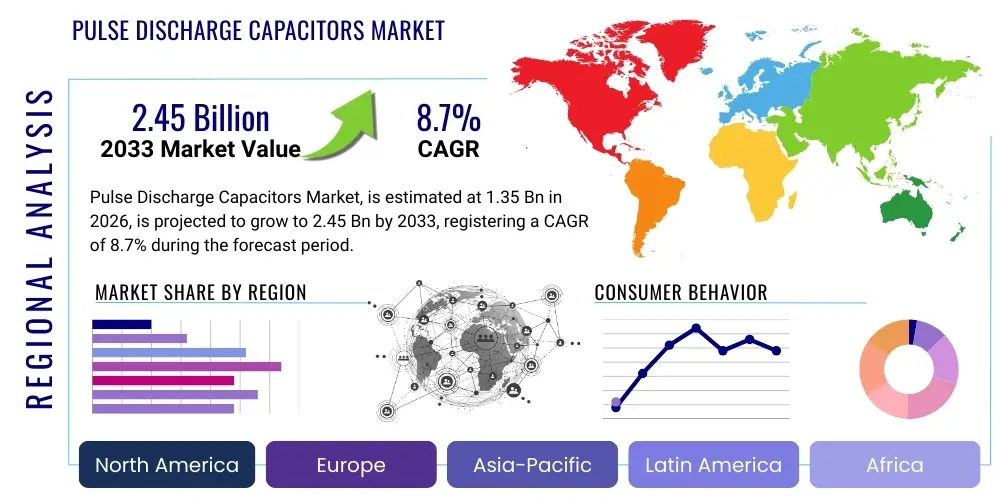

Pulse Discharge Capacitors Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440055 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Pulse Discharge Capacitors Market Size

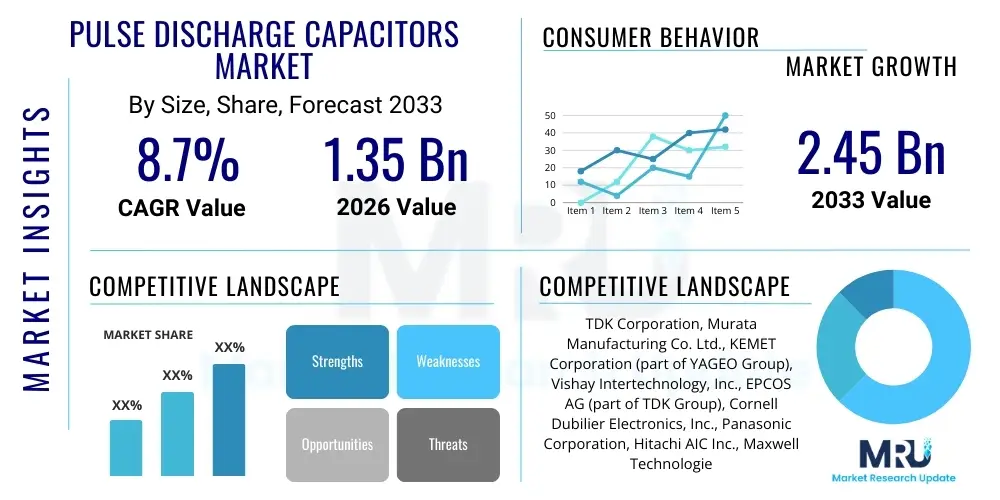

The Pulse Discharge Capacitors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.7% between 2026 and 2033. The market is estimated at USD 1.35 Billion in 2026 and is projected to reach USD 2.45 Billion by the end of the forecast period in 2033. This growth is primarily driven by escalating demand from high-power applications across various industries, including defense, medical, industrial lasers, and renewable energy systems. Technological advancements in dielectric materials, electrode design, and packaging solutions are enabling the development of capacitors with higher energy density, longer lifespans, and improved reliability, addressing critical requirements for rapid energy discharge and storage. The market's expansion is intrinsically linked to the increasing sophistication of modern electronics and energy systems that require precise and powerful energy pulses for operation, from advanced weapon systems and diagnostic imaging equipment to electric vehicle charging infrastructure and industrial manufacturing processes. Furthermore, research and development efforts in fusion energy and high-energy physics are creating niche but significant opportunities for specialized ultra-high-power pulse discharge capacitors, pushing the boundaries of material science and engineering. The market also benefits from the ongoing global transition towards sustainable energy sources, where pulse discharge capacitors play a vital role in power conditioning and energy management in applications such as wind turbine pitch control and solar inverter systems, ensuring stable and efficient energy delivery. This dynamic environment fosters continuous innovation, attracting investments and propelling the market forward with new product developments tailored to specific high-performance demands.

Pulse Discharge Capacitors Market introduction

Pulse discharge capacitors are specialized electronic components designed for storing and rapidly releasing large amounts of electrical energy, providing high-power pulses in very short durations. Unlike conventional capacitors used for filtering or energy smoothing, pulse discharge capacitors are engineered to withstand extreme voltage and current stresses associated with rapid charge and discharge cycles, making them indispensable in applications requiring instantaneous bursts of power. Their unique design involves robust dielectric materials, optimized electrode configurations, and advanced packaging to manage thermal loads and ensure operational stability under demanding conditions. These critical components find widespread use across a diverse array of major applications, including pulsed lasers in industrial material processing, medical aesthetic treatments, and scientific research; radar systems for defense and weather forecasting; high-energy physics experiments such as particle accelerators and fusion research facilities; electromagnetic pulse (EMP) generators; and electric vehicle (EV) charging infrastructure where rapid power delivery is crucial. The primary benefits of pulse discharge capacitors include their ability to deliver extremely high peak power, excellent energy density for their size, rapid charging and discharging capabilities, and superior reliability in high-stress environments. These attributes are essential for enabling advancements in numerous sectors, facilitating precision manufacturing, enhancing diagnostic and therapeutic medical procedures, improving national security capabilities, and supporting the development of next-generation energy technologies. The market is fundamentally driven by the escalating global demand for higher power output, increased efficiency, and compact energy storage solutions in both established and emerging technological domains, pushing manufacturers to continuously innovate in material science and design methodologies to meet increasingly stringent performance requirements.

Pulse Discharge Capacitors Market Executive Summary

The Pulse Discharge Capacitors Market is experiencing robust growth fueled by several key business trends, regional dynamics, and significant segment developments. Globally, the market is characterized by a strong emphasis on research and development into advanced dielectric materials, such as improved ceramic compounds, polymer films, and electrolyte formulations, aimed at enhancing energy density, operational lifespan, and temperature stability. There is a discernible trend towards miniaturization, driven by the increasing integration of high-power systems into compact devices, requiring capacitors with smaller form factors without compromising performance. Furthermore, manufacturers are investing in smart capacitor technologies that incorporate sensors and monitoring capabilities for predictive maintenance and optimized performance, particularly in critical applications like defense and industrial automation. From a regional perspective, North America continues to be a dominant force, largely due to substantial defense spending, advanced medical technology development, and a strong presence of research institutions driving innovation in high-energy physics. Europe maintains a significant market share, propelled by its robust industrial manufacturing base, automotive sector growth (especially in EV charging infrastructure), and stringent regulatory frameworks promoting energy efficiency. The Asia Pacific region is rapidly emerging as a critical growth engine, primarily due to expanding industrialization, increasing investments in renewable energy, and the burgeoning electric vehicle market in countries like China, Japan, and South Korea, coupled with a highly competitive manufacturing landscape. In terms of segment trends, the defense and aerospace sector consistently demands ultra-reliable, high-voltage pulse capacitors for radar, electronic warfare, and directed energy weapons. The medical sector is witnessing increased adoption for diagnostic imaging (MRI, CT scanners) and therapeutic devices (defibrillators, electrosurgery). Industrial applications, particularly in laser systems for cutting, welding, and marking, represent a significant and growing segment. Additionally, the automotive segment is poised for substantial growth, driven by the proliferation of electric and hybrid vehicles requiring efficient power electronics for propulsion and fast-charging systems. These interconnected trends highlight a dynamic and evolving market driven by continuous technological innovation and expanding application areas across various high-value industries worldwide.

AI Impact Analysis on Pulse Discharge Capacitors Market

The integration of Artificial Intelligence (AI) is poised to significantly transform the Pulse Discharge Capacitors market, addressing common user questions about efficiency, reliability, design optimization, and predictive maintenance. Users frequently inquire about how AI can enhance the performance and longevity of these critical components, reduce manufacturing defects, and lower operational costs. There is keen interest in AI's role in developing novel materials for higher energy density and improved thermal management, as well as its potential for real-time monitoring and fault detection in complex power systems. Concerns often revolve around the practical implementation challenges, the computational resources required, and the return on investment for adopting AI-driven solutions. However, the overarching expectation is that AI will usher in a new era of smart capacitors, capable of self-diagnosis, adaptive performance, and unparalleled reliability, thereby extending their application scope into more demanding and autonomous systems. AI's analytical capabilities are expected to revolutionize the entire lifecycle of pulse discharge capacitors, from initial design and manufacturing to in-service operation and end-of-life management. This includes leveraging machine learning algorithms to sift through vast datasets of material properties, performance characteristics, and failure modes, leading to more resilient and efficient capacitor designs. The goal is to move beyond conventional design methodologies, which are often iterative and time-consuming, towards an AI-accelerated approach that can predict optimal material combinations and structural configurations for specific application requirements. Furthermore, AI-powered quality control systems during manufacturing can identify micro-defects invisible to human inspection, ensuring higher product yields and significantly reducing warranty claims. The continuous learning capabilities of AI systems will enable capacitors to adapt to varying operational conditions, predict potential failures before they occur, and even self-correct or suggest optimal maintenance schedules, minimizing downtime and maximizing system availability. Ultimately, AI is anticipated to elevate the performance benchmarks and reliability standards of pulse discharge capacitors, making them more competitive and indispensable in future high-power electronics. The market seeks to understand how AI will make these components smarter, more durable, and more integrated into intelligent power management systems, anticipating benefits such as extended operational lifespan, reduced total cost of ownership, and enhanced safety in high-stress applications.

- AI-driven material discovery and optimization for enhanced dielectric properties, leading to higher energy density and improved thermal performance.

- Predictive maintenance analytics using sensor data from capacitors to forecast potential failures, optimizing operational lifespan and reducing downtime.

- AI-enhanced design and simulation tools for rapid prototyping and performance validation, accelerating product development cycles.

- Intelligent manufacturing processes for quality control, defect detection, and yield optimization through machine vision and anomaly detection algorithms.

- Smart energy management systems leveraging AI to optimize capacitor charging and discharging cycles for maximum efficiency and longevity in demanding applications.

- Autonomous fault detection and isolation in power systems, with AI identifying issues related to capacitor degradation and recommending corrective actions.

- Personalized capacitor solutions: AI algorithms analyzing specific application requirements to suggest customized capacitor designs and material choices for optimal performance.

- Development of self-healing or adaptive capacitors, where AI manages internal reconfigurations to mitigate damage and extend operational life.

- Improved thermal management strategies using AI to model and predict heat dissipation, enabling more compact and powerful capacitor designs.

- Enhanced supply chain efficiency and risk management for capacitor components, with AI forecasting demand and potential disruptions.

- AI-powered simulation of extreme operating conditions to test capacitor resilience and identify weak points without physical destruction.

- Optimized power conditioning and power factor correction in grid-level applications, leveraging AI to manage capacitor banks for stability and efficiency.

DRO & Impact Forces Of Pulse Discharge Capacitors Market

The Pulse Discharge Capacitors Market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and their collective impact forces, shaping its trajectory and competitive landscape. A primary driver is the accelerating demand from the defense and aerospace sectors for advanced radar systems, electronic warfare, directed energy weapons, and pulsed power applications requiring extremely reliable and high-energy-density capacitors capable of rapid discharge. Similarly, the medical industry's continuous innovation in diagnostic imaging equipment, therapeutic devices like defibrillators, and advanced surgical tools necessitates high-performance pulse capacitors. The rapid growth of industrial laser systems for precision cutting, welding, marking, and surface treatment also fuels demand, as these systems rely heavily on precise, high-power energy pulses. Furthermore, the global transition towards renewable energy and the burgeoning electric vehicle (EV) market contribute significantly, with pulse capacitors being critical components in power conditioning for solar inverters, wind turbine pitch control, and fast-charging infrastructure for EVs. Technological advancements in dielectric materials, electrode design, and packaging techniques are continually improving capacitor performance, energy density, and reliability, further driving adoption across various sectors. However, the market faces several significant restraints. The inherently high cost of specialized materials and complex manufacturing processes for high-performance pulse capacitors poses a barrier to entry and can limit adoption in price-sensitive applications. The physical size and weight of these components, particularly for ultra-high-power applications, can be substantial, presenting challenges for integration into compact systems. Material limitations, particularly concerning dielectric breakdown strength, thermal management, and long-term stability under extreme conditions, constrain performance improvements. Additionally, the relatively limited operational lifespan of some capacitor types under intense cycling and stringent regulatory standards for safety and environmental compliance can impede market expansion. Despite these challenges, numerous opportunities are emerging. Miniaturization, driven by advancements in multilayer ceramic capacitor (MLCC) technology and advanced film capacitors, promises to unlock new applications in compact portable devices and integrated systems. The development of novel dielectric materials with superior energy storage capabilities, higher temperature resistance, and self-healing properties presents significant growth potential. The integration of smart features, such as embedded sensors and predictive analytics, can enhance reliability and enable adaptive performance. Moreover, the expanding investment in high-energy physics research, fusion energy projects, and advanced industrial processes creates niche but high-value opportunities for cutting-edge pulse capacitor solutions. The combined impact of these forces results in a market characterized by intense innovation, strategic partnerships between material suppliers and capacitor manufacturers, and a constant drive to balance performance requirements with cost-effectiveness and reliability. Geopolitical factors, such as defense spending priorities and energy policies, also exert considerable influence on regional market dynamics and investment flows, particularly in areas like high-power military applications and large-scale renewable energy projects. This dynamic interplay ensures that the pulse discharge capacitors market remains a critical and evolving segment within the broader power electronics industry, continually adapting to the demands of an increasingly electrified and high-tech world.

Segmentation Analysis

The Pulse Discharge Capacitors Market is broadly segmented based on several key characteristics, including dielectric material, application, voltage range, and capacitance range, allowing for a granular understanding of market dynamics and catering to diverse industrial requirements. This segmentation helps in identifying specific growth drivers and challenges within each category, enabling manufacturers to tailor product development and market strategies. Understanding the varying demands from different end-use sectors, and the technical specifications required for each, is crucial for assessing market size and potential. The choice of dielectric material, for instance, directly impacts the capacitor's energy density, operating temperature, and lifespan, making it a fundamental differentiator. Similarly, the target application significantly influences the required voltage, capacitance, and form factor, from compact medical devices to large-scale industrial or defense systems. By dissecting the market along these lines, stakeholders can gain comprehensive insights into competitive landscapes, emerging technological trends, and strategic investment opportunities across the value chain, leading to more informed business decisions. This detailed segmentation analysis underpins the strategic planning for innovation, production, and distribution, ensuring that products are precisely matched to the technical and economic requirements of their intended uses.

- By Dielectric Material

- Film Capacitors (Polypropylene, Polyester, PTFE, PEN)

- Ceramic Capacitors (Class I, Class II, Multilayer Ceramic Capacitors - MLCCs)

- Electrolytic Capacitors (Aluminum Electrolytic, Tantalum Electrolytic, Niobium Oxide)

- Mica Capacitors

- Glass Capacitors

- Oil-filled Capacitors

- By Application

- Defense and Aerospace (Radar, Electronic Warfare, Directed Energy Weapons, Pulsed Power Systems)

- Medical (Defibrillators, MRI, CT Scanners, Electrosurgery, Lasers)

- Industrial (Laser Systems, Welding, Induction Heating, Particle Accelerators, Power Supplies, Plasma Generation)

- Automotive (Electric Vehicles (EVs), Hybrid Electric Vehicles (HEVs), Charging Infrastructure)

- Research and Development (High Energy Physics, Fusion Energy, Scientific Lasers)

- Renewable Energy (Wind Power, Solar Inverters, Grid Stabilization)

- By Voltage Range

- Low Voltage (Less than 1 kV)

- Medium Voltage (1 kV to 10 kV)

- High Voltage (Above 10 kV)

- By Capacitance Range

- Low Capacitance (picoFarad to nanoFarad)

- Medium Capacitance (microFarad)

- High Capacitance (milliFarad to Farad)

- By Packaging Type

- Surface Mount Devices (SMD)

- Through-Hole Devices (THD)

- Custom/Module

- By End-User Industry

- Electronics Manufacturing

- Automotive and Transportation

- Healthcare

- Energy and Power

- Industrial Manufacturing

- Telecommunications

- Aerospace and Defense

Value Chain Analysis For Pulse Discharge Capacitors Market

The value chain for the Pulse Discharge Capacitors Market is a sophisticated ecosystem encompassing multiple stages, from raw material sourcing to end-user consumption, involving a complex network of upstream suppliers, manufacturers, and downstream distribution channels. The upstream segment primarily involves the procurement of highly specialized raw materials critical for capacitor performance, including advanced dielectric films (e.g., polypropylene, polyester, PTFE), ceramic powders (e.g., barium titanate), aluminum foils, tantalum powders, and various electrode materials like copper and aluminum. These raw material suppliers are often niche players with significant expertise in material science, providing high-purity, high-performance compounds essential for manufacturing robust pulse capacitors capable of enduring extreme electrical and thermal stresses. The quality and availability of these specialized materials directly impact the final product's performance, cost, and reliability, making supplier relationships a crucial strategic consideration for capacitor manufacturers. Following this, the manufacturing stage involves intricate processes of component fabrication, where these raw materials are transformed into capacitor elements through precise winding, stacking, metallization, and assembly techniques. This stage includes specialized engineering for electrode design, impregnation processes for liquid-filled capacitors, and sophisticated packaging to ensure mechanical integrity and thermal management. The manufacturing segment requires substantial capital investment in advanced machinery, cleanroom facilities, and highly skilled labor, reflecting the technical complexity of producing high-performance pulse discharge capacitors. Once manufactured, these capacitors move through various distribution channels to reach end-users. Direct distribution channels are prevalent for large volume orders or highly customized products, where capacitor manufacturers engage directly with major original equipment manufacturers (OEMs) in defense, aerospace, medical, and large industrial sectors. This allows for close collaboration on technical specifications, co-development, and dedicated support. In contrast, indirect distribution channels involve a network of distributors, wholesalers, and specialized electronics component retailers that cater to a broader range of smaller OEMs, research institutions, and repair/maintenance markets. These indirect channels provide market reach, inventory management, and technical support, playing a vital role in ensuring product availability and accessibility across diverse geographical regions and application scales. Both direct and indirect channels are critical for market penetration, with the choice often depending on customer size, product complexity, and geographic dispersion. The efficiency and effectiveness of these distribution networks are paramount in ensuring timely delivery, technical assistance, and customer satisfaction, ultimately influencing market share and competitive positioning within the highly specialized pulse discharge capacitors industry.

Pulse Discharge Capacitors Market Potential Customers

The potential customers for Pulse Discharge Capacitors are predominantly businesses and institutions operating in high-tech, mission-critical sectors that require precise, high-power energy delivery for their core operations. These end-users are characterized by their demand for extremely reliable, durable, and high-performance components capable of operating under stringent conditions. A significant segment comprises companies within the Aerospace & Defense industry, including manufacturers of radar systems, electronic warfare equipment, missile guidance systems, and directed energy weapons, where robust and dependable pulsed power is non-negotiable for national security applications. Medical device manufacturers represent another crucial customer base, requiring these capacitors for life-saving and diagnostic equipment such as defibrillators, MRI and CT scanners, therapeutic laser systems, and electrosurgical units, where precision and safety are paramount. Industrial laser OEMs and integrators form a growing segment, utilizing pulse capacitors in systems for precision cutting, welding, marking, and surface treatment in manufacturing processes across various industries like automotive, electronics, and heavy machinery. Research institutions and universities, particularly those involved in high-energy physics, fusion energy research, and advanced materials science, also constitute key buyers for highly specialized, ultra-high-voltage and capacitance pulse capacitors for particle accelerators, plasma confinement experiments, and experimental setups. The burgeoning Electric Vehicle (EV) and Hybrid Electric Vehicle (HEV) sectors, along with the associated charging infrastructure providers, are increasingly becoming significant customers as they integrate pulse capacitors into power electronics for efficient energy conversion, motor drives, and fast-charging systems. Moreover, companies involved in renewable energy generation, such as wind turbine manufacturers and solar inverter developers, use these capacitors for power conditioning and grid stabilization applications, ensuring the reliable integration of intermittent energy sources. Semiconductor manufacturers employ pulse capacitors in equipment for etching, deposition, and ion implantation processes, where precise energy bursts are essential for advanced chip fabrication. The common thread among these diverse end-users is their need for specialized capacitors that can withstand rapid charge/discharge cycles, deliver high peak currents, maintain stability over a wide range of temperatures, and offer long-term reliability. Their purchasing decisions are driven by stringent technical specifications, long product lifecycles, and a strong emphasis on supplier reliability and quality assurance, often involving extensive qualification processes and collaborative design efforts to integrate these critical components effectively into their advanced systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.35 Billion |

| Market Forecast in 2033 | USD 2.45 Billion |

| Growth Rate | 8.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | TDK Corporation, Murata Manufacturing Co. Ltd., KEMET Corporation (part of YAGEO Group), Vishay Intertechnology, Inc., EPCOS AG (part of TDK Group), Cornell Dubilier Electronics, Inc., Panasonic Corporation, Hitachi AIC Inc., Maxwell Technologies (part of Tesla, Inc.), Advanced Energy Industries, Inc., General Atomics, Siemens AG, Eaton Corporation plc, ABB Ltd., AVX Corporation (part of Kyocera Group), Nichicon Corporation, Sumida Corporation, Custom Electronics, Inc., Celem S.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pulse Discharge Capacitors Market Key Technology Landscape

The technological landscape of the Pulse Discharge Capacitors Market is characterized by relentless innovation focused on enhancing energy density, improving power delivery capabilities, extending operational lifespan, and reducing overall form factors. A critical area of development involves advanced dielectric materials, which are the heart of any capacitor. Manufacturers are heavily investing in research and development of novel ceramic compositions, such as improved barium titanate formulations and lead-free alternatives, to achieve higher dielectric constants and breakdown strengths, enabling more compact and higher-voltage ceramic multilayer capacitors (MLCCs). Similarly, advancements in polymer film technology, including specialized polypropylene, polyester, and polytetrafluoroethylene (PTFE) films, are leading to film capacitors with superior self-healing properties, lower equivalent series resistance (ESR), and higher temperature ratings, making them ideal for high-frequency and high-current applications. Electrode design also plays a pivotal role, with innovations in metallization techniques and foil etching processes to maximize surface area and minimize inductance, thereby improving current handling capabilities and discharge efficiency. The shift towards stacked film technology and advanced winding techniques for film capacitors, as well as precise layering in MLCCs, allows for better thermal management and increased volumetric efficiency. Furthermore, packaging and encapsulation technologies are crucial for ensuring mechanical robustness, thermal dissipation, and environmental protection, especially in harsh operating environments like defense or industrial settings. This includes the use of robust epoxy resins, hermetic sealing, and specialized casings that can withstand extreme vibrations, shocks, and temperature fluctuations. Liquid-filled capacitors are also seeing advancements, particularly in the development of more environmentally friendly and stable dielectric fluids that offer improved insulation and cooling properties. Beyond material science, the integration of smart technologies is gaining traction. This involves embedding sensors within capacitors or power modules to monitor parameters such as temperature, voltage, and current in real-time. These sensors, combined with advanced algorithms and diagnostic software, can provide predictive maintenance capabilities, detect early signs of degradation, and optimize capacitor performance throughout its lifespan. This move towards "smart capacitors" enhances reliability, reduces downtime, and extends the operational life of complex systems. Thermal management solutions, including advanced cooling techniques like forced air, liquid cooling, and phase-change materials, are also vital to dissipate the significant heat generated during rapid charge and discharge cycles, which is critical for maintaining performance and preventing premature failure. The drive towards miniaturization continues to push the boundaries of materials science and manufacturing precision, enabling high-power components to be integrated into ever-smaller electronic systems, from portable medical devices to advanced avionics. These technological strides collectively aim to overcome the inherent trade-offs between energy density, power density, size, cost, and reliability, propelling the market towards more efficient, robust, and intelligent pulse discharge capacitor solutions for future high-power applications.

Regional Highlights

- North America: This region stands as a significant market for pulse discharge capacitors, primarily driven by robust investments in defense and aerospace sectors, particularly for radar systems, electronic warfare, and advanced weapon technologies requiring high-reliability, high-voltage pulse power. The strong presence of leading research and development institutions, coupled with substantial government funding for high-energy physics and fusion energy research, further fuels demand for cutting-edge capacitor solutions. Additionally, a flourishing medical device industry, focusing on advanced diagnostic and therapeutic equipment, contributes to the market's growth. The region's technological leadership and early adoption of advanced power electronics solutions ensure a continuous demand for innovative pulse discharge capacitors.

- Europe: Europe represents a mature yet dynamically growing market, largely due to its strong industrial base, particularly in automotive manufacturing, industrial lasers, and renewable energy. Germany, France, and the UK are key contributors, with significant R&D activities in power electronics and sustainable energy. The increasing adoption of electric vehicles and the widespread development of charging infrastructure across the continent are driving demand for high-performance capacitors. Furthermore, a well-established medical technology sector and substantial defense spending in certain countries contribute to the market's stability and growth. European manufacturers are also at the forefront of developing advanced dielectric materials and packaging technologies, maintaining a competitive edge.

- Asia Pacific (APAC): The APAC region is poised for the most rapid growth in the pulse discharge capacitors market, fueled by rapid industrialization, burgeoning electronics manufacturing, and massive investments in renewable energy and electric vehicles. Countries like China, Japan, South Korea, and India are leading this expansion. China's enormous manufacturing capacity and its aggressive push in EV production and renewable energy projects make it a dominant force. Japan and South Korea continue to be hubs for advanced electronics, automotive, and industrial technology, driving demand for high-quality components. The region's expanding defense budgets and increasing focus on technological self-sufficiency also contribute significantly to the market.

- Latin America: This region presents emerging opportunities, with growth primarily influenced by industrialization, infrastructure development, and increasing foreign investment. The expansion of mining, oil and gas, and manufacturing sectors, along with nascent developments in renewable energy, gradually increases the demand for pulse discharge capacitors. Brazil and Mexico are key markets within this region, characterized by a growing automotive industry and an increasing focus on modernizing industrial equipment. While smaller than other regions, it offers potential for long-term growth as economic development continues to foster technological adoption.

- Middle East and Africa (MEA): The MEA market for pulse discharge capacitors is characterized by increasing investments in industrial diversification, defense modernization, and renewable energy projects, particularly in the Gulf Cooperation Council (GCC) countries. Growing defense expenditures in response to regional security concerns drive demand for advanced military electronics. Furthermore, large-scale solar power projects and the development of new industrial zones contribute to the market's nascent but promising growth. While currently a smaller market share, the region's strategic importance and ongoing development initiatives suggest future growth potential for specialized power electronics components.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pulse Discharge Capacitors Market.- TDK Corporation

- Murata Manufacturing Co. Ltd.

- KEMET Corporation (part of YAGEO Group)

- Vishay Intertechnology, Inc.

- EPCOS AG (part of TDK Group)

- Cornell Dubilier Electronics, Inc.

- Panasonic Corporation

- Hitachi AIC Inc.

- Maxwell Technologies (part of Tesla, Inc.)

- Advanced Energy Industries, Inc.

- General Atomics

- Siemens AG

- Eaton Corporation plc

- ABB Ltd.

- AVX Corporation (part of Kyocera Group)

- Nichicon Corporation

- Sumida Corporation

- Custom Electronics, Inc.

- Celem S.A.

- SBE Inc.

Frequently Asked Questions

What are pulse discharge capacitors primarily used for?

Pulse discharge capacitors are specialized components designed to store electrical energy and rapidly release it in powerful, short bursts. Their primary applications include defense and aerospace systems (radar, electronic warfare), medical devices (defibrillators, lasers), industrial lasers (cutting, welding), high-energy physics research, and electric vehicle charging infrastructure, where instantaneous high-power delivery is critical.

How do pulse discharge capacitors differ from standard capacitors?

Unlike standard capacitors used for filtering or energy smoothing, pulse discharge capacitors are engineered for extremely rapid charge and discharge cycles under high voltage and current stresses. They feature robust dielectric materials, optimized electrode designs, and advanced packaging to withstand these demanding conditions, focusing on peak power delivery rather than continuous power flow.

What technological advancements are driving the Pulse Discharge Capacitors Market?

Key technological advancements include the development of novel dielectric materials (e.g., advanced ceramics, polymer films) for higher energy density and temperature stability, optimized electrode designs for lower ESR and ESL, improved thermal management solutions, and miniaturization techniques (like MLCCs). The integration of smart features for predictive maintenance and real-time monitoring is also a significant driver.

Which industries are the major consumers of pulse discharge capacitors?

The major consumer industries include Aerospace & Defense, Healthcare (Medical Devices), Industrial Manufacturing (especially laser systems and welding), Automotive (Electric Vehicles and charging infrastructure), and Research & Development (High-Energy Physics, Fusion Energy). These sectors rely on precise and powerful energy pulses for their critical operations.

What are the main challenges faced by the Pulse Discharge Capacitors Market?

The market faces challenges such as the high manufacturing cost of specialized, high-performance materials, inherent material limitations regarding breakdown strength and thermal stability, the relatively large size and weight for ultra-high-power applications, limited operational lifespan under intense cycling, and stringent regulatory requirements that add to development and production complexities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager