Press Fit Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431539 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Press Fit Machines Market Size

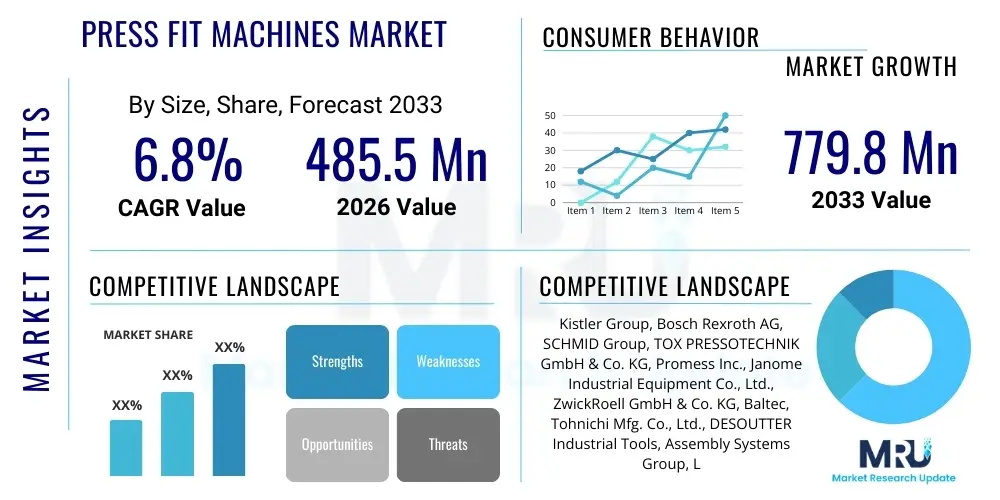

The Press Fit Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 485.5 Million in 2026 and is projected to reach USD 779.8 Million by the end of the forecast period in 2033.

Press Fit Machines Market introduction

Press Fit Machines are precision assembly tools designed to insert one component into another using controlled force, typically without requiring soldering, welding, or additional adhesives. This technology, also known as interference fit or friction fit, is critical in applications demanding high reliability and repeatability, such as connecting electronic components, securing automotive fasteners, and assembling complex mechanical structures. The primary product description encompasses a range of equipment, from manual lever presses and desktop electro-mechanical presses to fully automated, high-force hydraulic or servo-driven systems integrated into production lines. These machines offer superior joint integrity, reducing material fatigue and optimizing production cycle times, positioning them as indispensable assets in high-volume, precision manufacturing environments. The major applications span across the automotive sector for engine and chassis components, the electronics industry for PCB connectors and sensor integration, and the medical device field for intricate implant assembly.

The core benefits derived from utilizing sophisticated press fit technology include enhanced dimensional accuracy, consistent applied force monitoring capabilities, reduced risk of thermal damage associated with soldering, and improved overall sustainability due to easier component disassembly and recycling. Driving factors influencing the market include the global trend toward miniaturization in electronics, the increasing complexity of vehicle manufacturing requiring precise and reliable connections (especially in electric vehicle battery assemblies), and stringent quality control standards mandated across regulated industries. Furthermore, the push for Industry 4.0 integration necessitates advanced press-fit solutions equipped with sophisticated data logging and real-time process monitoring features, further propelling market demand for highly digitized machinery capable of immediate feedback and automated adjustments.

Press Fit Machines Market Executive Summary

The Press Fit Machines Market is experiencing robust expansion driven by sustained capital investments in the automotive and electronics sectors, particularly in regions prioritizing high-precision manufacturing automation. Business trends indicate a strong shift towards electro-mechanical servo presses, favored for their superior energy efficiency, precise force and displacement control, and adaptability compared to traditional hydraulic or pneumatic systems. Key market players are focusing on developing scalable, modular machine designs that facilitate easier integration into existing assembly lines and emphasize software platforms for advanced diagnostics and predictive maintenance, catering directly to the demands of smart factories. Consolidation activities, primarily through strategic partnerships between machinery manufacturers and specialized sensor technology providers, are accelerating the development of highly accurate force sensing and quality assurance features embedded within the pressing mechanism, creating a competitive advantage.

Regionally, Asia Pacific (APAC) continues to dominate the market share, fueled by massive manufacturing bases in China, South Korea, and Japan, which are primary producers of electronic components and vehicles. North America and Europe demonstrate mature market characteristics, focusing on adopting high-end, fully automated systems optimized for zero-defect assembly, especially within aerospace and high-reliability defense applications. Segment trends show that the automotive application segment maintains the largest market share due to the proliferation of complex electronic control units (ECUs) and the critical nature of connections in powertrain components. Technologically, the servo-electric press segment is forecasted to exhibit the highest Compound Annual Growth Rate, underscoring the industry preference for cleaner, quieter, and highly controllable actuation methods essential for modern, automated assembly processes.

AI Impact Analysis on Press Fit Machines Market

Users frequently inquire about how Artificial Intelligence (AI) and Machine Learning (ML) can move beyond simple data logging to genuinely optimize the press-fit process, specifically focusing on achieving zero-defect assembly under varying material conditions and component tolerances. Common themes revolve around using AI for predictive quality control, where algorithms learn the acceptable force-displacement curve variation specific to a component type, automatically rejecting outliers or dynamically adjusting machine parameters in real-time to maintain optimal pressure profiles. Concerns also center on the feasibility and cost of retrofitting older, non-AI-enabled machines with sophisticated sensing and processing units, and the expected ROI derived from reduced scrap rates and increased throughput. Expectations are high that AI will transform press-fit monitoring from a reactive process (analyzing failures post-assembly) into a proactive, adaptive system capable of compensating for minor manufacturing inconsistencies on the fly, thereby revolutionizing the reliability of critical component integration in sectors like aerospace and medical devices.

- AI enables real-time, adaptive force-displacement curve analysis, significantly improving defect detection sensitivity beyond standard tolerance checks.

- Predictive maintenance algorithms utilize machine vibration and energy consumption data to forecast potential mechanical failures in the press mechanisms, minimizing unexpected downtime.

- Machine Learning models optimize the setup parameters for new components faster by analyzing historical data from similar assembly jobs, reducing commissioning time.

- AI-driven process feedback loops allow the machine to autonomously adjust pressing speed or maximum force based on temperature or material batch variations, ensuring consistent joint quality.

- Enhanced quality assurance documentation is facilitated through automated data aggregation and anomaly reporting, meeting stringent regulatory compliance requirements (e.g., ISO 13485 for medical devices).

- Integration of visual AI (Machine Vision) systems with press-fit machines ensures correct component alignment and orientation before the pressing sequence commences, eliminating errors.

DRO & Impact Forces Of Press Fit Machines Market

The dynamic interplay of drivers, restraints, and opportunities shapes the trajectory of the Press Fit Machines Market, collectively categorized as DRO and subject to overarching impact forces. The primary drivers revolve around the expanding need for high-reliability connections in complex products, particularly within the fast-growing electric vehicle (EV) battery assembly segment and the consumer electronics sector, which demands increasingly compact and durable connections. However, the market faces constraints, chiefly the substantial initial capital investment required for high-precision servo-press systems and the complexity associated with integrating these advanced machines into legacy production environments. Opportunities arise through the proliferation of Industry 4.0 initiatives, driving demand for smart, connected press-fit systems capable of extensive data acquisition and remote monitoring. These factors are critically influenced by impact forces such as stringent quality regulations and the fluctuating costs of raw materials, which determine manufacturing investment cycles and the cost of end products.

Drivers fueling market growth include the inherent superiority of press-fit technology over soldering and welding for specific high-stress applications, ensuring longevity and durability of assembled products. The automotive industry’s rapid transition towards electrification necessitates highly reliable methods for connecting busbars, terminals, and sensitive electronic control units, making press-fit technology indispensable. Furthermore, the global push towards automation across industrial sectors, seeking improved efficiency and reduced manual error, directly translates into increased procurement of automated press-fit solutions. Restraints challenging the market include the prerequisite for exceptionally high dimensional precision in components designed for press-fit assembly; any deviation in component tolerance can lead to significant assembly failures. Moreover, the required expertise for maintaining and programming sophisticated servo-electric presses represents a barrier to entry for smaller or less technologically mature manufacturing operations, limiting broader adoption.

The core opportunities lie in developing highly adaptive, modular press systems that can handle a wide variety of component sizes and material pairings with minimal retooling time, addressing the demand for flexible manufacturing. The application expansion into new sectors such as renewable energy infrastructure assembly (e.g., precise connections in solar inverter units) and specialized defense electronics provides untapped avenues for growth. Impact forces, particularly environmental regulations promoting sustainable manufacturing, favor press-fit technology as it eliminates the need for potentially hazardous flux or lead-based solders, aligning with green manufacturing goals. Geopolitical factors influencing global supply chains also impact capital expenditure decisions, prompting manufacturers to invest in resilient, highly automated domestic production capabilities, thereby sustaining the demand for advanced press-fit machinery across key industrial regions.

Segmentation Analysis

The Press Fit Machines Market is comprehensively segmented based on technology type, force capacity, application, and geographic region. Analyzing these segments provides a granular view of market dynamics, identifying high-growth niches and established areas. The segmentation by technology (e.g., Servo-Electric, Hydraulic, Pneumatic) reflects the ongoing transition toward precision and energy efficiency, while segmentation by force capacity helps delineate the suitable applications, ranging from micro-assembly in medical devices (low force) to heavy-duty automotive bearing insertions (high force). Application segmentation—covering Automotive, Electronics, Aerospace, and Industrial Machinery—is vital for strategic targeting, as each sector presents distinct requirements regarding speed, accuracy, and quality assurance documentation.

- By Technology:

- Servo-Electric Press Fit Machines

- Hydraulic Press Fit Machines

- Pneumatic Press Fit Machines

- Hydro-Pneumatic Press Fit Machines

- By Force Capacity:

- Low Force (Up to 5 kN)

- Medium Force (5 kN to 50 kN)

- High Force (Above 50 kN)

- By Automation Level:

- Manual/Benchtop

- Semi-Automatic

- Fully Automatic/Integrated Systems

- By Application:

- Automotive Manufacturing (Powertrain, Chassis, EV Batteries, ECU Connectors)

- Electronics & Consumer Goods (PCB Connectors, Sensor Mounting)

- Aerospace & Defense (Precision Fastening, Critical Component Assembly)

- Medical Devices (Implants, Surgical Instruments Assembly)

- Industrial Machinery & Equipment

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Press Fit Machines Market

The value chain for the Press Fit Machines Market starts with upstream activities involving raw material sourcing and the manufacturing of critical components such as servo motors, high-precision linear guides, load cells, and advanced control electronics. Specialized suppliers provide high-reliability sensors and software necessary for the control systems, impacting the overall machine accuracy and responsiveness. Upstream efficiency and quality directly influence the performance and reliability of the final press-fit machine. Key players often engage in vertical integration concerning crucial components like force transducers to maintain proprietary control over measurement accuracy, a differentiating factor in this precision-focused market.

The midstream focuses on the design, assembly, and testing of the press-fit machinery itself. Manufacturers invest heavily in R&D to enhance software capabilities, user interface design, and mechanical rigidity, crucial for maintaining accuracy under high-force operations. Quality assurance and calibration services form a crucial part of this stage, ensuring that the machine meets international standards for measurement traceability. Downstream activities involve distribution channels, installation, commissioning, and comprehensive after-sales support. Given the technical nature of the equipment, specialized distributors with technical sales teams are preferred over general industrial distributors, ensuring customers receive adequate pre-sale consultation regarding application-specific requirements.

The distribution channel primarily relies on a mix of direct sales for large, complex, custom-engineered systems and indirect channels (authorized distributors or system integrators) for standardized, smaller benchtop models. Direct engagement allows manufacturers to provide bespoke engineering solutions, crucial for high-tolerance industries like aerospace. Indirect channels, conversely, offer wider market penetration, especially in emerging industrial economies. Post-sale, the provision of remote diagnostics, software updates, and calibration services is a significant value driver, ensuring the longevity and continued performance compliance of the installed machinery throughout its lifecycle and strengthening customer loyalty.

Press Fit Machines Market Potential Customers

The primary potential customers and end-users of Press Fit Machines span major industrial sectors that necessitate high-precision, repeatable, and non-destructive assembly processes. The Automotive manufacturing sector is the largest consumer, utilizing these machines for crucial assemblies in engines, gearboxes, brakes, and increasingly, the complex task of integrating electronic connectors onto printed circuit boards (PCBs) and assembling EV battery modules where thermal stability is paramount. These customers demand high throughput capabilities combined with sophisticated data logging for mandatory quality documentation and traceability, making them highly receptive to advanced servo-electric systems capable of immediate feedback control.

Another significant customer base resides within the Electronics and Consumer Goods industry. As devices become smaller and more feature-dense, traditional soldering methods often risk damaging sensitive components. Press-fit technology offers a robust, high-density connection method for memory modules, high-speed connectors, and sensor mounting onto PCBs without thermal stress. These buyers prioritize speed, miniaturization capabilities, and low-force precision, often opting for dedicated robotic integration systems where the press-fit machine acts as an end-effector within a larger automated cell.

Furthermore, specialized segments like Medical Device manufacturers and the Aerospace & Defense industry represent high-value potential customers. In medical devices, press-fit machines are used for assembling critical components like surgical instruments and internal implants, demanding extreme precision (often sub-micron level) and exhaustive validation and documentation protocols to comply with regulatory standards like FDA requirements. Similarly, the aerospace sector uses these systems for fastening critical structural components and assembling highly reliable electronic systems, where the cost of failure is exceptionally high, thereby justifying investment in the most accurate and fully redundant press-fit technology available on the market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 485.5 Million |

| Market Forecast in 2033 | USD 779.8 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kistler Group, Bosch Rexroth AG, SCHMID Group, TOX PRESSOTECHNIK GmbH & Co. KG, Promess Inc., Janome Industrial Equipment Co., Ltd., ZwickRoell GmbH & Co. KG, Baltec, Tohnichi Mfg. Co., Ltd., DESOUTTER Industrial Tools, Assembly Systems Group, LPKF Laser & Electronics AG, Atlas Copco, Schmidt Technology GmbH, WEISS North America. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Press Fit Machines Market Key Technology Landscape

The technological landscape of the Press Fit Machines Market is dominated by the transition from traditional fluid-power systems (hydraulic and pneumatic) to highly sophisticated electro-mechanical servo-driven presses. Servo-electric technology represents the vanguard of innovation, offering unparalleled control over the pressing profile, allowing users to precisely manage both the applied force and the displacement distance simultaneously throughout the entire assembly sequence. This precision is facilitated by high-resolution encoders and load cells, which provide real-time feedback (typically at sampling rates exceeding 1,000 Hz) to the central control unit. This high level of control is essential for preventing overstressing delicate components while ensuring the requisite mechanical interference fit, leading to superior joint reliability and lower defect rates, particularly critical in the assembly of sensitive electronic control units (ECUs).

A major technological advancement involves the integration of advanced process monitoring and quality assurance software. Modern press-fit machines are not merely actuators; they are sophisticated data acquisition systems. They analyze the force-displacement curve in detail, comparing the real-time profile against predefined acceptance windows. Anomalies, such as component misalignment, insufficient lubricity, or dimensional variations, are instantly identified based on deviations from the ideal curve shape. This data is timestamped, archived, and often integrated directly into a factory's Manufacturing Execution System (MES), ensuring full traceability for every single assembled part. Furthermore, the development of modular tooling systems and quick-change fixture interfaces allows manufacturers to rapidly reconfigure machines for different product lines, significantly enhancing operational flexibility and reducing downtime associated with product changeovers.

Future technological trends are heavily focused on leveraging IoT connectivity and cloud-based analytics to enhance operational efficiency. Press-fit machines are increasingly equipped with embedded network capabilities allowing for remote performance monitoring, predictive maintenance notifications, and centralized software updates across geographically dispersed manufacturing facilities. Furthermore, the push towards collaborative robotics (Cobots) is influencing the development of smaller, lighter, and more adaptable benchtop press units designed to work safely alongside human operators. This trend is driven by the need for flexible, small-batch manufacturing setups that require high accuracy but lack the scale for massive, fully automated assembly lines, indicating a hybridization of precision mechanics with advanced digital control systems tailored for diverse industrial needs.

Regional Highlights

- Asia Pacific (APAC): APAC is the global manufacturing powerhouse and consequently the largest market for Press Fit Machines. The region's dominance is attributed to high-volume production in the consumer electronics and automotive sectors, particularly in China, Japan, and South Korea. Rapid infrastructure development, coupled with governmental support for advanced manufacturing (e.g., China’s Made in China 2025 initiative), drives continuous investment in automated assembly technologies. The burgeoning electric vehicle (EV) market across the region creates immense demand for high-force presses used in battery module assembly and motor component integration.

- North America: North America represents a mature, high-value market characterized by early adoption of advanced servo-electric systems. Demand is highly concentrated in the aerospace & defense, medical device, and high-end automotive sectors. Manufacturers in this region prioritize quality, regulatory compliance (requiring detailed data logging), and speed. The focus is increasingly on retrofitting older hydraulic systems with modern sensor packages and control units to meet stringent quality standards while maintaining existing infrastructure integrity.

- Europe: Europe is a highly competitive market driven by stringent quality standards set by German automotive original equipment manufacturers (OEMs) and robust aerospace manufacturing in countries like France and the UK. Sustainability concerns drive the adoption of energy-efficient servo-presses. Key market growth is fueled by the need for precision assembly in powertrain components and the sophisticated electronics required for advanced driver-assistance systems (ADAS) in next-generation vehicles.

- Latin America (LATAM) & Middle East & Africa (MEA): These regions are emerging markets with moderate growth, primarily driven by automotive assembly (Mexico, Brazil) and capital expenditure in oil & gas and industrial machinery sectors. Market adoption generally favors cost-effective pneumatic and hydro-pneumatic solutions, though increasing foreign direct investment in local manufacturing hubs is beginning to stimulate demand for high-end, traceable press-fit technology, particularly in high-tech zones in the UAE and Saudi Arabia.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Press Fit Machines Market.- Kistler Group

- Bosch Rexroth AG

- SCHMID Group

- TOX PRESSOTECHNIK GmbH & Co. KG

- Promess Inc.

- Janome Industrial Equipment Co., Ltd.

- ZwickRoell GmbH & Co. KG

- Baltec

- Tohnichi Mfg. Co., Ltd.

- DESOUTTER Industrial Tools

- Assembly Systems Group

- LPKF Laser & Electronics AG

- Atlas Copco

- Schmidt Technology GmbH

- WEISS North America

- FlexLink AB

- A&D Company, Limited

- Shibaura Machine Co., Ltd.

- Yamaha Motor Co., Ltd.

- Sanko Engineering Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Press Fit Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Servo-Electric Press Fit Machines over Hydraulic systems?

Servo-electric press-fit machines offer superior energy efficiency, higher precision in force and displacement control (often measured in microns), significantly reduced noise levels, and cleaner operation free from hydraulic fluids. Their advanced digital control systems allow for real-time monitoring of the force-displacement curve, leading to better quality assurance and reduced scrap rates compared to traditional hydraulic systems which are typically less granular in control.

How does the Press Fit Machines Market support the manufacturing shift toward Electric Vehicles (EVs)?

The Press Fit Machines Market is critical to EV manufacturing, specifically in battery assembly (busbar connections, terminal insertions) and motor component assembly. Press-fit technology provides robust, vibration-resistant, and high-reliability electrical connections without introducing thermal stress, which is essential for the long-term performance and safety of high-voltage battery modules and sensitive electronic control units (ECUs) in electric vehicles.

What is a force-displacement curve and why is it essential for press-fit quality control?

The force-displacement curve is a graphical representation charting the applied force against the distance traveled by the pressing ram during the assembly cycle. It is the primary tool for quality control, as any deviation from the ideal, component-specific signature curve indicates a fault, such as component misalignment, incorrect tolerance, or debris interference. Real-time analysis of this curve ensures joint integrity and traceability for critical assemblies.

Which industrial segments are driving the highest demand for high-force press fit machinery?

The highest demand for high-force press fit machinery (typically above 50 kN) is driven by the Automotive industry, particularly for assembling powertrain components like bearings, bushings, and axles, as well as the heavy-duty assembly tasks required in large-scale Electric Vehicle battery pack structures. The Industrial Machinery sector also requires high-force presses for assembling large components and sub-assemblies in machine tools and construction equipment.

Is press-fit technology a viable replacement for traditional soldering in electronic assembly?

Yes, press-fit technology is increasingly replacing traditional soldering in high-reliability electronic assembly, particularly for connectors (e.g., backplane connectors, high-speed data ports) on Printed Circuit Boards (PCBs). The key advantage is avoiding thermal stress on components and eliminating the need for flux or lead, resulting in environmentally cleaner processes and joints that are highly resistant to vibration and thermal cycling, crucial for long-term product dependability.

The comprehensive analysis provided above reflects the current dynamics, technological advancements, and strategic implications within the global Press Fit Machines Market, offering a structured foundation for decision-making and strategic planning for stakeholders across the entire value chain.

This report has detailed the significant shift toward advanced servo-electric technologies, underlining their role in enabling the high-precision requirements of Industry 4.0 environments, particularly in the critical automotive and electronics sectors. The geographic analysis highlights APAC's dominance driven by mass production capabilities, while North America and Europe lead in the adoption of high-end, zero-defect quality control systems integrated with AI capabilities. The regulatory environment and the increasing global emphasis on product traceability continue to shape market behavior, driving sustained investment in advanced monitoring and data collection features embedded within press-fit machinery.

Further strategic considerations include the necessity for manufacturers to offer modular and adaptable solutions to cater to evolving production demands, particularly the quick reconfiguration required by flexible manufacturing lines. The rising complexity of assembled components, especially in medical devices and specialized aerospace applications, ensures a sustained premium for machines capable of sub-micron level precision and extensive validation documentation. The future competitive landscape will be defined by companies that can effectively merge mechanical excellence with sophisticated software analytics and AI-driven predictive capabilities, moving beyond simple assembly towards intelligent manufacturing orchestration.

The trajectory of the Press Fit Machines Market remains strongly positive, anchored by the fundamental industrial need for reliable, repeatable, and verifiable mechanical connections that withstand the rigors of modern product usage. As automation increases globally, especially post-pandemic, the demand for highly reliable, traceable assembly solutions like advanced press-fit systems will only intensify, solidifying their status as core capital equipment in precision manufacturing facilities worldwide.

Market stakeholders, including machinery suppliers, component manufacturers, and end-users, must continuously monitor technological trends, especially the convergence of AI, IoT, and high-resolution sensing technologies. Investing in training and technical expertise will be crucial for maximizing the utility and ROI derived from these sophisticated machines. Strategic alliances focusing on integrating proprietary press-fit technology with broader factory automation frameworks will be key to capturing significant market share and maintaining a competitive edge in the highly specialized field of precision assembly.

This detailed report offers actionable insights for businesses looking to navigate the market landscape, optimize their assembly processes, and capitalize on the growing demand for high-integrity connections across automotive, electronics, aerospace, and medical device manufacturing.

The shift towards miniaturization in electronics mandates the use of press-fit solutions due to their capability to handle fragile components where heat exposure must be minimized. The development of specialized low-force servo presses capable of handling delicate PCB connectors ensures integrity without damaging sensitive substrates. This niche segment within the broader electronics application market is poised for exceptional growth as consumer devices continue to trend towards higher density and reduced thickness, requiring non-destructive connection methods that guarantee long-term performance.

The emphasis on regulatory compliance, particularly in the medical and aerospace sectors, necessitates the robust data logging capabilities inherent in modern press-fit machines. These machines must provide undeniable proof of process adherence, generating detailed reports for every pressing cycle, including force profiles, time stamps, and machine settings. This level of traceability is non-negotiable for critical assemblies where product failure could have severe consequences, driving a premium on machines offering advanced software integration and standardized data export functionalities compatible with global regulatory standards.

Investment patterns in emerging markets, while historically favoring lower-cost pneumatic options, are showing signs of transformation. As local manufacturing standards evolve and global OEMs establish regional facilities, there is a corresponding increase in demand for high-accuracy servo-electric systems. This transition is slow but steady, supported by government initiatives promoting technological upgrades and foreign direct investment that introduces best-practice manufacturing standards, expanding the geographic scope for high-end press-fit machine suppliers over the forecast period.

The competitive landscape remains fragmented but is increasingly consolidating around key technological differentiators, such as proprietary force sensors and advanced software algorithms. Companies that offer comprehensive, turnkey solutions—combining the press-fit machine with customized tooling, automation handling, and integrated quality monitoring—are better positioned to secure major contracts, particularly those involving large-scale automotive or aerospace assembly lines requiring seamless system integration and minimized technical risk for the end-user.

Finally, sustainability is emerging as a powerful, indirect driver. By eliminating soldering and reducing the waste associated with thermal assembly processes, press-fit technology aligns perfectly with corporate sustainability goals. The low energy consumption of servo-electric presses further reinforces this alignment, making them an attractive long-term investment for manufacturers committed to reducing their carbon footprint and adhering to evolving environmental, social, and governance (ESG) standards across their operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager