Radiation Shielding Windows Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432017 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Radiation Shielding Windows Market Size

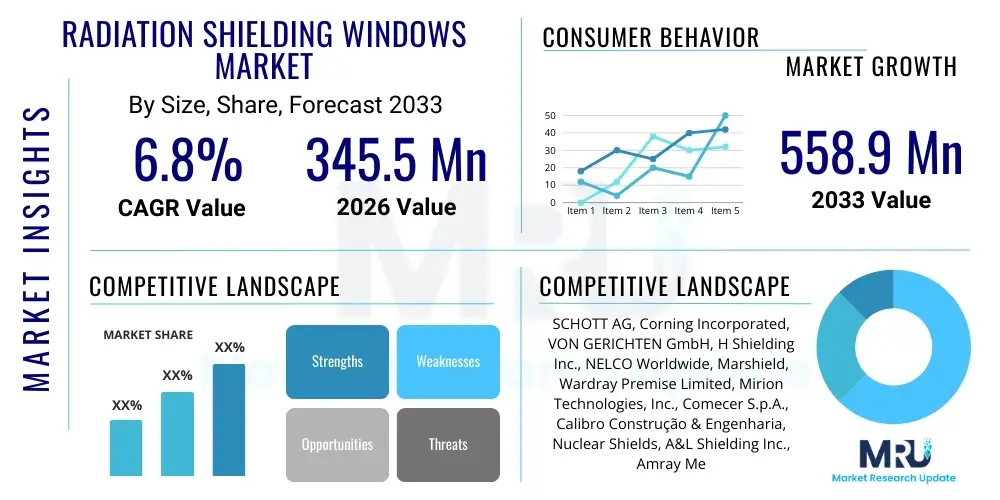

The Radiation Shielding Windows Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 345.5 Million in 2026 and is projected to reach USD 558.9 Million by the end of the forecast period in 2033.

Radiation Shielding Windows Market introduction

The Radiation Shielding Windows Market encompasses specialized transparent systems designed to protect personnel and sensitive electronic equipment from harmful ionizing radiation, including gamma rays, X-rays, and neutron flux, while allowing for clear visual observation. These products are crucial components in highly regulated environments such as nuclear power plants, medical facilities utilizing linear accelerators for radiation therapy, advanced research laboratories (hot cells), and industrial non-destructive testing (NDT) centers. Key products include high-density lead glass and advanced borosilicate compositions, engineered for specific shielding equivalents (measured in lead thickness). The market growth is primarily driven by the global increase in cancer prevalence demanding advanced radiotherapy centers, the necessity for stringent safety protocols in expanding nuclear energy infrastructure, and continuous technological advancements in diagnostic imaging equipment. The primary benefits provided by these windows include enhanced operational safety, regulatory compliance, and improved workflow efficiency by maintaining visibility into hazardous areas, positioning these systems as indispensable safety assets.

Radiation Shielding Windows Market Executive Summary

The global Radiation Shielding Windows Market is experiencing robust growth fueled by strategic infrastructure investments across healthcare and nuclear sectors globally. Business trends indicate a shift towards highly customized and modular shielding solutions, optimizing installation in existing facilities and facilitating higher lead equivalence for increased safety margins, particularly in facilities utilizing high-energy accelerators. Regionally, North America and Europe maintain dominance due to mature nuclear power infrastructure and high expenditure on advanced medical technology, while the Asia Pacific region is emerging as the fastest-growing market, driven by rapid nuclear power capacity expansion, notably in China and India, alongside significant improvements in regional healthcare accessibility. Segment trends show that the Lead Glass segment maintains the largest market share owing to its cost-effectiveness and proven efficacy, though specialized materials like composite polymers are gaining traction for applications requiring lighter weight or specific chemical resistance. The primary application segment driving demand remains the Healthcare sector, specifically diagnostics and radiation oncology, closely followed by the Nuclear Power and Research sectors, necessitating long-term protective solutions for critical operations and decommissioning projects.

AI Impact Analysis on Radiation Shielding Windows Market

User queries regarding AI's impact on the Radiation Shielding Windows Market frequently center on whether automation and remote operations will reduce the need for observation windows, or conversely, if AI can enhance the performance and durability of the windows themselves. Key concerns also revolve around AI’s role in optimizing material selection and predicting degradation under prolonged radiation exposure. Based on this analysis, the primary theme is that while AI and robotics may reduce human presence in hot zones, the need for high-integrity visual verification—often required by regulation—will persist, ensuring the continued relevance of shielding windows. Furthermore, AI is expected to revolutionize the manufacturing and quality control processes. Machine learning algorithms are being employed to optimize the composition of lead glass and dense materials, accurately modeling neutron and gamma attenuation properties, leading to the development of thinner, lighter, yet equally effective shielding solutions. AI-driven predictive maintenance models can also assess the potential for radiation-induced browning or material fatigue, enabling timely replacement and maximizing safety compliance.

- AI optimizes manufacturing processes for high-density glass homogeneity, improving batch consistency.

- Machine learning algorithms predict material degradation (browning, fatigue) due to cumulative radiation dose exposure.

- Integration of AI-powered remote monitoring systems reduces dependency on constant human presence for basic observation, but visual verification via windows remains mandatory for critical tasks.

- AI assists in designing complex geometries for shielding windows used in experimental fusion reactors and specialized particle accelerators.

- Enhanced material simulation via AI leads to the development of next-generation, non-leaded or advanced borosilicate compositions with superior shielding efficacy.

DRO & Impact Forces Of Radiation Shielding Windows Market

The market is predominantly driven by increasing global investments in nuclear medicine, especially the widespread adoption of Proton Therapy and PET/CT imaging, which require rigorous radiation protection standards. Restraints primarily involve the high initial cost of installation, the complexity of manufacturing high-quality lead glass components without defects, and regulatory hurdles concerning the handling and disposal of lead-containing materials. However, substantial opportunities exist in the nuclear decommissioning market, particularly in Europe and North America, where aging nuclear facilities require new shielding solutions for waste handling and dismantling operations. Further opportunities stem from the burgeoning advanced photonics and high-energy physics research sectors demanding ultra-high-density windows. The core impact forces driving this market include stringent governmental regulations mandating radiation safety in healthcare and nuclear operations (a major driver), high capital expenditure required for research facilities (a significant restraint), and ongoing innovation in composite materials offering superior optical clarity and structural integrity (a key opportunity force).

Segmentation Analysis

The Radiation Shielding Windows Market is segmented based on Material Type, Application, and End-User, providing a comprehensive overview of demand dynamics across varied industrial and scientific ecosystems. Material segmentation primarily divides the market into high-density Lead Glass and non-leaded specialized compositions, reflecting the trade-offs between cost, density, and optical quality required for different radiation types and energy levels. Application segmentation distinguishes demand based on functional requirements, notably covering hot cell observation, medical diagnostic viewing, and radiation therapy rooms. End-User analysis focuses on the institutional consumption patterns, dominated by Hospitals & Clinics and Nuclear Facilities. These segmentations are critical for manufacturers to tailor their product offerings, whether focusing on thick, high-lead equivalent windows for nuclear reactors or lighter, smaller windows for mobile diagnostic units, ensuring compliance with diverse international safety standards and operational needs.

- By Material Type:

- Lead Glass (High-density, standard density)

- Non-Leaded Glass (Borosilicate, specialized composite polymers)

- Liquid-filled Windows

- By Application:

- Hot Cell Observation

- Medical Diagnostics (X-ray rooms, CT scans, PET)

- Radiation Therapy Rooms (Linear Accelerators, Proton Therapy)

- Nuclear Reactor Viewing Ports

- Industrial Non-Destructive Testing (NDT)

- By End-User:

- Hospitals & Clinics

- Nuclear Power Plants

- Research & Academic Institutions (Particle Accelerators, Fusion Research)

- Defense & Aerospace

- Industrial Facilities

Value Chain Analysis For Radiation Shielding Windows Market

The value chain for the Radiation Shielding Windows Market is highly complex, starting with the specialized extraction and refinement of high-purity raw materials, particularly lead oxide and heavy metal oxides like barium and cerium, which are essential for achieving high specific gravity and minimizing radiation-induced browning. Upstream analysis involves a limited number of specialized glass manufacturers who possess the proprietary technology required for melting, casting, and annealing these high-density compositions under extremely controlled conditions to ensure optical clarity and defect-free structure. Due to the high precision and regulatory standards required, raw material sourcing and primary manufacturing form a critical bottleneck, dictating quality and cost across the entire value chain.

The midstream component involves subsequent fabrication, polishing, and encapsulation of the shielding glass into a complete window unit, often incorporating complex framing (usually stainless steel) and specialized sealants designed to maintain airtight integrity, especially in hot cell environments. Distribution channels are typically indirect, relying heavily on specialized engineering and construction firms (EPCs) that handle large-scale nuclear or hospital construction projects, integrating the windows into shielded rooms or hot cells. Direct sales are usually reserved for aftermarket replacements or small research facilities, while major OEMs often rely on certified distributors possessing expert knowledge in radiation protection installation protocols.

Downstream analysis focuses on installation, regulatory certification, and post-sale maintenance, particularly managing potential issues like lead weeping or optical degradation over time. The high-value, highly customized nature of these products ensures strong margins for manufacturers capable of meeting stringent ISO and regulatory body standards. The strong integration between manufacturers and EPC firms is crucial, as the window specifications must align precisely with the structural shielding requirements of the facility, making technical consultation and compliance documentation central to the downstream delivery process.

- Upstream Activities: High-purity lead oxide and heavy metal oxide sourcing; specialized high-temperature glass melting and casting.

- Midstream Activities: Precision grinding, annealing, polishing, and assembly into complete window frames (often stainless steel).

- Downstream Activities: Integration and installation by EPC firms; regulatory approval; maintenance and testing of shielding integrity.

- Distribution Channels: Primarily indirect through specialized construction contractors, distributors focused on nuclear/medical infrastructure, and direct sales for replacement units.

Radiation Shielding Windows Market Potential Customers

The primary customer base for radiation shielding windows comprises institutions and organizations engaged in activities generating or utilizing ionizing radiation that necessitates observation and containment. Hospitals and private specialized oncology centers represent the largest segment of end-users, requiring windows for treatment planning rooms, linear accelerator vaults, and brachytherapy suites, where safety compliance and reliable patient monitoring are paramount. Demand in this sector is driven by increasing global infrastructure dedicated to cancer treatment and diagnostic imaging, particularly in emerging economies expanding access to modern radiotherapy techniques.

A second major customer category includes operators of nuclear power plants, both fission and increasingly fusion research facilities. These customers require extremely high-density, often oil-filled or thick lead glass windows for viewing operations within reactor containment vessels, fuel reprocessing areas, and critical hot cells used for handling highly radioactive materials. The longevity, resistance to high doses, and large sizes required for these installations make them highly lucrative, albeit technically demanding, projects for shielding manufacturers. Furthermore, the global trend toward nuclear decommissioning has opened a sustained demand for temporary and permanent shielding solutions.

Lastly, research and academic institutions, encompassing particle accelerator laboratories (synchrotrons, cyclotrons) and advanced materials science research centers, constitute a growing niche. These facilities require specialized windows capable of withstanding both gamma and high-energy neutron fluxes, often demanding unique material compositions tailored to highly specific research protocols. The purchasing criteria for all potential customers are dominated by regulatory adherence (e.g., density specifications, structural integrity), certification standards, and the manufacturer’s proven track record in meeting stringent safety and optical clarity requirements under operational stress.

- Healthcare Providers: Public and private hospitals, specialized cancer treatment centers, diagnostic imaging clinics (PET, CT, SPECT).

- Nuclear Industry: Nuclear power plant operators (fission and fusion), fuel reprocessing facilities, nuclear waste management agencies.

- Scientific Research: National laboratories, university research centers operating particle accelerators, cyclotrons, and high-energy physics experiments.

- Industrial Users: Manufacturers utilizing industrial radiography for non-destructive testing (NDT) of large components (e.g., aerospace, pipelines).

- Government & Defense: Military facilities involved in nuclear material handling or specific defense research projects.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 345.5 Million |

| Market Forecast in 2033 | USD 558.9 Million |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SCHOTT AG, Corning Incorporated, VON GERICHTEN GmbH, H Shielding Inc., NELCO Worldwide, Marshield, Wardray Premise Limited, Mirion Technologies, Inc., Comecer S.p.A., Calibro Construção & Engenharia, Nuclear Shields, A&L Shielding Inc., Amray Medical, Ray-Bar Engineering Corp., G-TEK Engineering, Ltd., TISSA, Inc., Technical Glass Products, ISOMAX, Shielding International, Inc., Nuclear Technology Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Radiation Shielding Windows Market Key Technology Landscape

The core technology underpinning the Radiation Shielding Windows Market is the fabrication of high-density glass compositions capable of effective attenuation of high-energy photons and neutrons while maintaining superior optical clarity. The dominant technology involves specialized lead glass (e.g., high-lead silicate glass), which utilizes high concentrations of lead oxide (PbO) and occasionally barium and tungsten oxides, increasing the density up to 6.2 g/cm³ compared to standard glass (2.5 g/cm³). Technological advancements are focused on improving the anti-browning properties of the glass, utilizing cerium oxide additives to stabilize the glass matrix and prevent discoloration (solarization) caused by prolonged exposure to ionizing radiation, which would otherwise compromise viewing capabilities and necessitate premature replacement.

Further technological evolution involves the development of specialized composite materials and non-leaded alternatives to address growing environmental concerns regarding lead disposal. Manufacturers are exploring advanced borosilicate glasses, polymers embedded with heavy metal particles, and hybrid multi-layer designs that combine different materials to optimize shielding performance against mixed fields (e.g., gamma and neutrons) while minimizing weight. Furthermore, a significant technological area is the design and manufacturing of liquid-filled or oil-filled windows. These systems use highly dense, transparent fluids (like specific mineral oils or zinc bromide solutions) encased between outer glass panes, offering flexible and high-equivalent shielding for extremely thick walls, crucial for operations involving high curie sources in reprocessing plants.

Installation and structural technologies are also advancing, with a focus on modular, pre-fabricated stainless steel window frames designed for seamless integration into concrete or steel shielding walls, ensuring perfect alignment and minimizing radiation leakage paths (streaming). Precision machining, ultrasonic testing, and non-contact metrology are standard practices used during manufacturing to ensure the glass block is entirely defect-free. Future technological focus areas include developing self-monitoring windows integrated with fiber optic sensors to continuously assess internal radiation dose accumulation and structural integrity, crucial for high-reliability applications in nuclear facilities.

- High-Density Lead Glass Formulation: Incorporation of up to 80% lead oxide (PbO) for maximum gamma ray attenuation, optimized for density and homogeneity.

- Anti-Browning Additives: Use of cerium oxide (CeO2) to prevent solarization and maintain high optical transmittance over the lifespan of the window.

- Composite and Non-Leaded Shielding: Development of advanced borosilicate compositions and polymer matrices loaded with tungsten or barium salts for lighter, environmentally friendlier alternatives.

- Liquid-Filled Systems: Utilization of specialized dense mineral oils or aqueous heavy salt solutions (e.g., zinc bromide) for extremely high shielding equivalent requirements in hot cells.

- Advanced Fabrication Techniques: Precision casting, annealing under controlled atmosphere, and optical polishing to achieve zero-defect, highly uniform shielding thickness and clarity.

Regional Highlights

- North America: This region holds a dominant market share, driven by a well-established nuclear power infrastructure requiring continuous maintenance and decommissioning services, coupled with substantial investments in advanced medical technologies like proton therapy centers. The stringent safety regulations enforced by bodies like the NRC and FDA ensure persistent demand for certified, high-quality shielding solutions. The U.S. remains the largest consumer, leading in both nuclear medicine research and defense applications.

- Europe: Characterized by high environmental standards and significant investment in healthcare infrastructure, Europe is a mature market. Strong demand originates from nuclear decommissioning activities across countries like the UK, Germany, and France, alongside robust adoption of cutting-edge radiotherapy equipment. Regulatory compliance under Euratom directives strongly influences product specifications and market access.

- Asia Pacific (APAC): Expected to exhibit the fastest growth rate globally, APAC is driven by aggressive nuclear power expansion, particularly in China and India, aiming to meet rising energy demands. Furthermore, rapidly improving healthcare access and increased prevalence of modern diagnostic and treatment centers contribute significantly to the demand for shielding windows. Government initiatives focusing on national energy security and public health infrastructure accelerate market growth.

- Latin America (LATAM): The market is moderately growing, primarily focused on modernizing existing hospital facilities and establishing specialized cancer treatment centers in key economies like Brazil and Mexico. Economic volatility and variable regulatory landscapes can occasionally restrain investment, but the underlying need for safer medical environments ensures steady demand.

- Middle East and Africa (MEA): This region is an emerging market, largely spurred by significant oil revenue investments into diversifying energy portfolios (including nuclear projects in the UAE and Saudi Arabia) and rapidly expanding high-quality private healthcare sectors. Regulatory frameworks are quickly evolving, leading to increased adoption of internationally standardized shielding products.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Radiation Shielding Windows Market.- SCHOTT AG

- Corning Incorporated

- VON GERICHTEN GmbH

- H Shielding Inc.

- NELCO Worldwide

- Marshield

- Wardray Premise Limited

- Mirion Technologies, Inc.

- Comecer S.p.A.

- Calibro Construção & Engenharia

- Nuclear Shields

- A&L Shielding Inc.

- Amray Medical

- Ray-Bar Engineering Corp.

- G-TEK Engineering, Ltd.

- TISSA, Inc.

- Technical Glass Products

- ISOMAX

- Shielding International, Inc.

- Nuclear Technology Inc.

Frequently Asked Questions

Analyze common user questions about the Radiation Shielding Windows market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary materials used in high-performance radiation shielding windows?

The primary material is high-density lead glass, which incorporates high percentages of lead oxide (PbO) to maximize attenuation of gamma and X-rays. For specific applications requiring neutron shielding or reduced lead usage, advanced borosilicate glass, composite materials embedded with heavy elements, and specialized liquid-filled windows (using high-density fluids like zinc bromide) are employed to achieve required safety equivalence while maintaining optical clarity.

How is the required thickness and density of a shielding window determined for a specific facility?

The required thickness and density are determined through complex radiation transport calculations based on the maximum energy and type of radiation source (e.g., MeV of a linear accelerator or activity of a radioisotope), the necessary dose reduction factor, and local regulatory mandates. Manufacturers calculate the "lead equivalent" thickness needed, ensuring that the cumulative dose received by observers remains below occupational safety limits, often necessitating iterative design and simulation processes.

What is radiation-induced browning (solarization), and how is it prevented in shielding glass?

Radiation-induced browning, or solarization, is the discoloration of glass caused by cumulative radiation exposure, leading to reduced optical clarity and impaired observation. This phenomenon is largely mitigated by incorporating specific stabilizers, primarily cerium oxide (CeO2), into the glass formulation. Cerium oxide acts as a redox buffer, effectively trapping free electrons generated by ionizing radiation, thereby preventing the formation of color centers that cause the characteristic yellowish-brown discoloration.

Which end-user segment drives the highest current demand for radiation shielding windows?

The Healthcare segment, specifically hospitals and specialized oncology centers, currently drives the highest volume of demand. This is primarily due to the global expansion of advanced medical imaging facilities (PET, SPECT, CT) and the increasing deployment of high-energy radiation therapy devices, such as linear accelerators and proton therapy systems, which necessitate stringent, certified shielding for operator and patient protection, ensuring regulatory compliance and safe therapeutic delivery.

Are there viable alternatives to traditional lead glass windows, and why are they being adopted?

Yes, viable alternatives include non-leaded composite glass and advanced borosilicate materials. These alternatives are gaining adoption primarily driven by increasing environmental regulations concerning lead use and disposal, especially in construction. While sometimes requiring greater thickness to achieve the same lead equivalence, these newer materials offer advantages in terms of reduced weight, superior structural integrity in specific applications, and reduced environmental impact, positioning them as essential for future sustainable infrastructure projects, particularly in medical environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager