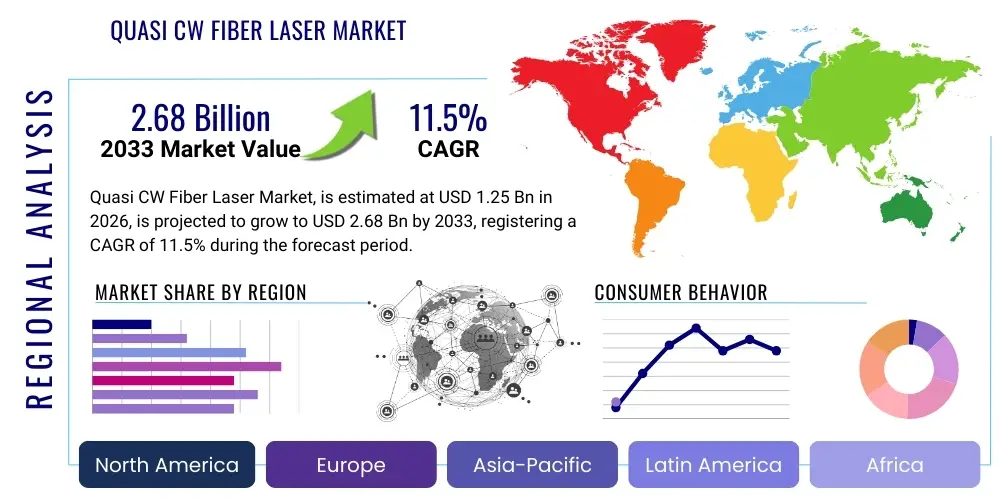

Quasi CW Fiber Laser Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437390 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Quasi CW Fiber Laser Market Size

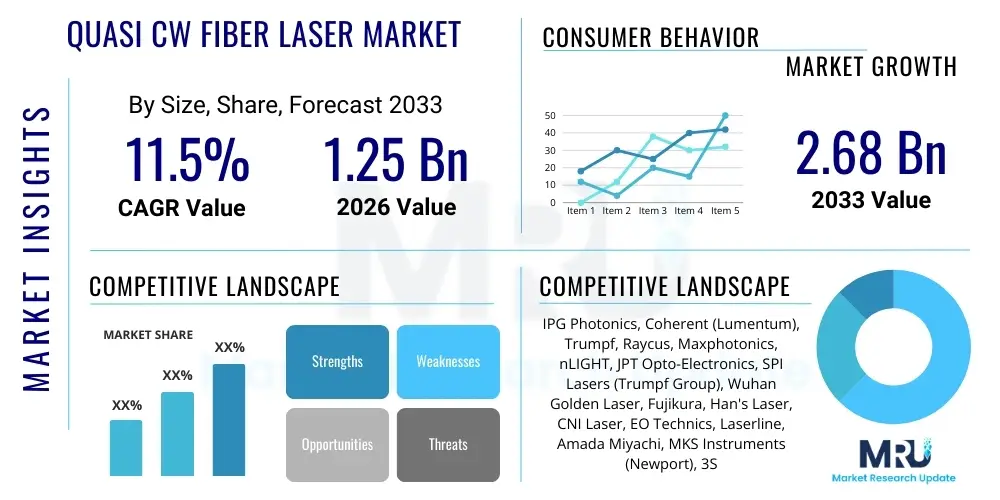

The Quasi CW Fiber Laser Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.5% between 2026 and 2033. The market is estimated at $1.25 Billion in 2026 and is projected to reach $2.68 Billion by the end of the forecast period in 2033.

Quasi CW Fiber Laser Market introduction

The Quasi Continuous Wave (QCW) Fiber Laser Market encompasses advanced solid-state laser systems that operate by delivering high peak power pulses at relatively low duty cycles, bridging the performance gap between true continuous wave (CW) lasers and high-energy pulsed lasers. These systems leverage the efficiency and beam quality inherent to fiber laser technology, making them exceptionally suitable for complex industrial applications where precise energy delivery and minimized heat affected zones (HAZ) are paramount. QCW fiber lasers are fundamentally recognized for their flexibility in pulse shaping and their superior electrical-to-optical conversion efficiency, significantly reducing operational costs compared to traditional flashlamp-pumped solid-state lasers (DPSS). This technological shift is driving extensive adoption across high-precision manufacturing sectors globally.

The primary application landscape for QCW fiber lasers is dominated by demanding material processing tasks, particularly highly reflective metals such as copper, gold, and aluminum, which are challenging for standard CW lasers. Their ability to deliver high peak power bursts momentarily overcomes reflectivity barriers and ensures deep penetration with minimal thermal stress on surrounding materials. Key applications include precision spot welding in electronics, battery manufacturing, fine cutting, and specialized surface treatment processes in the medical device sector. The inherent robustness, maintenance-free operation, and compact form factor further accelerate their integration into automated industrial production lines, providing a highly reliable alternative to older laser technologies.

Key market drivers fueling this growth include the rapid expansion of the electric vehicle (EV) battery manufacturing industry, which heavily relies on precision welding for cell connectivity and module assembly, and the escalating demand for miniaturized electronic components requiring ultrafine material processing. The benefits derived from QCW lasers—such as improved throughput, higher quality welds, and reduced energy consumption—position them as essential tools for modern high-tech manufacturing. Furthermore, ongoing research and development focusing on increasing power output and refining pulse modulation capabilities are continuously enhancing the versatility and market penetration of Quasi CW fiber laser systems across various global industrial hubs.

Quasi CW Fiber Laser Market Executive Summary

The Quasi CW Fiber Laser market is experiencing robust expansion, fundamentally driven by pervasive technological shifts within key manufacturing sectors, particularly e-mobility and advanced electronics. Business trends indicate a strong move toward higher power density and modular systems, enabling seamless integration into complex robotic automation environments. Leading manufacturers are focusing on vertical integration and enhanced software controls to offer sophisticated pulse management capabilities, addressing the critical need for process stability and repeatability in high-volume production. Furthermore, strategic partnerships between laser manufacturers and system integrators are becoming prevalent, optimizing turnkey solutions for end-users and accelerating the displacement of traditional lamp-pumped lasers globally. This competitive environment necessitates continuous innovation in core components, such as pump diodes and gain fibers, to maintain efficiency and reliability standards.

Regionally, the Asia Pacific (APAC) stands as the undisputed epicenter of market growth, primarily fueled by massive government and private investment in electric vehicle infrastructure and consumer electronics manufacturing across China, South Korea, and Japan. North America and Europe demonstrate mature market adoption, characterized by high demand for specialized applications in aerospace, medical device manufacturing, and high-security defense programs, often prioritizing ultra-high beam quality and specific wavelength optimization. Developing regions, while smaller in absolute terms, show emerging potential, especially as localized manufacturing shifts toward advanced processing techniques. The regional dynamics are heavily influenced by local regulatory standards related to battery manufacturing safety and precision engineering requirements.

Segment trends reveal that the Material Processing segment, particularly welding, remains the largest revenue contributor due to its essential role in EV battery pack assembly and intricate electronics soldering. Within the product type segmentation, high-power Quasi CW fiber lasers (above 500W peak power) are exhibiting the highest growth rate, reflecting the industry's need for faster processing speeds and deeper penetration capabilities in thicker materials. Another notable trend is the increasing demand for customized or tailored pulse shapes, moving beyond simple square waves to complex waveforms that optimize energy delivery for specific metallurgical requirements, further solidifying the market's trajectory towards specialization and precision engineering.

AI Impact Analysis on Quasi CW Fiber Laser Market

Common user inquiries regarding AI's impact on the Quasi CW Fiber Laser market center on leveraging machine learning for process optimization, defect detection, and predictive maintenance. Users frequently ask how AI algorithms can fine-tune pulse parameters (such as peak power, duty cycle, and frequency) in real-time to compensate for material variations or environmental changes, aiming for "zero-defect" manufacturing. There is significant interest in using computer vision and deep learning models to instantly analyze weld quality during high-speed production, moving beyond traditional statistical process control. Furthermore, inquiries highlight the expectation that AI will streamline complex laser parameter setup, currently a time-consuming task requiring high operator expertise, thereby democratizing the use of sophisticated QCW systems in smaller facilities. These themes underscore a collective expectation that AI will transform QCW fiber lasers from high-tech tools into intelligent, adaptive manufacturing assets.

- AI-driven real-time parameter adjustment maximizes yield and ensures consistent weld quality across diverse materials.

- Predictive maintenance algorithms analyze laser system telemetry (diode degradation, thermal stress) to minimize unplanned downtime.

- Machine Vision systems powered by AI enable instantaneous, non-destructive inspection of welding and cutting outputs, detecting microscopic defects.

- Optimization of complex pulse shaping sequences for novel materials and specialized joining processes using reinforcement learning.

- Autonomous system calibration and setup reduce reliance on highly specialized technicians, improving operational efficiency.

DRO & Impact Forces Of Quasi CW Fiber Laser Market

The Quasi CW Fiber Laser Market's trajectory is primarily shaped by a confluence of strong market drivers, specific technological restraints, considerable strategic opportunities, and powerful impact forces determining the long-term viability of this technology. The central driving force remains the global shift towards high-volume, high-precision manufacturing, particularly in sectors where heat input must be meticulously controlled, such as in the assembly of sensitive electronic components and lithium-ion batteries. However, market penetration is often restrained by the high initial capital expenditure associated with purchasing and integrating these advanced laser systems compared to conventional methods, coupled with the need for highly skilled technicians to manage and program complex pulse characteristics. Significant opportunities lie in developing next-generation QCW lasers that offer even greater power scalability and integrated intelligent process monitoring, which can appeal to a broader base of industrial users seeking enhanced automation solutions. The primary impact forces include rapid technological obsolescence and intense global competition, particularly from low-cost manufacturers in Asia, which necessitates constant innovation from established market leaders to maintain technological superiority and market share.

Drivers: The explosive growth in electric vehicle (EV) production, specifically the critical need for high-quality, repeatable battery welding processes (tab welding, busbar welding), stands as the paramount driver. The superior beam quality and high peak power capabilities of QCW lasers are perfectly suited for these demanding applications, ensuring minimal resistance and maximizing battery life and safety. Furthermore, the increasing complexity and miniaturization of consumer electronics components demand micro-welding and micro-cutting with extreme precision, a niche where QCW lasers inherently outperform alternative laser types. The long lifespan and relatively low maintenance requirements compared to older solid-state lasers also contribute significantly to reducing the Total Cost of Ownership (TCO), making them an increasingly attractive long-term investment for mass production facilities.

Restraints: Despite their advantages, the initial investment cost for high-power QCW fiber laser systems poses a significant barrier to entry, especially for Small and Medium-sized Enterprises (SMEs). Another critical restraint is the technical complexity involved in optimizing pulse parameters (duty cycle, peak power, rise time) for new materials or processes. Improper parameter settings can lead to defects such as porosity or cracking. Moreover, the sensitivity of optical components to contamination and high heat, although mitigated through robust design, still requires specialized environmental control in some high-precision applications. Furthermore, the limited availability of highly standardized, open-source process libraries for specialized QCW applications slows down adoption among new users who prefer established, validated manufacturing protocols.

Opportunities: Major opportunities exist in expanding QCW laser use into non-traditional sectors, such as additive manufacturing (metal 3D printing) where fine control over energy deposition is crucial for material microstructure. The development of dual-wavelength QCW systems could dramatically improve processing efficiency for materials with challenging absorption characteristics. Geographically, there is substantial opportunity in emerging industrial hubs in Southeast Asia and Latin America, driven by foreign direct investment in electronics and automotive supply chains. Strategic opportunities also involve developing user-friendly interfaces and automated process setup tools, potentially powered by AI, to simplify operation and broaden the market appeal beyond highly specialized R&D departments into standard factory floors. Customization of fiber delivery systems for complex robot paths also represents a significant growth area.

Impact Forces: The most immediate impact force is the intensified competitive landscape, characterized by fierce price wars, especially for standard power range systems. This pressure mandates continuous cost reduction in manufacturing components. Technological impact forces include the constant evolution of ultra-fast pulsed lasers (picosecond and femtosecond), which, while currently more expensive, pose a long-term substitutional threat in micro-processing tasks where HAZ must be zero. Supply chain stability, particularly for high-power pump diodes, remains a critical operational impact force. Furthermore, global intellectual property (IP) disputes regarding core fiber laser architecture can affect market expansion strategies and R&D investment decisions for key players. Economic instability in major manufacturing regions can impact capital expenditure cycles, thereby slowing down system upgrades and new deployments.

Segmentation Analysis

The Quasi CW Fiber Laser Market is comprehensively segmented based on power output, major application areas, and end-user industries, reflecting the diverse requirements of modern industrial processes. Segmentation by power distinguishes between Low Power (typically below 100W peak), Medium Power (100W to 500W), and High Power (above 500W peak), with power levels directly correlating to material thickness and processing speed requirements. The Application segmentation clearly defines the primary uses, such as welding, cutting, drilling, and cleaning, with welding dominating revenue share due to its foundational role in battery and microelectronics manufacturing. This detailed segmentation allows manufacturers to tailor product specifications—including pulse duration, repetition rate, and beam profile—to specific market needs, optimizing resource allocation and strategic product development across various verticals.

The growth dynamics across these segments are not uniform; for instance, the High Power segment is currently demonstrating the highest growth velocity, driven by large-scale EV production lines demanding faster, deeper welds. Conversely, the Low Power segment maintains stable demand in highly specialized, delicate processes within the medical device and precision sensor manufacturing sectors where micron-level accuracy is essential. Understanding these differential growth rates is crucial for market participants planning capital investments. Furthermore, the end-user segmentation, encompassing Automotive, Electronics, Medical, Aerospace, and Jewelry, highlights the pervasive nature of QCW technology, underscoring its versatility as a cross-industry enabling technology. The continued drive towards automation and precision across all industrial verticals ensures sustained demand across all defined segments.

- By Power (Peak Power Output):

- Low Power (Up to 100W)

- Medium Power (100W to 500W)

- High Power (Above 500W)

- By Application:

- Precision Welding (Dominant segment due to EV batteries)

- Cutting and Drilling (Specialized fine feature processing)

- Marking and Engraving (Deep engraving and surface modification)

- Cladding and Brazing

- Surface Treatment and Cleaning

- By End-User Industry:

- Automotive (Battery and component manufacturing)

- Electronics and Semiconductors (Micro-joining, PCB processing)

- Medical Devices (Implants, instruments, micro-machining)

- Aerospace and Defense (Specialized alloy processing)

- Jewelry and Watchmaking (Precision joining and refurbishment)

- Industrial Machinery

- Research & Development

- By Wavelength:

- 1064 nm (Standard Ytterbium fiber laser wavelength)

- Other Wavelengths (Green, Blue for specific material absorption)

Value Chain Analysis For Quasi CW Fiber Laser Market

The value chain for the Quasi CW Fiber Laser market is highly integrated and complex, starting with the core component suppliers and extending through system integrators to the final end-user. Upstream activities involve the procurement and manufacturing of critical raw materials, primarily specialized optical fibers (double-clad fibers), high-power pump diodes (often 9xx nm), and high-reliability optical components (combiners, isolators, beam delivery optics). The quality and reliability of pump diodes, often sourced from highly specialized semiconductor companies, are critical determinants of the final laser system's performance and lifetime. Manufacturing specialization is high, leading to significant reliance on a select few global component suppliers, posing a potential vulnerability to supply chain shocks. Laser system manufacturers then undertake the complex task of fiber drawing, splicing, and electronic integration, where proprietary know-how in thermal management and pulse shaping control provides competitive differentiation.

Midstream activities are characterized by the assembly, integration, and calibration of the complete laser engine and its control unit. Direct sales channels, typically involving the primary laser manufacturer selling directly to large Original Equipment Manufacturers (OEMs) in the automotive or electronics sectors, ensure close technical collaboration and customized solution development. These large transactions often require extensive pre-sales consultation and post-sales technical support. Conversely, indirect distribution channels involve system integrators and specialized distributors who incorporate the QCW laser engine into larger processing machinery, such as robotic welding cells or gantry systems. This channel is crucial for reaching smaller end-users and geographically dispersed markets, providing localized support and application expertise that the core manufacturer might lack.

Downstream analysis focuses on the end-user adoption and aftermarket services. The market dynamics at this stage are driven by the need for application support, spare parts (especially pump diodes and protective covers), and preventative maintenance contracts. The longevity and continuous high performance of QCW lasers necessitate specialized maintenance capabilities, often leading to lucrative long-term service contracts for manufacturers. The effectiveness of the distribution channel directly impacts market penetration, especially in regions like APAC where rapid industrialization demands quick, reliable deployment of automated systems. The overall efficiency of the value chain is increasingly being judged by the system's uptime and the ability to rapidly integrate customized pulse profiles necessary for specialized manufacturing tasks.

Quasi CW Fiber Laser Market Potential Customers

The primary customers for Quasi CW Fiber Lasers are large-scale industrial manufacturers and specialized contract manufacturers who require high-speed, high-precision material processing capabilities, particularly for reflective metals. The largest buying segment is the electric vehicle (EV) battery manufacturers and their associated supply chain partners (Tier 1 and Tier 2 automotive suppliers) who use QCW lasers for high-integrity welding of battery tabs, casings, and busbars. The demand here is driven by the need for superior electrical conductivity and robust mechanical joints, which QCW peak power bursts achieve effectively while controlling heat input to protect sensitive internal cell structures. These buyers prioritize high throughput, system redundancy, and proven reliability in 24/7 operational environments.

Another critical customer base includes multinational companies in the consumer electronics sector, which require micro-welding for sensor integration, flexible circuit board assembly, and housing closure. The precision requirements in this segment are extremely demanding, often involving sub-micron tolerances. Potential customers in the medical device industry utilize QCW lasers for joining dissimilar metals, precision cutting of stents, and welding miniature surgical tools where biocompatibility and cleanliness are paramount. Procurement decisions among these sophisticated buyers are often heavily influenced by application-specific performance benchmarks, documented process stability, and the ability of the laser system vendor to provide specialized pulse sequencing software tailored to unique manufacturing challenges.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.25 Billion |

| Market Forecast in 2033 | $2.68 Billion |

| Growth Rate | 11.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | IPG Photonics, Coherent (Lumentum), Trumpf, Raycus, Maxphotonics, nLIGHT, JPT Opto-Electronics, SPI Lasers (Trumpf Group), Wuhan Golden Laser, Fujikura, Han's Laser, CNI Laser, EO Technics, Laserline, Amada Miyachi, MKS Instruments (Newport), 3SP Technologies, Lasea, Keopsys, Shenzhen Chuangxin Laser. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Quasi CW Fiber Laser Market Key Technology Landscape

The core technology underpinning the Quasi CW Fiber Laser market is the utilization of Ytterbium-doped double-clad optical fibers, which serve as both the gain medium and the waveguiding structure. This architecture allows for highly efficient conversion of pump light (typically from high-power diode lasers operating around 915 nm or 976 nm) into coherent laser light at the 1064 nm wavelength range. The key technological differentiator for QCW systems, compared to standard CW lasers, lies in the specialized electronic drive systems and thermal management solutions that enable the rapid switching and high-peak-power pulsing capabilities. Advanced pulse shaping techniques, facilitated by sophisticated digital signal processors (DSPs) and custom software, allow for the generation of complex waveforms, essential for controlling material flow and minimizing spatter during sensitive joining processes like battery welding. Furthermore, the development of robust, high-power fiber Bragg gratings (FBGs) and advanced pump combiners is critical for scaling output power while maintaining optimal beam quality (M² < 1.1) in industrial environments.

Recent technological advancements focus heavily on enhancing the electrical-to-optical efficiency and increasing the peak power achievable from a given core size without inducing non-linear effects or catastrophic optical damage (COD). Innovations in high-brightness, highly reliable pump diode modules are continuously driving down system costs and improving lifetime. Another significant trend is the integration of real-time monitoring and feedback systems, often utilizing in-situ optical sensors (pyrometers, photodiodes) to measure process variables like temperature and plume formation. These systems enable closed-loop control, allowing the laser to dynamically adjust its output parameters during the processing cycle to ensure consistent quality, particularly crucial for high-speed automated production. The ongoing miniaturization and ruggedization of the laser head also facilitate easier integration onto multi-axis robotic arms, expanding application possibilities in complex manufacturing geometries.

The competitive technology landscape also features ongoing research into specialized QCW systems, including those operating at alternative wavelengths (e.g., green or blue QCW lasers) designed specifically for highly reflective materials like pure copper, where 1064 nm absorption is low. This development addresses a critical industry need, especially in high-density power electronics manufacturing. Moreover, manufacturers are exploring advanced beam delivery optics, such as high-speed galvanometric scanners and specialized process heads, to maximize the flexibility and efficiency of the QCW beam application on the workpiece. The convergence of QCW technology with AI for automated parameter control represents the next major leap, focusing on creating fully autonomous laser processing stations capable of self-diagnostics and process optimization, further cementing the technology's dominance in precision industrial tasks.

Regional Highlights

The Quasi CW Fiber Laser Market exhibits significant regional disparities in terms of market maturity, growth rate, and application focus. These differences stem from varying industrial infrastructure, governmental policies supporting high-tech manufacturing, and the localized presence of key end-user industries such as automotive and electronics.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market, overwhelmingly dominating global demand. This leadership is driven by the region's massive manufacturing base, particularly in China and South Korea, which are global hubs for EV battery manufacturing (e.g., CATL, LG Energy Solution) and consumer electronics production (e.g., Samsung, Foxconn). Aggressive government investment in automation and the availability of low-cost system integration further accelerate adoption.

- North America: Characterized by high technological maturity, North America maintains strong demand for QCW lasers in high-value, stringent sectors, notably aerospace and defense (for precision component welding and refurbishment) and high-end medical device manufacturing. Market growth is stable, focused heavily on customized, high-reliability systems and advanced R&D applications.

- Europe: Europe is a key market, propelled by Germany's robust automotive and machinery sectors (Industry 4.0 initiatives). Demand is focused on high-quality, efficient manufacturing solutions, with strong penetration in industrial automation and specialty applications like jewelry and high-precision tooling. Regulatory emphasis on sustainable manufacturing also favors the high energy efficiency of fiber lasers.

- Latin America (LATAM): Currently a nascent market, LATAM shows emerging potential, driven by expanding automotive assembly operations (Mexico and Brazil) and increasing foreign investment in localized electronics manufacturing. Adoption is gradual, often following global supply chain integration requirements.

- Middle East and Africa (MEA): This region is the smallest but is showing moderate growth, linked primarily to infrastructure projects, oil and gas sector tooling requirements, and nascent high-tech manufacturing diversification efforts, particularly in the UAE and Saudi Arabia.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Quasi CW Fiber Laser Market.- IPG Photonics

- Coherent (Lumentum)

- Trumpf

- Raycus

- Maxphotonics

- nLIGHT

- JPT Opto-Electronics

- SPI Lasers (Trumpf Group)

- Wuhan Golden Laser

- Fujikura

- Han's Laser

- CNI Laser

- EO Technics

- Laserline

- Amada Miyachi

- MKS Instruments (Newport)

- 3SP Technologies

- Lasea

- Keopsys

- Shenzhen Chuangxin Laser

Frequently Asked Questions

Analyze common user questions about the Quasi CW Fiber Laser market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of a Quasi CW Fiber Laser over a standard CW laser?

The primary advantage is the ability to deliver very high peak power pulses (often 5 to 10 times the average power) at low duty cycles. This high peak power is crucial for efficiently processing highly reflective materials like copper and aluminum, minimizing the heat affected zone (HAZ), and achieving deep penetration welds quickly, which is essential for EV battery manufacturing.

Which industry currently drives the largest demand for Quasi CW Fiber Lasers globally?

The Electric Vehicle (EV) manufacturing industry drives the largest demand. QCW lasers are vital for precision welding of complex battery components (busbars, tabs, and casings) where weld quality and consistency directly impact battery performance, safety, and lifespan.

What are the typical power ranges for QCW lasers and how do they relate to applications?

Power ranges typically categorize into Low (up to 100W peak) for micro-machining and medical devices; Medium (100W to 500W peak) for specialized electronics welding; and High (above 500W peak) for demanding applications like thick material welding and high-speed battery production lines.

How does the total cost of ownership (TCO) compare for QCW fiber lasers versus traditional solid-state lasers?

QCW fiber lasers typically offer a significantly lower TCO than older flashlamp-pumped solid-state lasers. This reduction is due to their superior wall-plug efficiency, lack of consumables (like flashlamps), and much longer diode lifetimes, resulting in minimal maintenance and lower operational energy costs over the system's lifespan.

What role does Artificial Intelligence (AI) play in advancing QCW fiber laser technology?

AI is increasingly used for autonomous process optimization, enabling real-time adjustment of pulse parameters based on material feedback, predictive maintenance scheduling, and automated defect detection through machine vision, enhancing manufacturing yield and system reliability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager