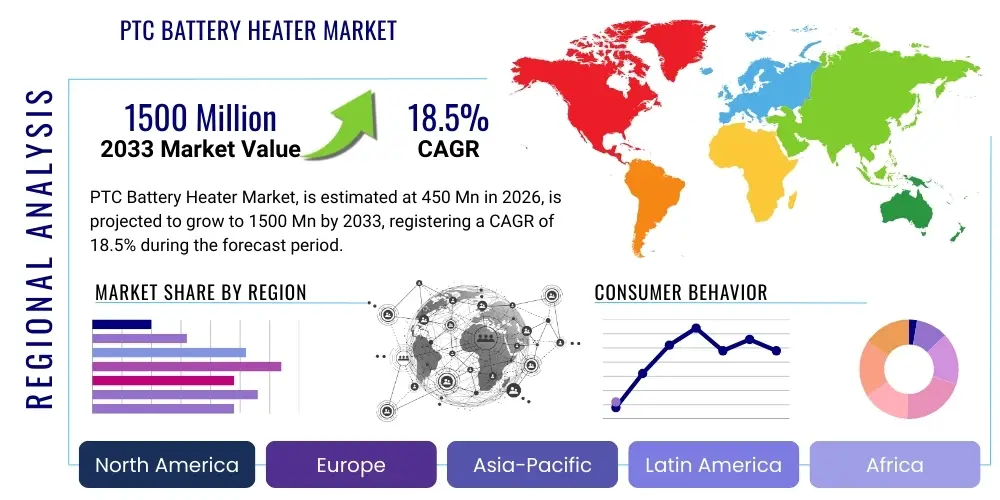

PTC Battery Heater Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439654 | Date : Jan, 2026 | Pages : 248 | Region : Global | Publisher : MRU

PTC Battery Heater Market Size

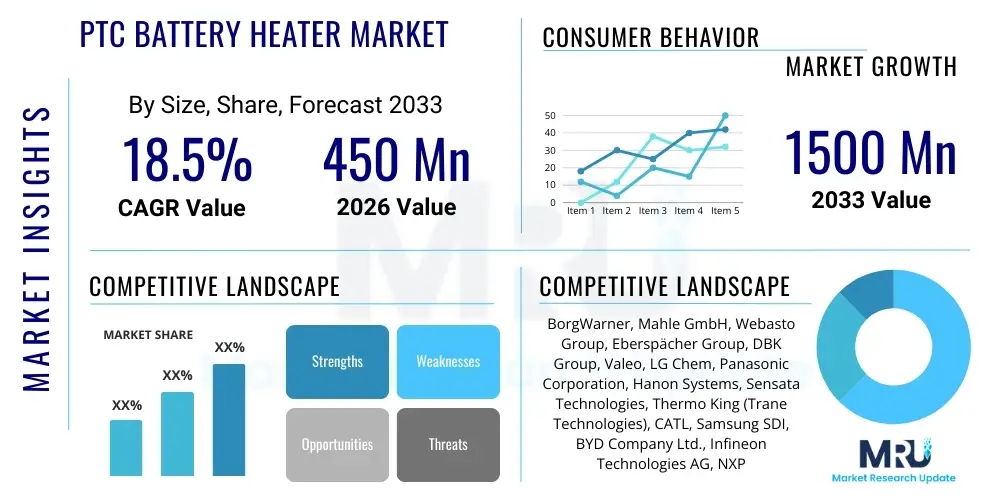

The PTC Battery Heater Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 1500 Million by the end of the forecast period in 2033. This substantial growth trajectory is primarily driven by the accelerating global adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs), which necessitate advanced thermal management solutions for optimal battery performance and longevity. As automotive manufacturers increasingly prioritize efficiency, safety, and rapid charging capabilities in their electric powertrains, the demand for sophisticated PTC battery heaters is experiencing a significant surge.

The market expansion is further bolstered by evolving regulatory landscapes that mandate enhanced cold-weather performance and extend battery life for electric vehicles. Countries across North America, Europe, and Asia Pacific are implementing stricter emissions standards and offering incentives for EV purchases, which directly translates into a higher volume of vehicles requiring robust thermal management. Furthermore, the development of more powerful and energy-dense battery packs, such as those employing advanced lithium-ion chemistries, amplifies the need for precise temperature control during charging and operation, thereby solidifying the critical role of PTC battery heaters.

PTC Battery Heater Market introduction

The PTC Battery Heater Market encompasses the design, manufacturing, and distribution of Positive Temperature Coefficient (PTC) heating elements specifically engineered to optimize the performance and lifespan of battery systems, particularly in electric vehicles (EVs), hybrid electric vehicles (HEVs), and stationary energy storage applications. These heaters utilize a unique characteristic where their electrical resistance increases sharply with temperature, allowing for self-regulating temperature control, thus preventing overheating while ensuring efficient heating. This inherent safety feature is crucial for maintaining the optimal operating temperature range of lithium-ion batteries, which are highly sensitive to extreme cold, leading to reduced efficiency, slower charging times, and accelerated degradation.

Major applications for PTC battery heaters include integration into battery packs of various vehicle types, from passenger cars to commercial fleets, as well as in grid-scale energy storage solutions and portable electronic devices requiring robust thermal management. The primary benefits derived from these heaters include enhanced battery efficiency, particularly in sub-zero conditions, significantly faster charging speeds by bringing batteries to optimal temperatures, and an extended overall battery lifespan by mitigating stress from cold-induced performance issues. Moreover, they contribute to vehicle safety by preventing thermal runaway incidents associated with uncontrolled heating.

The market's growth is fundamentally driven by several overarching factors. Foremost among these is the exponential global shift towards electric mobility, fueled by environmental concerns, government incentives, and advancements in battery technology. This transition necessitates reliable and efficient thermal management systems to unlock the full potential of EV batteries. Additionally, increasing consumer expectations for vehicle range, rapid charging, and reliable performance in diverse climates further propel the demand for sophisticated PTC battery heating solutions. Technological advancements in material science and electronic controls are also playing a pivotal role in refining heater designs, making them more compact, energy-efficient, and cost-effective, thereby accelerating their widespread adoption across various battery-powered applications.

PTC Battery Heater Market Executive Summary

The PTC Battery Heater Market is experiencing robust expansion, primarily fueled by the accelerating global electrification of transportation and the critical need for advanced battery thermal management. Business trends indicate a strong focus on innovation, with manufacturers investing heavily in developing more compact, energy-efficient, and integrated PTC heating solutions that can seamlessly interface with sophisticated battery management systems (BMS). Strategic partnerships between automotive OEMs, battery manufacturers, and specialized heating component suppliers are becoming prevalent, aiming to create holistic thermal solutions that enhance performance, safety, and longevity of electric vehicle batteries. Furthermore, the market is witnessing a trend towards modular designs and customized solutions to cater to the diverse requirements of different battery chemistries and vehicle architectures, addressing both passenger and commercial vehicle segments. The rising emphasis on fast charging capabilities and extending battery life in extreme temperatures is a central driver for product development and market penetration.

From a regional perspective, Asia Pacific continues to dominate the market, largely due to China's leading position in EV production and adoption, along with significant growth in South Korea and Japan's automotive industries. Europe is also emerging as a high-growth region, driven by stringent emission regulations, ambitious electrification targets, and robust government support for EV infrastructure and sales. North America, particularly the United States, is poised for substantial growth, propelled by significant investments in EV manufacturing capacity and increasing consumer demand for electric vehicles. These regions are characterized by a strong emphasis on research and development to address specific climatic challenges and energy efficiency goals, fostering a competitive landscape among local and international players. Emerging markets in Latin America, the Middle East, and Africa are showing nascent but growing potential as EV adoption slowly begins to gain traction, creating future opportunities for market expansion.

Segmentation trends highlight the increasing demand for high-power PTC heaters designed for large-capacity EV battery packs, catering to longer range requirements and commercial vehicle applications. The "By Type" segment sees both ceramic PTC heaters and film PTC heaters evolving, with film heaters gaining traction for their flexibility and integration advantages in compact spaces. The "By Application" segment is overwhelmingly driven by electric vehicles (EVs), with hybrid electric vehicles (HEVs) also contributing significantly, while stationary energy storage systems represent a growing niche. The market is also seeing differentiation based on vehicle type, with passenger cars forming the largest share, but commercial vehicles exhibiting strong future growth potential. Overall, there is a clear market shift towards integrated, intelligent, and highly efficient PTC heating solutions that can contribute to the overall performance envelope of electric powertrains.

AI Impact Analysis on PTC Battery Heater Market

The integration of Artificial Intelligence (AI) is poised to significantly transform the PTC Battery Heater Market, addressing common user questions about system optimization, predictive maintenance, and energy efficiency. Users are increasingly curious about how AI can move beyond simple temperature regulation to enable smart thermal management that anticipates needs rather than merely reacting to them. Key concerns revolve around AI's ability to minimize energy consumption, extend battery lifespan through intelligent heating strategies, and predict potential thermal issues before they escalate. Expectations include more adaptive and context-aware heating, where AI algorithms learn from driving patterns, environmental conditions, and battery state-of-health data to dynamically adjust PTC heater operation. This shift promises a future where battery thermal management is not only more effective but also contributes meaningfully to overall vehicle efficiency and range, rather than being an auxiliary energy drain.

- AI-driven Predictive Thermal Management: Enables PTC heaters to anticipate heating needs based on driving patterns, navigation data, and external temperature forecasts, optimizing energy use.

- Enhanced Battery State-of-Health (SoH) Monitoring: AI algorithms analyze heater performance and battery response to fine-tune heating cycles, preventing thermal stress and extending battery lifespan.

- Optimized Energy Consumption: Machine learning models can determine the most energy-efficient heating profiles for specific conditions, reducing the parasitic load on the battery.

- Fault Detection and Diagnostics: AI can identify anomalies in PTC heater operation or battery temperature gradients, predicting potential failures and enabling proactive maintenance.

- Adaptive Control Systems: AI allows PTC heaters to adapt in real-time to varying environmental conditions, charging speeds, and battery degradation levels, ensuring consistent optimal performance.

- Integration with Advanced Driver-Assistance Systems (ADAS): AI can integrate thermal management with other vehicle systems for a holistic approach to energy efficiency and performance.

- Improved Fast Charging Efficiency: AI-optimized pre-heating strategies can bring batteries to ideal charging temperatures more rapidly and efficiently, reducing overall charging time.

DRO & Impact Forces Of PTC Battery Heater Market

The PTC Battery Heater Market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively form the Impact Forces shaping its trajectory. A primary driver is the relentless global push towards vehicle electrification, spurred by escalating environmental concerns and government mandates for reduced carbon emissions. This transition necessitates robust thermal management solutions for the rapidly expanding fleet of electric and hybrid vehicles. Additionally, the growing consumer demand for faster charging capabilities and extended battery life in diverse climatic conditions further propels the adoption of PTC battery heaters, as they are crucial for maintaining optimal battery performance. Innovations in battery technology, leading to higher energy density and power output, inadvertently increase the need for precise temperature control, thereby boosting the market for these heating elements. The stringent safety regulations governing lithium-ion battery operation also serve as a strong driver, as PTC heaters provide a reliable and safe method for thermal management, preventing potential thermal runaway events.

However, the market also faces notable restraints. The relatively high initial cost of integrating sophisticated PTC battery heating systems into vehicles can be a deterrent for some manufacturers, particularly in budget-conscious segments. The added complexity of integrating these systems with existing battery management systems (BMS) and vehicle architectures presents technical challenges that require significant engineering effort and can increase development costs. Furthermore, competition from alternative thermal management solutions, such as liquid cooling or thermoelectric modules, although often less efficient for targeted heating, can also pose a restraint, especially where cost-effectiveness is prioritized over precise temperature control. The overall energy consumption of heating elements, even self-regulating PTCs, adds a parasitic load to the battery, which can slightly impact vehicle range, presenting a trade-off that manufacturers must balance.

Despite these challenges, substantial opportunities exist for market growth. The continuous development of advanced materials and manufacturing processes promises to make PTC heaters more efficient, compact, and cost-effective, thereby overcoming current restraints. The emergence of autonomous vehicles and advanced driver-assistance systems (ADAS) creates new avenues for intelligent thermal management, where PTC heaters can be integrated into holistic vehicle energy management strategies. Expansion into new geographical markets, particularly developing nations where EV adoption is still nascent but rapidly growing, offers significant untapped potential. Moreover, the increasing adoption of stationary energy storage systems for grid stabilization and renewable energy integration presents a growing niche for large-scale PTC battery heating solutions. The drive towards sustainable and circular economy practices also encourages the development of more durable and recyclable PTC heater components, creating opportunities for innovation and market differentiation. Ultimately, the impact forces of technological advancement, regulatory changes, and evolving consumer preferences will continue to shape the innovation and adoption landscape of the PTC battery heater market.

Segmentation Analysis

The PTC Battery Heater Market is meticulously segmented to provide a granular understanding of its diverse components, applications, and technological approaches. This segmentation allows for a detailed analysis of market dynamics, growth drivers, and competitive landscapes across various dimensions, including the type of heating element, the specific application areas, the types of vehicles they are integrated into, and their power output. Understanding these distinct segments is crucial for stakeholders to identify key growth areas, tailor product development strategies, and optimize market entry approaches. The market's complexity reflects the varied requirements of battery thermal management across different industries and product categories, from compact passenger EVs to large-scale commercial vehicles and stationary energy storage solutions.

- By Type

- Ceramic PTC Heaters

- Film PTC Heaters

- By Application

- Electric Vehicles (EVs)

- Hybrid Electric Vehicles (HEVs)

- Plug-in Hybrid Electric Vehicles (PHEVs)

- Stationary Energy Storage Systems

- Other Battery Applications

- By Vehicle Type

- Passenger Cars

- Commercial Vehicles (Buses, Trucks)

- By Power Output

- Low Power (<500W)

- Medium Power (500W-1500W)

- High Power (>1500W)

Value Chain Analysis For PTC Battery Heater Market

The value chain for the PTC Battery Heater Market begins with upstream activities involving the sourcing and processing of raw materials. This includes specialized ceramic materials (like barium titanate for ceramic PTCs), polymer films, conductive inks, electrodes, insulation materials, and connection components. Key suppliers in this stage are chemical companies, material science innovators, and specialized component manufacturers. The quality and cost-effectiveness of these foundational materials directly impact the final product's performance, durability, and manufacturing efficiency. Research and development in material science at this stage are crucial for creating more efficient, compact, and reliable PTC elements, often focusing on enhancing thermal conductivity, electrical stability, and overall robustness in extreme conditions. Strong relationships with reliable suppliers are paramount for ensuring consistent quality and managing supply chain risks, especially given the global nature of material sourcing.

Moving downstream, the value chain encompasses the manufacturing and assembly of PTC heating elements, their integration into complete thermal management modules, and ultimately their distribution to end-users. Manufacturers specialize in designing and producing the PTC chips, encapsulating them into robust heater modules, and incorporating necessary wiring, sensors, and control interfaces. This stage often involves advanced automation, precision engineering, and rigorous quality control to meet automotive-grade reliability and safety standards. Integration into larger battery packs or thermal management systems is a critical step, often performed by Tier 1 suppliers or directly by automotive OEMs. The distribution channels for PTC battery heaters are primarily business-to-business (B2B), involving direct sales to automotive manufacturers (OEMs), Tier 1 suppliers specializing in battery packs or thermal systems, and increasingly to manufacturers of stationary energy storage systems.

Both direct and indirect distribution channels play a role. Direct channels involve manufacturers selling their PTC heater products straight to large automotive OEMs or major battery pack assemblers, facilitating custom solutions and close collaboration on design and integration. Indirect channels typically involve distribution networks, specialized automotive parts suppliers, or electronics distributors that cater to smaller manufacturers, aftermarket needs, or more generalized industrial applications. The effectiveness of these channels is crucial for market penetration and customer reach. Given the specialized nature of PTC battery heaters and their critical role in battery performance, customer support, technical assistance, and post-sales service are also vital components of the value chain, ensuring proper integration, troubleshooting, and long-term performance optimization for end-users. This holistic approach ensures that the products not only reach the market but are also effectively utilized and maintained throughout their lifecycle.

PTC Battery Heater Market Potential Customers

The potential customers for PTC Battery Heaters are predominantly manufacturers and assemblers operating within the electric mobility and energy storage sectors. The largest segment of end-users consists of automotive original equipment manufacturers (OEMs) that produce Electric Vehicles (EVs), Hybrid Electric Vehicles (HEVs), and Plug-in Hybrid Electric Vehicles (PHEVs). These companies integrate PTC heaters directly into their battery packs to ensure optimal performance, extended range, faster charging, and enhanced safety in various climatic conditions, particularly cold environments. Their demand is driven by the need to meet stringent performance metrics, comply with regulatory standards, and deliver a superior customer experience in an increasingly competitive market. The focus here is on high-volume, highly integrated, and customized solutions that can withstand the rigors of automotive environments.

Beyond the direct automotive OEMs, Tier 1 automotive suppliers play a crucial role as potential customers. These suppliers specialize in manufacturing complete battery packs, thermal management modules, or entire powertrain systems, which then get supplied to OEMs. They require high-quality, reliable PTC heating components that can be seamlessly incorporated into their larger assemblies. Their purchasing decisions are often influenced by factors such as component reliability, integration ease, cost-effectiveness at scale, and technical support from the heater manufacturer. The rapid expansion of electric truck, bus, and off-highway vehicle segments also broadens the customer base, as commercial vehicle manufacturers seek robust thermal solutions for larger and more complex battery systems.

Furthermore, manufacturers of stationary energy storage systems (ESS) represent a significant and growing customer segment. These systems, used for grid stabilization, renewable energy integration, and industrial backup power, also rely on large battery arrays that require precise thermal management to ensure efficiency, longevity, and safety, especially in outdoor or unconditioned environments. Companies developing and deploying these large-scale battery solutions purchase PTC heaters for similar reasons as the automotive sector – to optimize performance in varying temperatures and prolong the life of expensive battery assets. Additionally, smaller niche markets, such as manufacturers of specialized industrial battery applications, high-performance power tools, or even certain medical devices requiring stable battery temperatures, also constitute potential customers for tailored PTC heating solutions, although in lower volumes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 1500 Million |

| Growth Rate | 18.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BorgWarner, Mahle GmbH, Webasto Group, Eberspächer Group, DBK Group, Valeo, LG Chem, Panasonic Corporation, Hanon Systems, Sensata Technologies, Thermo King (Trane Technologies), CATL, Samsung SDI, BYD Company Ltd., Infineon Technologies AG, NXP Semiconductors, Vitesco Technologies, Rheinmetall AG, Denso Corporation, CALB |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

PTC Battery Heater Market Key Technology Landscape

The PTC Battery Heater market's technological landscape is characterized by continuous innovation aimed at enhancing efficiency, safety, and integration capabilities within advanced battery thermal management systems. At its core, the technology revolves around Positive Temperature Coefficient (PTC) thermistors, typically made from ceramic compounds like barium titanate, or increasingly, from conductive polymer composites. These materials exhibit the self-regulating property where their resistance increases sharply above a certain Curie temperature, limiting current flow and preventing overheating without external control. This inherent safety feature is a significant advantage, reducing the complexity and cost of external control circuitry compared to traditional resistive heaters. Ongoing research focuses on optimizing the composition and sintering processes of ceramic PTC materials to achieve specific temperature characteristics, faster response times, and higher power densities, while also improving their long-term stability and reliability under repeated thermal cycling.

Beyond traditional ceramic PTC elements, the market is witnessing a strong push towards flexible film PTC heaters. These heaters utilize conductive polymer or composite films printed with PTC characteristics, allowing for ultra-thin, lightweight, and conformable designs. This flexibility is particularly advantageous for integration within compact and irregularly shaped battery packs, where space is at a premium. Film heaters can be custom-shaped to fit around individual battery cells or modules, providing more uniform heating and reducing thermal gradients within the pack. Advancements in printing technologies and conductive polymer formulations are driving the performance improvements of these film-based solutions, making them more durable and efficient for high-volume automotive applications. The ease of manufacturing and potential for lower material consumption also position film PTC heaters as a strong contender for future market growth.

Another crucial aspect of the technology landscape involves the integration of PTC heaters with sophisticated battery management systems (BMS) and vehicle control units (VCU). This includes developing smart heating modules equipped with integrated temperature sensors, microcontrollers, and communication interfaces (e.g., CAN bus). These integrated solutions enable precise, real-time control of heating cycles based on battery state-of-charge (SoC), state-of-health (SoH), ambient temperature, and charging conditions. The goal is to maximize energy efficiency by only heating when necessary and to the precise temperature required, thereby minimizing the parasitic load on the battery. Further technological advancements include the exploration of multi-zone heating capabilities, allowing different parts of a battery pack to be heated independently, and the development of diagnostic features that can monitor heater performance and predict potential failures, contributing to overall system reliability and longevity. The convergence of material science, electronics, and software engineering is thus defining the cutting-edge of PTC battery heater technology.

Regional Highlights

- North America: This region is experiencing significant growth driven by substantial investments in electric vehicle manufacturing, particularly in the United States and Canada. Government incentives, such as tax credits for EV purchases and infrastructure development, are accelerating adoption. The presence of major automotive OEMs and a strong focus on advanced battery technologies contribute to a high demand for sophisticated PTC battery heaters, especially given the diverse climatic conditions across the continent, requiring robust cold-weather performance.

- Europe: Europe stands as a frontrunner in EV adoption and stringent emission regulations, fostering a highly dynamic market for PTC battery heaters. Countries like Germany, Norway, France, and the UK are leading the charge with aggressive electrification targets and supportive policies. The region's strong automotive R&D ecosystem and the demand for premium, high-performance electric vehicles necessitate advanced thermal management solutions, making it a key growth hub.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market for PTC battery heaters, primarily due to the dominance of China in EV production and sales. India, Japan, and South Korea are also rapidly expanding their EV manufacturing capabilities and adoption rates. The sheer volume of EV production, coupled with a focus on cost-effective yet reliable solutions, drives innovation and market expansion in this region. Government support, large domestic markets, and strong supply chains make APAC a critical region.

- Latin America: While currently a smaller market, Latin America is showing nascent but increasing potential for EV adoption, particularly in countries like Brazil and Mexico. Urbanization, environmental initiatives, and the gradual development of charging infrastructure are paving the way for future growth in the PTC battery heater market as electrification gains momentum.

- Middle East and Africa (MEA): The MEA region is at an early stage of EV adoption, but with growing awareness of environmental sustainability and government initiatives to diversify economies away from fossil fuels, there is emerging potential. Countries like the UAE and Saudi Arabia are investing in smart city initiatives and sustainable transportation, which could drive future demand for battery thermal management solutions as the EV ecosystem matures.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the PTC Battery Heater Market.- BorgWarner

- Mahle GmbH

- Webasto Group

- Eberspächer Group

- DBK Group

- Valeo

- LG Chem

- Panasonic Corporation

- Hanon Systems

- Sensata Technologies

- Thermo King (Trane Technologies)

- CATL

- Samsung SDI

- BYD Company Ltd.

- Infineon Technologies AG

- NXP Semiconductors

- Vitesco Technologies

- Rheinmetall AG

- Denso Corporation

- CALB

Frequently Asked Questions

What is a PTC Battery Heater and why is it important?

A PTC (Positive Temperature Coefficient) Battery Heater is an electrical resistive heater that self-regulates its temperature due to a characteristic where its resistance increases sharply with temperature. This prevents overheating and ensures optimal operating conditions for batteries, particularly in electric vehicles (EVs) and stationary energy storage. It is crucial for maintaining battery efficiency, prolonging lifespan, enabling faster charging in cold weather, and enhancing safety by preventing thermal stress.

How do PTC Battery Heaters improve EV performance?

PTC Battery Heaters improve EV performance by ensuring the battery operates within its optimal temperature range, especially in cold environments. This leads to significantly enhanced charging efficiency and speed, as cold batteries charge slower and less effectively. They also help maintain battery capacity and range, reduce power degradation, and extend the overall lifespan of the battery pack, providing a more consistent and reliable driving experience.

What are the main types of PTC Battery Heaters?

The main types of PTC Battery Heaters are Ceramic PTC Heaters and Film PTC Heaters. Ceramic PTC heaters typically use barium titanate ceramics and are known for their robust, self-regulating properties. Film PTC heaters, on the other hand, utilize conductive polymer composites in a thin, flexible film format, allowing for more compact integration and uniform heating in complex battery geometries. Both types offer unique advantages depending on the application's specific requirements for power density, flexibility, and space.

What challenges does the PTC Battery Heater market face?

The PTC Battery Heater market faces challenges such as the relatively high initial cost of integrating advanced heating systems, which can impact overall vehicle cost. Technical complexities related to seamless integration with sophisticated battery management systems (BMS) and vehicle architectures also pose a hurdle. Additionally, there is competition from alternative thermal management solutions, and the energy consumption of heating elements, while optimized, still represents a parasitic load on the battery's overall energy budget, requiring careful balance.

How is sustainability impacting the PTC Battery Heater market?

Sustainability is increasingly impacting the PTC Battery Heater market by driving demand for more energy-efficient designs and the use of environmentally friendly materials. Manufacturers are focusing on reducing the parasitic energy consumption of heaters to extend EV range and optimize battery life, thereby contributing to the overall sustainability of electric vehicles. Additionally, there's a growing emphasis on the recyclability and responsible sourcing of materials used in heater components, aligning with broader circular economy principles in the automotive and energy storage industries.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager