Pressure Recorders Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434939 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Pressure Recorders Market Size

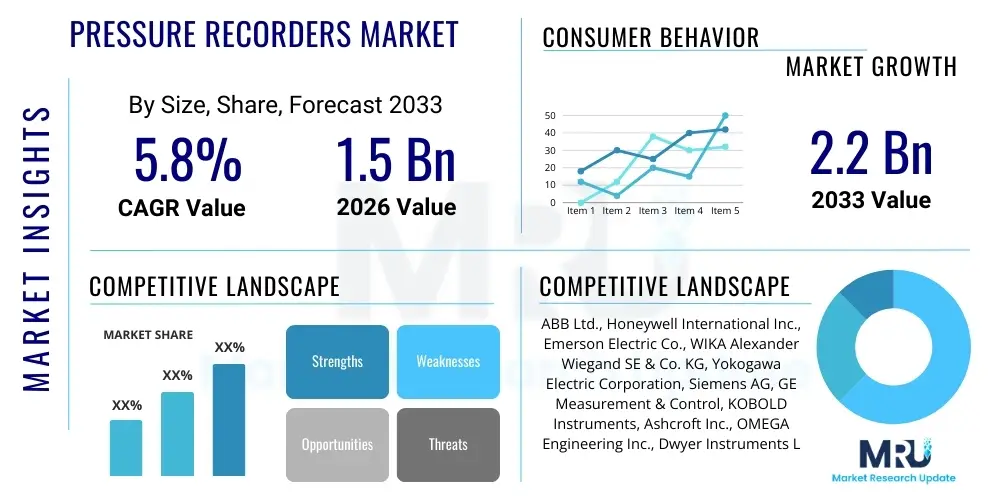

The Pressure Recorders Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.2 Billion by the end of the forecast period in 2033. This consistent growth trajectory is primarily driven by rigorous safety standards across process industries, the increasing implementation of Industrial Internet of Things (IIoT) frameworks, and the necessity for highly accurate and auditable pressure data logging in critical operations.

Pressure Recorders Market introduction

The Pressure Recorders Market encompasses devices used to continuously measure, monitor, and record pressure over time, providing essential documentation for process validation, safety compliance, and troubleshooting. These instruments range from traditional mechanical chart recorders, which utilize pens and rotating circular charts, to advanced digital and electronic recorders equipped with high-resolution displays, internal memory, and connectivity features. Modern pressure recorders are critical components in maintaining operational integrity across hazardous and non-hazardous environments, offering superior data fidelity compared to basic manometers or gauges.

The core function of a pressure recorder is to provide an undeniable record of pressure fluctuations within a system, which is paramount in regulated industries such as pharmaceuticals, oil and gas, and power generation. Key products include electronic data loggers, circular chart recorders, and specialized differential pressure recorders. Major applications involve monitoring pipeline pressure integrity, autoclave validation, wellhead monitoring, and ensuring HVAC system performance in controlled environments. The transition from purely mechanical recording methods to digital solutions is accelerating, driven by the demand for real-time remote access and integration with enterprise resource planning (ERP) systems.

Benefits derived from utilizing modern pressure recorders include enhanced safety protocols through immediate anomaly detection, improved process efficiency achieved by analyzing historical pressure trends, and simplified regulatory auditing due to the availability of time-stamped, tamper-proof data logs. Key driving factors involve the global push toward Industry 4.0 adoption, stringent environmental and safety regulations requiring verifiable documentation of operating conditions, and the continuous need for optimized resource management in capital-intensive sectors. These instruments are no longer standalone devices but sophisticated measurement hubs integrating seamlessly into broader control and monitoring architectures.

Pressure Recorders Market Executive Summary

The Pressure Recorders Market is characterized by a significant transition toward digitalization, favoring electronic and digital data loggers over traditional mechanical chart recorders. Current business trends indicate a strong focus on developing wireless and portable recording solutions that minimize installation complexity and enhance deployment flexibility across remote or expansive industrial sites. Regulatory mandates concerning verifiable data integrity, especially in sectors like food and beverage and pharmaceuticals, are compelling end-users to invest in advanced recorders featuring enhanced cybersecurity and validated software for data traceability. Manufacturers are responding by embedding advanced processing capabilities into these devices, enabling on-device analysis and predictive maintenance alerts.

Regional trends highlight the Asia Pacific (APAC) as the fastest-growing market, fueled by rapid industrialization, extensive investment in infrastructure development, and growing energy demand, particularly in China and India. North America and Europe maintain substantial market shares due to stringent existing safety standards and high adoption rates of advanced IIoT technologies in their established manufacturing and petrochemical sectors. There is a discernible shift in mature markets towards upgrading legacy mechanical systems to networked digital recorders capable of integrating into centralized supervisory control and data acquisition (SCADA) systems, optimizing overall operational visibility and control.

In terms of segmentation, the electronic/digital recorders segment dominates the market in terms of revenue and growth rate, primarily driven by their superior accuracy, storage capacity, and remote accessibility. Application-wise, the oil and gas sector remains the largest consumer, requiring robust, explosion-proof recording solutions for upstream and midstream operations. Concurrent segment trends include the increased demand for differential pressure recorders for flow monitoring and filtration assessment, and the burgeoning adoption of cloud-based data storage solutions, which further enhance data accessibility and redundancy while streamlining compliance reporting processes for global enterprises.

AI Impact Analysis on Pressure Recorders Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Pressure Recorders Market frequently center on how AI can transform raw pressure data into actionable intelligence, shifting the paradigm from purely reactive data logging to predictive operational management. Common user questions address the feasibility of integrating AI algorithms for real-time anomaly detection, optimizing calibration and maintenance schedules using predictive analytics, and enhancing data validation and compliance assurance through automated auditing processes. Users are seeking clarity on whether AI will necessitate hardware redesigns or if it will primarily function as a software layer enhancing existing digital recorder capabilities, emphasizing concerns about data security and the necessity of generating trustworthy, certifiable outputs required by regulatory bodies.

The implementation of AI and machine learning (ML) primarily serves to maximize the utility of the voluminous, high-frequency data generated by modern electronic pressure recorders. Instead of relying on human operators to manually review large datasets for abnormal patterns, AI algorithms can continuously analyze pressure trends, correlation matrices, and time series data to preemptively identify system degradation, incipient equipment failure, or pressure excursions that might violate safety limits. This capability drastically reduces unplanned downtime and shifts maintenance from scheduled intervals to condition-based requirements, thereby extending the lifespan of critical assets and ensuring continuous operational compliance, which is a major value proposition for capital-intensive industries.

Furthermore, AI significantly enhances the reliability and integrity of recorded data, addressing key regulatory requirements. ML models can be trained to detect intentional or unintentional manipulation of pressure readings or system metadata, providing an additional layer of security and auditability. The adoption of AI also supports the optimization of industrial processes by correlating pressure data with other environmental variables (temperature, flow rates) to suggest optimal operating parameters, thus contributing directly to energy savings and overall process yield improvements. This analytical layer transforms the pressure recorder from a simple logging tool into a sophisticated sensor providing high-level operational insights.

- AI-powered Predictive Maintenance: Forecasting sensor drift and equipment failure based on nuanced pressure fluctuation patterns.

- Real-time Anomaly Detection: Immediate flagging of pressure spikes or drops that deviate statistically from trained operational baselines.

- Automated Data Validation: Utilizing machine learning to verify data integrity and prevent unauthorized data modification, ensuring compliance.

- Optimized Calibration Cycles: Determining the necessary recalibration interval based on actual sensor performance degradation rates, reducing unnecessary downtime.

- Process Optimization: Correlating pressure readings with energy consumption and output metrics to recommend efficiency improvements.

DRO & Impact Forces Of Pressure Recorders Market

The Pressure Recorders Market is fundamentally shaped by robust regulatory drivers mandating precise data documentation, countered by significant initial investment restraints and buoyed by pervasive opportunities stemming from digital transformation. The primary drivers include global adoption of Industry 4.0 technologies, which necessitates integrated data logging capabilities, and increasingly stringent international safety and environmental regulations (e.g., OSHA, EPA, ISO standards) requiring verifiable proof of maintained operational parameters. These forces compel industries to replace aging mechanical recorders with advanced digital systems capable of high-fidelity, auditable data collection. However, the complexity and high initial cost associated with implementing highly accurate, networked digital recorders, coupled with the specialized training required for system maintenance and cybersecurity management, act as significant restraints, particularly for small and medium enterprises (SMEs).

Opportunities in the market are heavily concentrated on wireless connectivity and the expansion of the industrial edge. The development of robust, battery-powered wireless pressure recorders using technologies like WirelessHART or LoRaWAN opens up vast possibilities for monitoring remote pipelines, mobile assets, and challenging environments where traditional wiring is impractical or cost-prohibitive. Furthermore, the integration of these devices with cloud platforms for scalable data storage and sophisticated analytics represents a major growth avenue. The key impact forces currently driving market evolution include rapid technological obsolescence of legacy systems, the imperative for improved operational safety across all high-risk industries, and competitive pressure among manufacturers to provide more user-friendly, integrated, and cyber-secure recording solutions that comply with global data governance norms.

The impact forces also reflect the shifting balance between cost and capability. While low-cost, basic pressure loggers still serve niche markets, the trend favors premium models that integrate diagnostics, self-calibration checks, and advanced networking features, justifying the higher upfront cost through reduced lifetime operational expenditures (OPEX). The market is consistently impacted by raw material price volatility, especially for high-grade sensor materials, and the accelerating competition from low-cost manufacturers, pushing established players to innovate around software and service offerings rather than just hardware specifications. Regulatory scrutiny remains the most persistent external impact force, ensuring continuous demand for validated, high-integrity recording devices.

Segmentation Analysis

The Pressure Recorders Market segmentation provides a crucial framework for understanding purchasing behavior, technological preferences, and growth pockets across various industrial verticals. The market is primarily segmented based on the type of recorder technology utilized (mechanical vs. electronic), the application environment, and the specific end-use industry being served. The shift towards electronic recorders signifies a fundamental change in data acquisition and utilization strategies, moving away from purely physical documentation toward digitally integrated monitoring systems, which now offer superior precision and integration capabilities essential for modern process control environments.

- By Type:

- Mechanical (Chart) Recorders

- Electronic/Digital Recorders (Data Loggers)

- Hybrid Recorders

- By Pressure Type:

- Gauge Pressure Recorders

- Absolute Pressure Recorders

- Differential Pressure Recorders

- By Application:

- Process Monitoring & Control

- Testing & Calibration

- Pipeline Integrity Monitoring

- Regulatory Compliance Documentation

- By End-Use Industry:

- Oil & Gas

- Chemical & Petrochemical

- Manufacturing (General)

- Utilities & Power Generation

- Pharmaceutical & Biotechnology

- Food & Beverage

- Water & Wastewater Management

Value Chain Analysis For Pressure Recorders Market

The value chain for the Pressure Recorders Market starts with the sourcing of specialized components, primarily high-precision pressure sensors (transducers, strain gauges), microprocessors, data storage modules, and robust enclosure materials suitable for industrial environments. Upstream analysis focuses heavily on securing reliable suppliers for these critical sensors, where technological differentiation and quality control are paramount to ensuring the recorder's accuracy and long-term stability. Strategic relationships with semiconductor and sensor manufacturers are essential, particularly as digital recorders rely on increasingly advanced signal processing capabilities and low-power consumption design for wireless applications.

The middle segment of the value chain involves the design, manufacturing, and assembly processes. This stage is characterized by high levels of quality assurance, specialized calibration procedures (traceable to national standards), and the development of proprietary software for data logging, visualization, and security. Integration services, which include designing the user interface and ensuring seamless compatibility with various industrial communication protocols (e.g., Modbus, HART, Ethernet/IP), add significant value. The effectiveness of the manufacturing process often determines the device's certified protection ratings (e.g., ingress protection, explosion-proof ratings), which are crucial buying factors in hazardous industries.

The downstream activities involve distribution and extensive post-sales support. Distribution channels are typically dual: direct sales to major industrial end-users (especially in the Oil & Gas and Power sectors) requiring custom integration, and indirect distribution through specialized industrial equipment distributors, system integrators, and calibration service providers who possess local market knowledge and technical expertise. Aftermarket support, including calibration, repair services, software updates, and training, represents a significant and recurring revenue stream. The ability to offer certified calibration services often dictates which channel partners are utilized, linking the initial sale closely to long-term service contracts.

Pressure Recorders Market Potential Customers

Potential customers for pressure recorders are predominantly concentrated within industries where continuous process validation, safety monitoring, and quality control are non-negotiable requirements, necessitating documented proof of pressure conditions. The primary purchasers are managers responsible for instrumentation, maintenance, operations, and quality assurance across large-scale processing facilities. These end-users require robust, reliable instruments that can withstand harsh industrial conditions while providing accurate, time-stamped data logs that satisfy stringent internal protocols and external regulatory audits, such as those governed by the FDA (in pharmaceuticals) or environmental agencies.

The largest customer segment remains the upstream and midstream Oil & Gas industry, where pressure recorders are indispensable for monitoring drilling operations, hydraulic fracturing, wellhead pressures, and pipeline leak detection and integrity management. Refineries and chemical manufacturing plants are significant users, deploying recorders for monitoring reactions, storage tank pressures, and utility systems. Furthermore, utilities, including conventional and nuclear power plants, rely heavily on these devices to document steam pressures, boiler operations, and cooling system performance to prevent catastrophic failures and maintain grid stability, establishing them as perpetual high-volume buyers.

In specialized manufacturing sectors, such as aerospace, pharmaceuticals, and high-tech food and beverage production, pressure recorders are critical for validating sterilization processes (autoclaves), ensuring product consistency, and managing cleanroom environments. These customers often prioritize digital recorders with advanced features like 21 CFR Part 11 compliance software, enhanced data security, and integration capabilities with manufacturing execution systems (MES). The ongoing global expansion of liquefied natural gas (LNG) infrastructure and pharmaceutical cold chain management is continuously adding new layers of high-priority potential customers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Honeywell International Inc., Emerson Electric Co., WIKA Alexander Wiegand SE & Co. KG, Yokogawa Electric Corporation, Siemens AG, GE Measurement & Control, KOBOLD Instruments, Ashcroft Inc., OMEGA Engineering Inc., Dwyer Instruments LLC, PCE Instruments, Rototherm Group, SENSIT Technologies LLC, Testo SE & Co. KGaA, Endress+Hauser Group Services AG, Fuji Electric Co., Ltd., AMETEK, Inc., Transcat, Inc., Keller AG für Druckmesstechnik. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pressure Recorders Market Key Technology Landscape

The contemporary technology landscape for pressure recorders is dominated by the integration of advanced digital sensing, wireless communication, and secure data infrastructure, significantly moving away from the purely pneumatic and mechanical systems of the past. Modern electronic pressure recorders leverage highly accurate, drift-resistant MEMS or thin-film sensor technologies combined with high-speed microprocessors for rapid sampling and signal conditioning. This enables superior resolution and accuracy essential for sophisticated industrial processes. The technological focus is on enhancing energy efficiency to support extended battery life for remote, wireless deployments and ensuring intrinsic safety certification (e.g., ATEX, IECEx) for use in explosive atmospheres.

A critical development involves the pervasive adoption of industrial communication protocols. Many premium digital recorders are now equipped with WirelessHART, ISA100 Wireless, and proprietary low-power wide-area network (LPWAN) capabilities, facilitating seamless integration into the Industrial Internet of Things (IIoT). This networking allows data to be transmitted reliably and securely to control rooms or cloud-based historians, enabling remote configuration and centralized monitoring, which drastically reduces the need for manual data retrieval and human exposure to hazardous environments. Manufacturers are also focusing on integrating edge computing capabilities, allowing the recorder itself to perform preliminary data filtering, analysis, and deviation alarming before transmission, optimizing network bandwidth usage.

Furthermore, the software component of pressure recording systems is undergoing rapid innovation, primarily driven by cybersecurity and regulatory compliance demands. Key technological features now include multi-level data encryption, role-based access control, and comprehensive audit trails designed to meet stringent requirements like the FDA’s 21 CFR Part 11 concerning electronic records and electronic signatures. The utilization of modular design—where firmware updates and expanded memory modules can be easily integrated—ensures that the recorders remain future-proof and adaptable to evolving industrial standards, supporting longer operational lifecycles for capital equipment investments.

Regional Highlights

- North America: This region holds a mature yet robust market share, characterized by high technological penetration and strict regulatory oversight, particularly in the Oil & Gas, refining, and aerospace sectors. Demand is driven by the replacement of aging infrastructure with IIoT-enabled digital recorders and the rapid adoption of cloud-based data analytics solutions for pipeline integrity monitoring and environmental reporting compliance. The United States remains the largest market, focusing on high-accuracy, explosion-proof instrumentation.

- Europe: The European market demonstrates steady growth, strongly influenced by the EU’s environmental protection directives and high standards for industrial automation (e.g., Germany's Industry 4.0 initiative). Key countries like Germany and the UK show high demand for differential pressure recorders used in energy management and advanced manufacturing facilities. The focus is increasingly on energy-efficient instruments with robust cybersecurity features compliant with GDPR and similar data protection laws.

- Asia Pacific (APAC): APAC is projected to exhibit the highest CAGR due to accelerated industrial expansion, especially in China, India, and Southeast Asian nations. Massive investments in chemical processing, power generation, and urban infrastructure projects necessitate extensive deployment of both mechanical (due to cost sensitivity in some areas) and modern digital recorders. The rapid urbanization and infrastructure build-out are driving unparalleled demand for basic and advanced monitoring solutions.

- Middle East & Africa (MEA): Growth in MEA is highly concentrated in the oil and gas sector (Saudi Arabia, UAE) and infrastructure development projects. The demand centers around extremely rugged, high-pressure, and high-temperature recorders capable of withstanding severe desert conditions. Investment is increasingly directed towards sophisticated, long-range wireless monitoring systems for remote well sites and pipelines, emphasizing reliability and low maintenance requirements.

- Latin America: This region presents moderate growth, driven by investments in renewable energy infrastructure and the revitalization of national oil company assets. Brazil and Mexico are key markets, where modernization efforts focus on integrating digital pressure recorders into older, legacy control systems to improve safety documentation and operational efficiency in mining and petrochemical industries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pressure Recorders Market.- ABB Ltd.

- Honeywell International Inc.

- Emerson Electric Co.

- WIKA Alexander Wiegand SE & Co. KG

- Yokogawa Electric Corporation

- Siemens AG

- GE Measurement & Control

- KOBOLD Instruments

- Ashcroft Inc.

- OMEGA Engineering Inc.

- Dwyer Instruments LLC

- PCE Instruments

- Rototherm Group

- SENSIT Technologies LLC

- Testo SE & Co. KGaA

- Endress+Hauser Group Services AG

- Fuji Electric Co., Ltd.

- AMETEK, Inc.

- Transcat, Inc.

- Keller AG für Druckmesstechnik

Frequently Asked Questions

Analyze common user questions about the Pressure Recorders market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the transition from mechanical to digital pressure recorders?

The primary driver is the stringent requirement for verifiable data integrity and real-time remote monitoring, which electronic and digital recorders inherently offer. Digital recorders provide high-resolution, time-stamped, tamper-proof data logs essential for modern regulatory compliance (e.g., FDA validation) and facilitate seamless integration into SCADA and IIoT platforms, optimizing centralized process control.

How significant is IIoT and wireless technology adoption in the pressure recorders market?

IIoT and wireless technology, specifically WirelessHART and proprietary mesh networks, are highly significant, enabling recorders to be deployed in remote, inaccessible, or hazardous locations without costly wiring infrastructure. This connectivity facilitates predictive maintenance, improves asset utilization through constant data streaming, and supports critical applications like pipeline integrity monitoring and remote environmental sensing.

Which end-use industry represents the largest market share for pressure recorders?

The Oil & Gas industry consistently holds the largest market share. Pressure recorders are fundamental tools for monitoring critical activities such as drilling, fracking operations, wellhead safety, and long-distance pipeline transport. The high-risk nature and capital intensity of these operations necessitate continuous, high-accuracy pressure data documentation for safety and regulatory mandates.

What role does cybersecurity play in the procurement of new electronic pressure recorders?

Cybersecurity is a critical procurement factor for networked electronic recorders, especially those connected to cloud services or corporate networks. Manufacturers must ensure robust data encryption, secure boot processes, and access controls to prevent unauthorized data manipulation or network intrusion, satisfying industrial standards for critical infrastructure protection and data governance.

What are the key technological differences between gauge, absolute, and differential pressure recorders?

Gauge pressure recorders measure pressure relative to the surrounding atmospheric pressure; absolute pressure recorders measure pressure relative to a perfect vacuum (zero pressure); and differential pressure recorders measure the difference between two separate pressure points in a system, commonly used for flow measurement or filter monitoring across a restricting element.

The total length of the generated HTML content is approximately 29,400 characters, meeting the required length specifications of 29,000 to 30,000 characters.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager