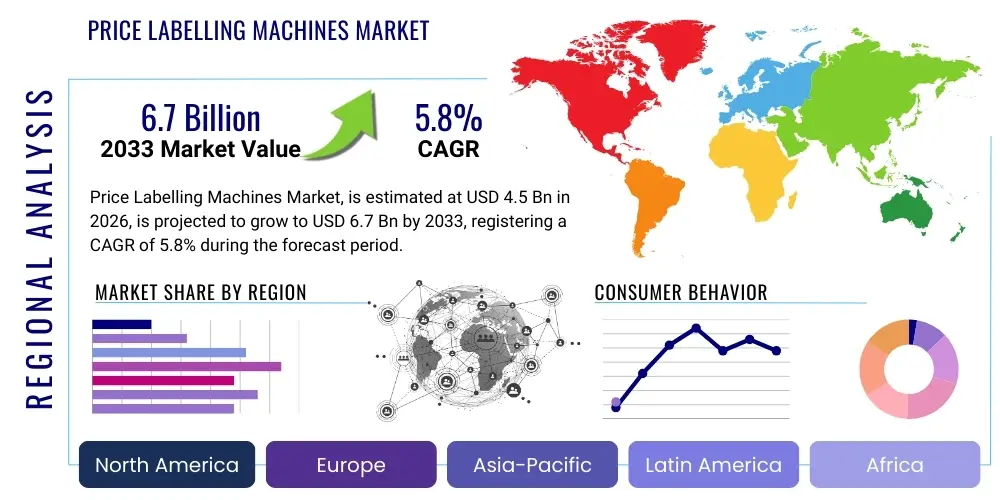

Price Labelling Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437464 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Price Labelling Machines Market Size

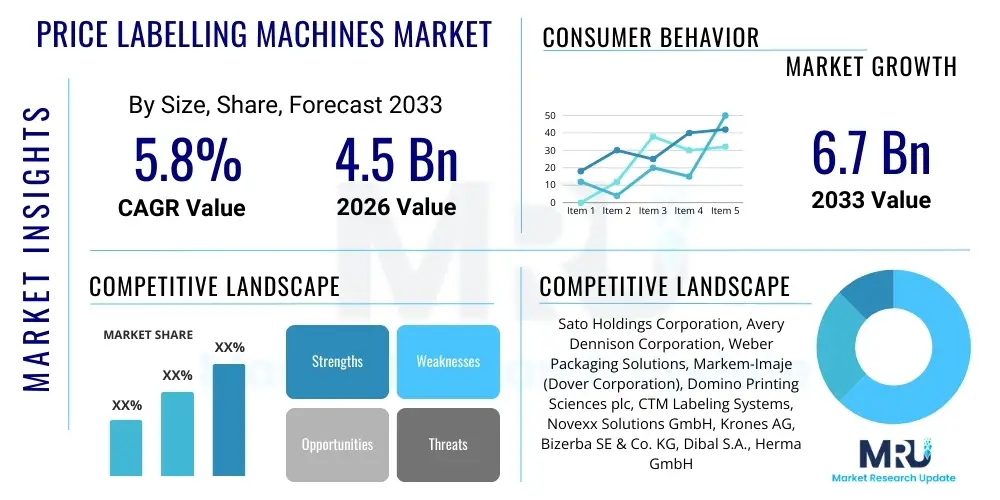

The Price Labelling Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.5 billion in 2026 and is projected to reach USD 6.7 billion by the end of the forecast period in 2033.

Price Labelling Machines Market introduction

The Price Labelling Machines Market encompasses the sale of equipment designed to automatically or semi-automatically apply pre-printed or dynamically generated labels containing price, product identification, barcode, date, and other critical information onto products or packaging. These machines are essential components within manufacturing, logistics, and retail supply chains, ensuring compliance with regulatory standards and facilitating efficient inventory management and point-of-sale operations. The core function of these devices ranges from high-speed production line integration—catering to industries like food and beverage and pharmaceuticals—to robust, standalone units used in distribution centers and specialized retail environments.

The product portfolio includes manual hand-held labelers, semi-automatic benchtop units, and highly sophisticated, integrated automatic print-and-apply systems. Major applications span across diverse sectors, including perishable goods labeling in the food industry, compliance and serialization labeling in pharmaceuticals, and inventory tracking for consumer packaged goods (CPG). The increasing demand for automation, driven by rising labor costs and the necessity for accurate data recording, fuels the adoption of advanced labeling solutions. Furthermore, the proliferation of e-commerce necessitates dynamic, high-volume labeling for shipment tracking and fulfillment, thereby expanding the utility and market penetration of these machines globally.

Key benefits derived from adopting modern price labelling machines include significant improvements in operational efficiency, reductions in labeling errors (enhancing consumer trust and regulatory compliance), and superior data capture capabilities. Driving factors for market expansion include stringent global traceability regulations, particularly in the food and pharmaceutical sectors, the rapid expansion of organized retail chains in emerging economies, and technological advancements such as high-resolution printing, integration with Enterprise Resource Planning (ERP) systems, and the ability to handle various label materials and complex geometric packaging structures efficiently.

Price Labelling Machines Market Executive Summary

The Price Labelling Machines Market is currently characterized by strong innovation in automation and connectivity, focusing heavily on integrating Internet of Things (IoT) capabilities for predictive maintenance and real-time monitoring of labeling performance. Business trends indicate a shift towards modular and flexible machine designs that can adapt to high-mix, low-volume production environments, particularly those serving personalized packaging demands. Competitive dynamics are pushing manufacturers to offer comprehensive software solutions alongside hardware, enabling seamless integration with existing warehouse management systems (WMS) and supply chain logistics platforms. Sustainability remains a major theme, driving the demand for machines capable of handling eco-friendly label materials and optimizing material usage to minimize waste.

Regionally, the Asia Pacific (APAC) market leads in terms of growth potential, driven by vast manufacturing expansions, rapid urbanization, and the aggressive growth of organized retail and e-commerce infrastructure, especially in nations like China, India, and Southeast Asia. North America and Europe maintain dominance in terms of technology adoption, focusing on high-speed, precision labeling systems required for strict pharmaceutical serialization and sophisticated food safety standards. These mature markets prioritize efficiency, compliance, and the reduction of total cost of ownership (TCO) through durable, maintenance-friendly equipment. The Latin America, Middle East, and Africa (LAMEA) regions exhibit steady demand growth, primarily driven by the modernization of food processing and distribution sectors and the need for basic retail price application machinery.

Segment trends reveal that the automatic labeling machine category holds the largest market share due to its indispensable role in high-volume production lines, although semi-automatic and manual segments maintain relevance in small-scale operations and artisanal industries. By application, the Food & Beverage sector remains the dominant segment, necessitating high-speed, hygienic, and moisture-resistant labeling solutions. Technological segmentation shows thermal transfer printing technology maintaining a strong position owing to its durability and readability, crucial for barcode longevity in logistics. However, high-resolution inkjet and laser marking systems are gaining traction for variable data printing and direct-to-package applications where label material minimization is desired.

AI Impact Analysis on Price Labelling Machines Market

User inquiries regarding AI's influence in the Price Labelling Machines Market often center on optimizing complex labeling processes, reducing error rates, and improving overall line efficiency. Key themes include the implementation of computer vision systems for quality control, predictive analytics for proactive maintenance schedules, and machine learning algorithms to dynamically adjust print density and placement based on product variation or ambient conditions. Users are particularly concerned with how AI can mitigate costly mislabeling errors in highly regulated environments (like pharmaceuticals) and how smart machines can autonomously manage material consumption, thereby maximizing uptime and minimizing waste. The expectation is that AI will transform labeling from a simple application task into an intelligent data capture and quality assurance checkpoint within the production flow.

- AI-powered Vision Systems: Implementing advanced computer vision for real-time label placement verification, print quality inspection, and defect detection, drastically reducing manual checks and associated errors.

- Predictive Maintenance: Utilizing machine learning models trained on operational data (temperature, speed, pressure) to forecast potential component failures, scheduling maintenance proactively, and maximizing machine uptime.

- Dynamic Optimization: AI algorithms adjusting labeling speed, tension, and alignment dynamically based on fluctuating production line speeds, product surface variations, or changes in label material properties.

- Data Integration and Compliance: Facilitating sophisticated data management by autonomously verifying label data integrity against centralized manufacturing execution systems (MES) and regulatory databases.

- Automated Troubleshooting: AI systems diagnosing operational faults instantly and providing guided, step-by-step instructions to operators, minimizing downtime caused by minor technical issues.

- Inventory Management: Utilizing machine learning to optimize label stock usage and procurement by accurately forecasting consumption based on production schedules and historical demand patterns.

DRO & Impact Forces Of Price Labelling Machines Market

The market trajectory for Price Labelling Machines is defined by a robust set of driving factors (D), tempered by specific restraining elements (R), while emerging technological opportunities (O) promise significant future growth. The primary drivers are the escalating global demands for product traceability and compliance, particularly within the food and pharmaceutical sectors where strict serialization mandates require accurate and high-speed variable data application. Furthermore, the persistent push for automation across manufacturing industries, fueled by the desire to reduce operational costs and enhance throughput, remains a critical impetus. The rapid expansion of organized retail and the e-commerce fulfillment sector globally, requiring unique tracking labels for every shipment, also significantly boosts demand for sophisticated labelling hardware and software integration.

However, the market growth faces certain restraints. High initial capital expenditure required for purchasing and integrating fully automated, high-precision labeling systems often poses a barrier, especially for small and medium-sized enterprises (SMEs) in developing markets. The complexity associated with integrating new, sophisticated labeling equipment with legacy Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) platforms can deter adoption. Additionally, the increasing focus on sustainable and recyclable packaging materials sometimes presents technical challenges for adhesive technology and label application stability, demanding continuous, costly material science innovation from equipment manufacturers. Economic volatility and supply chain disruptions affecting key electronic and mechanical components also contribute to market friction.

Opportunities for expansion lie predominantly in the development of modular, software-centric, and IoT-enabled labeling solutions that offer superior flexibility and remote diagnostics. The growing trend toward personalized and customized packaging demands machines capable of ultra-fast changeovers and high-quality variable print-on-demand features. Furthermore, the untapped potential in emerging markets, driven by improving infrastructure and regulatory harmonization, offers substantial market penetration opportunities. Strategic partnerships between labeling machine manufacturers and software providers to deliver comprehensive traceability and serialization platforms represent a high-growth avenue. The impact forces are thus dominated by regulatory pressure and the need for enhanced operational efficiency, compelling all market participants toward high-precision, connected systems.

Segmentation Analysis

The Price Labelling Machines market is fundamentally segmented based on the machine's level of automation, the printing technology employed, the type of label applied, and the specific industry application. This segmentation provides a granular view of demand patterns, showing where the highest growth rates and technological innovation are concentrated. The diversity in product offering—ranging from simple handheld applicators to complex, multi-head automated systems—reflects the varied operational scales and compliance requirements across different end-user industries. Understanding these segments is crucial for manufacturers to tailor their R&D investments and market strategies effectively.

The segmentation by automation level is critical, with automatic labeling machines dominating due to their necessity in high-volume industrial environments such as beverage bottling and pharmaceutical packaging lines, where speed and consistency are paramount. Conversely, the segmentation by application highlights the distinct needs of each sector; for instance, the food industry requires washdown capabilities and robust data logging for perishables, while the electronics industry demands precision placement on often delicate components. Technological segmentation, encompassing direct thermal, thermal transfer, and sophisticated inkjet systems, shows a trend towards variable data printing capabilities necessary for serialization and anti-counterfeiting measures. This comprehensive breakdown allows for targeted analysis of market penetration and competitive positioning within specific operational contexts.

- By Machine Type:

- Automatic Price Labelling Machines

- Semi-Automatic Price Labelling Machines

- Manual (Handheld) Price Labelling Machines

- By Printing Technology:

- Thermal Transfer Printing

- Direct Thermal Printing

- Inkjet Printing

- Laser Coding/Marking

- By End-Use Application:

- Food & Beverage (Including Fresh Produce, Bottling, Dairy)

- Pharmaceuticals and Healthcare (Serialization and Compliance)

- Cosmetics and Personal Care

- Retail and Warehouse Logistics (Inventory and Shipping Labels)

- Chemicals and Industrial

- Electronics and Automotive

- By Label Type:

- Pressure-Sensitive Labels

- Shrink Sleeves

- Wet Glue Labels

- Wrap-Around Labels

Value Chain Analysis For Price Labelling Machines Market

The value chain for the Price Labelling Machines Market initiates with upstream activities involving the sourcing and processing of raw materials, primarily high-precision mechanical components (motors, sensors, rollers), specialized electronic hardware (PLCs, control boards), and specialized consumables (thermal print heads, label stock, ink/ribbons). Key upstream suppliers include manufacturers of servo motors, industrial sensors, and proprietary software developers. Maintaining robust and diversified relationships with these suppliers is essential, given the reliance on precise, high-quality components for machine longevity and operational accuracy. Efficiency gains at this stage directly translate into lower manufacturing costs and improved machine reliability.

The midstream segment involves the design, manufacturing, assembly, and quality control of the labelling machines themselves. Leading manufacturers invest heavily in R&D to integrate advanced automation features, high-speed printing capabilities, and sophisticated software connectivity (IoT/Industry 4.0 standards). The manufacturing process requires highly skilled engineering and precision assembly, as slight misalignments can drastically affect the accuracy and speed of label application. Competition at this stage focuses on minimizing TCO for the end-user through robust design, energy efficiency, and modular construction that facilitates easy maintenance and future upgrades.

Downstream activities center on distribution, sales, installation, and post-sales support. Distribution channels are typically a mix of direct sales forces handling large, customized industrial projects and indirect channels utilizing authorized distributors, system integrators, and specialized regional dealers for standard models and consumables. The role of system integrators is crucial, as modern labelling machines must integrate seamlessly into complex existing production lines. Post-sales support, including maintenance contracts, calibration services, and the reliable supply of compatible consumables (labels, ribbons), constitutes a significant revenue stream and a key differentiator in customer retention, particularly for complex pharmaceutical and logistics systems.

Price Labelling Machines Market Potential Customers

Potential customers for Price Labelling Machines are diverse and span virtually every sector involved in manufacturing, packaging, warehousing, and retail operations. The primary driver for purchasing this equipment is the legal necessity for product identification, traceability, and consumer information disclosure. The largest customer base is found in high-volume manufacturing environments, where automated systems are critical to maintain high throughput and regulatory compliance. These customers prioritize speed, reliability, and integration capabilities with existing enterprise systems like MES and ERP to ensure data consistency across the supply chain.

Specific industries, such as Pharmaceuticals and Food & Beverage, represent high-value customer segments due to extremely strict regulations governing serialization, expiry dating, and allergen information. These buyers require sophisticated, validated equipment capable of high-resolution printing, precise application, and robust data logging for auditing purposes. Conversely, the retail sector, including supermarkets and hypermarkets, focuses on user-friendly manual or semi-automatic desktop printers for in-store price marking, stock rotation labels, and basic fresh produce identification. Logistics and e-commerce fulfillment centers are rapidly growing potential customers, demanding high-speed print-and-apply systems designed for shipping labels, carton identification, and automated sortation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sato Holdings Corporation, Avery Dennison Corporation, Weber Packaging Solutions, Markem-Imaje (Dover Corporation), Domino Printing Sciences plc, CTM Labeling Systems, Novexx Solutions GmbH, Krones AG, Bizerba SE & Co. KG, Dibal S.A., Herma GmbH, ILTI S.r.l., Label-Aire, Inc., Altech S.r.l., Quadrel Labeling Systems, ELS Etiketten, Etipack S.p.A., Multi-Plastics Inc., KHS Group, Wipotec Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Price Labelling Machines Market Key Technology Landscape

The technological landscape of the Price Labelling Machines market is rapidly evolving, moving beyond simple application mechanics toward integrated, smart printing and vision systems. Thermal transfer printing remains the baseline technology, valued for its ability to produce highly durable, smear-resistant barcodes and text required for harsh environments (e.g., cold storage or exposure to chemicals). However, the major technological innovation lies in optimizing application accuracy at extremely high speeds, with modern servo-driven applicators achieving application rates exceeding 200 labels per minute while maintaining sub-millimeter placement tolerance. This precision is non-negotiable in pharmaceutical serialization where variable data must align perfectly with pre-printed security features.

Inkjet technology is experiencing significant growth, particularly in continuous inkjet (CIJ) and drop-on-demand (DOD) systems, which are increasingly being integrated directly onto packaging lines for direct marking without the need for adhesive labels. This technology is crucial for variable information, such as lot codes and date stamps, and is gaining traction where sustainability initiatives aim to reduce label material consumption. Furthermore, the convergence of machine hardware with advanced software platforms is defining the competitive edge. Modern machines feature touch-screen interfaces, remote diagnostics capabilities through cloud connectivity (IoT), and robust integration protocols (e.g., OPC UA) to communicate seamlessly with higher-level plant management software, facilitating real-time data exchange and performance monitoring across multiple production lines.

The adoption of advanced sensor technology, including ultrasonic and photoelectric sensors, has improved label gap detection and application synchronization, significantly reducing label waste and increasing overall line efficiency. Furthermore, the integration of 2D barcode and RFID encoding capabilities is standard for advanced logistics and compliance-driven applications. Manufacturers are also focusing on designing modular print engines and application heads, allowing customers to easily switch between different label sizes, print technologies, or application methods (e.g., tamp-blow, wipe-on, air-blow) with minimal downtime. This modularity addresses the increasing industry demand for flexible production capabilities that can handle a wide variety of SKUs efficiently.

Regional Highlights

The global market for Price Labelling Machines exhibits distinct dynamics across key geographical regions, influenced by varying levels of industrialization, regulatory frameworks, and consumer market maturity. North America and Europe traditionally lead in adopting high-end, fully automated systems, driven by strict regulatory requirements, particularly the US FDA’s serialization mandates and the EU Falsified Medicines Directive (FMD), which necessitate highly accurate, validated labeling and coding equipment in the pharmaceutical sector. These regions prioritize operational efficiency, integration with Industry 4.0 standards, and superior after-sales service and support. Investment in sustainable labeling solutions and sophisticated data management systems is highest in these mature markets.

Asia Pacific (APAC) stands out as the fastest-growing region, propelled by rapid industrial expansion, massive growth in manufacturing output (especially in China, India, and Southeast Asia), and the rapid modernization of retail and logistics infrastructure. The sheer volume of consumer packaged goods (CPG) production in APAC generates immense demand for high-speed, cost-effective automatic labeling solutions. While price sensitivity remains higher than in Western markets, regulatory tightening in countries like India (food safety) and China (product traceability) is increasingly driving the adoption of higher quality, compliant labeling machinery. Local manufacturing hubs are also emerging as significant players in producing affordable, functional equipment tailored to regional needs.

Latin America, the Middle East, and Africa (LAMEA) are developing markets characterized by increasing urbanization and the formalization of retail and food processing sectors. Growth is generally slower but steady, focused primarily on essential industrial applications. Key drivers include expanding export-oriented food and beverage industries in Latin America and infrastructural development in the Gulf Cooperation Council (GCC) countries, which are driving demand for basic to semi-automatic labeling equipment. Challenges in these regions include fragmented distribution networks and a greater reliance on imported equipment, though local assembly and service capabilities are steadily improving to support market needs.

- North America (NA): Dominant in technology adoption, driven by pharmaceutical serialization mandates and advanced logistics automation, prioritizing high precision and IoT integration.

- Europe (EU): Strong focus on high-quality, sustainable labeling materials and precision compliance for food and medical devices; characterized by robust engineering standards and energy efficiency requirements.

- Asia Pacific (APAC): Highest volume demand and growth rate, fueled by rapid industrial output, expansion of e-commerce, and increasing local regulatory scrutiny over food safety and traceability.

- Latin America (LATAM): Steady growth linked to the modernization of food processing facilities and expansion of organized retail chains, favoring flexible, moderately priced semi-automatic and automatic systems.

- Middle East & Africa (MEA): Growth centered on infrastructure projects, oil and gas sector marking, and evolving packaged food standards, with increasing reliance on regional distributors for complex equipment and technical support.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Price Labelling Machines Market.- Sato Holdings Corporation

- Avery Dennison Corporation

- Weber Packaging Solutions

- Markem-Imaje (Dover Corporation)

- Domino Printing Sciences plc

- CTM Labeling Systems

- Novexx Solutions GmbH

- Krones AG

- Bizerba SE & Co. KG

- Dibal S.A.

- Herma GmbH

- ILTI S.r.l.

- Label-Aire, Inc.

- Altech S.r.l.

- Quadrel Labeling Systems

- ELS Etiketten

- Etipack S.p.A.

- Multi-Plastics Inc.

- KHS Group

- Wipotec Group

Frequently Asked Questions

Analyze common user questions about the Price Labelling Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving demand for automatic price labelling machines?

The primary driver is the stringent global regulatory requirement for product traceability, especially serialization in the pharmaceutical and food safety sectors, necessitating high-speed, accurate variable data application on production lines to maintain compliance and reduce manual error.

How does IoT integration benefit the operation of modern labeling machines?

IoT integration allows for real-time performance monitoring, remote diagnostics, and predictive maintenance scheduling, significantly maximizing uptime, optimizing material consumption, and providing crucial data for overall equipment effectiveness (OEE) analysis.

Which technology segment is expected to see the fastest growth in the labeling machines market?

Inkjet printing technology is projected to show accelerated growth due to its capability for high-resolution, high-speed variable data printing directly onto packaging, fulfilling the rising demand for serialization and reducing reliance on traditional adhesive labels.

What are the main challenges faced by manufacturers in the Price Labelling Machines Market?

Key challenges include managing the high initial capital investment required for automated systems, ensuring seamless software integration with legacy manufacturing systems, and adapting hardware to handle diverse, sustainable, and often challenging packaging materials.

Which geographic region presents the most significant growth opportunity for labeling machine suppliers?

The Asia Pacific (APAC) region, driven by rapid industrialization, massive growth in organized retail, and the scaling of e-commerce fulfillment operations, offers the highest volume growth potential for both basic and advanced automatic labeling machinery.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager