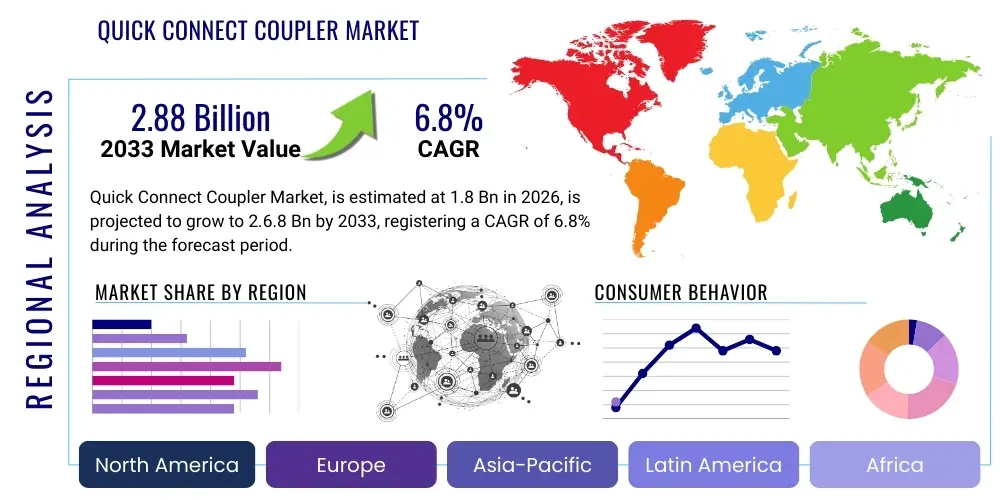

Quick Connect Coupler Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440392 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Quick Connect Coupler Market Size

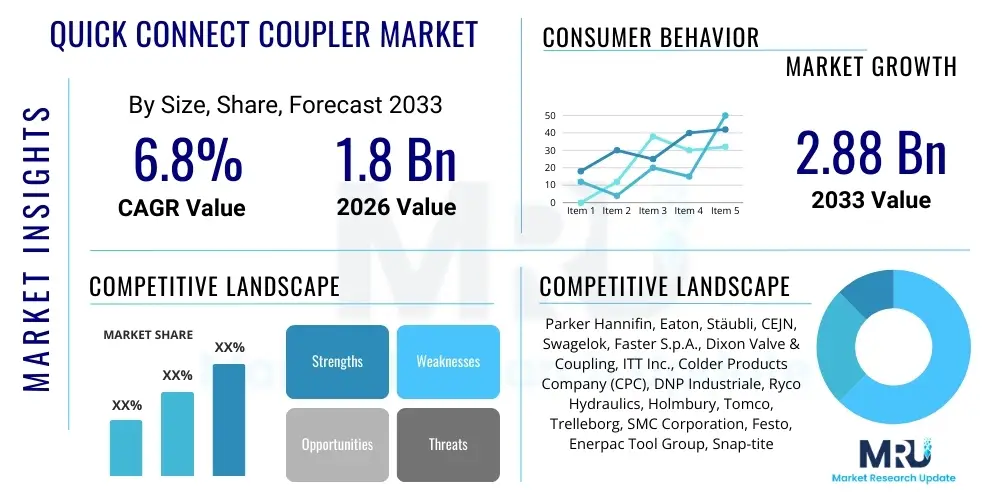

The Quick Connect Coupler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.8 Billion in 2026 and is projected to reach USD 2.88 Billion by the end of the forecast period in 2033.

Quick Connect Coupler Market introduction

The Quick Connect Coupler Market encompasses devices designed for swift, secure, and leak-free connection and disconnection of fluid lines, including hydraulic, pneumatic, and chemical transfer systems, without the need for tools or extensive downtime. These essential components facilitate operational efficiency across a multitude of industries by enabling rapid interchangeability of equipment and reducing fluid loss. The fundamental purpose of a quick connect coupler is to provide a reliable seal when connected and an efficient shut-off when disconnected, thereby minimizing contamination and maximizing safety during fluid transfer operations. Their robust design typically features a male insert and a female body, engineered to create a secure, positive lock.

Major applications for quick connect couplers span a vast array of sectors, including heavy industrial manufacturing, construction, agriculture, automotive, aerospace, and medical equipment. In manufacturing, they are critical for powering pneumatic tools and robotic systems, while in construction, they ensure the rapid attachment and detachment of hydraulic implements on excavators and loaders. The benefits of adopting quick connect couplers are substantial, including enhanced operational efficiency, improved safety by reducing manual intervention, significant reductions in fluid spillage and environmental contamination, and minimized equipment downtime due to faster changeovers. These advantages collectively contribute to higher productivity and lower operational costs, making them indispensable in modern industrial practices.

The market is primarily driven by the accelerating trend of industrial automation and the increasing demand for high-efficiency fluid power systems. Industries are continually seeking ways to streamline operations, reduce human error, and improve throughput, which quick connect couplers directly support. Furthermore, stringent safety regulations concerning fluid handling and environmental protection are compelling industries to adopt more reliable and leak-proof connection solutions. The expansion of manufacturing capabilities globally, particularly in emerging economies, alongside the continuous innovation in coupler design, such as lighter materials and more robust sealing mechanisms, further propels market growth. These factors collectively underscore the vital role quick connect couplers play in the industrial landscape.

Quick Connect Coupler Market Executive Summary

The Quick Connect Coupler Market is experiencing robust growth driven by significant business, regional, and segment trends. Business trends highlight a strong push towards automation and smart manufacturing, where quick connect couplers are integral to flexible production lines and robotic systems. There is an increasing demand for specialized and customized coupler solutions to meet unique application requirements, fostering innovation in materials and design. Companies are focusing on product differentiation through enhanced durability, leak-proof performance, and ease of use, often integrating advanced sealing technologies and lighter, more resilient materials to improve overall product lifecycle and operational efficiency for end-users. Sustainability initiatives are also influencing product development, with a growing interest in environmentally friendly materials and designs that minimize fluid loss.

Regionally, Asia Pacific stands out as the fastest-growing market, propelled by rapid industrialization, burgeoning manufacturing sectors, and extensive investments in infrastructure and construction projects, particularly in countries like China, India, and Southeast Asian nations. North America and Europe represent mature markets characterized by stringent safety standards and a strong emphasis on high-performance, technologically advanced couplers for specialized applications in aerospace, medical, and advanced manufacturing. Latin America, the Middle East, and Africa are emerging markets showing considerable potential, driven by increasing industrial activity and urbanization, creating new avenues for market expansion. Each region presents distinct opportunities and challenges, requiring tailored market strategies from manufacturers.

Segmentation trends indicate a strong demand for hydraulic quick connect couplers, particularly in heavy machinery and construction, due to their ability to handle high pressures. Pneumatic couplers also maintain a significant share, driven by industrial automation and robotics. Material-wise, stainless steel couplers are gaining traction due to their corrosion resistance and durability in harsh environments, while advancements in polymer composites are enabling lightweight and cost-effective solutions for specific applications. The market is also witnessing the proliferation of multi-coupling systems and specialized medical quick connectors, reflecting the need for complex, integrated solutions. These segment-specific dynamics underscore the diverse needs of the global quick connect coupler market and highlight areas for focused innovation and investment.

AI Impact Analysis on Quick Connect Coupler Market

Users frequently inquire about how artificial intelligence (AI) can transcend traditional quick connect coupler functionalities, moving beyond simple mechanical connection to intelligent, predictive systems. Common questions revolve around AI's role in predictive maintenance, enhancing operational efficiency through smart diagnostics, optimizing design and material selection, and improving quality control during manufacturing processes. Users are keen to understand if AI can enable couplers to self-monitor, signal impending failures, or even optimize fluid flow based on real-time data. The core themes emerging from these inquiries highlight a strong desire for quick connect couplers to become smarter, more reliable, and integrate seamlessly into broader Industry 4.0 ecosystems, reducing unplanned downtime and enhancing safety through data-driven insights. There is a clear expectation that AI will transform couplers from passive components into active participants in system management and predictive analytics.

- AI-powered predictive maintenance for quick connect couplers, forecasting wear and potential leaks to prevent failures.

- Integration of AI in smart manufacturing processes for precision assembly and quality control of couplers, reducing defects.

- AI-driven optimization of coupler design for enhanced fluid dynamics, material strength, and thermal management.

- Development of intelligent quick connect couplers with embedded sensors and AI algorithms for real-time performance monitoring.

- AI facilitating the analysis of operational data from couplers to identify usage patterns, optimize maintenance schedules, and improve system efficiency.

- Enhanced supply chain management for coupler components through AI-driven demand forecasting and inventory optimization.

- AI-assisted fault detection and diagnostics in fluid power systems by analyzing data streams from connected couplers.

- Personalized coupler solutions through AI, matching optimal designs and materials to specific application requirements based on operational parameters.

DRO & Impact Forces Of Quick Connect Coupler Market

The Quick Connect Coupler Market is shaped by a complex interplay of Drivers, Restraints, and Opportunities, collectively influenced by various impact forces. Key drivers include the escalating global demand for industrial automation, which necessitates efficient and rapid tooling changes in manufacturing and assembly lines. The continuous expansion of construction, agriculture, and heavy machinery sectors globally fuels the need for robust hydraulic and pneumatic quick connect systems. Furthermore, stringent safety regulations and environmental concerns regarding fluid spillage are pushing industries towards more secure and leak-proof connection solutions, thereby accelerating the adoption of advanced quick connect couplers. The emphasis on operational efficiency and reduced downtime across all industrial verticals also serves as a significant impetus for market growth, as these couplers offer considerable time-saving benefits during equipment setup and maintenance.

However, the market faces several restraints that could impede its growth. The relatively high initial investment associated with premium quick connect coupler systems, especially for specialized or multi-coupling units, can be a barrier for smaller enterprises or those with tighter budgets. Issues pertaining to compatibility and standardization across different manufacturers’ products often lead to complexity in procurement and inventory management for end-users. Furthermore, while designed for durability, quick connect couplers still require regular maintenance and occasional replacement of seals or components, contributing to ongoing operational costs. The volatility in raw material prices, particularly for metals like stainless steel and brass, which are crucial for coupler manufacturing, can also impact production costs and market pricing, presenting challenges for manufacturers in maintaining consistent profit margins.

Opportunities for growth are abundant within the quick connect coupler market. The emergence of smart couplers integrated with IoT capabilities for real-time monitoring and predictive maintenance presents a significant growth avenue, aligning with Industry 4.0 trends. There is also a substantial opportunity in catering to customized solutions for niche and highly specialized applications, such as in aerospace, medical devices, and clean energy, where standard couplers may not suffice. The increasing adoption of quick connect couplers in emerging economies, driven by industrialization and infrastructure development, offers vast untapped market potential. Moreover, ongoing research and development into miniaturization, lightweight materials, and more sustainable and eco-friendly designs provide pathways for innovation and market differentiation, allowing companies to address evolving customer needs and environmental regulations. These dynamic opportunities are poised to shape the future trajectory of the market.

Segmentation Analysis

The Quick Connect Coupler Market is broadly segmented based on several crucial parameters, providing a detailed view of its diverse landscape. These segmentations allow for a comprehensive understanding of market dynamics, identifying specific areas of growth, demand, and technological innovation. Analyzing the market through these various lenses helps stakeholders tailor product offerings, develop targeted marketing strategies, and optimize distribution channels to meet the distinct needs of different industries and applications. From the type of fluid handled to the materials used and the specific end-use sectors, each segment reveals unique market characteristics and growth opportunities, reflecting the versatility and adaptability of quick connect coupler technology.

- By Type:

- Hydraulic Quick Connect Couplers

- Pneumatic Quick Connect Couplers

- Fluid Transfer Quick Connect Couplers (for water, chemicals, etc.)

- Medical Quick Connect Couplers

- Specialty/Multi-Coupling Systems

- By Material:

- Steel (Carbon Steel)

- Stainless Steel

- Brass

- Aluminum

- Plastics/Composites

- By Application:

- Industrial Manufacturing & Automation

- Construction Equipment

- Agriculture Machinery

- Automotive & Transportation

- Oil & Gas

- Aerospace & Defense

- Medical & Life Sciences

- Food & Beverage

- Mining

- By End-Use Industry:

- Heavy Equipment

- Chemical Processing

- Pharmaceuticals

- Electronics

- Robotics

- Utilities

- Other Industrial Applications

Value Chain Analysis For Quick Connect Coupler Market

The value chain for the Quick Connect Coupler Market begins with upstream activities, primarily encompassing the sourcing and processing of raw materials. This includes specialized metals such as stainless steel, carbon steel, brass, and aluminum, alongside polymers and elastomers for seals. Suppliers in this segment focus on material quality, consistency, and cost-effectiveness, as these directly impact the performance and durability of the final product. Precision machining and casting companies also play a critical upstream role, transforming raw materials into components that meet stringent specifications for strength, corrosion resistance, and dimensional accuracy. Innovation in material science, such as the development of high-performance plastics or advanced coatings, often originates at this stage, influencing downstream product capabilities and market differentiation.

Moving downstream, the value chain involves the design, manufacturing, assembly, and testing of quick connect couplers. Manufacturers leverage advanced CAD/CAM software for precision engineering, ensuring optimal fluid dynamics, secure locking mechanisms, and robust sealing technologies. The assembly process often includes automated lines for efficiency and consistency, followed by rigorous quality control and testing to ensure leak-proof performance and reliability under various operating conditions. Post-manufacturing, distribution channels become pivotal. Direct sales typically involve large-volume orders to Original Equipment Manufacturers (OEMs) who integrate couplers into their machinery, such as construction equipment, agricultural tractors, or industrial robots. This direct approach allows for close collaboration and customization.

Indirect distribution, on the other hand, relies heavily on a network of industrial distributors, wholesalers, and retailers. These intermediaries maintain extensive inventories, provide local availability, offer technical support, and serve smaller businesses, MRO (Maintenance, Repair, and Operations) clients, and end-users who require off-the-shelf solutions. Online platforms and e-commerce have also emerged as significant indirect channels, expanding market reach and offering convenience to a broader customer base. The efficiency of these distribution networks is crucial for timely product delivery and responsiveness to market demand. Ultimately, the successful delivery of quick connect couplers to end-users hinges on the seamless coordination across this entire value chain, from raw material sourcing to final product delivery and post-sales support.

Quick Connect Coupler Market Potential Customers

Potential customers for quick connect couplers are diverse, spanning virtually every industrial sector where fluid transfer and power systems are utilized. The primary end-users or buyers are manufacturing companies involved in heavy industries, where pneumatic tools, hydraulic systems, and robotic arms require frequent, secure, and efficient connections. This includes automotive manufacturers using couplers for assembly lines, metal fabrication shops, and general industrial machinery producers. The construction sector represents a significant customer base, with equipment manufacturers and construction firms relying heavily on hydraulic quick connect couplers for excavators, loaders, and other heavy machinery to facilitate rapid attachment changes and enhance operational flexibility on job sites. Agricultural machinery manufacturers and large-scale farming operations also constitute a key segment, utilizing couplers for tractors and various implements.

Beyond traditional heavy industries, there is a growing demand from specialized sectors. Medical device manufacturers use sterile quick connect couplers for critical applications in hospitals and laboratories, requiring precise and contamination-free fluid handling. The aerospace and defense industry relies on high-performance, lightweight quick connect couplers for aircraft hydraulic systems and ground support equipment, where safety and reliability are paramount. The oil and gas sector employs robust couplers for drilling, exploration, and refining operations, often in harsh and demanding environments. Furthermore, companies engaged in chemical processing, food and beverage production, and even semiconductor manufacturing increasingly seek specialized quick connect solutions that can withstand corrosive substances, high temperatures, or maintain ultra-clean conditions, demonstrating the broad applicability and expanding customer base for these essential components.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.8 Billion |

| Market Forecast in 2033 | USD 2.88 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Parker Hannifin, Eaton, Stäubli, CEJN, Swagelok, Faster S.p.A., Dixon Valve & Coupling, ITT Inc., Colder Products Company (CPC), DNP Industriale, Ryco Hydraulics, Holmbury, Tomco, Trelleborg, SMC Corporation, Festo, Enerpac Tool Group, Snap-tite, Link-Seal, Safeway Hydraulics |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Quick Connect Coupler Market Key Technology Landscape

The Quick Connect Coupler Market is continuously evolving, driven by advancements in several key technological areas that enhance performance, durability, and user convenience. Material science plays a pivotal role, with ongoing research into lightweight composites, high-strength alloys (such as specialized stainless steels and aerospace-grade aluminum), and advanced polymer blends. These innovations aim to produce couplers that are more resistant to corrosion, wear, and extreme temperatures, while also reducing overall weight for efficiency in applications like aerospace and robotics. The development of advanced sealing technologies, including optimized O-ring designs, specialized elastomers, and proprietary seal geometries, is critical to ensuring superior leak prevention, even under high pressure and pulsation, which is a fundamental requirement for hydraulic and pneumatic systems.

Precision engineering and manufacturing techniques are also central to the technological landscape. Modern quick connect couplers benefit from highly precise machining (CNC), laser cutting, and additive manufacturing (3D printing) for intricate components, ensuring tighter tolerances and superior fit. These methods enable the creation of complex internal geometries that optimize fluid flow, minimize pressure drop, and reduce turbulence, thereby enhancing system efficiency. Furthermore, surface treatment technologies, such as hardening, plating, and specialized coatings, are applied to extend the service life of couplers by improving their resistance to abrasion, chemical exposure, and environmental degradation, which is particularly crucial in harsh industrial and outdoor environments.

The integration of smart technologies, aligning with the principles of Industry 4.0, is another transformative aspect. This includes the incorporation of sensors (e.g., pressure, temperature, flow sensors) directly into couplers, enabling real-time monitoring of system performance and health. Coupled with IoT connectivity, these smart couplers can transmit data for predictive maintenance analytics, alerting operators to potential issues before they lead to costly downtime. The development of multi-coupling systems, which allow for the simultaneous connection of multiple fluid lines, electrical connections, and even data lines with a single action, represents a significant leap in operational efficiency, particularly in applications requiring rapid tool changes and complex system integration, such as robotics and automated assembly lines.

Regional Highlights

- North America: A mature market characterized by high adoption rates in industrial manufacturing, automotive, and aerospace sectors. Strict safety regulations and a strong emphasis on high-performance, specialized couplers drive innovation. The region sees significant demand for hydraulic couplers in construction and agriculture.

- Europe: Known for its advanced engineering and adherence to stringent quality and environmental standards. Germany, France, and the UK are key markets, with robust demand from manufacturing, automotive, and medical industries. Focus on energy efficiency and smart hydraulic/pneumatic systems.

- Asia Pacific (APAC): The fastest-growing region, driven by rapid industrialization, expanding manufacturing bases (especially in China, India, Japan, and South Korea), and massive infrastructure projects. Increasing automation and favorable government policies stimulate market expansion for both hydraulic and pneumatic couplers.

- Latin America: An emerging market with growing industrialization and investments in mining, construction, and agriculture. Brazil and Mexico are leading countries, demonstrating increasing demand for quick connect couplers to enhance operational efficiency in heavy machinery and industrial applications.

- Middle East and Africa (MEA): Growth is primarily fueled by investments in oil & gas, construction, and infrastructure development projects. Countries like Saudi Arabia, UAE, and South Africa are key contributors, with increasing adoption of robust couplers for challenging operating conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Quick Connect Coupler Market.- Parker Hannifin

- Eaton

- Stäubli

- CEJN

- Swagelok

- Faster S.p.A.

- Dixon Valve & Coupling

- ITT Inc.

- Colder Products Company (CPC)

- DNP Industriale

- Ryco Hydraulics

- Holmbury

- Tomco

- Trelleborg

- SMC Corporation

- Festo

- Enerpac Tool Group

- Snap-tite (a Parker Hannifin brand)

- Link-Seal (a product of Link-Pipe Inc.)

- Safeway Hydraulics (a part of Allied-Precision Inc.)

Frequently Asked Questions

Analyze common user questions about the Quick Connect Coupler market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a quick connect coupler and why is it important?

A quick connect coupler is a mechanical device used for rapid, secure, and leak-free connection and disconnection of fluid lines (hydraulic, pneumatic, etc.) without tools. It is crucial for enhancing operational efficiency, improving safety, and reducing downtime in industrial processes by facilitating quick equipment changes and preventing fluid loss.

Which industries are the primary end-users of quick connect couplers?

Key end-user industries include industrial manufacturing and automation, construction, agriculture, automotive, aerospace and defense, oil & gas, and medical & life sciences. These sectors rely on couplers for various applications requiring efficient fluid transfer and power connections.

What are the main types of quick connect couplers available in the market?

The main types are hydraulic quick connect couplers (for high-pressure fluid systems), pneumatic quick connect couplers (for air and gas lines), fluid transfer couplers (for water, chemicals), medical couplers (for sterile environments), and specialty/multi-coupling systems for complex integrations.

How is technological advancement impacting the quick connect coupler market?

Technological advancements are driving innovation in materials (lightweight, high-strength), sealing technologies (leak prevention), precision engineering, and smart integration (IoT sensors for predictive maintenance). These innovations lead to more durable, efficient, and intelligent coupler solutions.

What are the key growth drivers and potential challenges for this market?

Growth drivers include rising industrial automation, demand for operational efficiency, and stringent safety regulations. Challenges involve high initial costs, compatibility issues across brands, and volatility in raw material prices. Opportunities lie in smart couplers, customization, and expansion into emerging economies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager