers span across a multitude of industries, including robotics and automation, machine tools, packaging machinery, medical equipment, aerospace and defense, and semiconductor manufacturing. In robotics, they are crucial for achieving exact joint movements and repeatable performance, directly contributing to the robot's accuracy and payload capacity. For machine tools, these reducers enable high-speed, high-precision machining, reducing cycle times and improving surface finishes. The benefits extend beyond mere functionality; they include enhanced system efficiency, reduced wear and tear on motors, extended equipment lifespan, and improved overall operational reliability. Their ability to deliver high torque with low inertia makes them ideal for dynamic applications where rapid acceleration and deceleration are common, protecting the motor from excessive stress and ensuring smooth, controlled motion.

The primary driving factors behind the sustained growth of the precision planetary speed reducer market include the accelerating global trend of industrial automation and the increasing adoption of robotics across manufacturing processes. Industries are continuously striving for higher productivity, improved product quality, and reduced operational costs, all of which are significantly supported by advanced automation solutions that rely heavily on precision motion control components. Furthermore, the expansion of industries such as electric vehicles, smart manufacturing (Industry 4.0), and advanced healthcare technologies creates new avenues for these reducers. The growing demand for energy-efficient solutions and the ongoing technological advancements in materials science and manufacturing processes, leading to more compact, durable, and performant reducers, further fuel market expansion. The strategic shift towards high-value manufacturing and the necessity for intricate, repeatable tasks in complex assembly lines globally underscores the indispensable role of these precision components.

Precision Planetary Speed Reducer Market Executive Summary

The precision planetary speed reducer market is experiencing robust growth, driven by an escalating demand for automation and precision control across various industries. Key business trends indicate a strong focus on developing more compact, modular, and energy-efficient designs, often integrating smart features for enhanced diagnostics and predictive maintenance capabilities. Manufacturers are also emphasizing customization to meet the specific requirements of niche applications, moving away from a one-size-fits-all approach. Strategic partnerships and collaborations between reducer manufacturers and robotics companies or system integrators are becoming increasingly common, aiming to provide comprehensive motion control solutions. Furthermore, the market is witnessing a rise in mergers and acquisitions as companies seek to expand their product portfolios, technological expertise, and geographical reach, consolidating their positions in a competitive landscape.

From a regional perspective, Asia Pacific continues to dominate the market, primarily due to the rapid industrialization, extensive manufacturing base, and significant investments in automation, particularly in countries like China, Japan, South Korea, and India. The region's robust electronics, automotive, and general manufacturing sectors are major consumers of precision planetary speed reducers. Europe follows closely, driven by advanced manufacturing capabilities, stringent quality standards, and a strong emphasis on Industry 4.0 initiatives in countries such as Germany and Italy. North America also represents a substantial market, with growth propelled by the aerospace and defense, medical devices, and advanced robotics industries. Emerging markets in Latin America and the Middle East and Africa are showing promising growth potential as they progressively adopt modern manufacturing techniques and expand their industrial infrastructure, albeit from a smaller base, indicating future opportunities.

Segmentation trends highlight a significant demand for low backlash and ultra-low backlash reducers, crucial for high-precision applications like surgical robotics and sophisticated machine tools where even minimal positional errors are unacceptable. The robotics and automation application segment remains the largest and fastest-growing, reflecting the global surge in automated production lines and autonomous systems. There is also a notable trend towards higher torque capacity reducers to support heavier payloads and more demanding industrial tasks. Furthermore, the market is seeing increased adoption of integrated motor-reducer units, simplifying installation and optimizing performance. Industry-specific solutions, particularly for medical, semiconductor, and food & beverage sectors, are gaining traction, as these industries require specialized materials, hygiene standards, and operational parameters that standard reducers may not fully address, leading to a more fragmented yet specialized market development.

AI Impact Analysis on Precision Planetary Speed Reducer Market

The integration of Artificial Intelligence (AI) is set to profoundly reshape the precision planetary speed reducer market, addressing common user questions around efficiency, predictive maintenance, and autonomous operation. Users are primarily concerned with how AI can extend the lifespan of these critical components, optimize their performance in real-time, and enable seamless integration into smart factory ecosystems. The expectation is that AI will move these components beyond mere mechanical functionality, transforming them into intelligent assets capable of self-diagnosis and adaptive behavior. There's a strong desire to leverage AI for reducing downtime, minimizing maintenance costs, and maximizing the operational uptime of automated systems, all while ensuring unparalleled precision and reliability. Furthermore, questions arise regarding AI's role in the design and manufacturing process, aiming for enhanced customization and accelerated product development cycles that meet increasingly complex and dynamic application demands.

- Predictive Maintenance: AI algorithms analyze sensor data (vibration, temperature, torque) from reducers to predict potential failures, enabling proactive maintenance and significantly reducing unscheduled downtime.

- Optimized Performance: AI-driven control systems can dynamically adjust reducer parameters (e.g., speed, torque) based on real-time operational conditions, optimizing energy consumption and extending component life.

- Smart Manufacturing Integration: Precision reducers with integrated AI capabilities can seamlessly communicate with broader Industry 4.0 platforms, contributing to fully autonomous production lines and intelligent material handling systems.

- Design & Customization: AI-powered generative design tools can rapidly create optimized reducer geometries and material compositions, leading to more efficient, lighter, and application-specific components.

- Quality Control: AI vision systems and machine learning models can enhance quality inspection during manufacturing, identifying microscopic defects and ensuring consistent precision performance.

- Enhanced Diagnostics: AI facilitates advanced troubleshooting by identifying root causes of operational anomalies, streamlining repair processes and improving overall system reliability.

- Adaptive Motion Control: AI enables reducers to adapt to varying load conditions and environmental changes, ensuring consistent precision and preventing mechanical stress under dynamic operations.

DRO & Impact Forces Of Precision Planetary Speed Reducer Market

The Precision Planetary Speed Reducer Market is significantly influenced by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces that collectively shape its growth trajectory and competitive landscape. A primary driver is the accelerating global adoption of industrial automation and advanced robotics across manufacturing, logistics, and healthcare sectors, all of which critically rely on precise motion control. The relentless pursuit of higher productivity, enhanced efficiency, and superior product quality by industries worldwide further amplifies the demand for these sophisticated components. Moreover, the inherent benefits of planetary reducers, such as high torque density, compact design, low backlash, and high positional accuracy, make them indispensable for applications demanding stringent performance criteria. The expansion of emerging industries, including electric vehicle manufacturing and autonomous systems, also fuels demand for specialized and robust precision reducers, pushing technological boundaries.

However, the market faces several restraints that could impede its growth. The high initial investment costs associated with precision planetary speed reducers, driven by complex manufacturing processes and specialized materials, can be a barrier for small and medium-sized enterprises (SMEs) or in cost-sensitive applications. The technical complexity involved in their design, selection, and integration into existing systems often requires specialized expertise, adding to overall implementation costs and potential delays. Furthermore, the competitive landscape includes alternative transmission technologies, such as harmonic drives or cycloidal reducers, which, while having different characteristics, can sometimes be viable substitutes depending on specific application requirements. Economic uncertainties and fluctuations in raw material prices can also impact manufacturing costs and market stability, influencing pricing strategies and profit margins for manufacturers in the sector.

Despite these challenges, numerous opportunities are poised to drive the market forward. The increasing penetration of Industry 4.0 and the Internet of Things (IoT) provides avenues for integrating smart features into reducers, enabling predictive maintenance, real-time monitoring, and enhanced connectivity. This technological convergence offers significant value proposition for end-users seeking higher operational efficiency and reduced downtime. Expanding applications in nascent fields like collaborative robots (cobots), drones, and advanced medical prosthetics present new growth frontiers. Furthermore, continuous advancements in material science, additive manufacturing (3D printing), and design optimization techniques are leading to the development of more durable, lightweight, and cost-effective reducers. The growing focus on customization and modularity allows manufacturers to cater to specific industrial needs, unlocking untapped market segments and fostering innovation. Broader impact forces, including global economic growth, geopolitical stability, and evolving trade policies, also play a crucial role in shaping market dynamics, influencing investment in automation and industrial expansion across various regions, particularly impacting global supply chains and manufacturing footprints.

Segmentation Analysis

The Precision Planetary Speed Reducer Market is meticulously segmented across various dimensions to provide a granular understanding of its diverse landscape and cater to the specific needs of different industries and applications. This segmentation allows manufacturers to tailor their product offerings, marketing strategies, and R&D efforts more effectively. The primary segmentation categories include type, backlash level, torque capacity, application, and end-use industry, each revealing distinct market trends and growth drivers. Understanding these segments is crucial for stakeholders to identify lucrative niches, anticipate demand shifts, and develop targeted solutions that resonate with particular customer requirements, from highly sensitive medical devices to robust heavy industrial machinery. The intricate demands of modern automation necessitate such detailed breakdowns, ensuring that the right precision reducer is deployed for optimal performance and efficiency, thereby driving both innovation and market expansion.

- By Type

- Inline Planetary Gearboxes

- Right-Angle Planetary Gearboxes

- Flange-Mounted Planetary Gearboxes

- Shaft-Mounted Planetary Gearboxes

- Custom Planetary Gearboxes

- By Backlash

- Standard Backlash

- Low Backlash

- Ultra-Low Backlash

- By Torque Capacity

- Low Torque (<100 Nm)

- Medium Torque (100-500 Nm)

- High Torque (>500 Nm)

- By Application

- Robotics & Automation

- Machine Tools

- Packaging Machinery

- Printing Machinery

- Medical Equipment

- Aerospace & Defense

- Material Handling

- Food & Beverage Processing

- Automotive Manufacturing

- Textile Machinery

- Semiconductor Manufacturing Equipment

- General Industrial Automation

- By End-Use Industry

- Automotive

- Aerospace

- Robotics & Automation

- Machine Tools

- Medical & Healthcare

- Food & Beverage

- Packaging

- Logistics & Warehousing

- Energy

- Textile

- Semiconductor

- Other Manufacturing

Value Chain Analysis For Precision Planetary Speed Reducer Market

The value chain for the Precision Planetary Speed Reducer Market is a complex ecosystem involving multiple stages, from raw material sourcing to end-user deployment, each contributing to the final product's value and market availability. At the upstream end, the chain begins with the procurement of high-quality raw materials, primarily specialized steels, aluminum alloys, and advanced plastics or composites, which are essential for gear components, casings, and shafts. Suppliers of precision bearings, seals, lubricants, and electronic sensors also form a critical part of the upstream segment, ensuring the durability, efficiency, and intelligence of the final reducer. These material and component suppliers often adhere to strict quality standards and certifications, given the high-precision nature of the end product. The quality and availability of these foundational elements directly impact the manufacturing cost, performance, and lead times of precision planetary speed reducers, making strong supplier relationships crucial for manufacturers.

Moving downstream, the value chain encompasses the design, manufacturing, assembly, testing, and distribution phases. Precision engineering firms and specialized manufacturers are responsible for the intricate processes of gear cutting, heat treatment, grinding, and surface finishing, which are vital for achieving the ultra-low backlash and high accuracy demanded by the market. Advanced manufacturing techniques, including CNC machining and lean production principles, are extensively utilized to ensure consistent quality and efficiency. After rigorous testing and quality assurance checks, the finished reducers are then channeled to end-users through various distribution models. Direct sales channels are often employed for large industrial clients or highly customized solutions, allowing for direct technical support and consultation. Indirect channels, involving a network of distributors, agents, and system integrators, serve a broader market, providing local availability, inventory management, and application expertise, particularly for standard products or smaller volume orders.

The distribution network plays a pivotal role in market penetration and customer reach, acting as a crucial link between manufacturers and diverse end-use industries. Both direct and indirect distribution channels are strategically employed to optimize market coverage. Direct channels facilitate closer customer relationships, enabling manufacturers to gather direct feedback, offer bespoke solutions, and provide specialized after-sales support, which is particularly valuable for complex, high-value projects in sectors like aerospace or advanced robotics. Indirect channels, on the other hand, leverage the established logistics and customer bases of distributors and integrators, allowing manufacturers to access a wider geographic spread and cater to a fragmented customer base without incurring the full overhead of direct sales offices. These intermediaries often add value through local stockholding, rapid delivery, technical pre-sales support, and integration services, making the product more accessible and easier for end-users to incorporate into their systems. The effectiveness of this dual-channel approach is critical for maximizing market share and ensuring efficient delivery of precision planetary speed reducers to a global clientele.

Precision Planetary Speed Reducer Market Potential Customers

The potential customers for precision planetary speed reducers are diverse and span across a multitude of industries where accurate, reliable, and high-performance motion control is paramount. These end-users typically include manufacturers of advanced machinery and equipment, system integrators developing automated solutions, and companies engaged in high-precision manufacturing processes. The inherent characteristics of these reducers—such as high torque density, compact size, minimal backlash, and excellent positional accuracy—make them indispensable for applications demanding precise synchronization, smooth acceleration and deceleration, and repeatable motion sequences. Industries undergoing significant digital transformation and automation initiatives form the core customer base, constantly seeking ways to enhance productivity, reduce operational costs, and improve product quality through advanced mechanical components.

Key end-user segments include the robotics and automation industry, where manufacturers of industrial robots, collaborative robots (cobots), and autonomous guided vehicles (AGVs) extensively integrate these reducers for joint actuation, movement control, and payload handling. Machine tool builders represent another significant customer group, utilizing precision reducers in CNC machines, lathes, milling machines, and grinding equipment to achieve superior machining accuracy and faster cycle times. The packaging machinery sector relies on them for precise material handling, filling, sealing, and labeling operations, ensuring consistency and efficiency on production lines. Furthermore, the medical equipment industry employs these reducers in surgical robots, diagnostic imaging systems, and rehabilitation devices, where human-level precision and reliability are non-negotiable for patient safety and treatment efficacy.

Beyond these, the aerospace and defense sector is a crucial customer for high-reliability, lightweight precision reducers used in aircraft control surfaces, radar systems, and satellite positioning. The semiconductor manufacturing equipment industry demands ultra-high precision for wafer handling, inspection, and processing, making these reducers vital components. Other significant buyers include manufacturers in the food and beverage industry for automated processing and packaging, material handling equipment producers for conveyor systems and gantry robots, and the automotive industry for assembly lines, painting robots, and test equipment. Essentially, any sector striving for enhanced automation, improved operational accuracy, and optimized performance in motion control applications represents a potential customer for precision planetary speed reducers, highlighting their pervasive utility across modern industrial landscapes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.10 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | WITTENSTEIN SE, Neugart GmbH, STOBER Antriebstechnik GmbH, Apex Dynamics Inc., Harmonic Drive Systems Inc., Nabtesco Corporation, Bonfiglioli Riduttori S.p.A., Sumitomo Drive Technologies, SEW-EURODRIVE GmbH & Co KG, Bosch Rexroth AG, ZF Friedrichshafen AG, Nidec-Shimpo Corporation, GAM Enterprises, Inc., Redex Andantex, Suzhou JVL Co., Ltd., Sesame Motor Corp., GuangDong S.ROBO Drive Technology Co., Ltd., Tandler Zahnrad- und Getriebefabrik GmbH & Co KG, Dana Inc. (Brevini), Cone Drive. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Precision Planetary Speed Reducer Market Key Technology Landscape

The precision planetary speed reducer market is underpinned by a sophisticated technological landscape constantly evolving to meet the escalating demands for higher accuracy, greater efficiency, and enhanced durability in motion control systems. A fundamental aspect of this landscape involves advanced gear manufacturing techniques, such as precision hobbing, grinding, and honing, which are crucial for achieving the extremely tight tolerances and smooth surface finishes required for minimal backlash and high torque transmission. Materials science plays a vital role, with manufacturers increasingly utilizing specialized high-strength steels, carburized and hardened alloys, and sometimes ceramic or composite materials to improve wear resistance, reduce inertia, and enable operation in harsh environments. Lubrication technology has also seen significant advancements, with synthetic greases and oils designed for extended life, lower friction, and wider temperature ranges, contributing directly to the reducer's longevity and performance consistency under varying operational loads.

Beyond core mechanical components, the integration of smart technologies is rapidly transforming the market. This includes the incorporation of sensors for real-time monitoring of critical parameters such as temperature, vibration, and torque. These sensors, coupled with embedded microcontrollers, enable advanced diagnostics and predictive maintenance capabilities, allowing for early detection of potential failures and proactive servicing, thereby minimizing downtime and extending the operational life of machinery. Connectivity features, often leveraging industrial communication protocols like EtherCAT, PROFINET, or IO-Link, facilitate seamless integration of these smart reducers into broader Industry 4.0 architectures and IoT ecosystems. This enables data exchange with central control systems, facilitating optimized performance, energy management, and integration into overall factory automation strategies, further enhancing their value proposition for end-users seeking highly connected and intelligent manufacturing environments.

Furthermore, design methodologies are heavily influenced by advanced simulation and modeling software, including Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), allowing engineers to optimize gear geometry, housing stiffness, and thermal management for maximum performance and minimum size. Modular design principles are also prevalent, offering greater flexibility and easier customization to specific application requirements, reducing lead times and engineering costs. The emphasis on compact and lightweight designs, especially for applications in robotics, aerospace, and portable medical devices, drives innovation in material selection and structural optimization. Emerging manufacturing technologies like additive manufacturing (3D printing) are beginning to explore possibilities for creating complex internal geometries or customized components that were previously impossible with traditional methods, paving the way for even more innovative and performance-optimized precision planetary speed reducers in the future, thus continually pushing the boundaries of what these critical components can achieve.

Regional Highlights

- Asia Pacific: This region stands as the largest and fastest-growing market, primarily fueled by extensive industrialization, robust manufacturing bases (especially in China, Japan, South Korea, and India), and significant investments in factory automation and robotics. The burgeoning electronics, automotive, and general machinery sectors are major contributors to demand, coupled with government initiatives promoting smart manufacturing.

- Europe: A mature market characterized by strong emphasis on high-precision engineering, Industry 4.0 initiatives, and advanced manufacturing technologies. Countries like Germany, Italy, and Switzerland are at the forefront, with high adoption rates in machine tools, automotive, and specialized automation. Stringent quality standards and a focus on energy efficiency drive innovation.

- North America: This region holds a substantial market share, driven by a strong aerospace and defense sector, advanced robotics development, medical device manufacturing, and the re-shoring of manufacturing activities. High labor costs encourage automation adoption, propelling demand for precision components across diverse industries, particularly in the US and Canada.

- Latin America: An emerging market showing promising growth due to increasing foreign direct investments in manufacturing, infrastructure development, and growing adoption of automation in industries like automotive and food & beverage. Brazil and Mexico are key players, gradually modernizing their industrial processes and creating new opportunities for precision reducers.

- Middle East and Africa (MEA): While currently a smaller market, the MEA region is witnessing gradual growth driven by diversification efforts away from oil economies, investments in manufacturing infrastructure, and automation initiatives in sectors such as logistics, packaging, and food processing. Strategic initiatives and industrial expansion projects are creating a nascent but growing demand for advanced industrial components.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Precision Planetary Speed Reducer Market.- WITTENSTEIN SE

- Neugart GmbH

- STOBER Antriebstechnik GmbH

- Apex Dynamics Inc.

- Harmonic Drive Systems Inc.

- Nabtesco Corporation

- Bonfiglioli Riduttori S.p.A.

- Sumitomo Drive Technologies

- SEW-EURODRIVE GmbH & Co KG

- Bosch Rexroth AG

- ZF Friedrichshafen AG

- Nidec-Shimpo Corporation

- GAM Enterprises, Inc.

- Redex Andantex

- Suzhou JVL Co., Ltd.

- Sesame Motor Corp.

- GuangDong S.ROBO Drive Technology Co., Ltd.

- Tandler Zahnrad- und Getriebefabrik GmbH & Co KG

- Dana Inc. (Brevini)

- Cone Drive

Frequently Asked Questions

Analyze common user questions about the Precision Planetary Speed Reducer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a precision planetary speed reducer and how does it differ from standard gearboxes?

A precision planetary speed reducer is a type of gearbox featuring a central sun gear, multiple planetary gears, and an outer ring gear, designed for high torque transmission, exceptional accuracy, and minimal backlash. Unlike standard gearboxes, precision reducers prioritize positional accuracy and repeatability, making them crucial for applications requiring precise motion control rather than just speed reduction.

What are the primary applications of precision planetary speed reducers?

Precision planetary speed reducers are extensively used in applications demanding high accuracy and reliability. Key sectors include robotics and industrial automation, machine tools, packaging machinery, medical equipment, aerospace and defense, and semiconductor manufacturing, where precise motion control is critical for operational efficiency and product quality.

What are the key benefits of using a precision planetary speed reducer?

The main benefits include high torque density in a compact size, low backlash for superior positional accuracy, high efficiency due to multi-tooth contact, excellent rigidity, and long service life. These features contribute to improved machine performance, reduced energy consumption, and enhanced operational reliability in automated systems.

How does AI impact the Precision Planetary Speed Reducer Market?

AI significantly impacts the market by enabling predictive maintenance through sensor data analysis, optimizing reducer performance in real-time, facilitating integration into smart manufacturing ecosystems, and assisting in generative design for customized components. This leads to reduced downtime, extended lifespan, and more intelligent automation solutions.

What factors should be considered when selecting a precision planetary speed reducer?

Key factors include the required torque capacity, reduction ratio, backlash specifications (standard, low, ultra-low), input/output configurations, environmental conditions, operational duty cycle, and the specific application's precision requirements. Matching these factors to the reducer's specifications ensures optimal performance and longevity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager