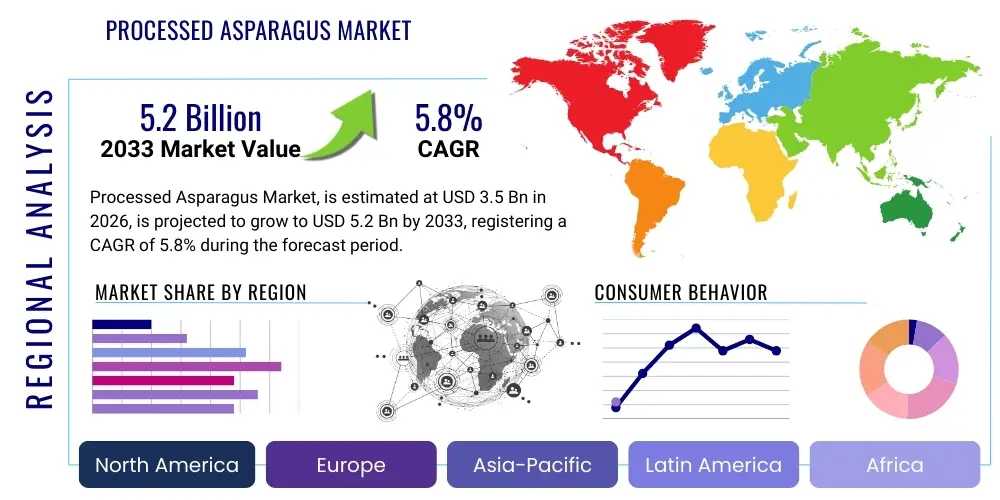

Processed Asparagus Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437326 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Processed Asparagus Market Size

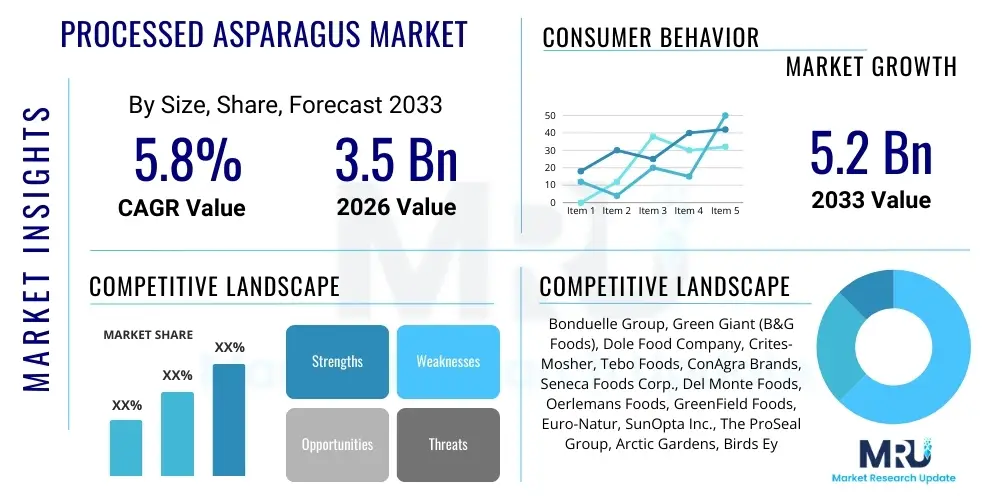

The Processed Asparagus Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.2 Billion by the end of the forecast period in 2033.

Processed Asparagus Market introduction

The Processed Asparagus Market encompasses the industry involved in converting freshly harvested asparagus spears into various shelf-stable or ready-to-use forms, including canned, frozen, pickled, and dehydrated products. This processing is essential for extending the shelf life of the highly perishable vegetable, facilitating its distribution across diverse geographical regions and ensuring year-round availability for both residential consumers and the commercial foodservice sector. Asparagus processing employs critical techniques such as blanching, freezing shock, canning sterilization, and controlled atmospheric drying, ensuring retention of nutritional value and desirable texture while adhering to stringent food safety regulations. The primary product benefits include convenience, reduced preparation time, and consistent quality regardless of the harvest season, addressing the modern consumer's demand for efficient, high-quality meal components. Major applications span ready meals, side dishes, gourmet salads, and ingredients in institutional catering operations, highlighting its versatility in the culinary landscape.

Driving factors for sustained market expansion include the increasing adoption of convenient packaged foods due to rapid urbanization and busy lifestyles globally, coupled with a heightened awareness of asparagus's significant health benefits, such as high levels of folate, vitamins A, C, and K, and dietary fiber. Furthermore, advancements in preservation technologies, specifically in Individual Quick Freezing (IQF) and retort processing, have substantially improved the sensory quality of processed asparagus, making it a more appealing alternative to fresh produce when out of season. Economic considerations also play a role, as global trade liberalization facilitates the sourcing of raw materials from major producing regions like Peru, China, and Mexico, stabilizing supply chains and potentially lowering input costs for processors, thereby driving penetration in emerging markets.

The market environment is characterized by intense competition and a focus on product innovation, particularly in organic and low-sodium variants catering to specific dietary trends. Processors are increasingly integrating sustainable sourcing practices and utilizing eco-friendly packaging materials, responding to escalating consumer preference for environmentally responsible brands. The market structure involves a complex network stretching from large-scale agricultural operations specialized in high-yield cultivation to multinational food conglomerates managing extensive processing and distribution networks. This dynamic interplay ensures continuous supply and adaptation to fluctuating consumer demands, positioning processed asparagus as a vital component of the global vegetable trade.

Processed Asparagus Market Executive Summary

The Processed Asparagus Market is poised for steady growth, driven primarily by evolving global consumption patterns favoring convenience, extended shelf life, and the inherent nutritional value of asparagus. Key business trends indicate a strong shift towards advanced freezing techniques (IQF) and retort packaging to maintain product quality and flavor profile, significantly outpacing traditional canning methods in terms of growth rate. Regional trends highlight Asia Pacific (APAC) as the fastest-growing market, propelled by expanding urban populations, rising disposable incomes, and the increasing adoption of Western dietary habits, complementing the established maturity of North America and Europe. Segment trends reveal the frozen asparagus category dominating market share due to its proximity to fresh quality, while the foodservice sector remains the largest end-user, demanding bulk, consistent supply for large-scale operations. Innovation is concentrated on clean label ingredients and sustainable packaging solutions, which are becoming non-negotiable competitive factors across all major segments and geographies, compelling leading players to restructure supply chains for improved traceability and ethical sourcing.

AI Impact Analysis on Processed Asparagus Market

User queries regarding the impact of Artificial Intelligence (AI) on the Processed Asparagus Market primarily revolve around optimizing agricultural yields, enhancing quality control during processing, and streamlining complex global supply chains. Users seek to understand how AI-driven precision agriculture, utilizing satellite imagery and machine learning models, can predict optimal harvesting times and detect crop diseases early, thereby minimizing raw material loss. A major concern focuses on the deployment of computer vision systems in processing plants for real-time defect detection and automated sorting, ensuring consistent product grading, especially for high-value segments like whole-spear canned or frozen products. Furthermore, expectations are high regarding AI's ability to forecast demand accurately across various packaged forms (canned vs. frozen) and global regions, optimizing inventory management and reducing spoilage, a critical issue in the perishable food industry. This summary confirms that the primary user focus is on AI’s capacity to enhance efficiency, reduce costs, and guarantee superior product quality from farm to consumer.

- AI-powered precision agriculture optimizes irrigation, nutrient delivery, and pest control, maximizing asparagus yield per hectare.

- Machine learning algorithms predict ideal harvest windows, ensuring peak freshness and uniformity of raw input for processing.

- Computer vision systems deployed on processing lines conduct automated, high-speed sorting based on length, thickness, and color, significantly improving quality assurance and grading consistency.

- Predictive maintenance schedules for processing machinery are generated by AI, minimizing unexpected downtime and maximizing plant operational efficiency.

- AI-driven demand forecasting models improve inventory management, reducing storage costs and minimizing post-harvest losses throughout the complex cold chain logistics.

- Robotics integrated with AI facilitates precise cutting, trimming, and packaging operations, increasing throughput speed and reducing reliance on manual labor.

- Blockchain technologies, often augmented by AI for data analysis, enhance supply chain traceability, boosting consumer trust in product origin and safety standards.

- AI analyzes consumer reviews and sales data to inform new product development, such as preferred pickling flavors or specific spear sizes for ready-meal applications.

DRO & Impact Forces Of Processed Asparagus Market

The Processed Asparagus Market dynamics are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively form the Impact Forces determining market trajectory. The primary driver is the accelerating consumer preference for convenience foods that offer nutritional benefits without extensive preparation, coupled with stable global supply due to optimized cultivation techniques in major exporting nations. However, growth is significantly restrained by the inherent volatility in raw material pricing, influenced heavily by weather patterns and fluctuating energy costs required for deep freezing and retort sterilization, which directly impact the final product cost and profitability margins. Opportunities lie predominantly in technological integration, specifically the adoption of High-Pressure Processing (HPP) to offer minimally processed, nutrient-dense products, and expanding market penetration in rapidly industrializing regions where frozen food infrastructure is still developing but consumer income is rising.

The impact forces are categorized into macroeconomic, technological, and regulatory pressures. Macroeconomic forces, such as global inflation and currency fluctuations, directly affect the cost of importing raw or processed goods, potentially dampening consumer purchasing power in price-sensitive markets. Technological forces, including continuous improvements in packaging materials like barrier films and recyclable pouches, enhance product preservation and appeal. Regulatory forces, particularly the enforcement of strict international food safety standards (e.g., HACCP, ISO 22000), act as both a restraint—increasing compliance costs for smaller players—and a driver—ensuring consumer confidence in the safety and quality of processed asparagus products marketed internationally. Navigating these concurrent pressures requires strategic investment in supply chain resilience and advanced processing infrastructure to maintain competitive edge and profitability.

The collective impact of these forces suggests a moderately bullish outlook, provided key industry players successfully mitigate the climate-related risks associated with raw material supply and manage the substantial capital expenditure required for adopting advanced processing technologies. Successful market penetration hinges on product differentiation based on quality attributes such as organic certification, non-GMO status, and unique seasoning profiles, moving beyond basic commodity status. Furthermore, leveraging direct-to-consumer and specialized foodservice distribution channels will be crucial for capitalizing on opportunities presented by evolving consumer eating habits and the recovery of the global hospitality sector post-pandemic turbulence.

Segmentation Analysis

The Processed Asparagus Market is comprehensively segmented based on its physical form, the nature of the end-user utilizing the product, the type of packaging employed, and the distribution channels through which the product reaches the final consumer. This detailed segmentation allows stakeholders to accurately gauge market penetration, identify high-growth niches, and tailor marketing strategies effectively. The Form segment, comprising Canned, Frozen, and Pickled/Marinated, represents the fundamental division, with Frozen Asparagus typically capturing the premium market share due to its superior preservation of texture and nutritional integrity. The End-User analysis differentiates between residential consumption (retail) and commercial usage (foodservice and institutional), providing insights into bulk versus small-format packaging requirements and pricing sensitivities. Analyzing these segments is essential for understanding the overall dynamics of demand generation and optimizing production portfolios across varied consumer needs globally.

- By Form

- Canned Asparagus (Spears, Cuts, Tips)

- Frozen Asparagus (IQF Spears, Cuts)

- Pickled/Marinated Asparagus

- Dried/Dehydrated Asparagus

- By Packaging Type

- Cans (Metal)

- Glass Jars

- Flexible Pouches and Bags

- Trays and Cartons (for frozen)

- By Distribution Channel

- Supermarkets and Hypermarkets

- Convenience Stores

- Online Retail and E-commerce Platforms

- Foodservice (Hotels, Restaurants, Catering)

- By End-User

- Residential/Retail Consumers

- Commercial/Foodservice Industry

- Industrial Ingredient Manufacturers

Value Chain Analysis For Processed Asparagus Market

The Value Chain for the Processed Asparagus Market begins with Upstream Analysis, which encompasses seed development, specialized agricultural cultivation, and raw material harvesting. Given the perennial nature of asparagus crops and the labor-intensive harvesting process, this stage is critical for ensuring a consistent supply of high-quality raw spears, requiring significant capital investment in farm infrastructure, irrigation systems, and labor management. Key activities include precision farming techniques, quality grading immediately post-harvest, and rapid transportation to processing facilities to mitigate deterioration. Efficiency and cost control at the upstream level directly influence the profitability of the entire chain, making contractual agreements with specialized growers essential for stability.

The midstream section, focused on Processing and Manufacturing, involves stringent quality control checks, washing, trimming, blanching (to deactivate enzymes), and the specific preservation process—whether canning (sterilization via retort), freezing (IQF technology), or pickling/drying. This stage requires advanced machinery, high energy input, and adherence to global food safety standards (e.g., FDA, EFSA). Processing activities transform the highly perishable commodity into shelf-stable packaged goods. The choice of preservation method significantly influences the product's final selling price, nutrient retention, and target market. Effective waste management from trimming and processing also forms a critical part of optimizing costs and complying with environmental regulations.

Downstream Analysis and Distribution Channel management cover logistics, warehousing, sales, and marketing. Distribution channels are categorized as Direct (selling directly to large institutional buyers or through proprietary brand e-commerce) or Indirect (utilizing third-party distributors, wholesalers, and retail chains like supermarkets). Due to the bulk nature of canned goods and the cold chain requirement for frozen products, efficient logistics and temperature-controlled storage are paramount. The indirect channel dominates residential sales, relying on strong brand visibility and strategic shelf placement. Marketing efforts focus on highlighting convenience, health benefits, and recipe applications to drive consumer pull and ensure optimal rotation of stock in retail environments.

Processed Asparagus Market Potential Customers

Potential customers for the Processed Asparagus Market span a broad spectrum, fundamentally categorized into Residential Consumers, Commercial Foodservice Operators, and Industrial Food Manufacturers. Residential consumers are the largest volume buyers, purchasing processed asparagus primarily through retail channels (supermarkets, convenience stores, and online platforms) for use in everyday home cooking and meal preparation. Their demand is driven by convenience, consistent quality, and year-round availability, favoring frozen and canned formats that reduce prep time and waste. Targeted marketing often focuses on time-saving attributes and recipe integration, appealing to urban, middle-income families and single households seeking nutritious yet easy-to-prepare vegetable options.

Commercial customers, including Hotels, Restaurants, and Catering (HORECA) services, represent a critical segment that demands high-volume, uniform products, often requiring bulk packaging and specific sizing (e.g., extra-large spears for plating). These end-users prioritize cost-effectiveness, reliability of supply, and minimal preparation required on-site, making frozen and large-format canned asparagus highly appealing. Institutional buyers, such as schools, hospitals, and military facilities, also fall under the commercial umbrella, seeking cost-efficient, nutritionally compliant processed vegetables that meet large-scale dietary requirements and procurement standards set by governmental or administrative bodies. Their purchasing decisions are heavily influenced by long-term contractual pricing and adherence to rigorous food safety certifications.

Finally, Industrial Food Manufacturers utilize processed asparagus as a key ingredient in secondary products, such as ready-to-eat meals, frozen dinners, soups, stews, and specialized vegetable blends. This segment requires processed asparagus in specific forms (e.g., diced, puréed, or dried flakes) and often demands highly customized specifications, emphasizing uniformity, microbial standards, and functional attributes suitable for further manufacturing processes. Processors must establish strong B2B relationships with these manufacturers, focusing on technical specifications, bulk pricing structures, and consistent supply reliability to fulfill continuous production schedules for popular consumer packaged goods.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bonduelle Group, Green Giant (B&G Foods), Dole Food Company, Crites-Mosher, Tebo Foods, ConAgra Brands, Seneca Foods Corp., Del Monte Foods, Oerlemans Foods, GreenField Foods, Euro-Natur, SunOpta Inc., The ProSeal Group, Arctic Gardens, Birds Eye (Nomad Foods) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Processed Asparagus Market Key Technology Landscape

The technological landscape of the Processed Asparagus Market is defined by the necessity of preserving sensory attributes, maximizing nutritional retention, and achieving regulatory compliance efficiently. A cornerstone technology remains Individual Quick Freezing (IQF), especially for high-value frozen segments. IQF rapidly freezes each asparagus spear separately, preventing clumping and crystal formation, which is crucial for maintaining cellular structure, flavor, and texture closest to the fresh state. Continuous advancements in IQF tunnel designs, incorporating cryogenic freezing methods or enhanced airflow management, are driving down operational costs while improving output quality. The sustained consumer preference for frozen vegetables over canned products, perceived as nutritionally superior, solidifies IQF as a mandatory investment for market leaders focusing on premium processed options.

In the canned segment, improvements in retort sterilization technology are vital. Modern retorting systems offer highly precise temperature and pressure controls, minimizing the total heat exposure necessary to achieve commercial sterility. This reduction in thermal load helps mitigate flavor degradation and textural mushiness, which historically constrained the quality of canned asparagus. Furthermore, packaging innovation, particularly in barrier films for flexible pouches and Bisphenol A (BPA)-non-intent linings for metal cans, addresses consumer safety concerns and extends shelf life while maintaining product integrity. These innovations enable processors to offer lighter, safer, and potentially microwave-ready packaging formats, appealing to the modern, convenience-oriented consumer base.

Beyond traditional methods, emerging technologies are gaining traction. High-Pressure Processing (HPP) is being explored for minimally processed, refrigerated pickled or marinated asparagus, as it inactivates pathogens without using heat, thus preserving inherent freshness and bright color. Automation and robotics are increasingly integrated into sorting, grading, and packaging lines to handle the fragile spears efficiently and quickly, minimizing manual errors and maximizing hygiene standards. Furthermore, digital technologies such as advanced sensor systems and data analytics are used throughout the processing environment to monitor parameters like blanching temperature, moisture content, and cooling rate in real-time, ensuring stringent quality control and operational consistency across large batches.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand, supply, and growth trajectory of the Processed Asparagus Market, driven by local dietary habits, economic development, and agricultural capabilities. North America, specifically the United States, represents a mature and significant consumer base, characterized by high adoption rates of frozen vegetables due to robust cold chain infrastructure and established retail networks. Demand in this region is largely driven by health consciousness and the pursuit of organic and non-GMO processed food options, prompting processors to focus heavily on clean labeling and sustainable sourcing practices to capture market loyalty. Europe, led by Germany, the UK, and France, also exhibits high per capita consumption, particularly favoring both premium canned products (often originating from Peru or Spain) and high-quality frozen cuts, with strict European Union regulations setting high barriers for entry but ensuring superior product safety standards.

Asia Pacific (APAC) is projected to be the engine of future market expansion, recording the highest growth rate during the forecast period. This rapid growth is attributable to substantial economic development, leading to increased urbanization and disposable incomes that facilitate the transition from traditional diets to Westernized convenience foods, including packaged vegetables. Countries like China, which is also a massive producer of raw asparagus, and India, with its expanding middle class, show immense potential for both consumption and local processing expansion. Investment in cold chain logistics and modern retail infrastructure in Southeast Asia is unlocking new avenues for frozen asparagus distribution. Furthermore, the region's strong tradition of pickling and preserving vegetables supports the growth of the pickled asparagus segment, blending traditional food preparation techniques with modern processing capabilities.

Latin America, dominated by Peru and Mexico, holds critical importance primarily as a global supply hub for raw asparagus, exporting large quantities to processing facilities in North America and Europe. While local consumption of processed asparagus is rising, its main role remains upstream—ensuring cost-effective, high-volume raw material supply necessary to feed global demand. The Middle East and Africa (MEA) region remains a relatively smaller market, largely dependent on imports of canned and frozen varieties. Growth here is tied to the expansion of organized retail and the hospitality sector in major urban centers and tourism hubs. Economic stability and increasing globalization are key factors that will govern future market penetration and consumer adoption of processed asparagus products in the MEA region, particularly as awareness of western dietary trends increases.

- North America (U.S., Canada, Mexico): Mature market with high frozen product penetration; driven by health and organic trends; strong presence of large commercial foodservice operations.

- Europe (Germany, UK, France, Italy, Spain): High per capita consumption of both canned and frozen asparagus; strict regulatory environment necessitating high quality and traceability; significant import dependency.

- Asia Pacific (China, India, Japan, Australia): Fastest-growing region driven by urbanization and rising disposable income; substantial potential for local processing capacity development; increasing demand for convenient, ready-to-use vegetables.

- Latin America (Peru, Brazil, Argentina): Crucial region for raw material sourcing and export; Peru is a global leader in cultivation; increasing domestic market sophistication.

- Middle East and Africa (MEA): Emerging market dependent on imports; growth linked to expanding tourism and organized retail sector development; focus on long-shelf-life canned products due to logistical challenges.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Processed Asparagus Market.- Bonduelle Group

- Green Giant (B&G Foods)

- Dole Food Company

- Crites-Mosher

- Tebo Foods

- ConAgra Brands

- Seneca Foods Corp.

- Del Monte Foods

- Oerlemans Foods

- GreenField Foods

- Euro-Natur

- SunOpta Inc.

- The ProSeal Group

- Arctic Gardens

- Birds Eye (Nomad Foods)

- Ingomar Packing Company

- Hengstenberg GmbH & Co. KG

- Madrigal Quality Foods

- Grupo Virto

- McCain Foods Limited

Frequently Asked Questions

Analyze common user questions about the Processed Asparagus market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Frozen Processed Asparagus segment?

The Frozen Processed Asparagus segment is primarily driven by the superior quality retention achieved through Individual Quick Freezing (IQF) technology, which preserves the texture, flavor, and nutrient profile closer to fresh asparagus, meeting increasing consumer demand for convenient, high-quality, and minimally processed foods.

Which geographical region is expected to show the highest growth rate in the market?

The Asia Pacific (APAC) region is projected to exhibit the highest Compound Annual Growth Rate (CAGR), fueled by rapid urbanization, substantial increases in disposable income, and the corresponding shift in dietary habits towards packaged, convenience-focused processed vegetable options.

How does AI impact the supply chain and processing efficiency of asparagus?

AI significantly impacts the supply chain by enabling precision agriculture for optimal yield prediction and using computer vision systems in processing plants for rapid, accurate sorting and quality grading, thereby reducing waste and ensuring higher product consistency.

What are the main restraints affecting market expansion and profitability?

The main restraints include the inherent volatility and fluctuation of raw material prices, heavily dependent on unpredictable climatic conditions and seasonal yields, alongside high operational costs related to energy-intensive preservation methods like deep freezing and thermal canning.

What role does the Foodservice industry play in the overall Processed Asparagus Market?

The Foodservice industry (HORECA) is a crucial and dominant end-user, accounting for significant bulk demand. It requires consistent, high-volume supply of processed asparagus in specific formats (often frozen or large-can size) for efficient integration into large-scale catering and restaurant operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager